Method for improving elongation of cold-rolled dual-phase steel by utilizing retained austenite

A technology of retained austenite and dual-phase steel, applied in the field of iron and steel materials, can solve problems that have not attracted attention, and achieve good plasticity, good plasticity, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

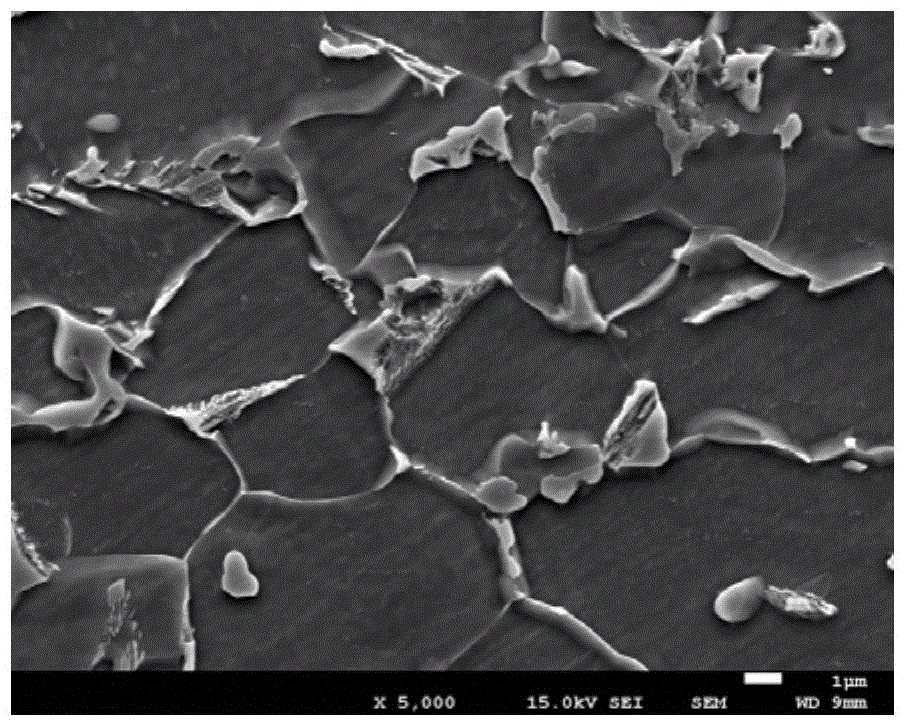

Image

Examples

Embodiment 1

[0027] 1) Internally controlled chemical composition of cold-rolled dual-phase steel DP600: C 0.08-0.11%, Si 0.25-0.35%, Mn 1.5-1.7%, Al0.027%, P0.01%, Cr0.3-0.5%, Fe quantity.

[0028] 2) Hot rolling is carried out after the slab is conventionally heated, the rolling thickness is 2.7mm, and the final rolling temperature is controlled at 880°C;

[0029] 3) Carry out conventional coiling, and control the coiling temperature at 650°C;

[0030] 4) Carry out conventional pickling;

[0031] 5) Carry out cold rolling, and control the cumulative reduction rate of cold rolling to 63%; roll into a steel plate with a thickness of 1.0mm;

[0032] 6) In the process of continuous annealing, firstly keep isothermal at 820°C for 100s, after 20s of slow cooling time, slowly cool to 700°C, and then rapidly cool to martensite at a cooling rate of 40≤Vc≤66°C / s Below the point Ms, about 320°C, continue isothermally maintaining at this temperature for 420s; the final cooling treatment temperatu...

Embodiment 2

[0037]The DP800 grade cold-rolled dual-phase steel trial-produced in the laboratory has introduced a small amount of retained austenite into the microstructure with ferrite matrix and martensite islands as the basic characteristics, thus ensuring that the strength level reaches the level of similar steel companies. At the same time, the elongation rate A 50 Stable increase to more than 20% (A 80 ≥18%). Its manufacturing process is as follows:

[0038] 1) The internal control chemical composition of cold-rolled dual-phase steel DP800 is C 0.14-0.18%, Si 0.3-0.6%, Mn 1.75-2.0%, Al 0.04-0.06%, Nb 0.03-0.05%, and the balance Fe.

[0039] 2) Hot rolling is performed on the slab after conventional heating, rolling to 3.6mm, and the final rolling temperature is controlled at: 860°C;

[0040] 3) Carry out coiling, control coiling temperature at 670 ℃;

[0041] 4) Carry out conventional pickling;

[0042] 5) Carry out cold rolling, and control the cumulative reduction rate of cold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com