Steel plate having low yield ratio, high strength and high uniform elongation and method for producing same

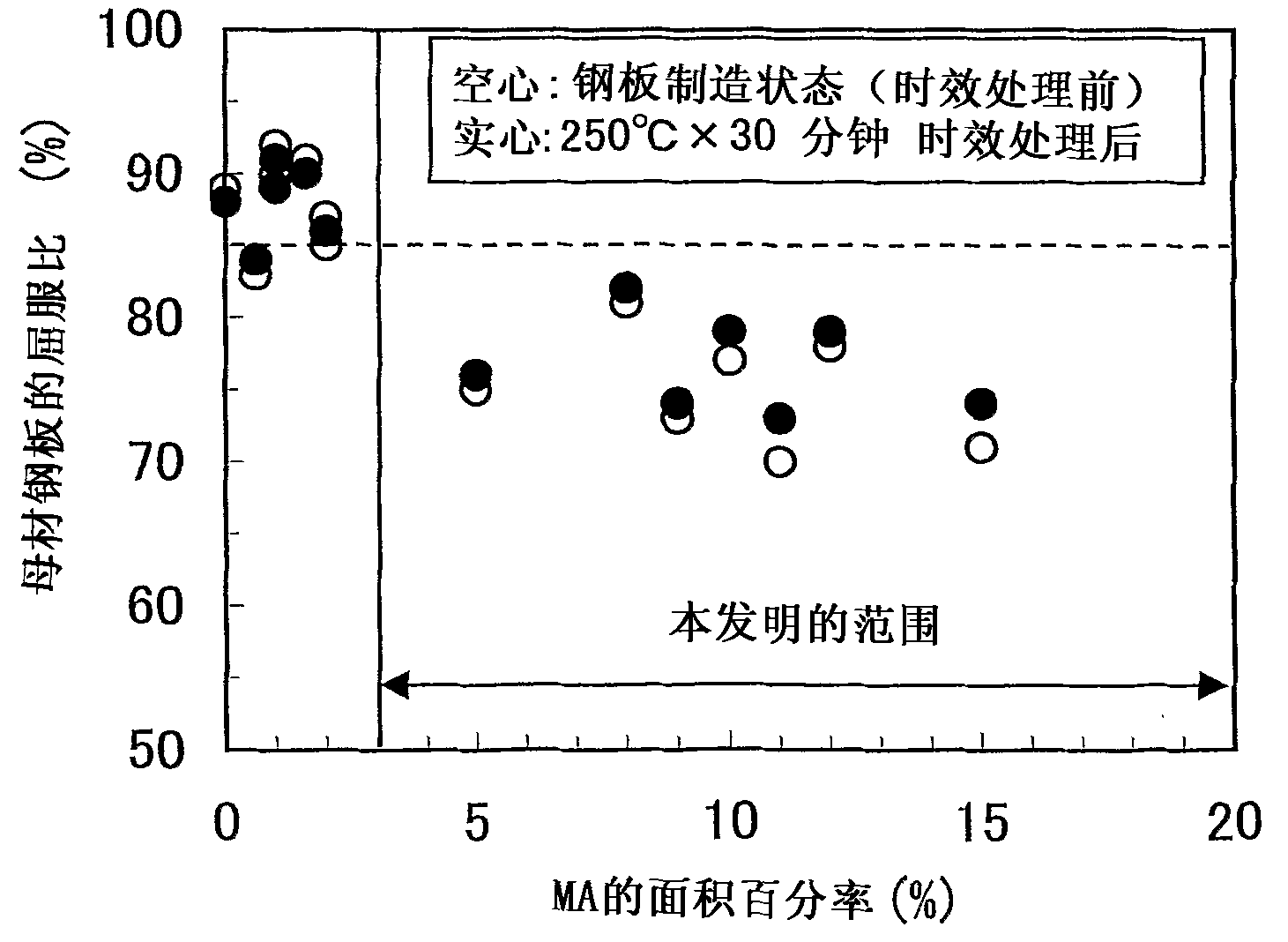

一种均匀伸长、低屈服比的技术,应用在具有低屈服比、高强度以及高均匀伸长率的钢板及其制造领域,能够解决屈服应力升高等问题,达到提高生产率以及经济性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] Steels (steel types A to J) having the composition shown in Table 1 were formed into slabs by a continuous casting method to manufacture thick steel plates (No. 1 to 16) with a plate thickness of 20 and 33 mm.

[0137] The heated slab is rolled by hot rolling, then immediately cooled using a water-cooled accelerated cooling device, and reheated using an induction heating furnace or a gas combustion furnace. The induction heating furnace is installed on the same production line as the accelerated cooling equipment.

[0138] Table 2 shows the production conditions of the respective steel sheets (No. 1 to 16). In addition, temperature, such as heating temperature, rolling completion temperature, cooling stop (finishing) temperature, and reheating temperature, was made into the average temperature of a steel plate. The average temperature is calculated from the surface temperature of the billet or steel plate using parameters such as plate thickness and thermal conductivit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com