Cold-rolled hot-dip galvanized steel and manufacturing method thereof

A manufacturing method, hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of large cold rolling reduction, small dew point range of annealing furnace, and increased production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0063] The cold-rolled hot-dip galvanized steel of embodiment 1-6 adopts the following steps to make:

[0064] (1) Carry out smelting and casting according to the mass percentage of each chemical element shown in Table 1.

[0065] (2) Hot rolling: heating the slab at 1100-1270°C, holding time for 0.5-3 hours, controlling the final rolling temperature at 800-950°C, and the coiling temperature at 400-650°C.

[0066] (3) pickling.

[0067] (5) Cold rolling: control the cold rolling deformation to 35-85%.

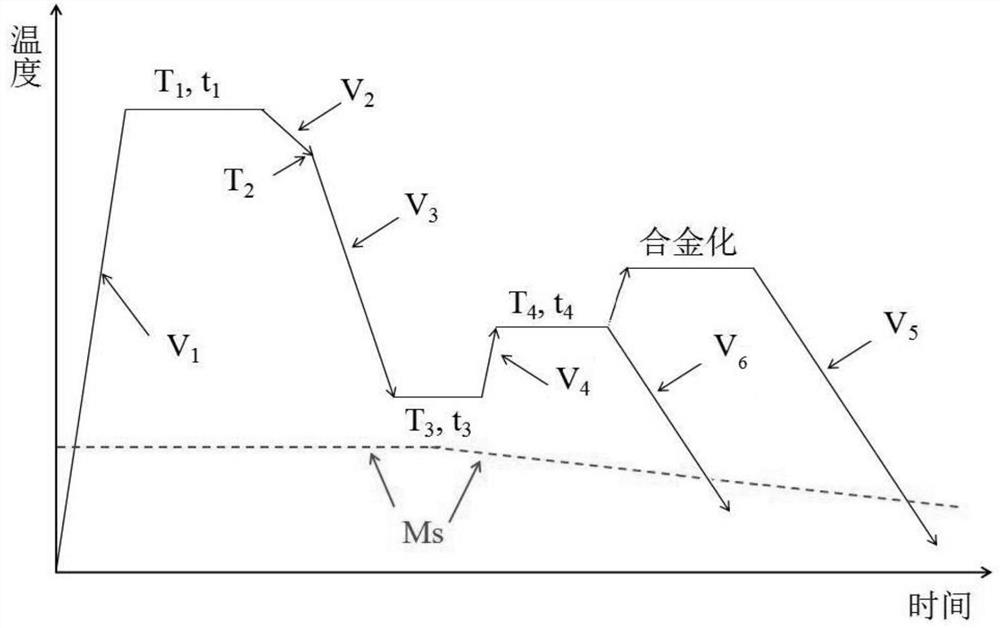

[0068] (5) Hot-dip galvanizing recrystallization annealing: heating the cold-rolled sheet to the soaking temperature T 1 keep warm for a while 1 , the soaking rate is denoted as V 1 ; Then the soaked steel plate is cooled at the first cooling rate V 2 to intermediate temperature T 2 , and then at the second cooling rate V 3 Cool to T 3 , keep warm for a period of time t 3 Then heat up to the zinc pool temperature T 4 keep warm for a while 4 , by T 3 Warming up to T ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com