A kind of x80 anti-large deformation pipeline steel and its manufacturing method

A technology of anti-large deformation and pipeline steel, applied in the field of pipeline steel, which can solve the problems of high band structure level and large difference in performance of the same plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

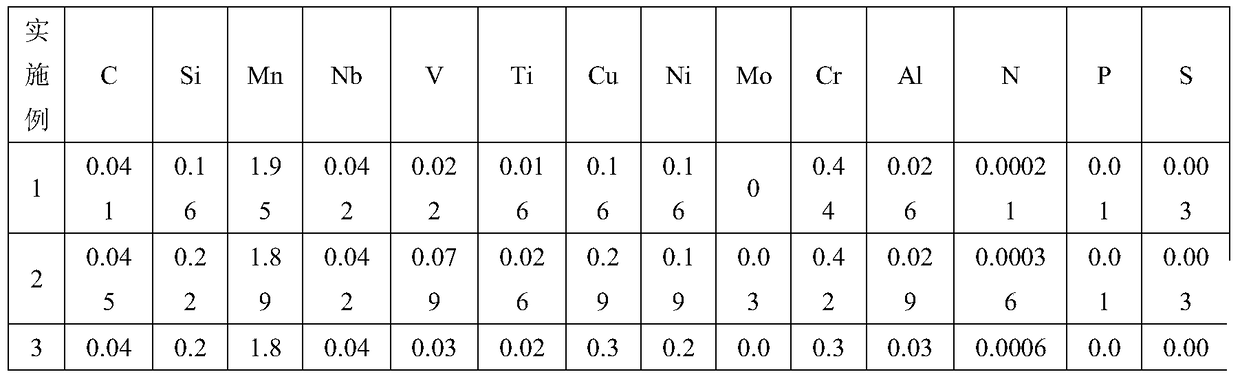

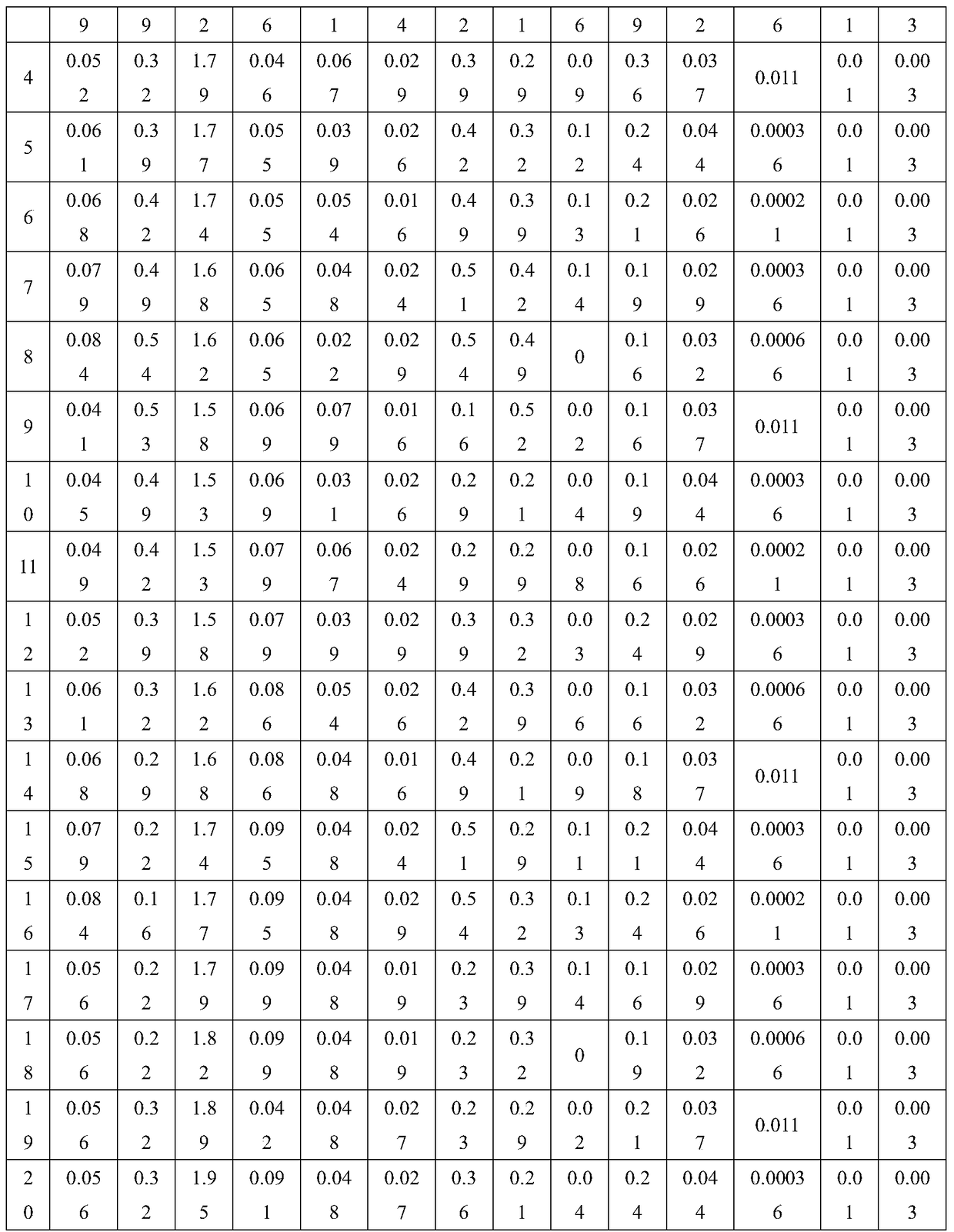

[0043] The invention relates to an X80 steel for large-deformation-resistant pipelines, wherein the mass percentages of chemical components in the steel are C 0.04%-0.09%, Si 0.15%-0.55%, Mn 1.50%-1.75%, Nb 0.04%-0.10%, V 0.02%-0.08%, Ti0.01%-0.03%, Cu 0.15%-0.55%, Ni 0.15-0.55%, Cr 0-0.15%, Mo 0.15%-0.45%, Al0.025%-0.045%, N 0.0002%-0.011%, P≤0.015%, S≤0.005%, the rest are Fe and other inevitable impurity elements.

[0044]The target structure of the large deformation-resistant pipeline steel plate in the present invention is composed of two phases with obvious differences in hardness, wherein the soft phase is ferrite, including polygonal ferrite, quasi-polygonal ferrite, or any mixture thereof; the hard phase is ferrite Tensite, MA component, martensite, or any mixture thereof; the volume fraction of ferrite is 40%-60%; the average diameter of ferrite grains is 4-10um.

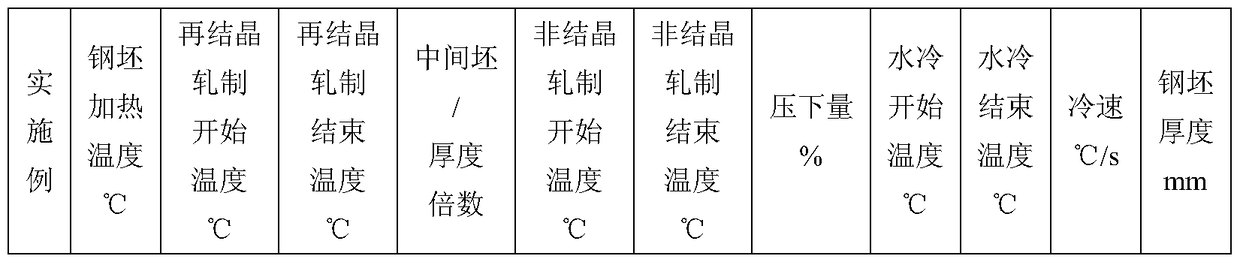

[0045] The TMCP hot-rolled steel sheet used in the X80 anti-large deformation pipeline steel in the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com