Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Improve galvanizing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

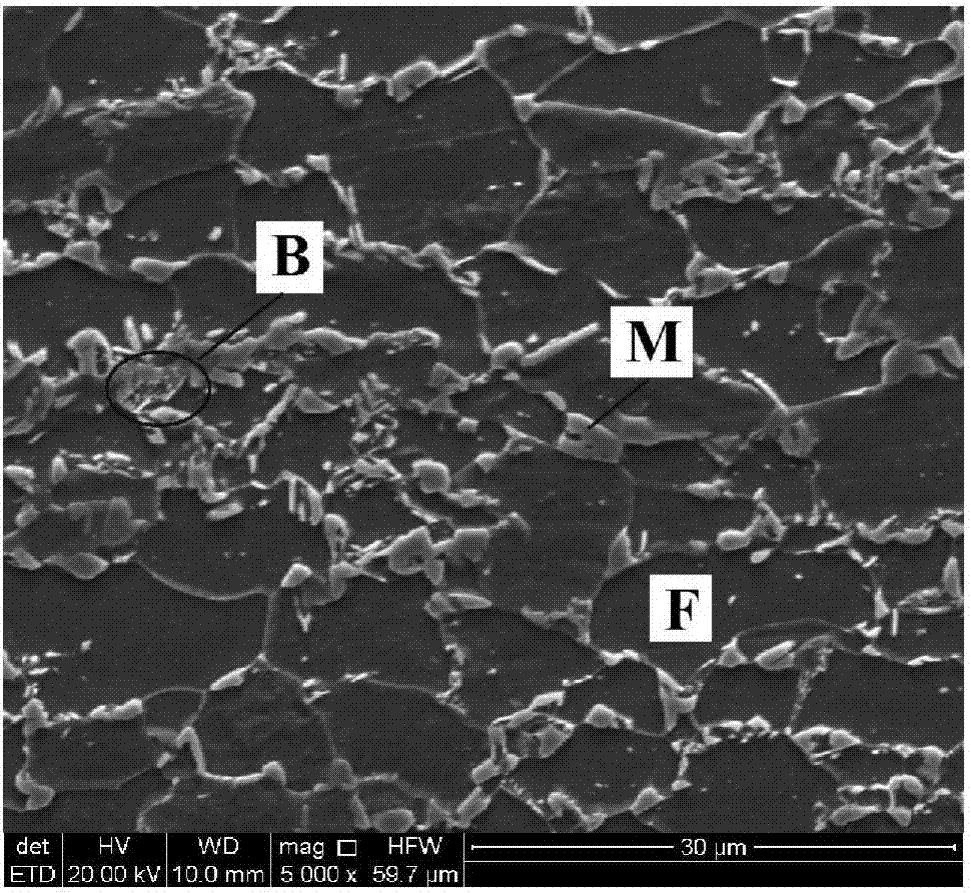

1000 MPa low-carbon hot-galvanized dual-phase steel and preparation method thereof

ActiveCN105950998AGood mechanical propertiesGood formabilityHot-dipping/immersion processesMechanical propertyImpurity

The invention belongs to the technical field of steel for high-strength automobiles and particularly relates to 1000 MPa low-carbon hot-galvanized dual-phase steel and a preparation method thereof. The 1000 MPa low-carbon hot-galvanized dual-phase steel comprises, by weight, 0.05-0.10% of C, 0.20-0.60% of Si, 1.40-1.90% of Mn, 0.20-0.70% of Cr, 0.20-0.50% of Mo, 0.02-0.06% of Al, 0.020-0.050% of Ti, 0.010-0.040% of Nb, 0.0010-0.0030% of B, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.006% of N, and the balance Fe and inevitable impurities. The 1000 MPa low-carbon hot-galvanized dual-phase steel has the high forming property and high welding property and the excellent galvanizing property and mechanical property. The 1000 MPa low-carbon hot-galvanized dual-phase steel is 630-700 MPa in yield strength, 1010-1050 MPa in tensile strength and 11-14% in elongation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

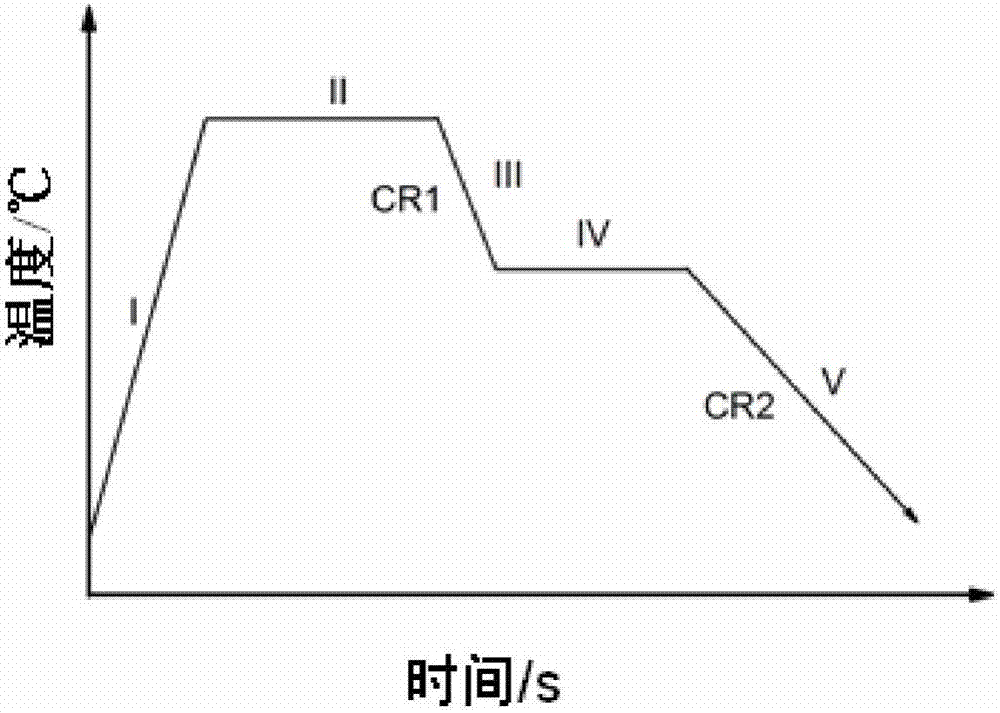

600MPa-level vanadium-containing hot-galvanizing dual-phase steel and preparation method thereof

ActiveCN105603325AImprove hardenabilityHigh strengthHot-dipping/immersion processesSocial benefitsUltimate tensile strength

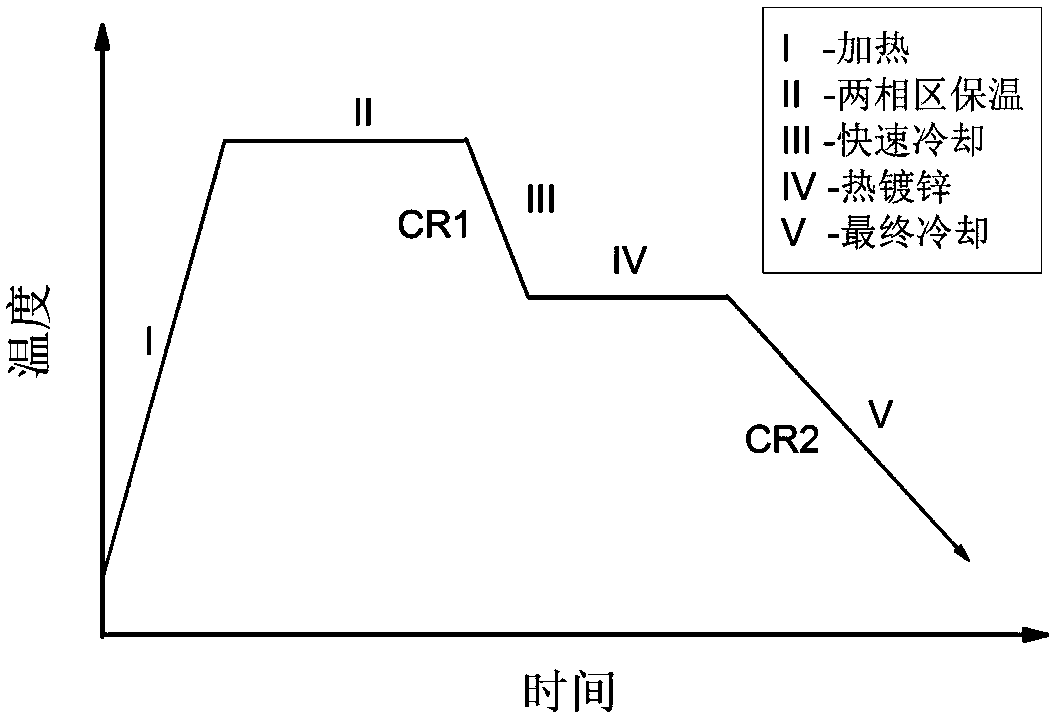

The invention belongs to the technical field of hot-galvanizing high-strength steel for automobiles and particularly relates to 600MPa-level vanadium-containing hot-galvanizing dual-phase steel and a preparation method thereof. The dual-phase steel comprises the following components in percentage by weight: 0.04%-0.10% of C, 0.10%-0.60% of Si, 1.30%-1.90% of Mn, 0.10%-0.50% of Cr, 0.05%-0.25% of Mo, 0.01%-0.06% of Al, 0.01%-0.05% of V, less than or equal to 0.020% of P, less than or equal to 0.015% of S, less than or equal to 0.006% of N and the balance of Fe and inevitable impurities. According to the dual-phase steel, partial Cr and Mo are replaced with trace V and Si, so that the strength and hardenability of the dual-phase steel are improved, and meanwhile, the production cost is lowered; and by combining with a pre-oxidization reduction process, the surface galvanizing quality of the dual-phase steel is improved. The hot-galvanizing dual-phase steel prepared by virtue of the preparation method has excellent forming property, welding property and galvanizing property, oblivious cost advantage and remarkable economic and social benefits.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Improved hot galvanizing method of iron handicraft or furniture

InactiveCN103668030ANo over-cleaning phenomenonImprove ductilityHot-dipping/immersion processesEthylenediamineThiourea

The invention relates to an improved hot galvanizing method of an iron handicraft or furniture. The method comprises the following steps: (1) uncoiling and degreasing a workpiece; (2) removing dust; (3) washing; (4) assisting plating; (5) baking; (6) galvanizing by dipping; (7) settling; (8) passivating; (9) cooling. In the method, a degreasant is changed into acidity and is composed of a sulfuric acid solution, OP-10 and di-o-tolyl-thiourea. Thus, a washing procedure can be saved; a water resource and the degreasant can be saved; the workpiece does not generate an over-cleaning phenomenon; a pickling solution is composed of a hydrochloric acid solution, phosphoric acid, alkylphenol ethoxylates, lauryl sodium sulfate and ethylenediamine tetraacetic acid, so that the pickling speed is improved, formation of acid mist and use of a complexing agent can be restricted, reduction of cadmia in galvanizing zinc is facilitated, the malleability of a zinc coating on the surface of the work-piece is improved, proper temperature and event are adopted in the subsequent galvanizing by dipping, and the thickness and the stability of the zinc coating at the surface of the workpiece are ensured. Thus, the improved hot galvanizing method is a method which is simple and convenient for operation and good in galvanized effect.

Owner:TIANJIN BIAODIAN METAL HANDICRAFT CO LTD

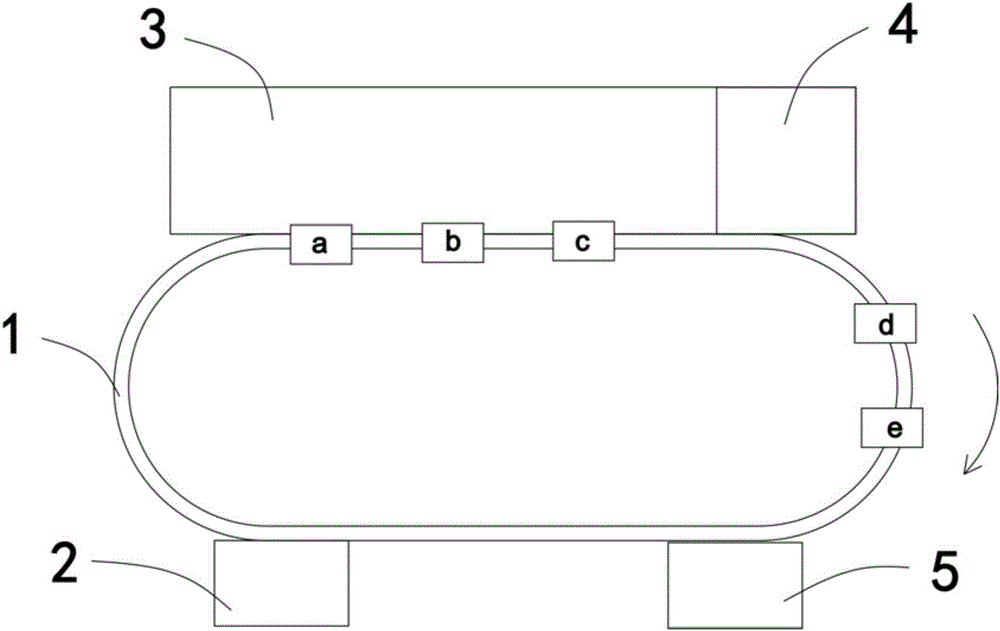

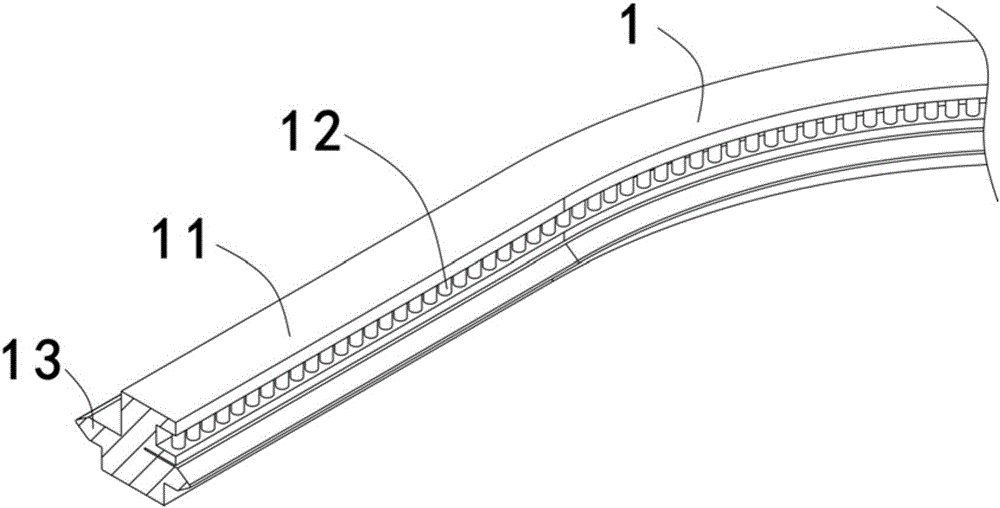

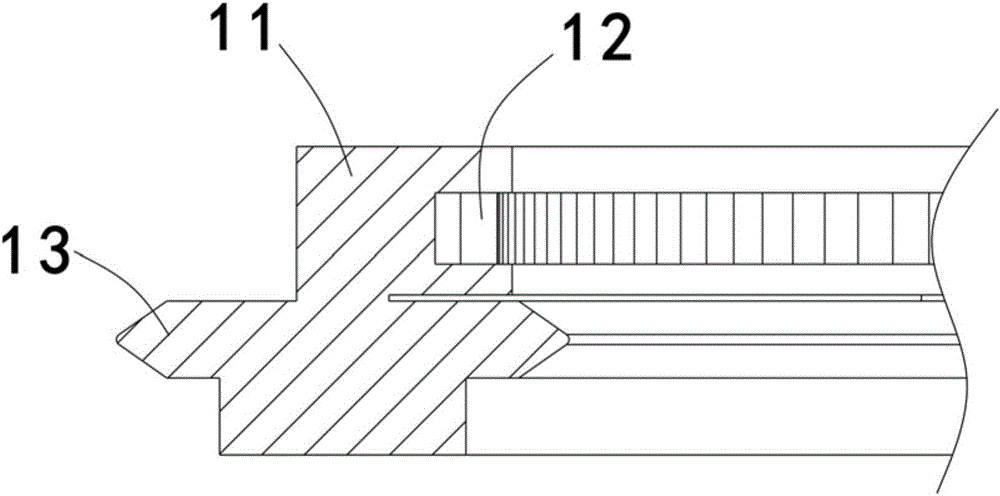

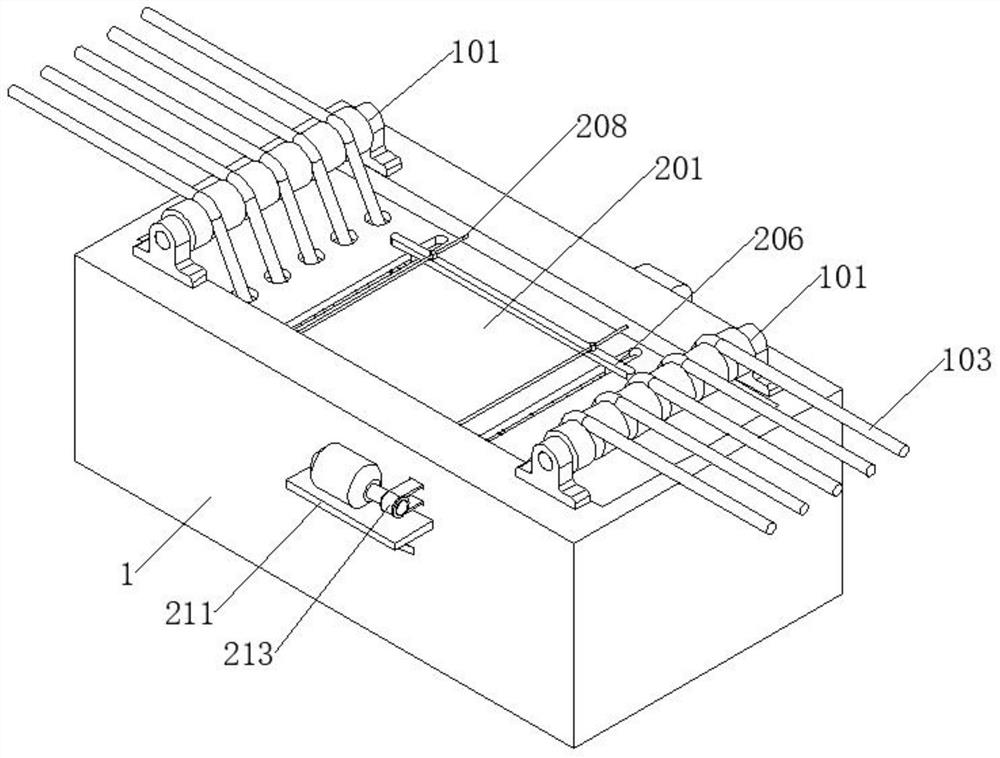

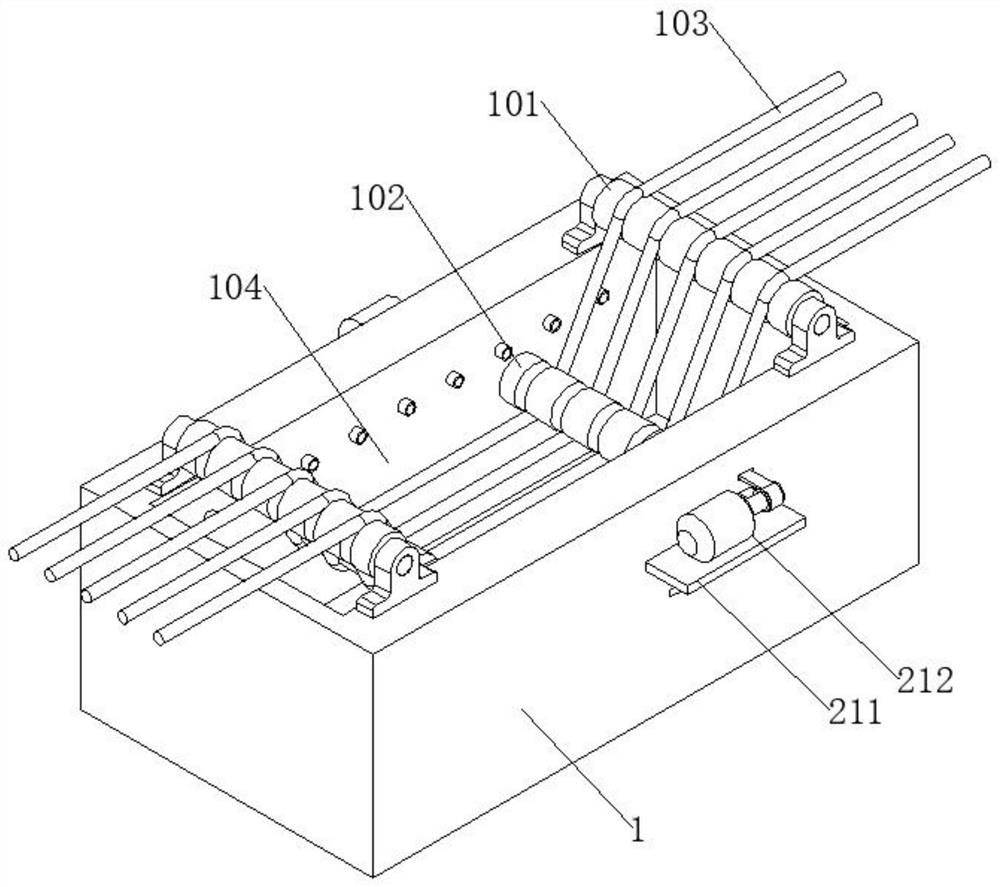

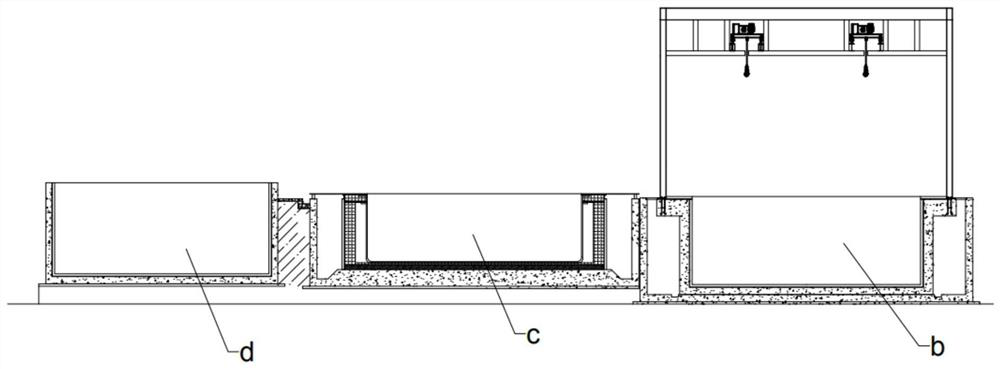

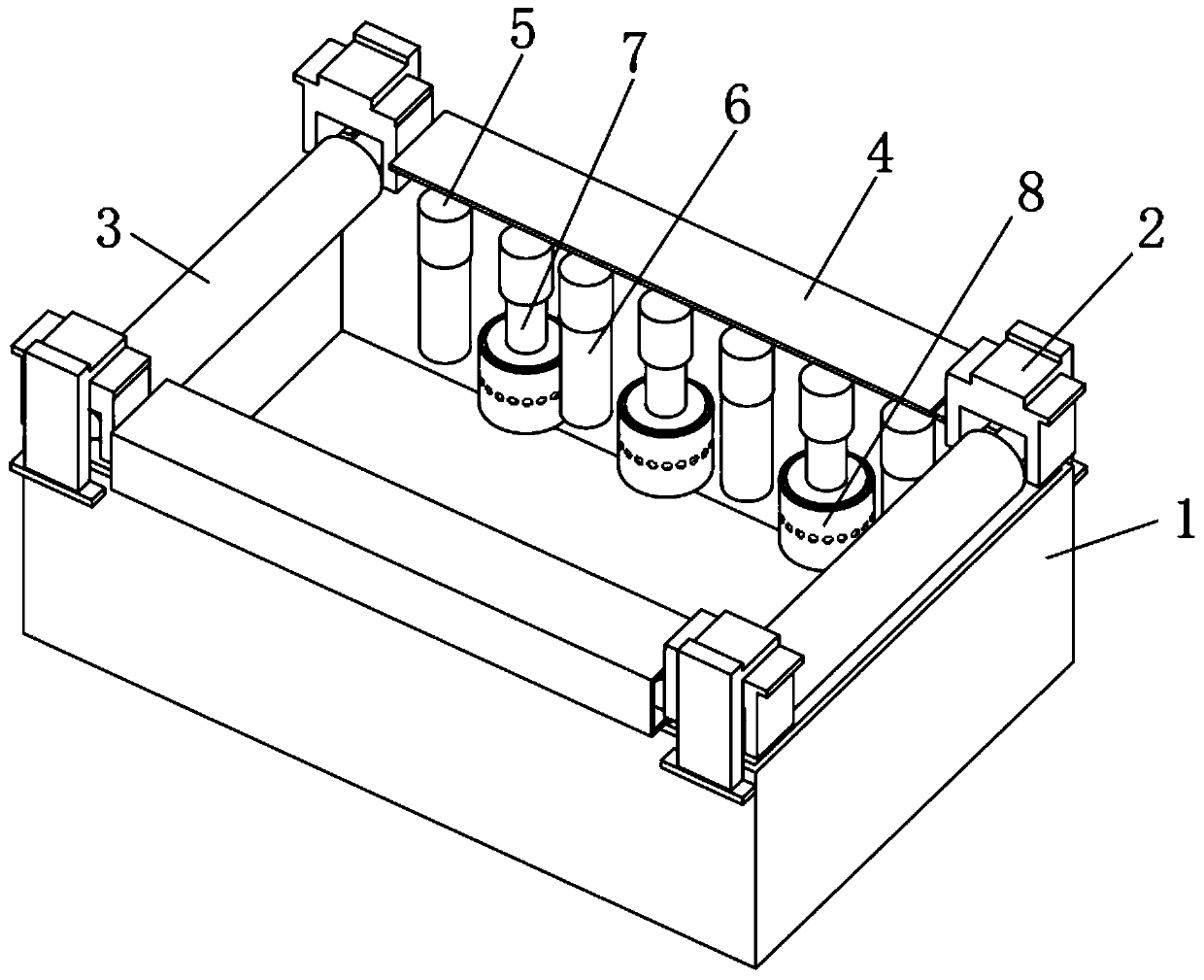

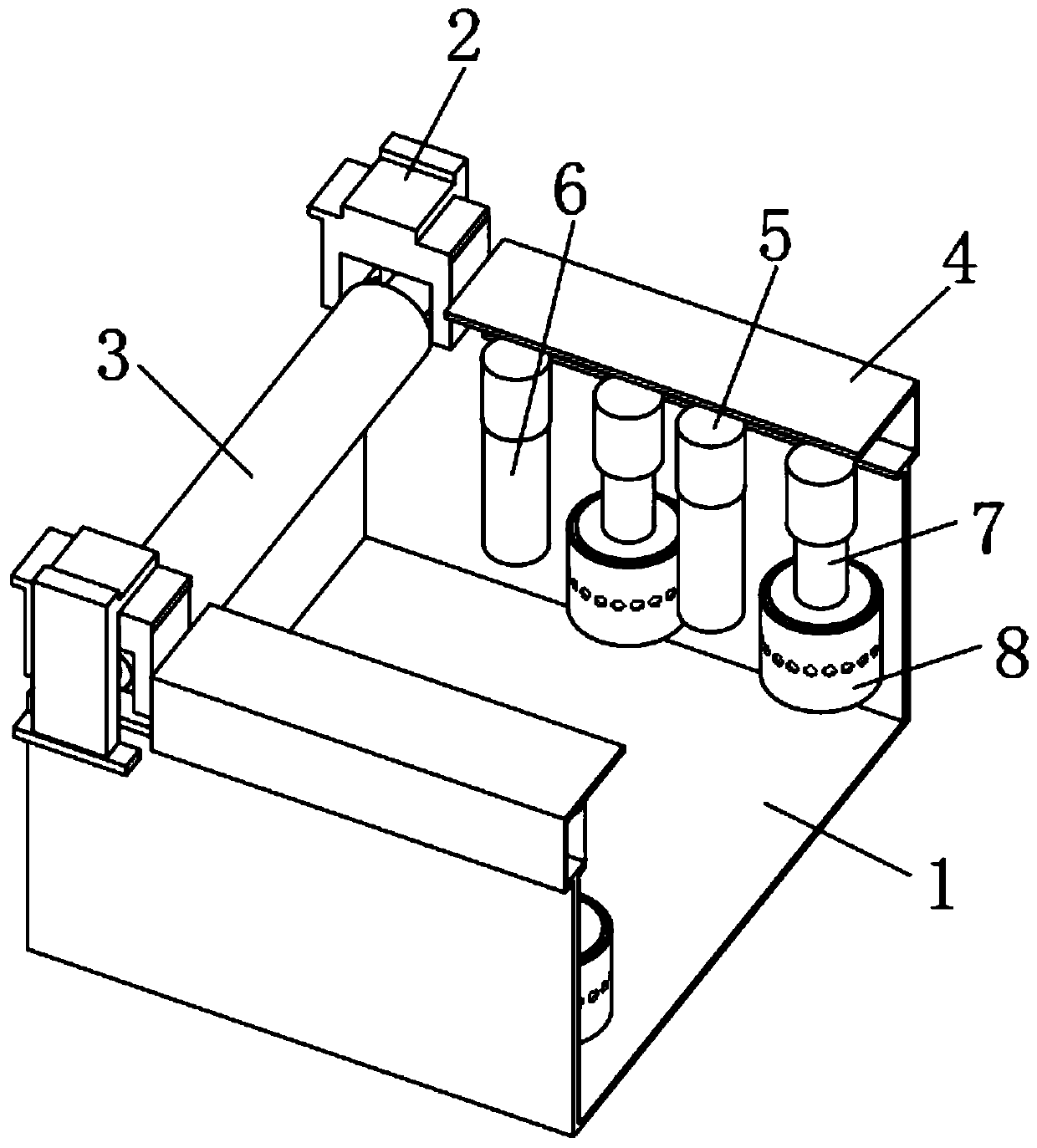

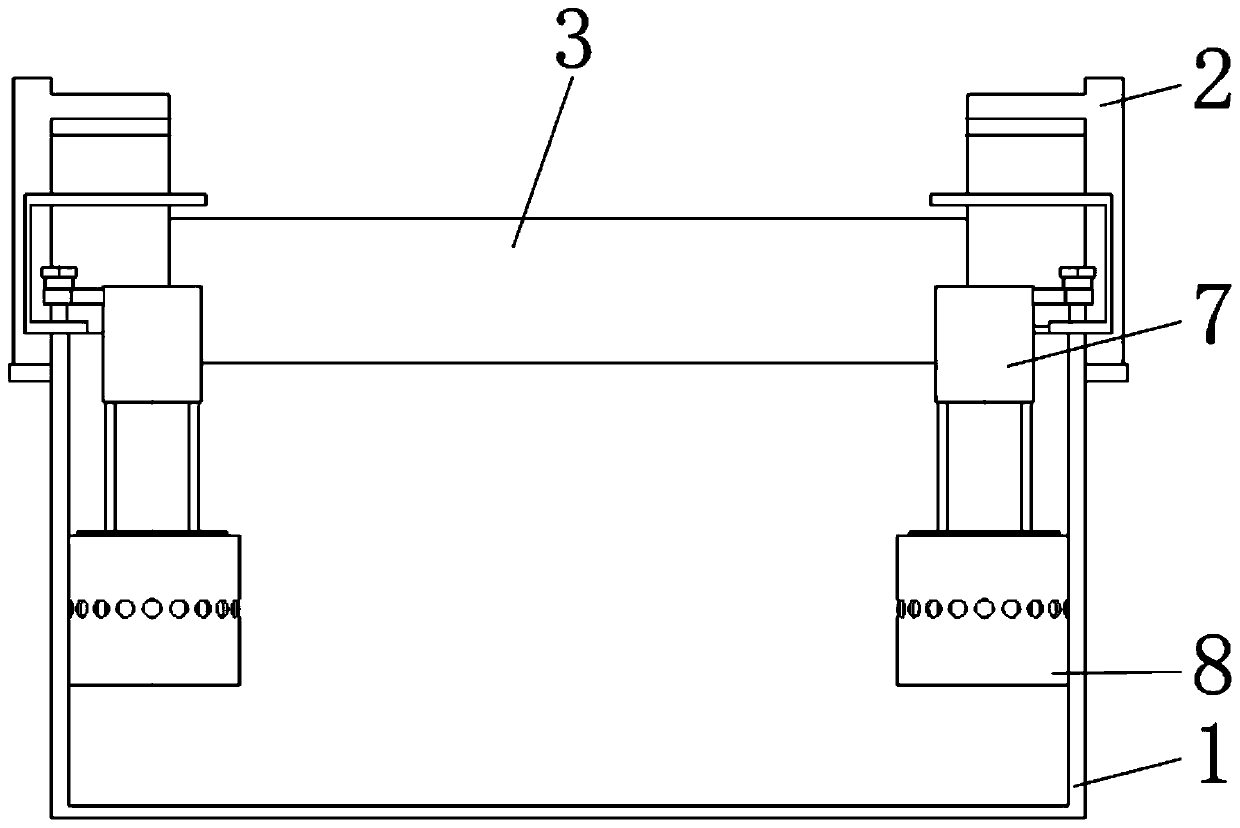

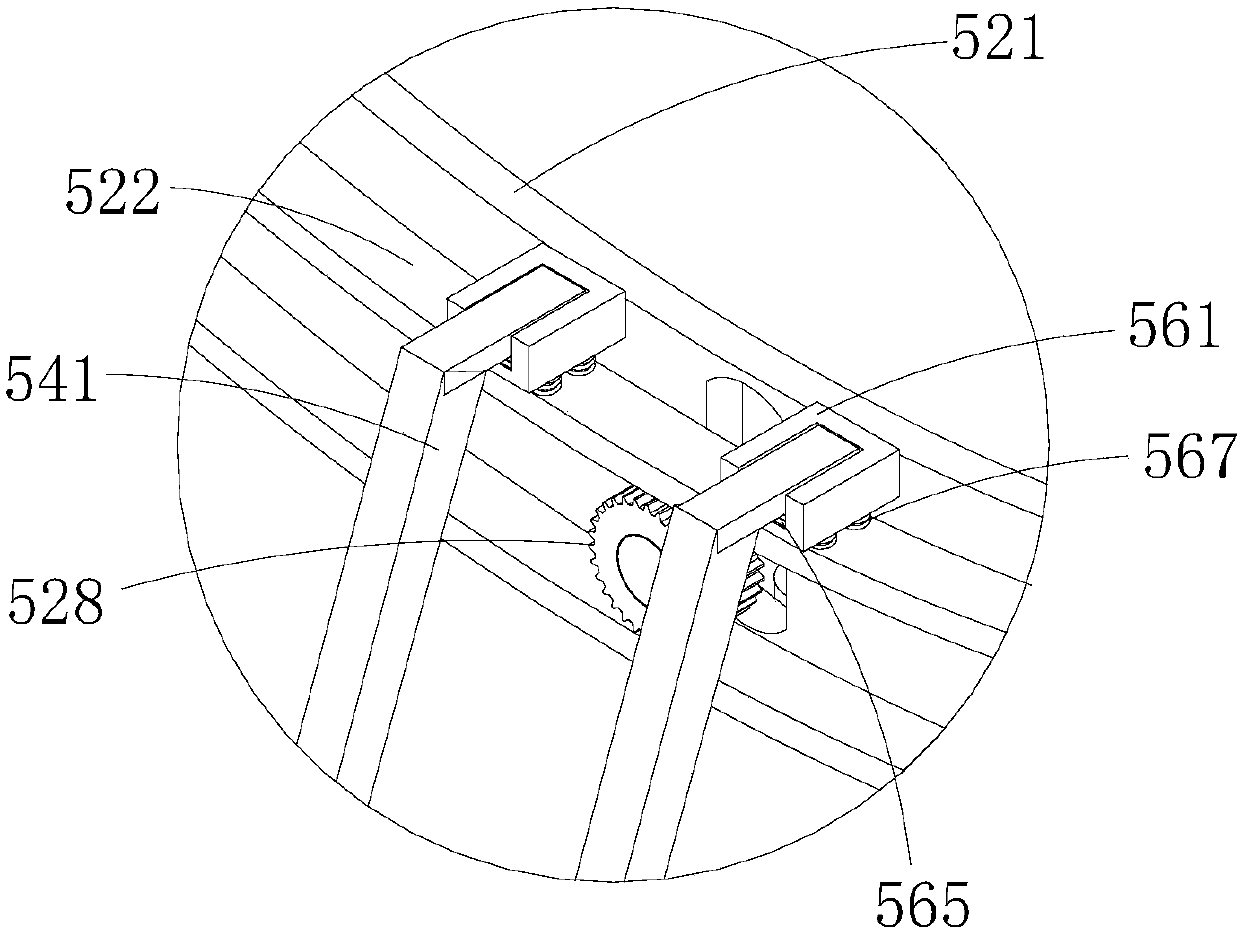

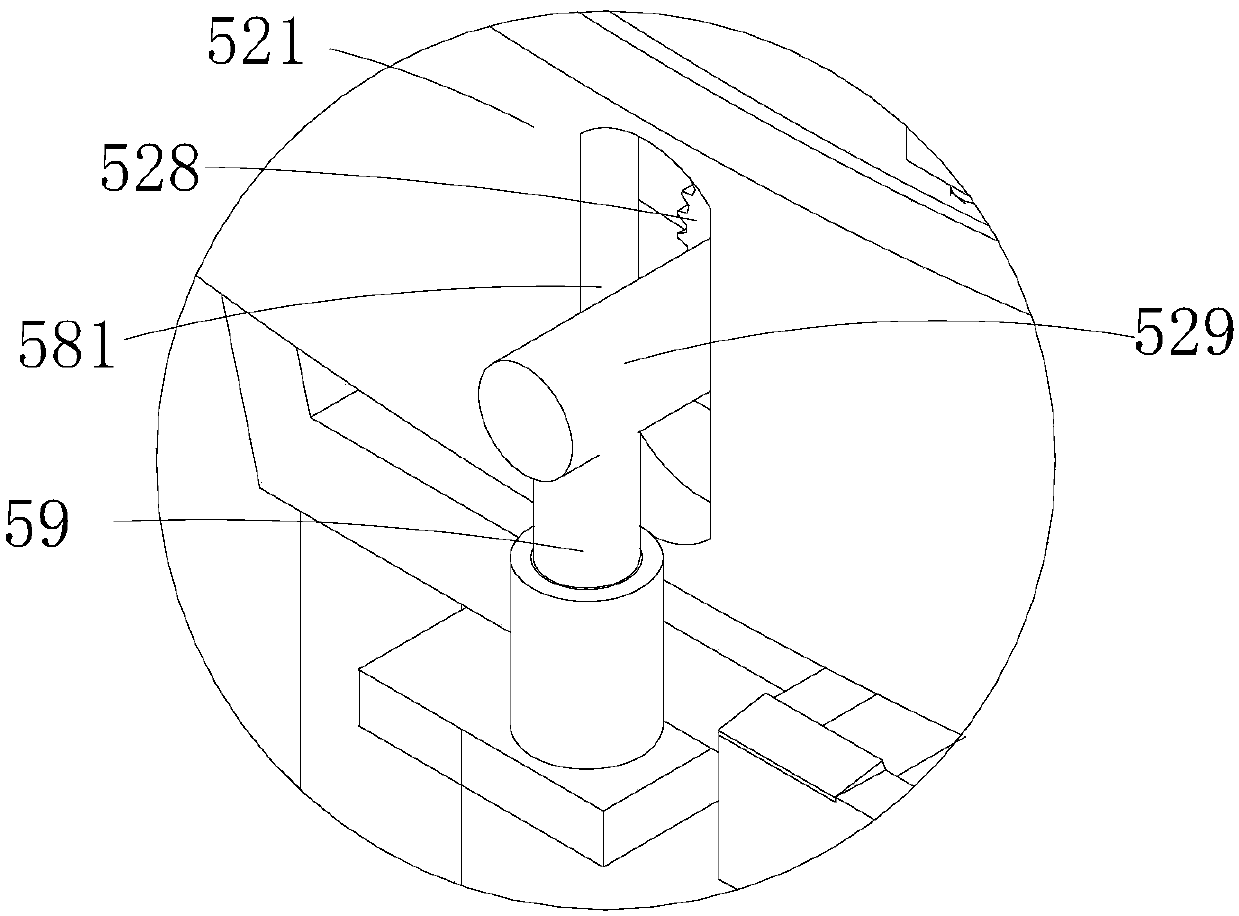

Centrifugal-type small part hot galvanizing system with parts

ActiveCN106222597ASimple structureGood galvanizing effectHot-dipping/immersion processesZincEngineering

The invention discloses a centrifugal-type small part hot galvanizing system with parts. The hot galvanizing system comprises a track mechanism, a feeding area, a galvanizing area and a discharging area, wherein the feeding area, the galvanizing area and the discharging area are arranged along the track mechanism. The track mechanism is movably provided with at least two feeding mechanisms. A centrifugal area is arranged at the terminal of the galvanizing area. The centrifugal area comprises centrifugal equipment and a grabbing mechanism. The grabbing mechanism can transfer charging baskets containing the parts to be machined to the grabbing mechanism from the feeding mechanisms for centrifugal galvanizing. According to the hot galvanizing system, the galvanizing area and the centrifugal area are adjacently arranged, the structure is simplified, and the galvanized machined parts can enter the centrifugal area at once for centrifugal galvanizing. The galvanizing effect is good, the process of repeatedly heating molten zinc to a designated temperature is omitted, and the energy-saving and cost-reducing effects are obvious. Moreover, the phenomenon that the galvanizing effect is influenced due to the fact that the machined parts are polluted when being transferred to the centrifugal area from the galvanizing area is avoided, so that production efficiency is improved, the coating quality is good and safety performance is high.

Owner:嘉兴宝利机械股份有限公司

800 MPa-grade low-carbon hot-galvanized dual-phase steel and preparation method thereof

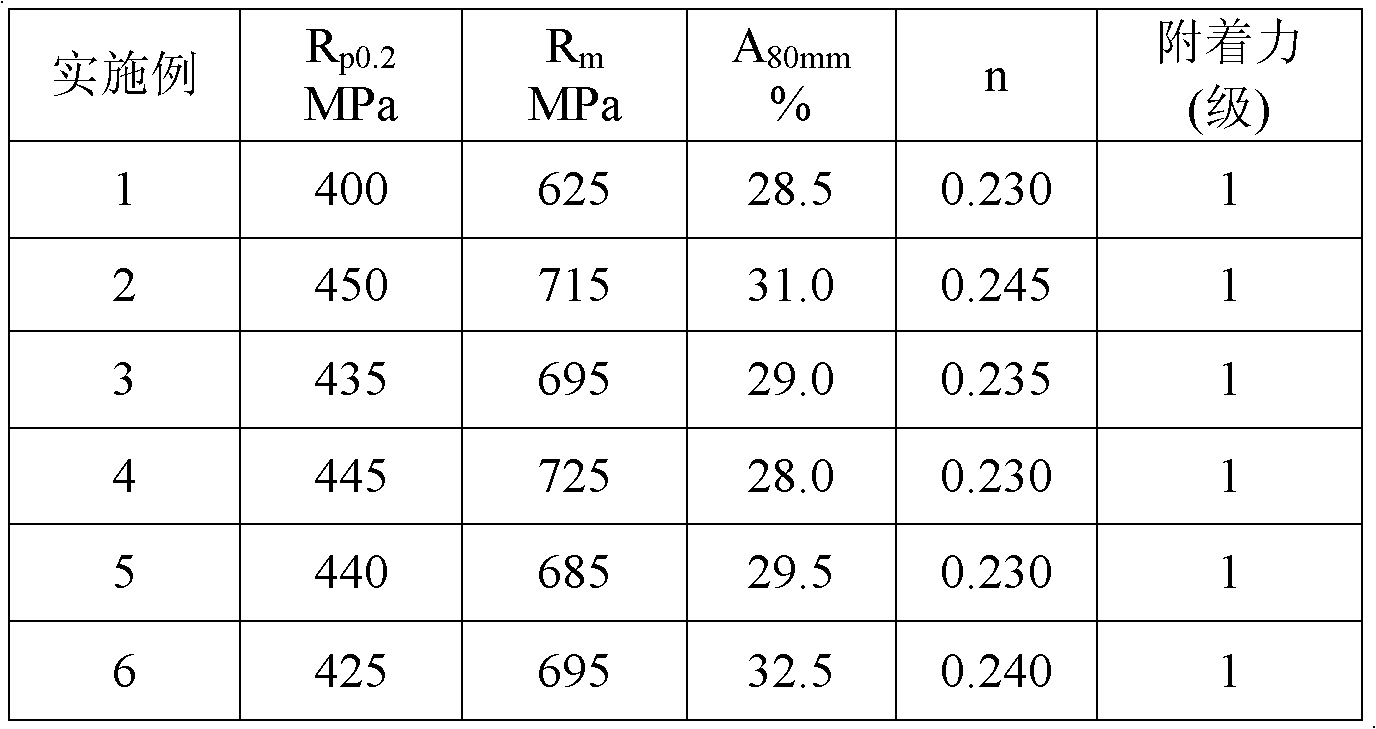

The invention belongs to the technical field of preparation of high-strength steel, and in particular, relates to 800 MPa-grade low-carbon hot-galvanized dual-phase steel and a preparation method thereof. The 800 MPa-grade low-carbon hot-galvanized dual-phase steel comprises the following components in percentage by weight: 0.05-0.10% of C, 0.20-0.60% of Si, 1.30-1.80% of Mn, 0.10-0.60% of Cr, 0.20-0.50% of Mo, 0.02-0.06% of Al, 0.05-0.10% of V, P not more than 0.015%, S not more than 0.005%, N not more than 0.006%, and the balance of Fe and inevitable impurities. The 800 MPa-grade low-carbon hot-galvanized dual-phase steel is low in production cost, high in forming performance and welding performance and excellent in galvanizing performance and mechanical performance, and reaches the yield strength of 450-520 MPa, the tensile strength of 805-840 MPa and the elongation of 15-18%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Hot-dip galvanizing technology

InactiveCN105648379AHot-dip galvanizing process is simpleEliminate repetitive processesHot-dipping/immersion processesWater coolingZinc

The invention discloses a hot-dip galvanizing technology. The hot-dip galvanizing technology is characterized by comprising steps as follows: 1) degreasing; 2) pickling; 3) preparation of a dip plating aid; 4) drying and preheating; 5) hot-dip galvanizing; 6) arrangement: workpiece arrangement after plating mainly includes removal of surface residual zinc and zinc nodules and is mainly completed by the aid of a special vibrator for hot-dip galvanizing; 7) passivation: passivation is performed by the aid of chromate such as 80-100 g / L of Na2Cr2O7 and 3-4 ml / L of sulfuric acid; 8) cooling: water cooling is adopted, but the temperature cannot be too low or too high, and the temperature is generally not lower than 30 DEG C and not higher than 70 DEG C. The hot-dip galvanizing technology is simple, multiple repeated procedures are avoided, the working efficiency is improved, and the galvanizing effect is good.

Owner:CHONGQING YEGAO FURNITURE CO LTD

High-strength hot-dip galvanized complex-phase steel and production method thereof

InactiveCN110343969AGood formabilityGood welding performanceHot-dipping/immersion processesDual-phase steelMaterials science

The invention relates to high-strength hot-dip galvanized complex-phase steel and a production method thereof, and belongs to the technical field of complex-phase steel metallurgy. The hot-dip galvanized complex-phase steel provided by the invention comprises the following chemical components of, in percentage by weight, 0.06%-0.13% of C, 0.20%-0.50% of Si, 1.50%-2.00% of Mn, less than or equal to0.025% of P, less than or equal to 0.005% of S, 0.10%-0.60% of Mo, 0.02%-0.08% of Al, 0.010%-0.070% of Nb, 0.050%-0.120% of Ti, less than or equal to 0.006% of N. The preparation method comprises thefollowing steps of smelting, hot rolling, acid rolling and a hot-dip galvanizing annealing process, wherein the hot-dip galvanizing annealing process adopts a peroxidation reduction process. The prepared hot-dip galvanized complex-phase steel has excellent forming performance, welding performance and galvanized performance, and the requirements of high strength and high elongation are met.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

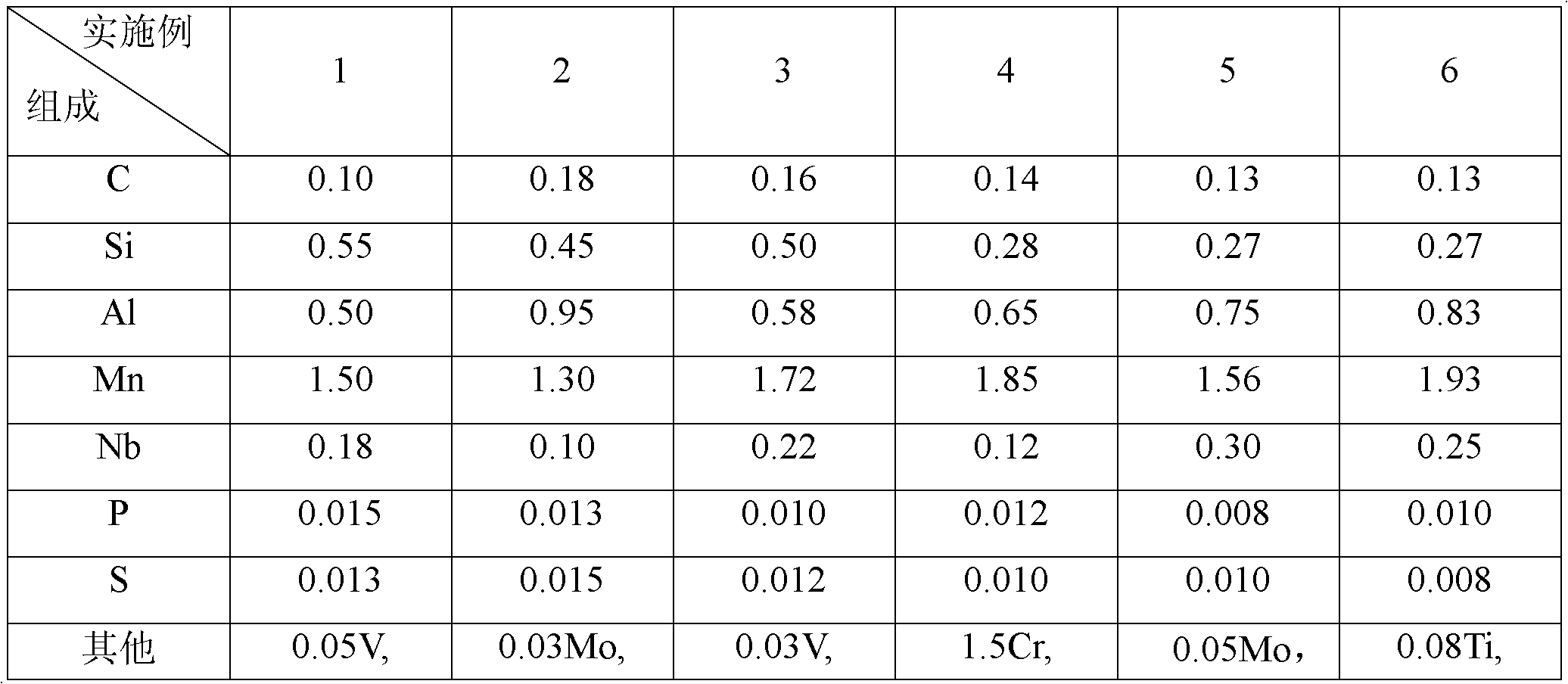

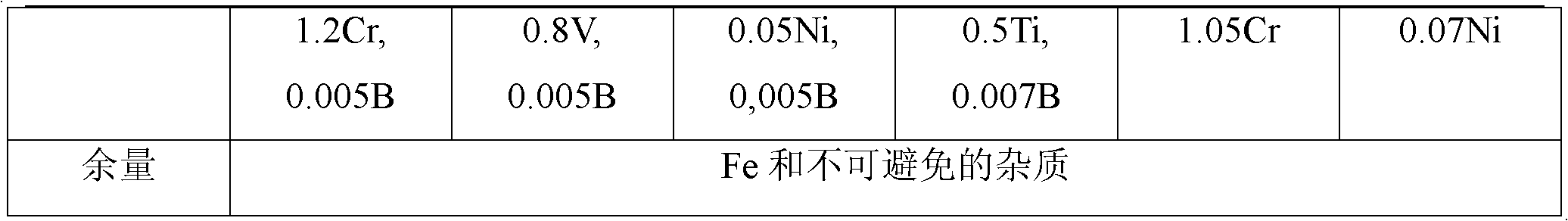

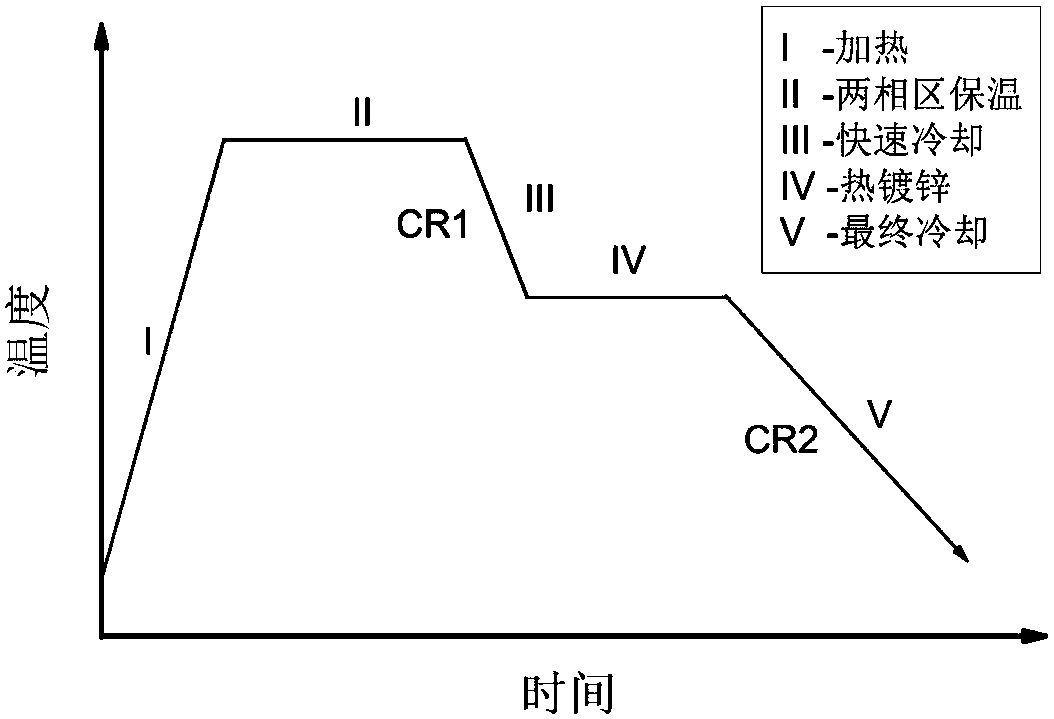

Preparation technique of phase transformation induced plasticity hot galvanizing steel plate

InactiveCN102154604AGood welding performanceGood formabilityHot-dipping/immersion processesImpurityMaterials science

The invention relates to a preparation technique of a phase transformation induced plasticity hot galvanizing steel plate, which comprises the steps of: putting the steel plate at the temperature of 510-530 DEG C into a zinc pot, and then carrying out hot galvanizing in hot-dip galvanizing liquid at the temperature of 460-490 DEG C for 3-15 seconds, wherein the galvanizing liquid comprises the components by weight percent: 0.20-0.24% of Al, 0.01-0.10% of Ni, the balance of Zn and unavoidable trace impurities; the steel plate comprises the components by weight percent: 0.10-0.20% of C, less than or equal to 0.60% of Si, 0.50-1.00% of Al, 1.30-2.0% of Mn, 0.10-0.30% of Nb, and one or more element(s) selected from 1.0-2.0% of Cr, 0.01-0.05% of Mo, 0.01-1.0% of V, 0.005-0.1% of Ti, 0.01-0.10% of Ni and 0.003-0.01% of B; and the steel plate also comprises less than or equal to 0.015% of P, less than or equal to 0.015% of S, the balance of Fe and the unavoidable impurities. The preparation technique is easy to popularize and apply, and the prepared phase transformation induced plasticity hot galvanizing steel plate is good in phase transformation induced plasticity, galvanizing performance and adhesion property of a zinc layer.

Owner:武钢集团有限公司

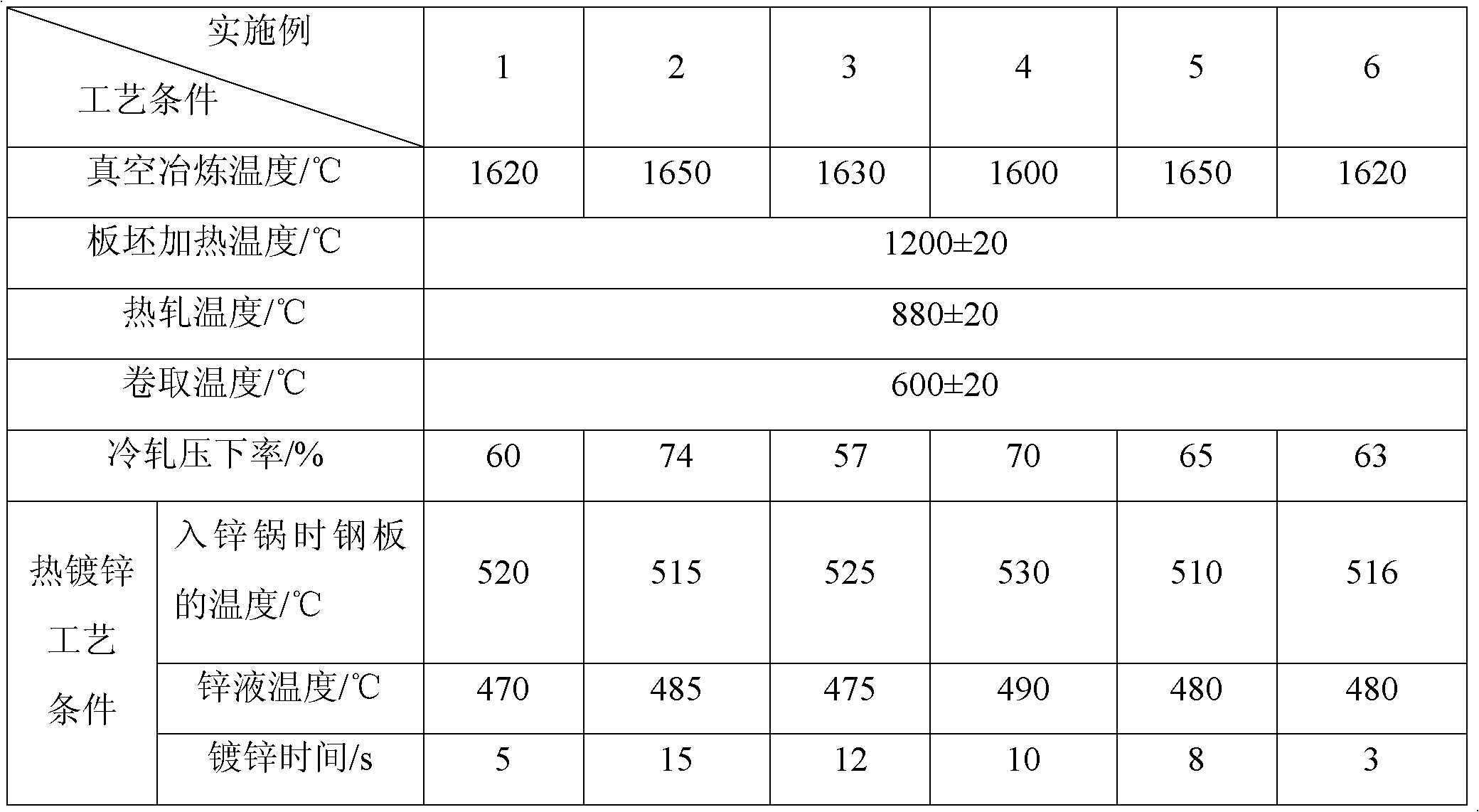

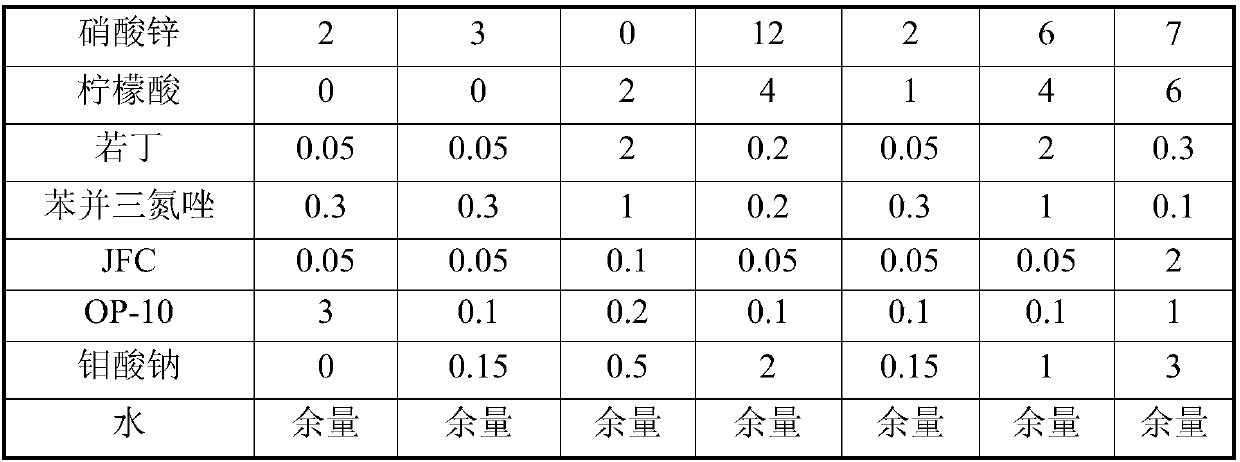

Environment-friendly rust removing and resisting agent applied to acid pickling

The invention relates to an environment-friendly rust removing and resisting agent applied to acid pickling. The rust removing and resisting agent is prepared from the following raw materials in percentage by mass: 17-35% of phosphorous acid, 1-8% of zinc dihydrogen phosphate, 1-8% of an oxidant, 1-10% of a complexing agent, 0.05-5% of a passivator, 0.01-2% of a surfactant, 0.01-2% of a corrosioninhibitor and the balance of water, wherein the oxidant is selected from one or two of cerous nitrate or zinc nitrate; the passivator is sodium molybdate; the corrosion inhibitor is selected from oneor two of rodine and benzotriazole; the surfactant is selected from JFC (fatty alcohol-polyoxyethylene ether) and OP-10 (alkylphenol polyethylene ether). Through the rust removing and resisting agent,the rust removing and resisting effect can be achieved by carrying out acid pickling under the normal temperature; a good galvanization effect can also be achieved after steel products are placed inthe air for a period of time after removing rust; meanwhile, the rust removing and resisting agent has the advantages of low production cost, simple operation process, no harm to operators and environment friendliness.

Owner:工大高腾科技江苏有限公司

Ultra-high-strength hot dip galvanizing complex-phase steel and production method thereof

ActiveCN110343971AGood welding performanceGood formabilityHot-dipping/immersion processesChemical compositionHigh intensity

The invention relates to an ultra-high-strength hot dip galvanizing complex-phase steel and a production method thereof, and belongs to the technical field of complex-phase steel metallurgy. The hot-dip zinc complex-phase steel comprises the chemical components of 0.09%-0.16% of C, 0.20%-0.50% of Si, 1.70%-2. 50% of Mn, equal to or less than 0.025% of P, equal to or less than 0.005% of S, 0.20%-0.60% of Mo, 0.02%-0.08% of Al, 0.010%-0.070% of Nb, 0.030%-0.070% of Ti, and equal to or less than 0.006% of N. The preparation method comprises steps of smelting, hot rolling, acid pickling and hot dip galvanizing annealing process, wherein a pre-oxidation reduction process is adopted in the hot dip galvanizing annealing. The forming performance, welding performance and galvanizing performance ofthe prepared hot dip galvanizing complex-phase steel are good, which reaches the requirements of high strength and high elongation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High strength galvanized steel sheet having excellent uniform elongation and zinc coatability and method for manufacturing the same

ActiveUS20130295410A1Increase in costHighly balanceHot-dipping/immersion processesFurnace typesPearliteSteel plates

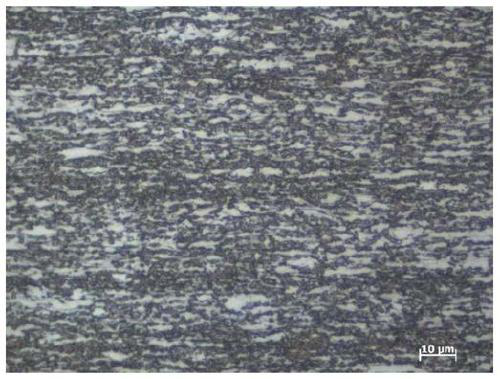

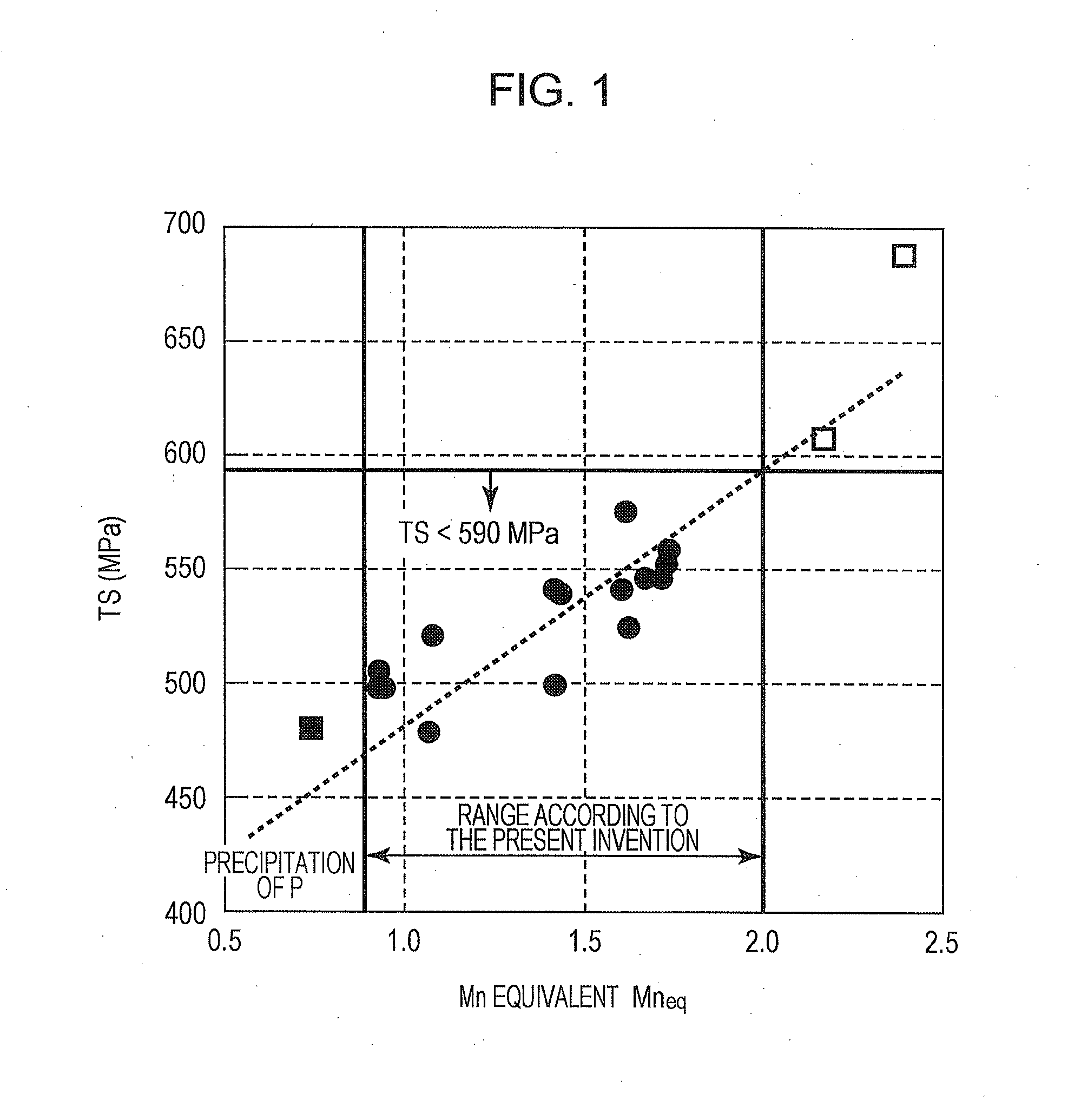

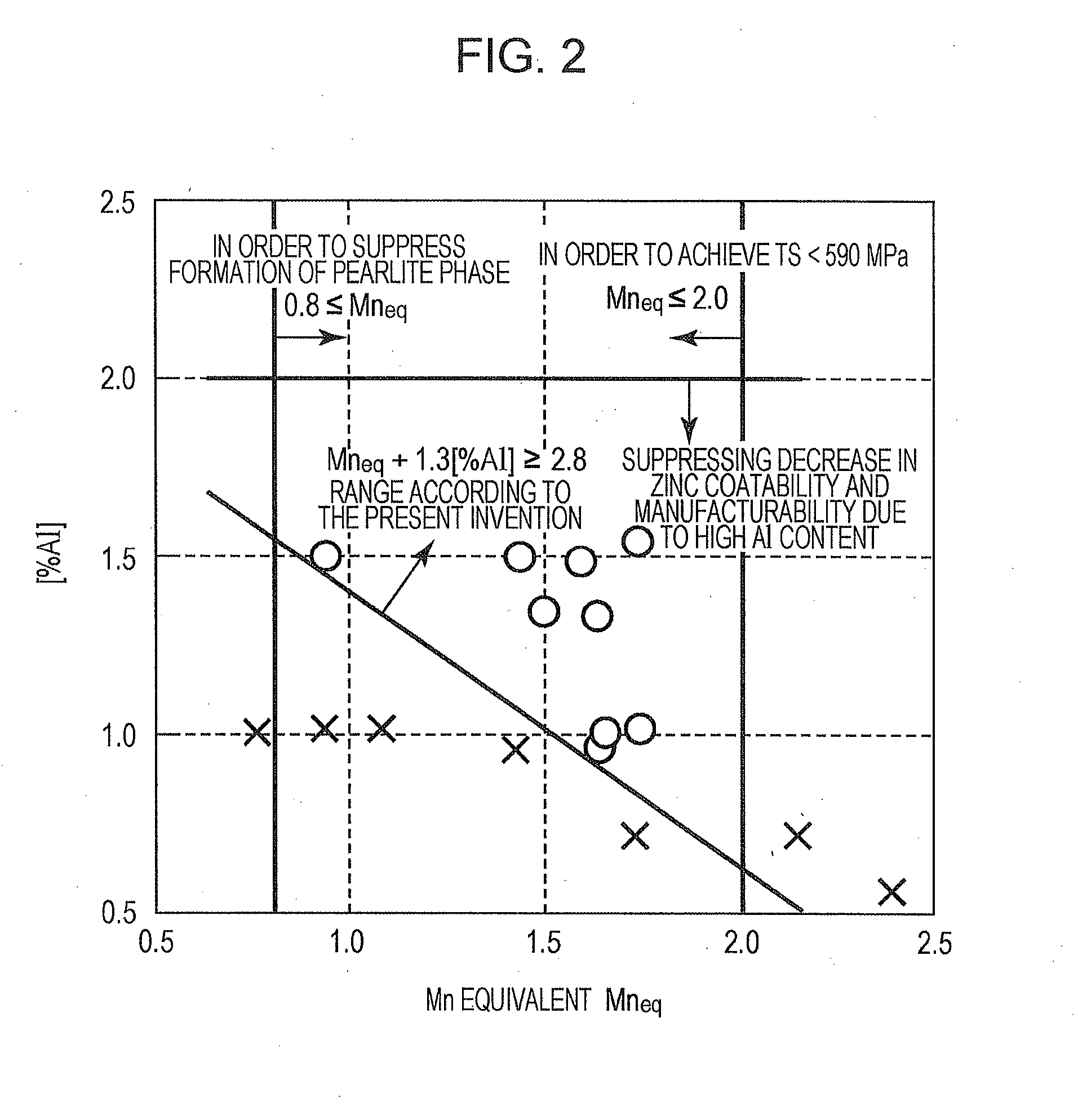

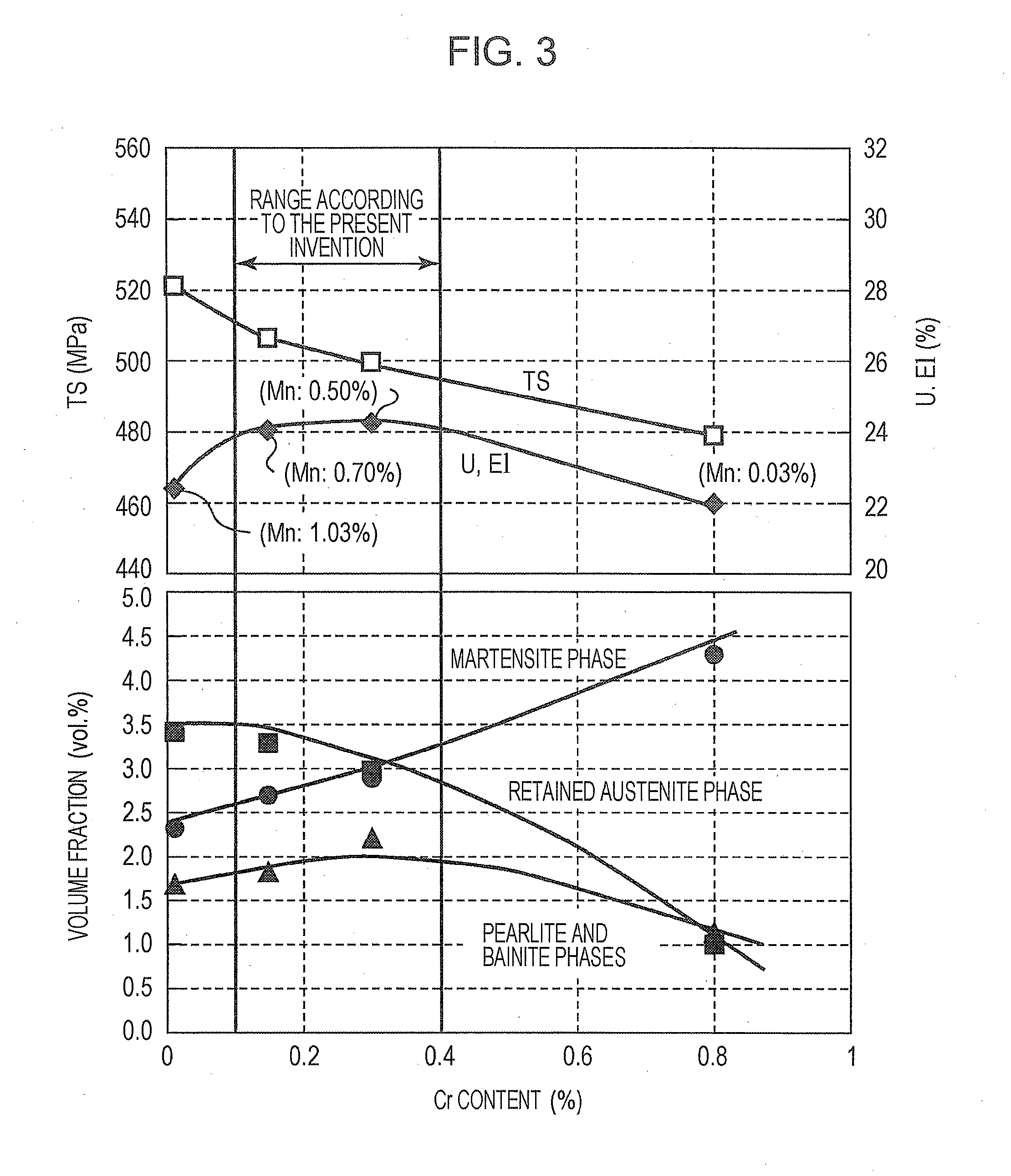

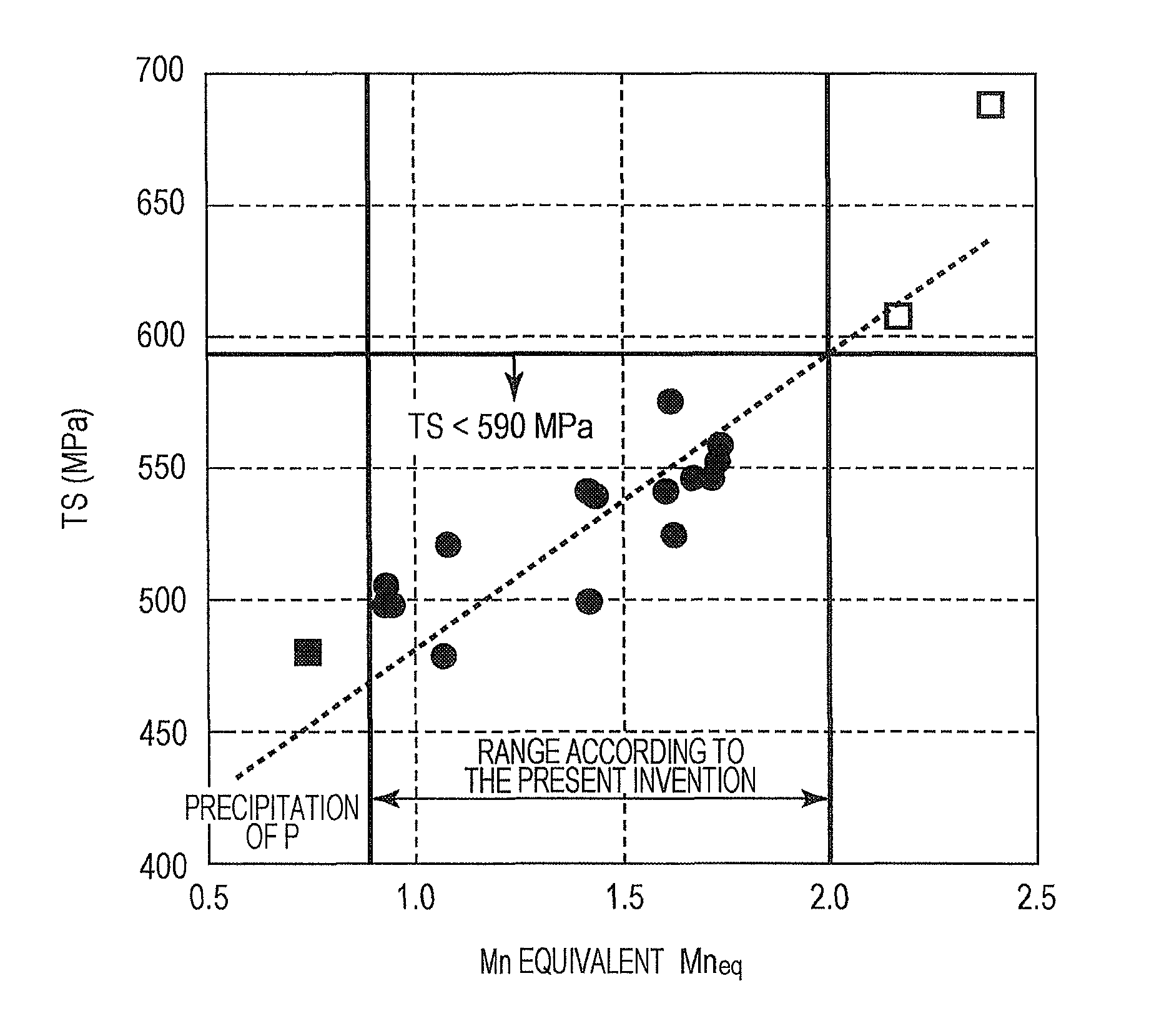

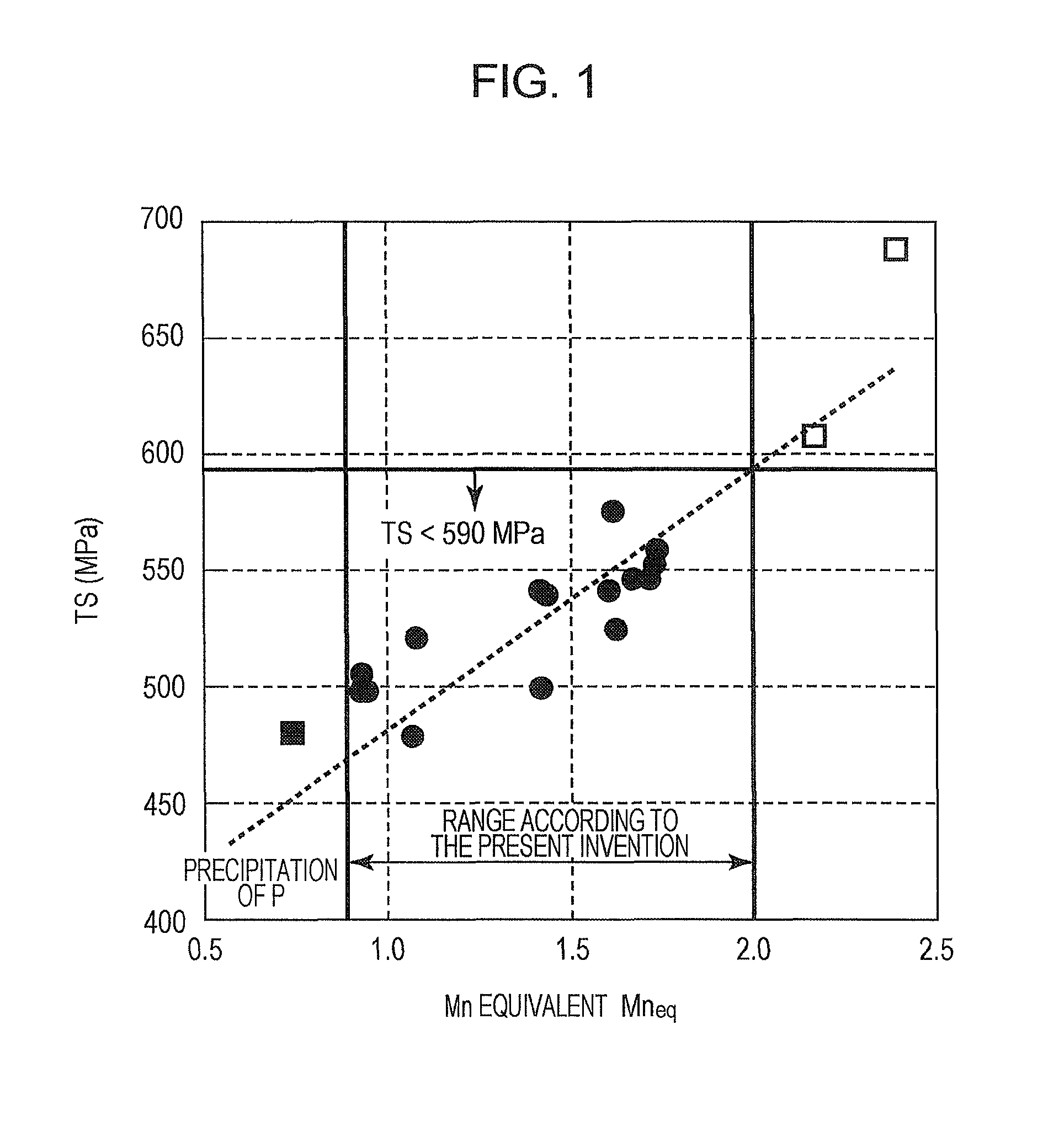

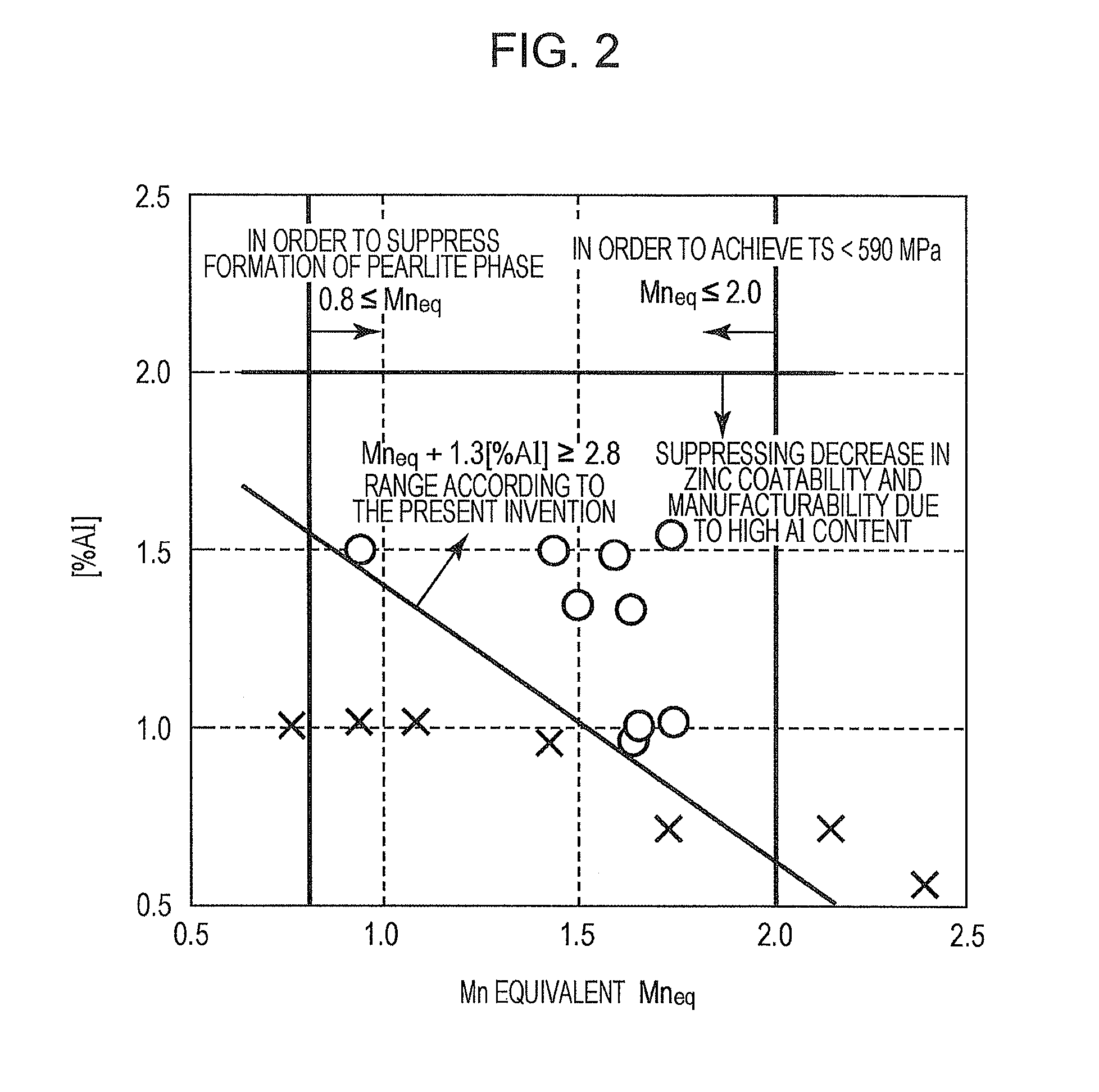

A high strength galvanized steel sheet is provided comprising steel containing C: 0.06% or more and 0.20% or less, Si: less than 0.50%, Mn: 0.5% or more and less than 2.0%, P: 0.05% or less, S: 0.02% or less, Al: 0.60% or more and 2.00% or less, N: less than 0.004%, Cr: 0.10% or more and 0.40% or less and B: 0.003% or less, satisfying the relationships 0.8≦Mneq≦2.0 and Mneq+1.3[% Al]≧2.8, and a microstructure containing a ferrite phase and a second phase whose volume fraction is 15% or less, the second phase having a martensite phase whose volume fraction is 3% or more, a retained austenite phase whose volume fraction is 3% or more and a sum of the volume fractions of a pearlite phase and a bainite phase being equal to or less than the volume fraction of the martensite phase and the volume fraction of the retained austenite phase.

Owner:JFE STEEL CORP

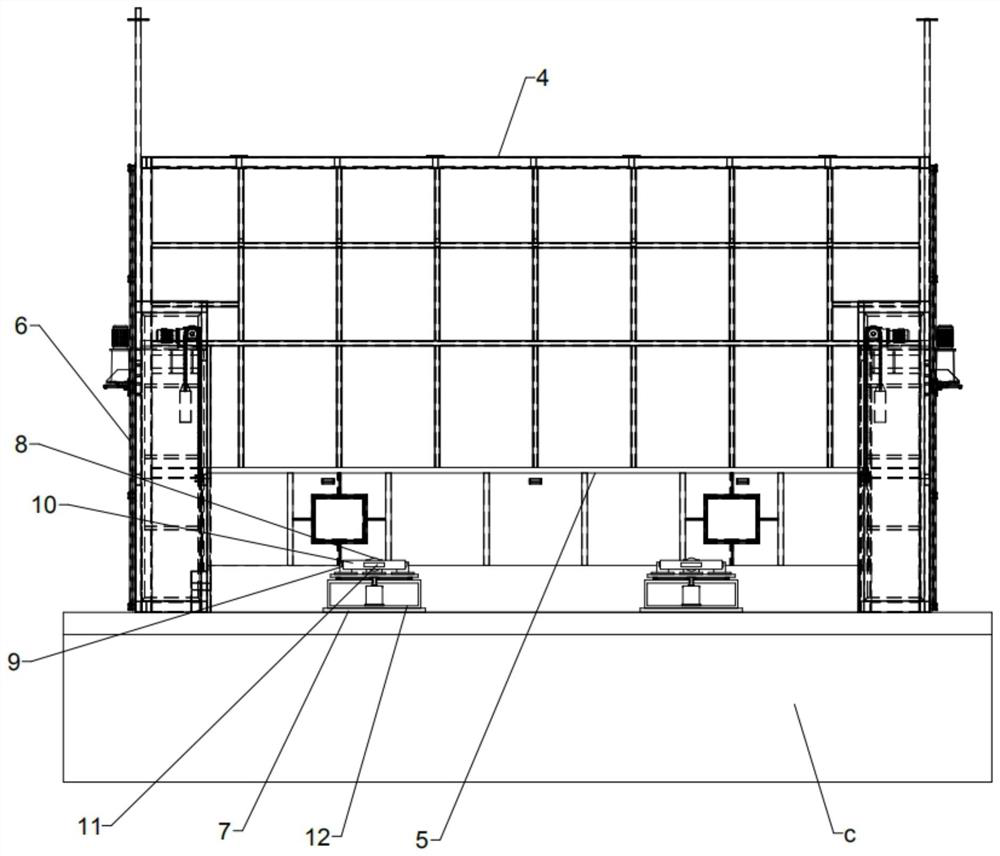

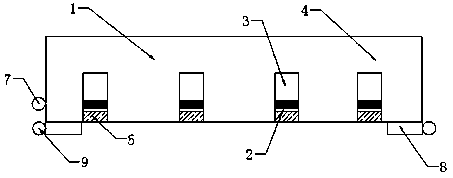

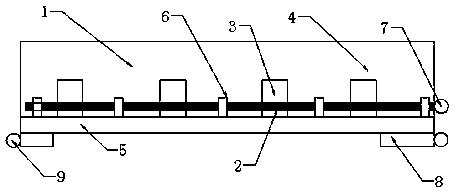

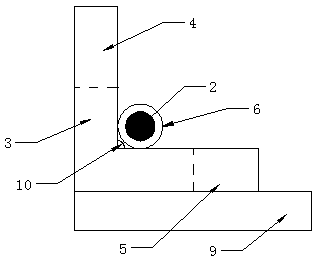

Continuous galvanizing line

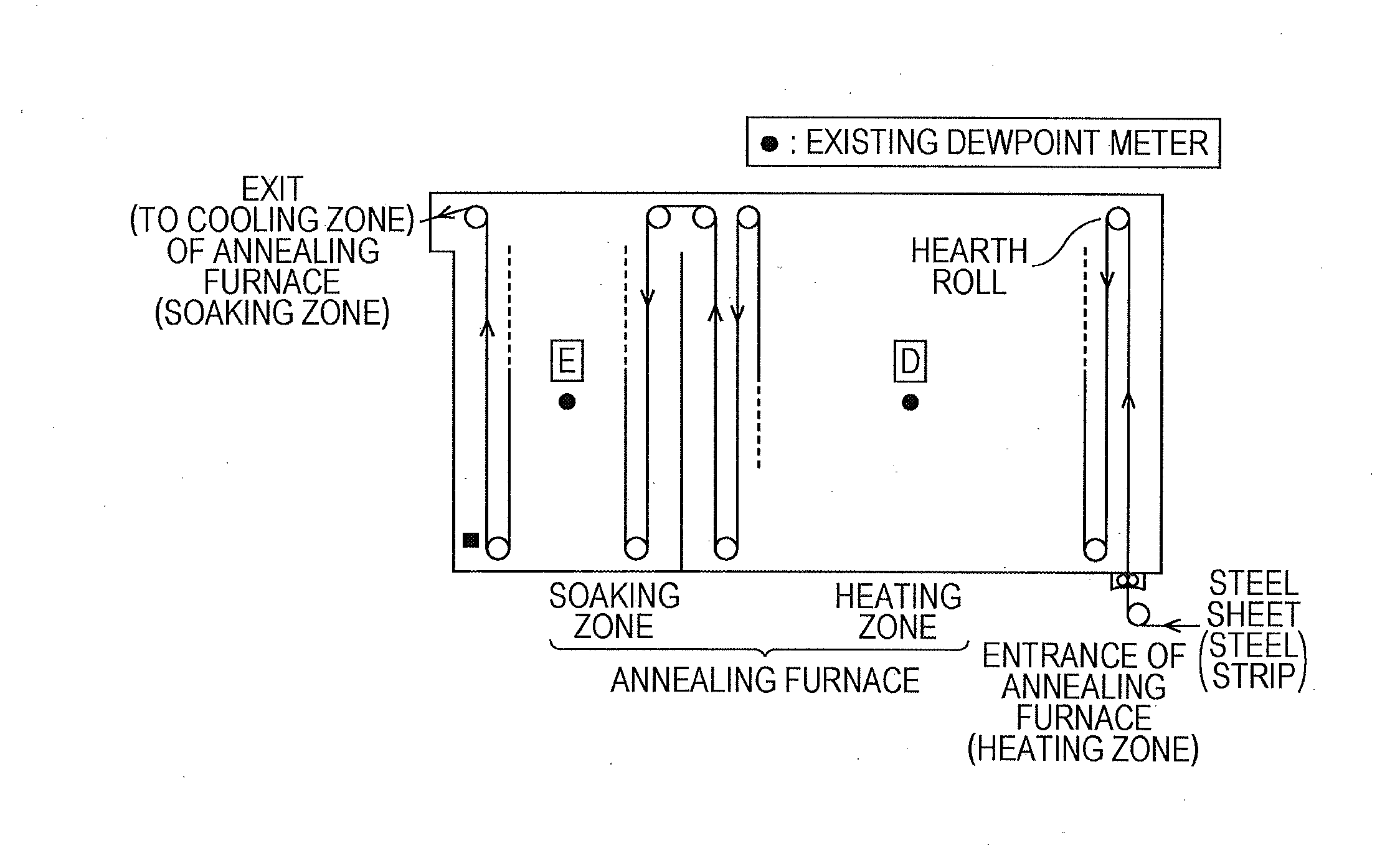

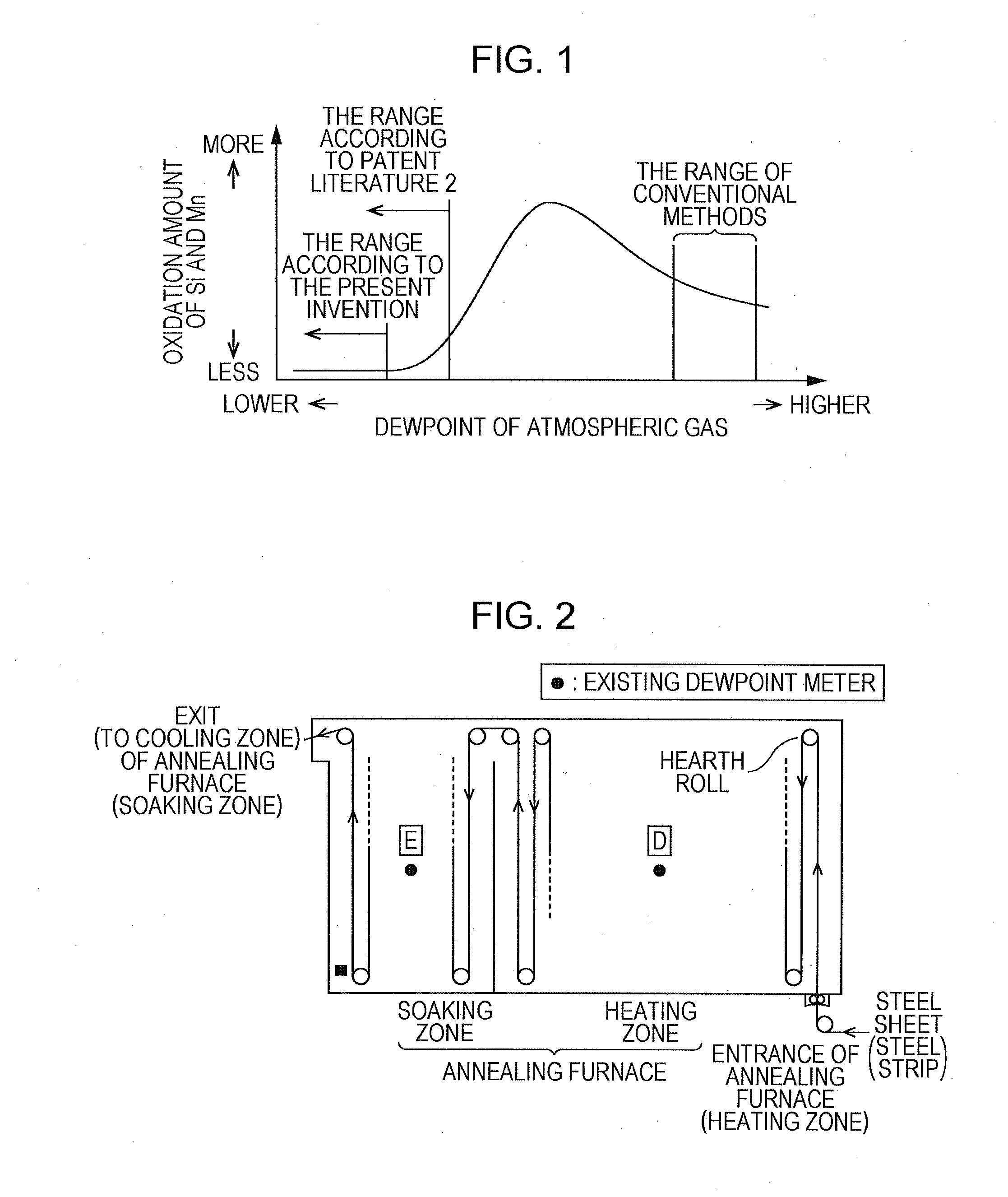

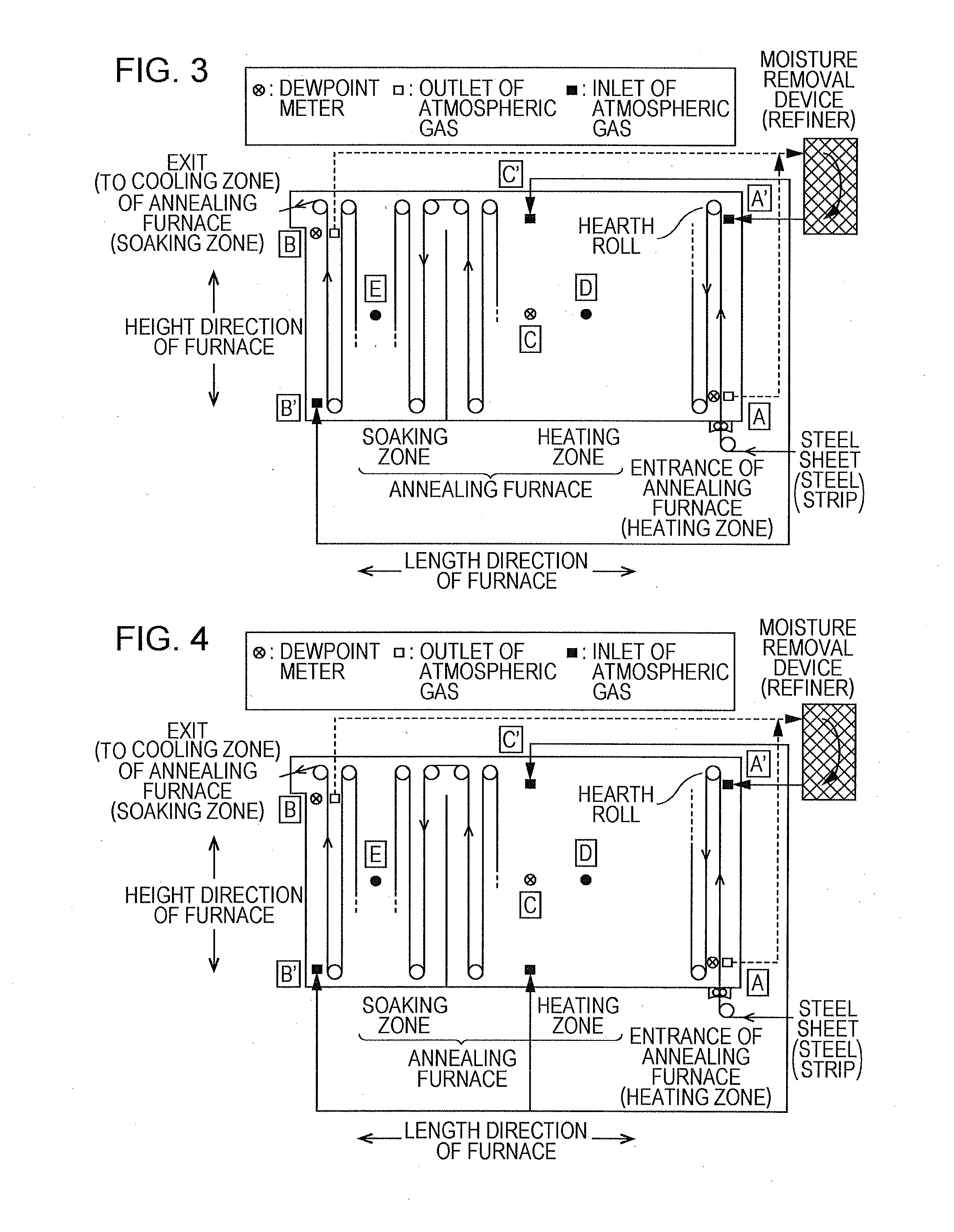

ActiveUS20150090182A1Improve galvanizing effectPrevent oxidationHot-dipping/immersion processesLiquid surface applicatorsMoistureManufacturing line

A continuous galvanizing line having an annealing furnace of an all radiant tube heating type includes a moisture removal device, dew-point meters, outlets through which the atmospheric gas in the furnace is collected and inlets through which the atmospheric gas from which moisture has been removed with the moisture removal device is fed into the furnace, the dew-point meters and the outlets being placed at least at two points which respectively exist on a side wall in the vicinity of the entrance of the annealing furnace and on a side wall in the vicinity of the furnace top or the furnace bottom at a position where a steel sheet has a maximum end-point temperature, the inlets being placed at two points which respectively exist on side walls on the sides opposite to the sides of the two points for the outlets in the height direction of the furnace, making it possible to steadily control the dew-point of the atmospheric gas to be −45° C. or lower and −80° C. or higher throughout the whole area of the annealing furnace.

Owner:JFE STEEL CORP

Titanium-reinforced low-cost Q390 grade hot rolled plate and production method thereof

The invention discloses a titanium-reinforced low-cost Q390 grade hot rolled plate and a production method thereof. The chemical component percentages of the hot rolled plate are, by mass, 0.15%-0.18%of C, less than or equal to 0.10% of Si, 0.45%-0.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.06% of S, 0.015%-0.060% of Als, 0.040%-0.055% of Ti, less than or equal to 0.0050% of N, and the balance Fe and inevitable impurities; and the method includes steps of smelting, refining, continuous casting, heating a plate blank, controlling rolling, controlling cooling and rolling. By adopting a low-manganese and titanium micro-alloy strengthening design, the hot rolled plate has a yield strength greater than or equal to 390 MPa, a strength of extension greater than or equal to 490 MPa, an elongation greater than or equal to 20%, and a Ceq from 0.23 to 0.28, so that the hot rolled plate and the production method thereof have the advantages such as good welding performance, low content of alloy, good effect of galvanization and low cost.

Owner:HEBEI IRON AND STEEL

High-formability high-strength hot-dip galvanized dual-phase steel and production method thereof

ActiveCN110331341AGood welding performanceGood formabilityHot-dipping/immersion processesHigh intensityDual-phase steel

The invention relates to high-formability high-strength hot-dip galvanized dual-phase steel and a production method thereof, and belongs to the technical field of dual-phase steel metallurgy. The hot-dip galvanized dual-phase steel comprises the following chemical components of 0.05-0.10% of C, 0.20-0.50% of Si, 1.50-2.50% of Mn, 0.40-1.00% of Cr, 0.10-0.50% of Mo, 0.02-0.06% of Al, 0.010-0.050% of Nb, 0.04-0.10% of V, less than or equal to 0.015% of P, less than or equal to 0.005% of S and less than or equal to 0.006% of N. The preparation method comprises the following steps of smelting, hotrolling, acid rolling and hot-dip galvanizing annealing, and the hot-dip galvanizing annealing adopts a pre-oxidation reduction process. The prepared hot-dip galvanized dual-phase steel has excellentformability, welding performance and galvanization performance, and meets the requirements of high strength and high elongation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High-strain hardening index hot-dip galvanized high-strength steel and production method thereof

InactiveCN101899619AGood extensibilityImprove ductilityHot-dipping/immersion processesSocial benefitsSheet steel

The invention relates to a hot-dip galvanized high-strength steel and a production method thereof. A base plate of the steel comprises the following components in percentage by weight: 0.11-0.20% of C, 0.51-1.22% of Al, 1.50-2.00% of Mn, 0.07-0.30% of Si, 1.0-2.0% of Cr, no more than 0.015% of P, no more than 0.015% of S, the balance Fe and unavoidable impurities. The production method comprises the following processing steps: smelting and continuously casting into billets; heating the continuous casting billets and maintaining the temperature; roughly rolling; finishing rolling; coiling and carrying out cold rolling; and carrying out hot-dip galvanizing: heating the steel plate after the cold rolling, maintaining the temperature, quickly cooling to 480-510 DEG C, galvanizing and carrying out dip plating for 5-9 seconds, and then cooling to room temperature. The invention solves the problem of galvanizing difficulty of the traditional high-Si content high-strength steel, has the advantages of favorable platability, high drawing performance and good welding performance, corrosion resistance and shaping performance, and has favorable market application prospects and prominent social benefit and economic benefit.

Owner:武汉钢铁有限公司

Galvanized steel wire galvanizing device

InactiveCN112251700AAvoid manual operationReduced chance of poisoningHot-dipping/immersion processesEngineeringGalvanization

The invention relates to the field of galvanizing, and particularly relates to a galvanized steel wire galvanizing device. The galvanized steel wire galvanizing device comprises a galvanizing tank, wherein a pair of guide rollers is mounted on the galvanizing tank, a galvanizing solution tank is dug in the galvanizing tank, a pair of limiting rollers are rotatably connected in the galvanizing solution tank, and steel wires are connected between the guide rollers and the limiting rollers; and an automatic heat preservation scraping mechanism is arranged in the galvanizing solution tank, arranged on the upper sides of the limiting rollers and comprises a cover plate. According to the galvanized steel wire galvanizing device, by arranging the corresponding mechanisms on the galvanizing tank,the solidification speed of a surface layer galvanizing solution is greatly decreased, an operator does not need to frequently conduct scraping work, meanwhile, the hands of the operator are liberated, the operator does not need to manually scrape the galvanizing solution solidified on the inner surface layer of the galvanizing tank, the whole device can be automatically removed, the safety of theoperator is greatly improved, meanwhile, the scraping efficiency is improved, the steel wire galvanizing effect is greatly improved, and the situation that the steel wires are affected by the solidified galvanizing solution is avoided.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

Technology for hot-dip galvanizing of steel tube

InactiveCN109811291AImprove adhesionImprove galvanizing effectHot-dipping/immersion processesWater coolingZinc

The invention discloses a technology for hot-dip galvanizing of a steel tube. The technology comprises the steps of (1) degreasing, (2) acid pickling, (3) galvanizing and (4) post-processing. The galvanizing technology disclosed by the invention has the advantages that the steel tube is cleaned and then treated with pre-galvanizing and hot-dip galvanizing successively, so the surface of the steeltube can be activated and adhesion of a zinc layer on the steel tube surface can be enhanced; and the steel tube is cooled by air blowing and water cooling successively, so the galvanized surface is uniform, the galvanizing effect is good and a color difference can be reduced.

Owner:江苏兴齐智能输电科技有限公司

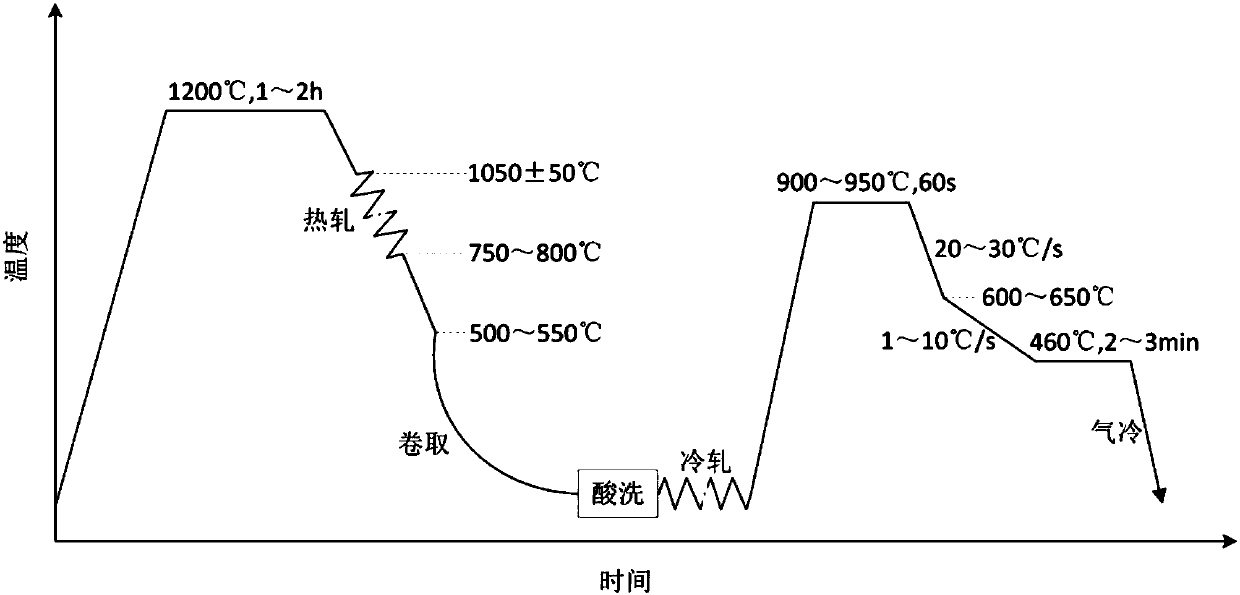

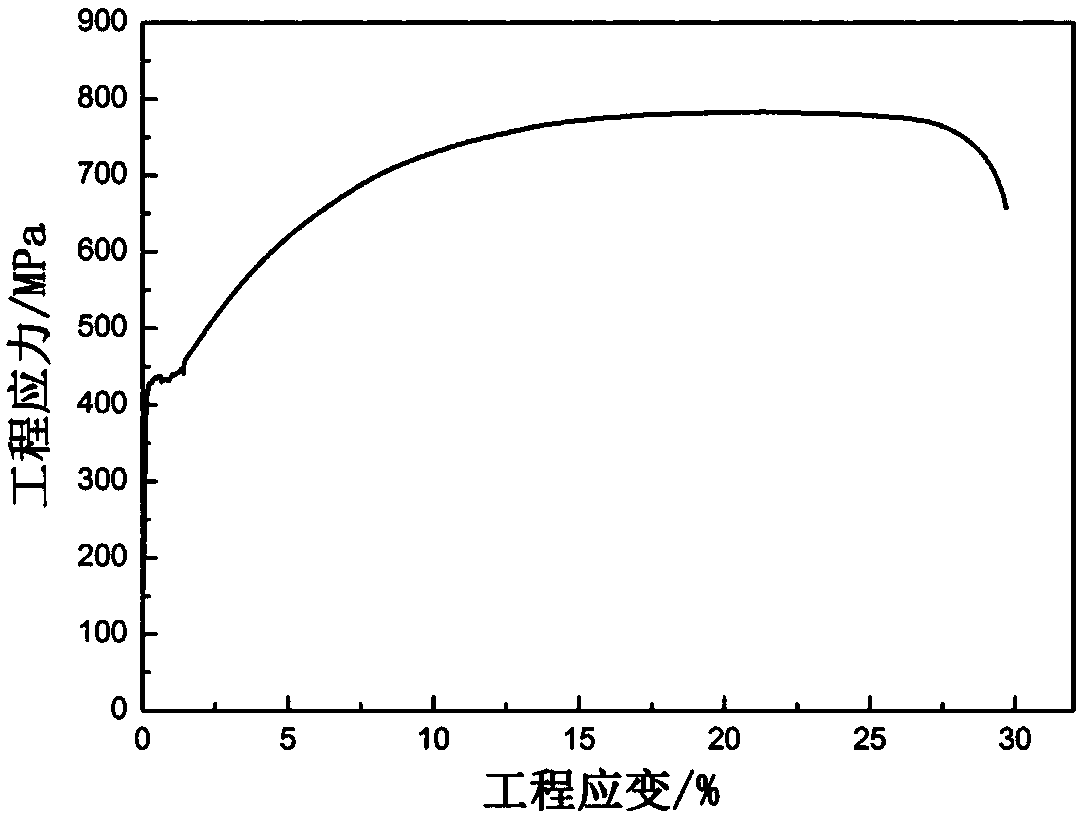

Economical high-aluminum and low-silicon TRIP steel for automobiles and preparation method of TRIP steel

ActiveCN107815593AFew ingredientsImprove recycling ratesProcess efficiency improvementHeat treatedHigh aluminum

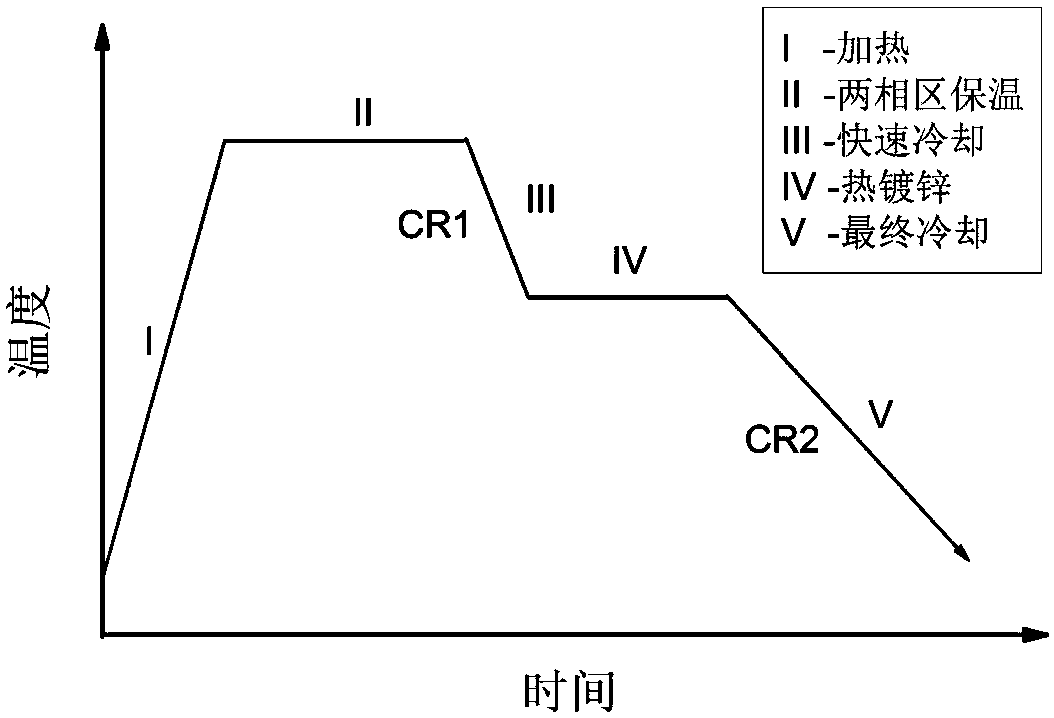

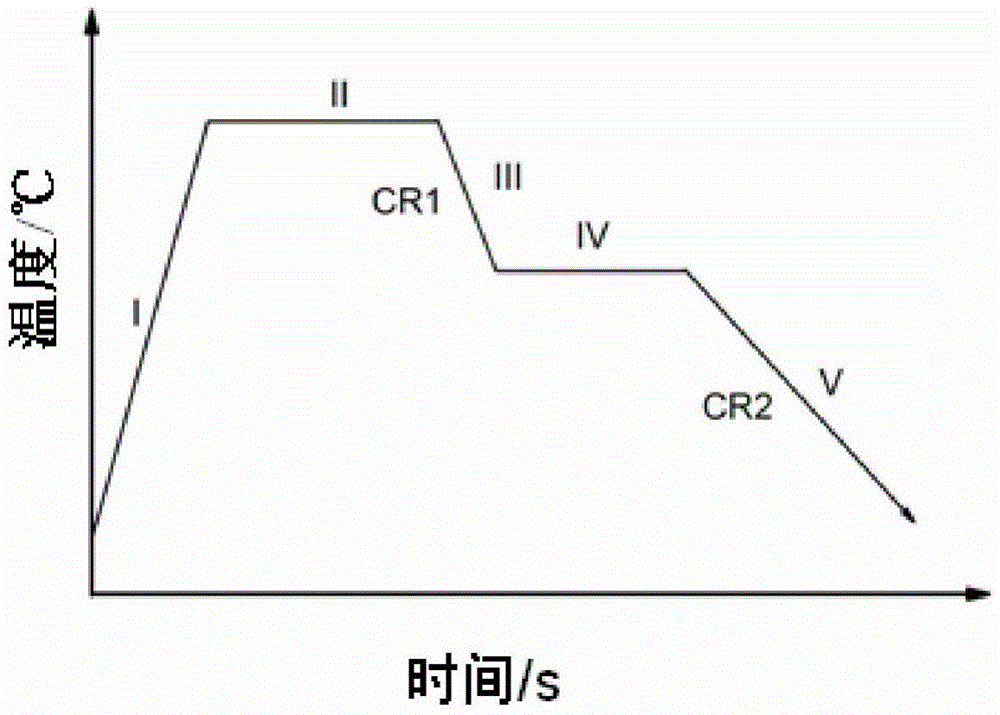

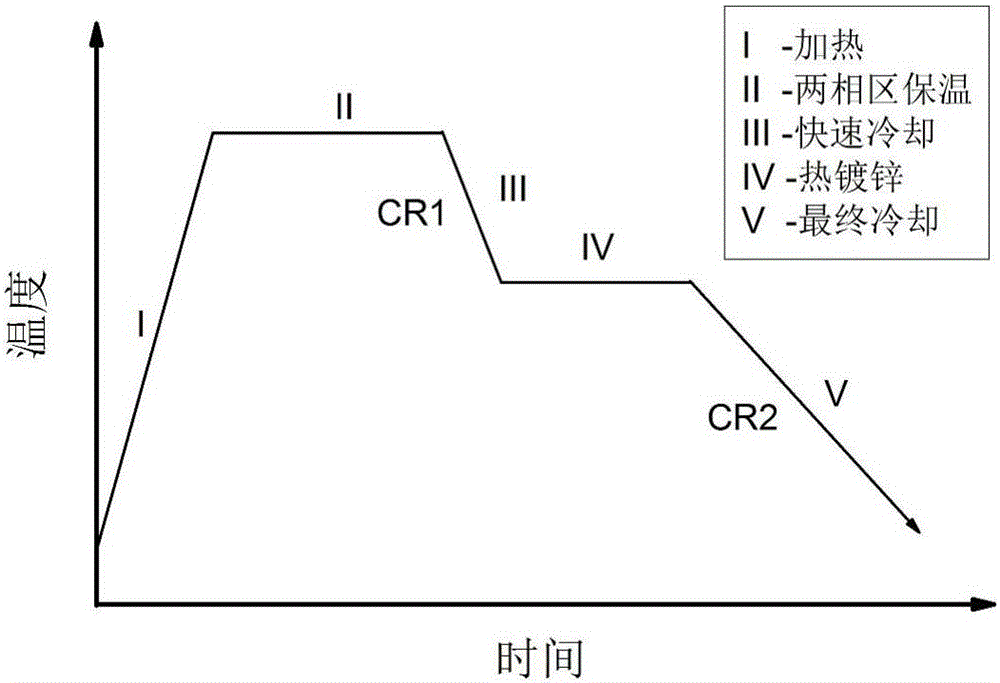

The invention discloses economical high-aluminum and low-silicon TRIP high-strength steel for automobiles and a preparation method of the TRIP steel, and belongs to the technical field of production of high-strength steel for automobiles. The TRIP steel comprises the components of, by mass, 0.15-0.25% of C, 0.1-0.5% of Si, 1.5-3.0% of Al, 1.5-2.5% of Mn, 0.1-1.0% of Cu, 0.01% of P and Lt, 0.005% of S and Lt and the balance Fe. The preparation method comprises the following steps of smelting, pouring, forging, heat preservation, hot rolling, thatching, acid pickling, cold rolling and annealingtreatment. Micro-alloy elements contained in the steel are less, so that the steel is economical and beneficial for being recovered; Si is partially replaced by Al, the ductility is improved, and thegalvanization performance of a cold rolled steel plate is improved; a small quantity of Cu is added, the defect of Al at the aspect of strength is made up through solid solution and precipitation strengthening, and the extension strength is improved. By adopting annealing in a two-phase area and heat preservation in a bainite area in the heat treatment technology, a cold rolled plate with the extension strength being larger than 780 MPa, the ductility being over 25%, the maximum ductility reaching 30% and the plate shape and the surface quality being good is obtained. The temperature of the bainite area is higher than 460 DEG C so as to be matched with the galvanization technology to achieve integration of annealing and galvanization, and thus the high-strength galvanized plate for the automobiles is produced.

Owner:NORTHEASTERN UNIV

Thick hot galvanized complex phase steel and production method thereof

InactiveCN110358967AExcellent welding performance and galvanizing performanceGood economic and social benefitsHot-dipping/immersion processesFurnace typesChemical compositionHigh intensity

The invention relates to thick hot galvanized complex phase steel and a production method thereof and belongs to the technical field of complex phase steel. The hot galvanized complex phase steel provided by the invention comprises 0.06-0.13% of C, 0.20-0.50% of Si, 1.50-2.00% of Mn, less than or equal to 0.025% of P, less than or equal to 0.005% of S, 0.10-0.60% of Mo, 0.02-0.08% of Al, 0.010-0.070% of Nb, 0.050-0.120% of Ti and less than or equal to 0.006% of N. The preparation method comprises the steps of smelting, hot rolling, acid pickling, and hot galvanizing and annealing. The pre-oxidization reduction process is adopted for hot galvanizing and annealing. The hot galvanized complex phase steel prepared through the method has excellent forming property, welding performance and galvanizing performance and meets the requirements for high strength and high elongation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High strength galvanized steel sheet having excellent uniform elongation and zinc coatability

ActiveUS9028973B2High strengthImprove galvanizing effectHot-dipping/immersion processesFurnace typesHigh intensityZinc

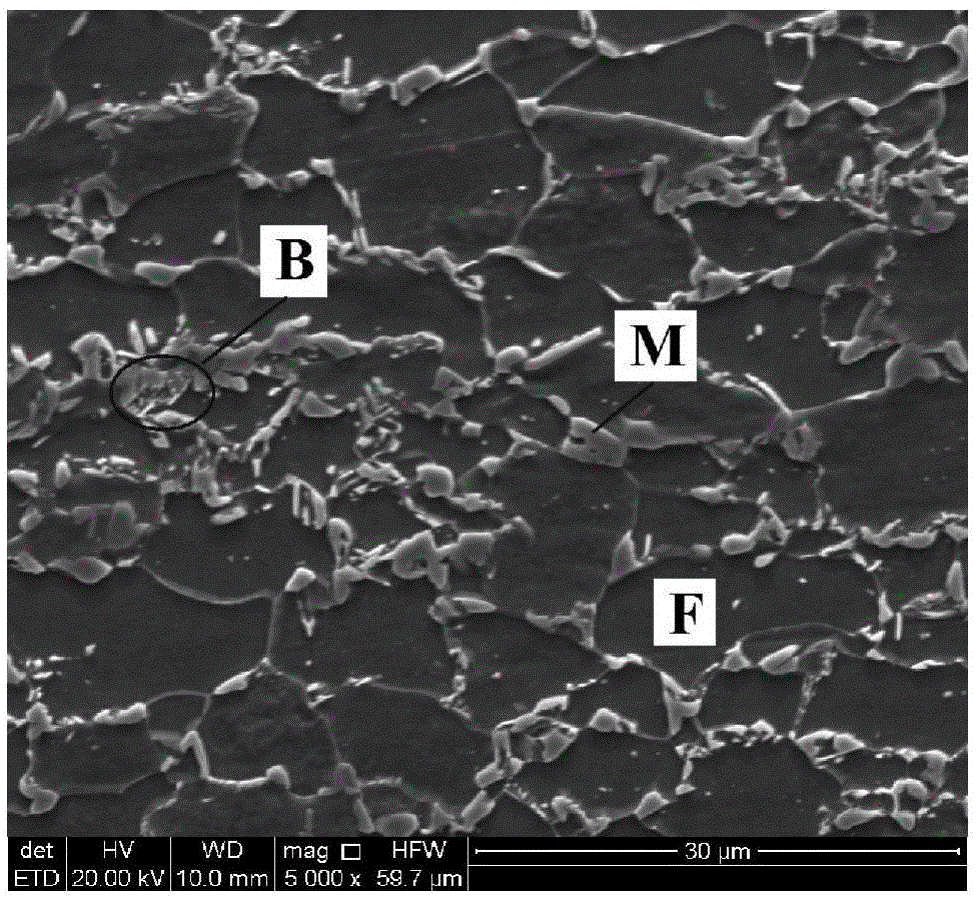

A high strength galvanized steel sheet is provided comprising steel containing C: 0.06% or more and 0.20% or less, Si: less than 0.50%, Mn: 0.5% or more and less than 2.0%, P: 0.05% or less, S: 0.02% or less, Al: 0.60% or more and 2.00% or less, N: less than 0.004%, Cr: 0.10% or more and 0.40% or less and B: 0.003% or less, satisfying the relationships 0.8≦Mneq≦2.0 and Mneq+1.3[% Al]≧2.8, and a microstructure containing a ferrite phase and a second phase whose volume fraction is 15% or less, the second phase having a martensite phase whose volume fraction is 3% or more, a retained austenite phase whose volume fraction is 3% or more and a sum of the volume fractions of a pearlite phase and a bainite phase being equal to or less than the volume fraction of the martensite phase and the volume fraction of the retained austenite phase.

Owner:JFE STEEL CORP

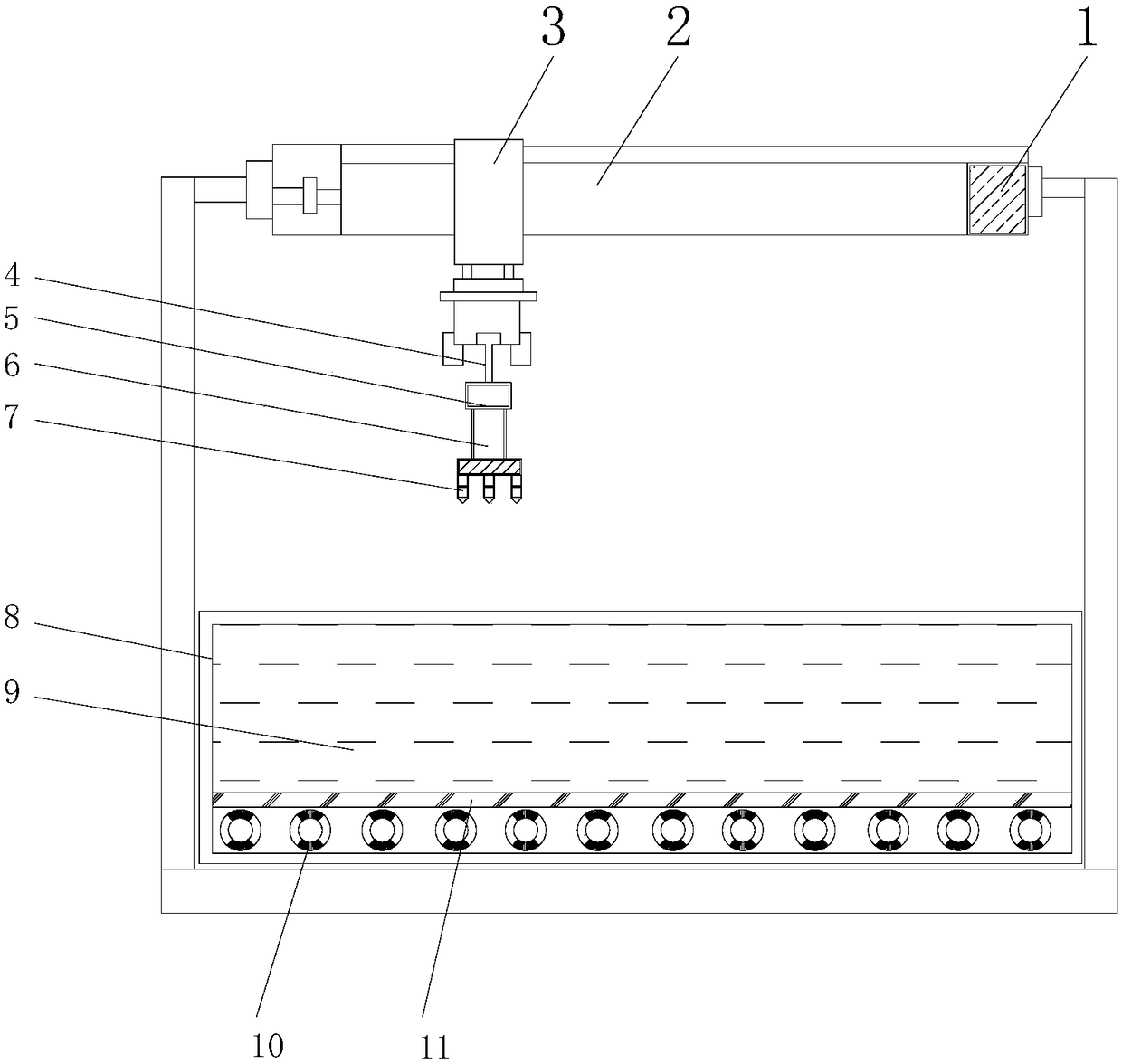

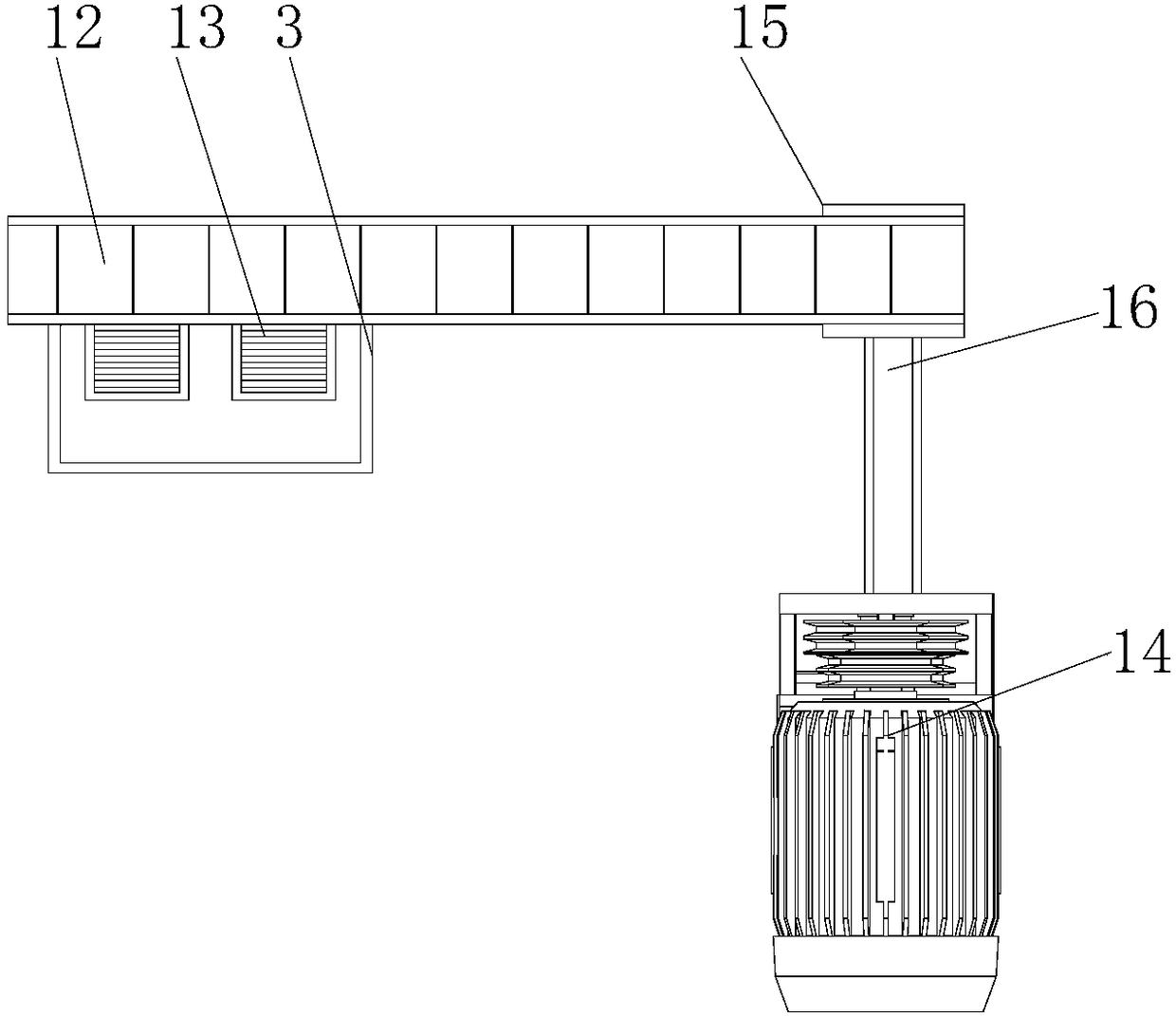

Automatic hot-dip galvanizing method and intelligent processing system

PendingCN112458389AFully automatedImprove galvanizing effectHot-dipping/immersion processesProduction lineSlag

The invention discloses an automatic hot-dip galvanizing method and an intelligent processing system. The automatic hot-dip galvanizing method comprises the following operation steps that S1, a workpiece is hung; S2, movable feeding is conducted; S3, acid pickling treatment is conducted; S4, hot-dip galvanizing is conducted; Step S5, cooling and passivating are conducted; S6, repairing and packaging are conducted; and S7, finished product warehousing is conducted. A whole production line is controlled by a central processing unit (PLC system) in a unified manner, and linkage actions of all units are coordinated, so that automation of the whole production line is achieved; meanwhile, an existing hot-dip galvanizing mechanism is improved, telescopic ash removing mechanisms are arranged at the two sides of an ash removing window of a zinc pot, after zinc dipping operation is completed, in the workpiece lifting process, the ash removing window is opened, the telescopic ash removing mechanisms are controlled to act to knock the workpiece, so that zinc slag on the workpiece falls off, and the galvanizing effect is improved; and a zinc slag collecting mechanism is arranged at the inner side of the ash removing window.

Owner:山东承泽智能装备科技有限公司

Spare part hot-dip galvanizing process

InactiveCN107858619AEasy Dip PlatingLow technical requirementsHot-dipping/immersion processesCarbonizationDip-coating

The invention discloses a spare part hot-dip galvanizing process. The spare part hot-dip galvanizing process comprises the steps of carbonizing to remove oil: carbonizing a hot forging part to removeoil by insulating the hot forging part with waste heat, and carbonizing a cold part to remove oil by burning of a continuous carbonizing furnace or gas flame; performing shot blasting: performing shotblasting on a workpiece to remove oxide skin from the surface of the workpiece; heating hydrogen to reduce: sending the workpiece to a reduction reaction channel, and heating the workpiece under thegas protection of reducing atmosphere, so that the temperature of the surface of the workpiece is increased to more than 600 DEG C, and reduction reaction occurs on the oxide layer of the surface of the workpiece; and performing dip plating: sending the workpiece to a container filled with liquid zinc through a discharge opening of the reduction reaction channel for dip plating, wherein the temperature of the liquid zinc is 420 to 580 DEG C. According to the spare part hot-dip galvanizing process, the production processes can be reduced, and severe pollution links of acid pickling, alkali washing, soaking in a plating support agent, drying after soaking in the plating support agent and soaking zinc with the plating support agent and subsequent waste liquid and waste water and waste gas treatment are omitted, so that the energy consumption is reduced, the pollution is reduced, the labor cost and the equipment cost are greatly reduced, and the production efficiency is improved.

Owner:宋德兴

A kind of 600mpa grade vanadium-containing hot-dip galvanized dual-phase steel and its preparation method

ActiveCN105603325BImprove hardenabilityHigh strengthHot-dipping/immersion processesSocial benefitsEconomic benefits

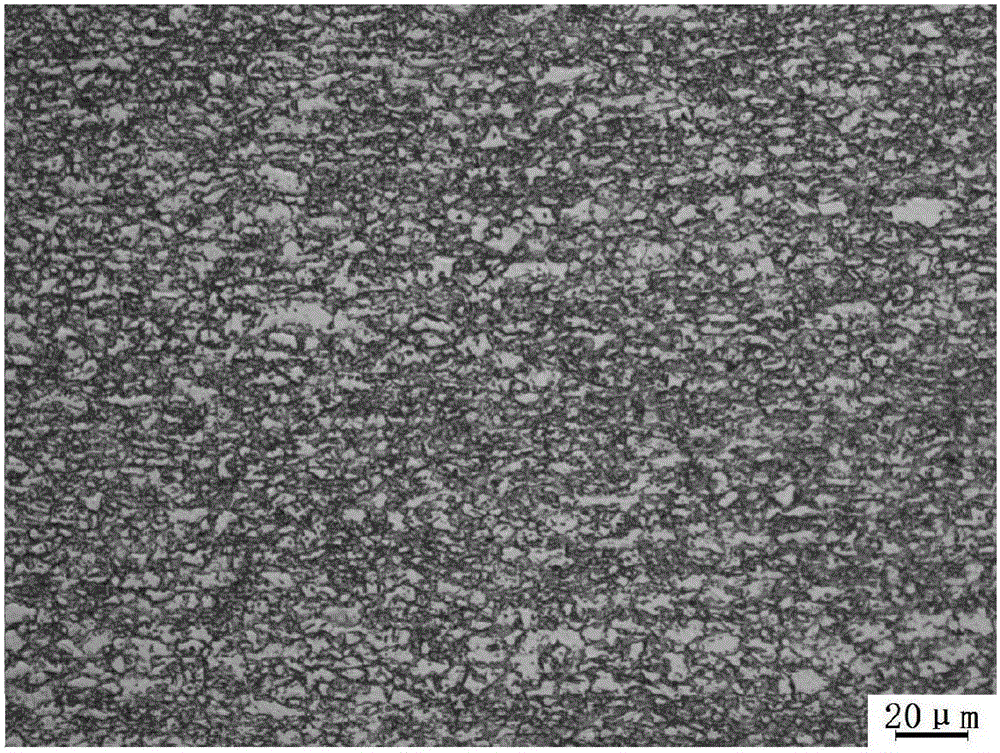

The invention belongs to the technical field of hot-galvanizing high-strength steel for automobiles and particularly relates to 600MPa-level vanadium-containing hot-galvanizing dual-phase steel and a preparation method thereof. The dual-phase steel comprises the following components in percentage by weight: 0.04%-0.10% of C, 0.10%-0.60% of Si, 1.30%-1.90% of Mn, 0.10%-0.50% of Cr, 0.05%-0.25% of Mo, 0.01%-0.06% of Al, 0.01%-0.05% of V, less than or equal to 0.020% of P, less than or equal to 0.015% of S, less than or equal to 0.006% of N and the balance of Fe and inevitable impurities. According to the dual-phase steel, partial Cr and Mo are replaced with trace V and Si, so that the strength and hardenability of the dual-phase steel are improved, and meanwhile, the production cost is lowered; and by combining with a pre-oxidization reduction process, the surface galvanizing quality of the dual-phase steel is improved. The hot-galvanizing dual-phase steel prepared by virtue of the preparation method has excellent forming property, welding property and galvanizing property, oblivious cost advantage and remarkable economic and social benefits.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Novel antitheft fence

InactiveCN105672757AImprove surface activityLow temperature requirementFencingEngineeringScrew thread

The invention discloses a novel antitheft fence. Three sets of transverse rods are arranged. Each set of transverse rods include a first transverse rod unit and a second transverse rod unit. The transverse rods are hollow square hot galvanizing steel pipes. The front side face and the rear side face of each first transverse rod unit are provided with a plurality of parallel and opposite first fixing holes. The front side face and the rear side face of each second transverse rod unit are provided with a plurality of parallel and opposite second fixing holes. Positioning holes are formed in the rear side faces of the second transverse rod units. Vertical rods are hollow square hot galvanizing steel pipes. Bolts are arranged between the first transverse rod units and the vertical rods. Nut sleeves are arranged between the second transverse rod units and the vertical rods. Each nut sleeve comprises a nut head and a sleeve, wherein tip protrusions are arranged at the two ends close to the nut head respectively. Ends of the bolts are installed in the sleeves through screw-thread fit. The tip protrusions are matched with the positioning holes. Elastic gaskets are arranged between the bolts and the first transverse rod units. The fence has the advantages of being high in corrosion resistance and long in service life, and the problem that a fence is stolen can be well solved.

Owner:润桐(苏州)技术服务有限公司

Hot galvanizing support tool device

InactiveCN108411234AGuaranteed galvanizing effectConstant internal temperatureHot-dipping/immersion processesEngineeringElectromagnetic heating

The invention discloses a hot galvanizing support tool device. The hot galvanizing support tool device comprises a power mechanism and a liquid zinc box. Liquid zinc is arranged inside the liquid zincbox, a heating plate is arranged below the liquid zinc, and electromagnetic heating coils are arranged below the heating plate. A sliding support is arranged on the left side of the power mechanism,a moving block is connected with the outer side of the sliding support in a sliding mode and connected with a support located at the bottom of the moving block, and the support is connected with a stretching rod through a fixing block. An electric motor is arranged inside the power mechanism and connected with a belt conveying groove through a rotating shaft, and the belt conveying groove is connected with a rotating wheel in the moving block through a conveying belt in a sliding mode. According to the hot galvanizing support tool device, the electric motor is connected with the belt conveyinggroove through the rotating shaft, the belt conveying groove is connected with the rotating wheel in the moving block through the conveying belt in the sliding mode, and therefore the moving block can stably and gently slide on the sliding support, the stretching rod downwards extends when the moving block arrives at the corresponding position, a mechanical arm can firmly catch a galvanized object, and the galvanizing effect of the galvanized object is guaranteed.

Owner:XIANGSHUI YIXIN WEIYE TECH CO LTD

Hot galvanizing hanging tool

ActiveCN109097716AUniform gapGood galvanizing effectHot-dipping/immersion processesEngineeringMechanical engineering

The invention discloses a hot galvanizing hanging tool. The hot galvanizing hanging tool comprises a hanging tool body and hanging tool clamping pins, wherein a plurality of rectangular holes are formed in the middle part of the hanging tool body in an equal spacing manner, and are parallel to the longitudinal axis of the hanging tool body; the hanging tool body is of a bent structure along a middle part horizontal axis; the bent structure is used for dividing the hanging tool body into a vertical section and a horizontal section; the included angle between the vertical section and the horizontal section is 90 degrees; a plurality of clamping rings are arranged on the upper side close to the vertical section, of the horizontal section, and each clamping ring is located between every two adjacent rectangular holes; an annular clamping pin head is arranged at one ends of the hanging tool clamping pins; the other end of each hanging tool clamping pin sequentially penetrates through the clamping rings to be movably connected with the horizontal section; and connecting plates are respectively arranged on lower sides of two ends of the horizontal section. The hot galvanizing hanging tooldisclosed by the invention is simple in structure and convenient to operate; and the discharging speed is increased, and the production efficiency is improved.

Owner:徐州科聚利鑫机械设备制造有限公司 +1

A kind of 1000mpa grade low-carbon hot-dip galvanized dual-phase steel and its preparation method

ActiveCN105950998BGood formabilityImprove welding effectHot-dipping/immersion processesHigh intensityMechanical property

The invention belongs to the technical field of steel for high-strength automobiles and particularly relates to 1000 MPa low-carbon hot-galvanized dual-phase steel and a preparation method thereof. The 1000 MPa low-carbon hot-galvanized dual-phase steel comprises, by weight, 0.05-0.10% of C, 0.20-0.60% of Si, 1.40-1.90% of Mn, 0.20-0.70% of Cr, 0.20-0.50% of Mo, 0.02-0.06% of Al, 0.020-0.050% of Ti, 0.010-0.040% of Nb, 0.0010-0.0030% of B, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.006% of N, and the balance Fe and inevitable impurities. The 1000 MPa low-carbon hot-galvanized dual-phase steel has the high forming property and high welding property and the excellent galvanizing property and mechanical property. The 1000 MPa low-carbon hot-galvanized dual-phase steel is 630-700 MPa in yield strength, 1010-1050 MPa in tensile strength and 11-14% in elongation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Steel wire galvanization method and galvanization device used in steel wire galvanization method

PendingCN110923599AImprove efficiency and effectivenessImprove the finishHot-dipping/immersion processesGalvanizationMetal

The invention provides a steel wire galvanization method and a galvanization device used in the steel wire galvanization method. According to the steel wire galvanization method, during rare earth adding in the galvanization process, rare earth is immersed in a galvanization pond through a rare earth adding device, the rare earth adding device is detachably connected to the galvanization pond, therare earth adding device prevents rare earth floating, and in the galvanization process, rare earth seeps out of reserved seepage holes through the rare earth adding device. Through the rare earth adding device, the rare earth is added in galvanization liquid, rare earth floating is prevented, the rare earth utilization rate is increased, the galvanized steel wire surface finish degree is high, and accumulated knots are avoided. Through the device, timely rare earth supplementing is convenient, an installing inserting rod can directly downwards move, then the installing inserting rod and a rare earth container can be taken out, after rare earth filling, the installing inserting rod is installed and arranged in a casing pipe in a sleeved manner so that rare earth metal can be continuouslysupplemented into zinc liquid, the structure design is simple and reasonable, usage is convenient, and very high practicability is achieved.

Owner:马鞍山市凯敏钢缆有限责任公司

A kind of 800mpa low-carbon hot-dip galvanized dual-phase steel and its preparation method

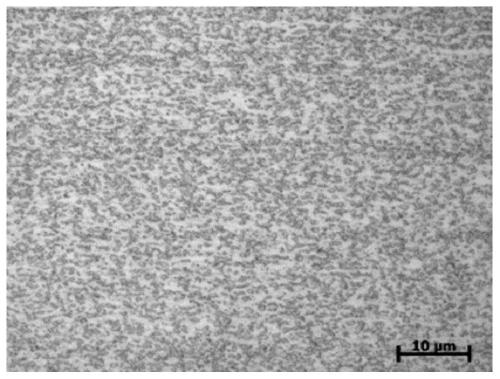

The invention belongs to the technical field of preparation of high-strength steel, and in particular, relates to 800 MPa-grade low-carbon hot-galvanized dual-phase steel and a preparation method thereof. The 800 MPa-grade low-carbon hot-galvanized dual-phase steel comprises the following components in percentage by weight: 0.05-0.10% of C, 0.20-0.60% of Si, 1.30-1.80% of Mn, 0.10-0.60% of Cr, 0.20-0.50% of Mo, 0.02-0.06% of Al, 0.05-0.10% of V, P not more than 0.015%, S not more than 0.005%, N not more than 0.006%, and the balance of Fe and inevitable impurities. The 800 MPa-grade low-carbon hot-galvanized dual-phase steel is low in production cost, high in forming performance and welding performance and excellent in galvanizing performance and mechanical performance, and reaches the yield strength of 450-520 MPa, the tensile strength of 805-840 MPa and the elongation of 15-18%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Process for plating zinc on surface of bolt

ActiveCN109594031AQuick washImprove galvanizing effectHot-dipping/immersion processesWater basedMegasonic cleaning

The invention discloses a process for plating zinc on the surface of a bolt. The process comprises the following steps of cleaning, wherein the bolt is placed into water containing a water-based cleaning agent and is subjected to ultrasonic cleaning; acid washing, wherein acid washing is carried out on the cleaned bolt by adopting composite acid; adding an auxiliary agent and putting the acid-washed bolt into a plating assisting agent for soaking; and performing drying and preheating, taking out the bolt from the plating assisting agent, and then placing the bolt in a nitrogen environment fordrying, and heating the bolt to 130-190 DEG C. The surface of the bolt is cleaned through ultrasonic waves, so that the cleaning capacity and the cleaning efficiency are high. The cleaning procedure is simplified. The bolt is placed in the nitrogen environment for heating, so that the surface of the bolt cannot be changed, and the zinc plating effect of the bolt is improved.

Owner:浙江格力威机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com