Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Save the washing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing nano hydroxyapatite powder

InactiveCN101734635ANo pollution in the processNo harmNanostructure manufacturePhosphorus compoundsWater bathsPolyethylene glycol

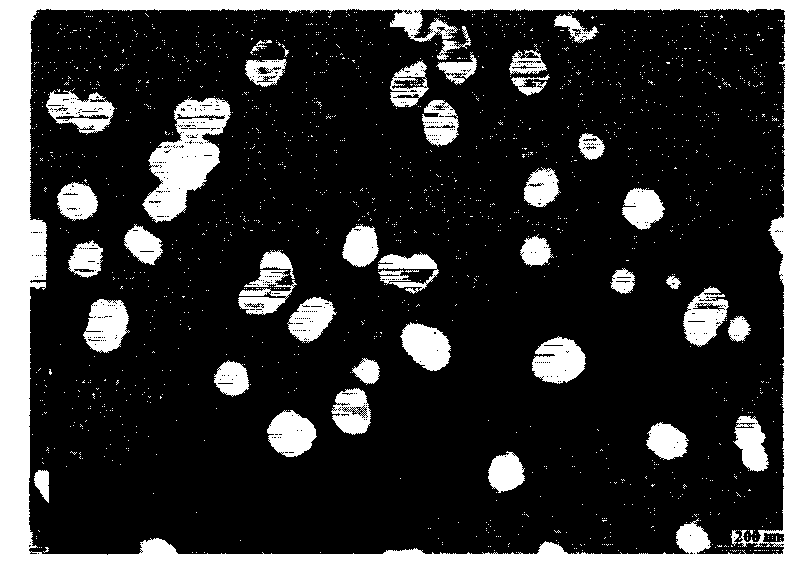

The invention relates to a method for preparing nano hydroxyapatite powder, belonging to the field of the biomedical material. The method for preparing the nano hydroxyapatite powder comprises the following steps: adding the organic polymer of polyethylene glycol to the initial reactants of calcium nitrate and diammonium phosphate solution to adjust and control the morphologies of the products of reaction; adding aqueous ammonia to adjust the pH values of the products of reaction, and making the aqueous ammonia react with the products of reaction at different water bath temperature to synthesize nano hydroxyapatite precipitate, wherein the agglomeration of the synthesized nano hydroxyapatite precipitate can be inhibited by the polyethylene glycol functioning as the dispersant; freezing and drying synthesized nano hydroxyapatite precipitate slurry to obtain dry nano hydroxyapatite powder which contains by-products of reaction and polyethylene glycol, and calcinating the dry nano hydroxyapatite powder at high temperature to remove the by-products of reaction and the polyethylene glycol which are contained in the dry nano hydroxyapatite powder to obtain the nano hydroxyapatite powder which is in the shape of the ball or the rod and in the particle size of 10-100 nm and has high yield and good dispersion. The method for preparing the nano hydroxyapatite powder is simple, needs short preparing period, causes no poison and pollution and is suitable for industrial production.

Owner:SICHUAN UNIV

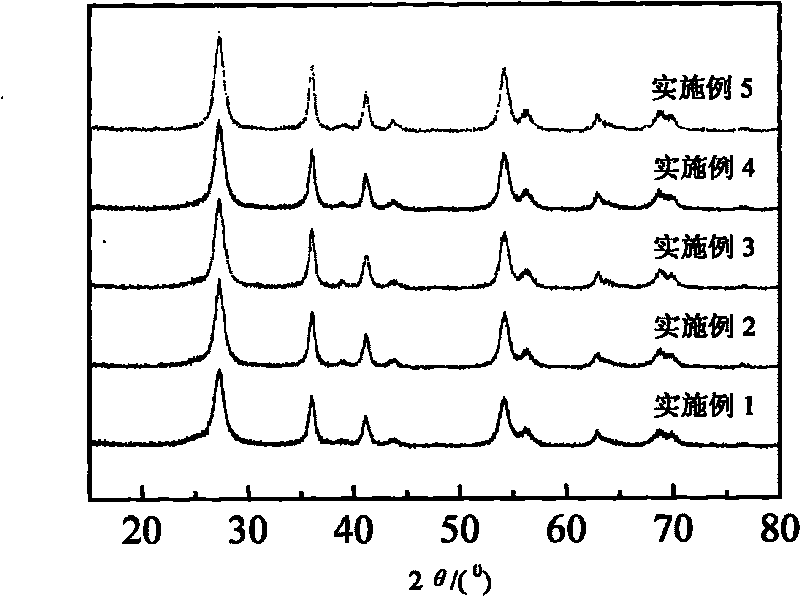

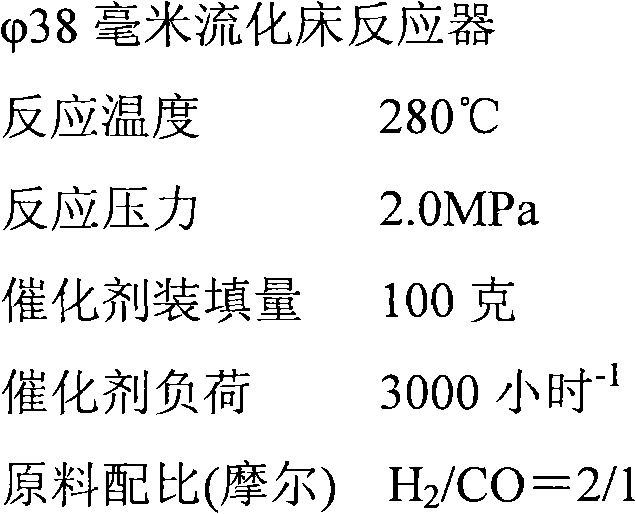

Preparation method of iron-based Fischer-Tropsch synthetic catalyst for fluid bed

InactiveCN101992097AStrong mechanical strengthReduce wear rateHydrocarbon from carbon oxidesCatalyst activation/preparationChemistryFischer–Tropsch process

The invention relates to a preparation method of an iron-based Fischer-Tropsch synthetic catalyst for a fluid bed, which mainly solves the problem that the catalyst preparation process is complicated in the prior art. The preparation method comprises the following steps: mixing a soluble iron salt solution with a soluble salt solution of A, uniformly mixing with a sol solution of a carrier C, adding a soluble salt or oxyhydroxide solution of B, beating, simultaneously adding an amount of acid and alkali regulator to regulate the pH value of the slurry so as to obtain an appropriate catalyst slurry; and then carrying out spray drying, and calcining to obtain the iron-based Fischer-Tropsch synthetic catalyst for the fluid bed, wherein A is at least one of Mn or Cu, B is one of alkali metals, and C is at least one of SiO2 and Al2O3. The technical scheme well solves the problem and can be used for the industrial preparation of the iron-based Fischer-Tropsch synthetic catalyst for the fluid bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wash-free dyeing method for silk

ActiveCN101275365AReduce consumptionEmission reductionHeating/cooling textile fabricsDyeing processWater savingSewage

The invention relates to a textiles dyeing method, especially to a silk facing material dyeing method. The object of the invention is to provide an improved method for silk dyeing. The invention has features of waterless or little water dyeing, reduced cost, reduced sewage water discharging and good products color fastness; the products hand feeling maintains the silk facing material special styles; and the invention is water-saving and energy-saving. The invention adopts the technical scheme: executing according to the following steps in sequence: preparing dye liquor, dyeing, pre baking, decatizing, soft liquid slop padding, drying and finishing.

Owner:杭州喜得宝集团有限公司

Gel preparation method for polytetrafluoroethylene fibre

InactiveCN1970857ASimple processLow costConjugated synthetic polymer artificial filamentsSpinning solutions preparationFiberEmulsion

The invention relates to a manufacturing method for polytetrafluoroethylene fiber. The method is that ptfe concentration dispersion emulsion and polyvinyl alcohol are mixed; gelling and spinning fluid is produced as the gel is formed by polyvinyl alcohol and borate or borax under the alkaline condition; the mixed fiber of polytetrafluoroethylene and polyvinyl alcohol is obtained by the dried spinning method, and the polytetrafluoroethylene fiber is produced by sintering and drawing so on. The polytetrafluoroethylene fiber produced by said method is provided with good quality and is applied in filtering material widely. Compared with prior technology it is provided with easy technology, low manufacturing method and no-pollution so on.

Owner:ZHEJIANG SCI-TECH UNIV +2

Improved hot galvanizing method of iron handicraft or furniture

InactiveCN103668030ANo over-cleaning phenomenonImprove ductilityHot-dipping/immersion processesEthylenediamineThiourea

The invention relates to an improved hot galvanizing method of an iron handicraft or furniture. The method comprises the following steps: (1) uncoiling and degreasing a workpiece; (2) removing dust; (3) washing; (4) assisting plating; (5) baking; (6) galvanizing by dipping; (7) settling; (8) passivating; (9) cooling. In the method, a degreasant is changed into acidity and is composed of a sulfuric acid solution, OP-10 and di-o-tolyl-thiourea. Thus, a washing procedure can be saved; a water resource and the degreasant can be saved; the workpiece does not generate an over-cleaning phenomenon; a pickling solution is composed of a hydrochloric acid solution, phosphoric acid, alkylphenol ethoxylates, lauryl sodium sulfate and ethylenediamine tetraacetic acid, so that the pickling speed is improved, formation of acid mist and use of a complexing agent can be restricted, reduction of cadmia in galvanizing zinc is facilitated, the malleability of a zinc coating on the surface of the work-piece is improved, proper temperature and event are adopted in the subsequent galvanizing by dipping, and the thickness and the stability of the zinc coating at the surface of the workpiece are ensured. Thus, the improved hot galvanizing method is a method which is simple and convenient for operation and good in galvanized effect.

Owner:TIANJIN BIAODIAN METAL HANDICRAFT CO LTD

Method for preparing CNT (carbon nano tube)-polyacrylonitrile fibre by melting spinning

InactiveCN102304786AReduce usageReduce consumptionMelt spinning methodsConjugated synthetic polymer artificial filamentsCarbon nanotubeIonic liquid

The invention relates to a method for preparing CNT (carbon nano tube)-polyacrylonitrile fibre by melting spinning. The method comprises the following steps of: (1) dispersing CNT in ion liquid, adding polyacrylonitrile and mixing uniformly to obtain a mixed solution, wherein the mass ratio of CNT to polyacrylonitrile is 4:1-1:10, the ratio of the total mass of CNT and polyacrylonitrile to the mass of the ion liquid is 1:1-1:100; (2) processing the mixed solution by using a melting spinning method to obtain CNT-polyacrylonitrile as-spun fibre, stretching and extracting the as-spun fibre, and then performing heat setting and winding to finally obtain CNT-polyacrylonitrile composite fibre. The method provided by the invention has the advantages of low cost, reduction in environmental pollution and is suitable for industrial production; and the prepared fibre can be subjected to high stretching and has excellent mechanical property, moreover the skin-core structure difference of sections of fibre is small.

Owner:DONGHUA UNIV

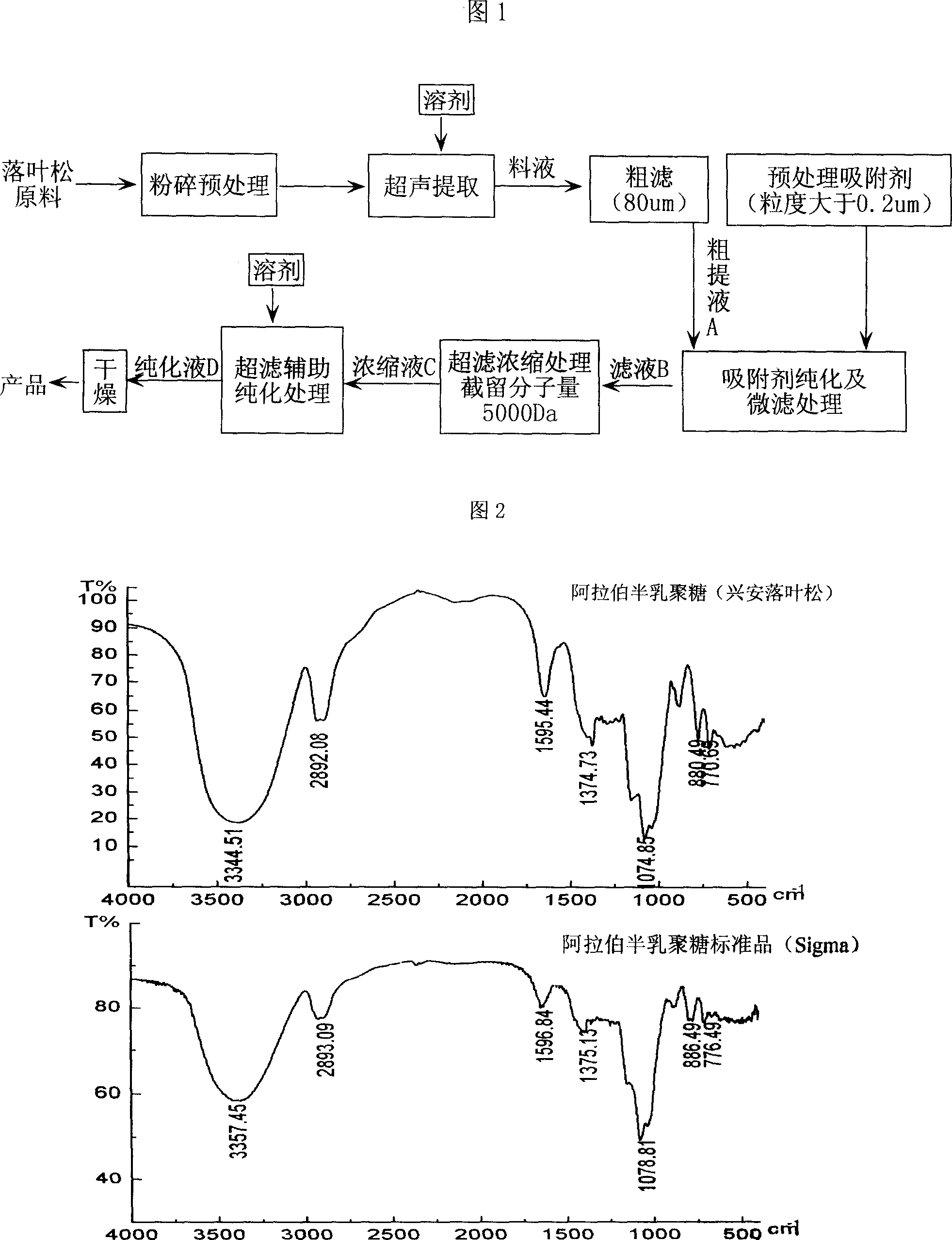

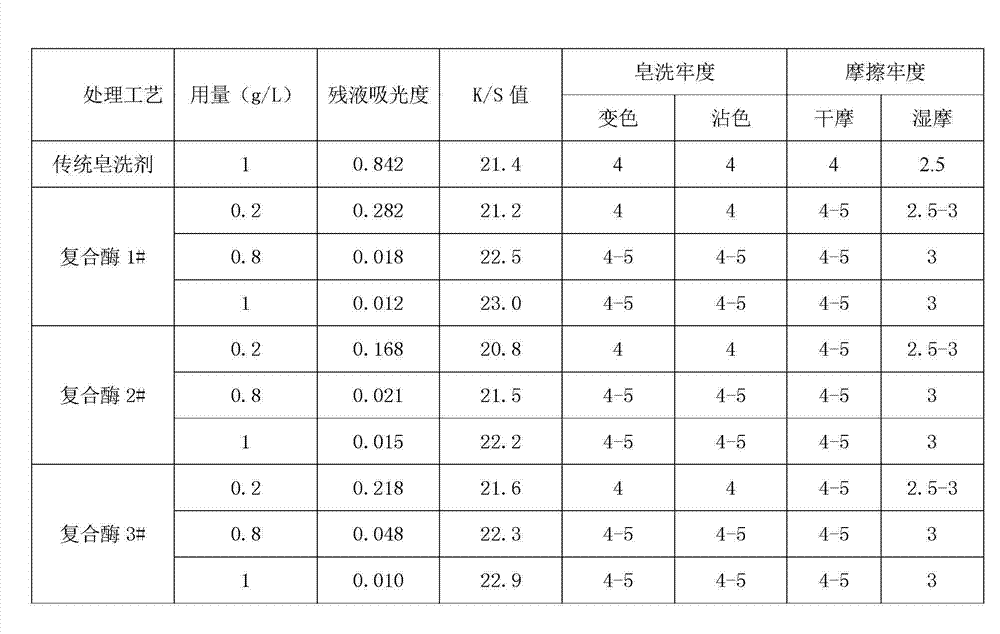

Method for preparing high-purity arabinogalactan

The invention discloses a technique which prepares high-purity arabogalactan from a dahuricia larch. The arabogalactan has effects of obvious increase of boy immunity, tumor resistance, mutation resistance, reduction of blood lipid, virus resistance and enhancement of the immunoreactive activity of monocytes, macrophages, T cells and natural killer cells in immune antigens. The preparation technique includes ultrasonic-assisted extraction, ultrafiltration concentration, washing purification and drying. The preprocessed dahuricia larch as a material is mixed with a designated solvent, extraction process is fulfilled in the energy field of ultrasonic energy, so that the crude extractant A of the arabogalactan is produced. The invention applies adsorbent to absorb the non-saccharide ingredients in the crude extractant A, and applies membrane separation techniques, such as microfiltration, ultrafiltration, etc., to separate arabogalactan, and after removing impurities in the crude extractant, small-molecule pigments and partial solvent, the purified arabogalactan solution D. The purified arabogalactan solution D is refrigerated and dried in order to obtain the white or light yellow powdery high-purity arabogalactan, and purity can reach over ninety five percent.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

Preparation process of neopentyl polyacohol octocapric acid ester

InactiveCN102030638ALow costHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention discloses a preparation process of neopentyl polyacohol octocapric acid ester. The preparation process comprises the following steps: carrying out esterification on neopentyl polyacohol and octocapric acid as raw materials and p-toluenesulphonic acid as catalyst at the temperature of 130-190 DEG C for 3-5 hours, draining the produced water by bubbling so as to obtain crude neopentyl polyacohol octocapric acid ester; and carrying out molecular distillation on the crude neopentyl polyacohol octocapric acid ester, so as to obtain the neopentyl polyacohol octocapric acid ester finished product. The molecular distillation comprises two stages: removing moisture, low molecular weight component and free p-toluenesulfonic acid under the conditions that processing temperature of a primary stage is 100-130 DEG C and vacuum degree is 100-2000Pa; and removing octocapric acid under the conditions that processing temperature of a secondary stage is 130-160 DEG C and vacuum degree is 1-100Pa. The preparation process has low production cost and is environment-friendly, and the obtained product has the advantages of light lustre, low acid value and high quality.

Owner:ZHEJIANG HUANGMA TECH

Multi-component direct-competitive immunoassay method for labeling haptens by using quantum dots of micromolecule organic matters

InactiveCN102520152AFluorescent quantum efficiency is high and stableHigh and stable quantum efficiencyFluorescence/phosphorescenceMicrospherePolystyrene

The invention provides a multi-component direct-competitive immunoassay method for labeling haptens by using quantum dots of micromolecule organic matters and relates to a multi-component direct-competitive immunoassay technology. The multi-component direct-competitive immunoassay method comprises the following steps of: labeling different target analyte haptens by using the highly-efficient water-soluble quantum dots with different fluorescence emission wavelengths, taking polystyrene magnetic microspheres on which different antibodies are fixed and commonly dispersing corresponding target analyte prototypes as well as the haptens labeled by the corresponding quantum dots in phosphate buffer solution to carry out competitive immune response; and quickly separating the polystyrene magnetic microspheres from a liquid phase in a magnetic field by using a reaction balance system, carrying out fluorescence scanning or multi-wavelength detection on the liquid phase under the excitation of ultraviolet light with the same wavelengths and establishing the multi-component direct-competitive immunoassay method for quickly detecting the haptens labeled by the quantum dots of the various target analyte micromolecule organic matters according to the principle that the ratio of the characteristic fluorescence intensity of labeling the haptens by using the ratio of the fluorescence intensity of the different quantum dots in a prototype system to the fluorescence intensity of corresponding blank control is proportional to the concentration of a corresponding target analyte.

Owner:YANGZHOU UNIV

Method for preparing age inhibitor 3100

ActiveCN102584596ALow costImprove conversion rateOrganic compound preparationAmino compound preparationOrganic sulfonic acidReaction temperature

The invention discloses a method for preparing an age inhibitor 3100. In the method, paraaminophenol, aniline and o-nitrotoluene are taken as raw material for condensation reaction under the effect of organic sulfonic acid catalyst, the reaction temperature is 110 to 220 DEG C, water and ammonia produced by the reaction can be led out through azeotropic solvent continuously, after the reaction reaches an end point, the temperature is lowered to 100 to 140 DEG C, filtering is performed while hot, and filter liquor is distilled for removing impurities. The method provided by the invention has a high raw material conversion rate, the contents of the obtained effective components are high, the cost is low, the three wastes are less, and the method is suitable for industrial production.

Owner:宜兴市聚金信科技有限公司

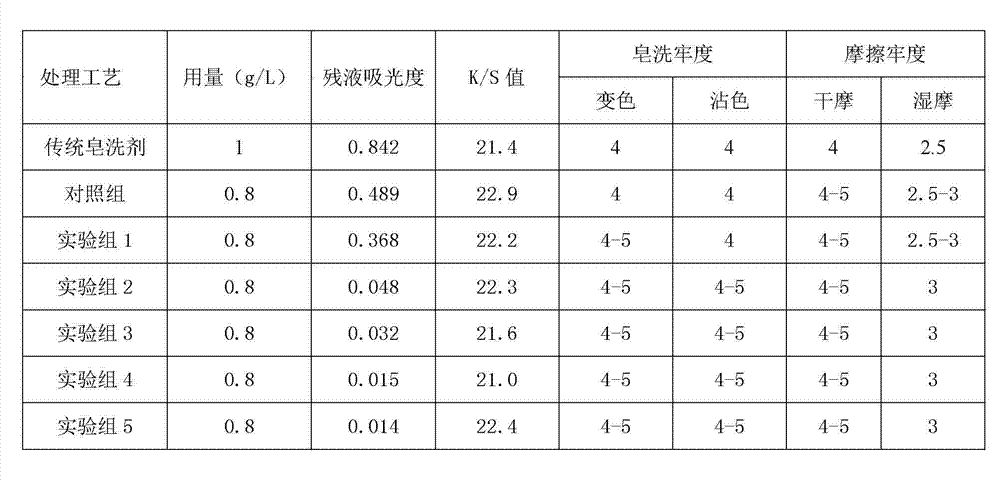

Soaping compound enzyme and application method thereof

ActiveCN102899195AImprove soaping effectLow absorbanceBiochemical fibre treatmentOrganic non-surface-active detergent compositionsTrisodium citrateChemistry

The invention relates to soaping compound enzyme and an application method thereof. The soaping compound enzyme comprises laccase, persulfate and PVP (polyvinylpyrrolidone), and sodium citrate is also added in the soaping compound enzyme. The soaping compound enzyme comprises the following compositions in percentage by mass: 55-80 of the laccase, 15-30 % of the persulfate, 4-10 % of the PVP, and 1-5 % of the sodium citrate. In the soaping compound enzyme disclosed in the invention, cooperative anxoaction can be generated between the sodium citrate and the laccase as well as between the persulfate and the PVP, and thus the whole soaping effect of the soaping compound enzyme is greatly increased. Compared with the traditional soaping technology, according to the soaping compound enzyme disclosed by the invention, the absorbance of raffinate after soaping is obviously reduced, the clarity is increased, and thus the treating difficulty of sewage is reduced; the fastness to wet rubbing of a cloth sample after soaping in increased by 0.5-1 level, and the soaping fastness is increased by 0.5 level; and three washing procedures are saved, 30% of the water consumption is saved, 30% of the procedure time is saved, the production cost is greatly reduced, and the environment pollution is reduced.

Owner:QINGDAO VLAND BIOTECH GRP

Desizing and decolorizing composite enzyme and nostalgic-style denim fabric washing process thereof

InactiveCN109338706APromote oxidationEven contactDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsEthylenediamineAcetic acid

The invention relates to a desizing and decolorizing composite enzyme and a nostalgic-style denim fabric washing process thereof. The desizing and decolorizing composite enzyme is prepared from the following components in percentage by weight: 30% to 35% of desizing enzyme, 13% to 16% of ligninase; 20 to 26% of neutral cellulase, 26% to 32% of tetrasodium ethylenediaminetetraacetate, 5% to 8% of anonionic surfactant and the balance of deionized water. The nostalgic-style denim fabric washing process comprises the following steps of: desizing and decoloring treatment, potassium permanganate strong decolorizing treatment, demanganization treatment, normal temperature washing, polishing soft treatment, dehydration and drying treatment. According to the process, the desizing and decolorizingare carried out in one bath, so that the water and energy are saved, the abrasion caused by machinery to denim fabrics is decreased, the strong damage is reduced, the discharge of harmful substances is decreased, and the washed denim fabrics are free of pilling and furring and have softer hand feeling.

Owner:青岛奥洛思新材料有限公司

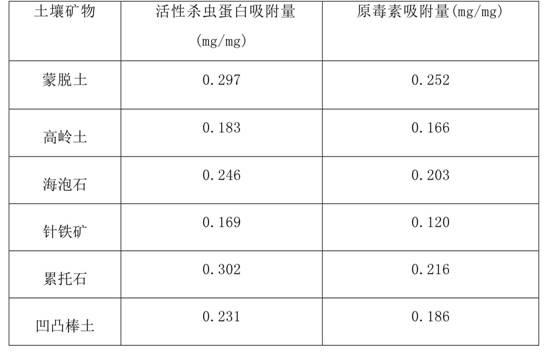

Preparation method of bacillus thuringiensis insecticidal protein and spore endospore adsorption composite dosage form

InactiveCN102038006ASimple methodLow costBiocideAnimal repellantsBacillus thuringiensisProtein adsorption

The invention discloses a preparation method of a bacillus thuringiensis insecticidal protein and spore endospore adsorption composite dosage form. The method comprises: adding a micron-level mineral adsorbent in bacillus thuringiensis fermentation liquor in advance; then, directly adding alkali-dissolving parasporal crystals; meanwhile, adsorbing the generated active insecticidal protein by a mineral carrier; and realizing fixed load to the active insecticidal protein. The bacillus thuringiensis insecticidal protein and spore endospore adsorption composite dosage form prepared with the method has simple method and low cost, omits the process that the bacillus thuringiensis cell crystal mixture is washed by a NaCl solution and sterile deionized water, and realizes synchronous preparation and adsorption of the active insecticidal protein. The obtained adsorption composite dosage form has large adsorption quantity and high insecticidal activity. In addition, because of the synergy of the spore endospore, the insecticidal activity of the active insecticidal protein adsorption preparation is further improved as compared with the original toxin adsorption dosage form.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Solvent-free polyurethane dispersoid with controllable particle size and waterborne polyurethane coating solution

ActiveCN111019077ANo pollution in the processNo stimulationGlovesCoatingsPolyurethane dispersionPolymer science

The invention discloses a solvent-free polyurethane dispersoid with particle size controllable and a waterborne polyurethane coating liquid, and particularly relates to the technical field of dispersoids and coating liquids; the average particle size of the solvent-free polyurethane dispersoid is 400-1500 [mu]m, and the solid content of the solvent-free polyurethane dispersoid is 10%-45%; the solvent-free polyurethane dispersoid can be made into the waterborne polyurethane coating liquid with the solid content of 9%-25%, and the waterborne polyurethane coating liquid is composed of the raw materials in parts by weight: 100 parts of the solvent-free polyurethane dispersoid, 0.1-3 parts of a thickening agent, 0.1-4 parts of a wetting agent, 0.1-5 parts of a defoaming agent and the balance being water. The invention aims to control the particle size of the waterborne polyurethane dispersoid particles, so that the waterborne polyurethane dispersoid is only coated on the outer surface of gloves and does not permeate into a glove fabric, and the gloves have good flexibility. The waterborne polyurethane coating liquid provided by the invention can ensure smooth film formation, is environment-friendly, and is non-toxic even after long-term use.

Owner:HONGBAOLI GRP CO LTD

Method for recycling gas-base direct reducted tail gas

InactiveCN102864265AEfficient use ofSave the washing processFluidised-bed furnacesEnvironmental resistanceReduction treatment

The invention discloses a method for recycling gas-base direct reduced tail gas. Firstly the gas-base direct reduced tail gas is used for conducting pre-heating and pre-reduction treatment on iron ore pellets, CO in the tail gas has a reaction that two COs are reacted to generate CO2 and C in the above treatment process, separated carbon black is deposited in holes and on surfaces of pre-reduced pellets where gaps are rich, and the pre-reduced pellets containing fine carbon black are formed. The pre-reduced carbon separated pellets are mixed with certain quantity of a reducing agent, and then added into an industrial microwave oven to conduct deep reduction, and then magnetic separating is carried out to obtain direct reduced iron. The method can effectively use tail gas in traditional gas-base direct reduction process and secondary heat reducing gas produced in a metallurgy process to conduct prereduction and carbon separation, and use high-efficient and rapid characteristics of microwave heating and excellent absorbing properties of carbon black to conduct direct reduction on the iron ore pellets so as to achieve a purpose of energy conservation and environmental protection production.

Owner:CENT SOUTH UNIV

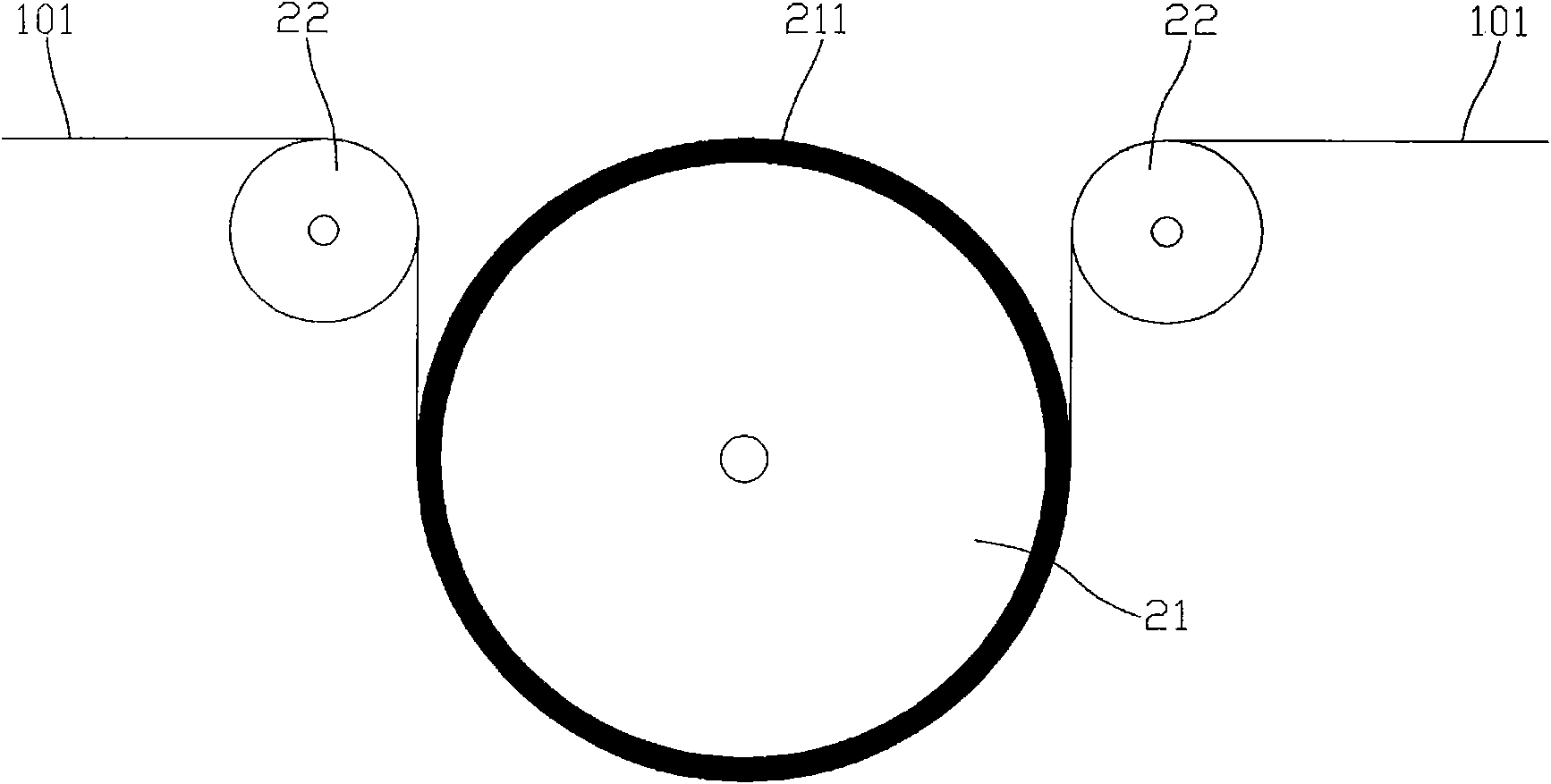

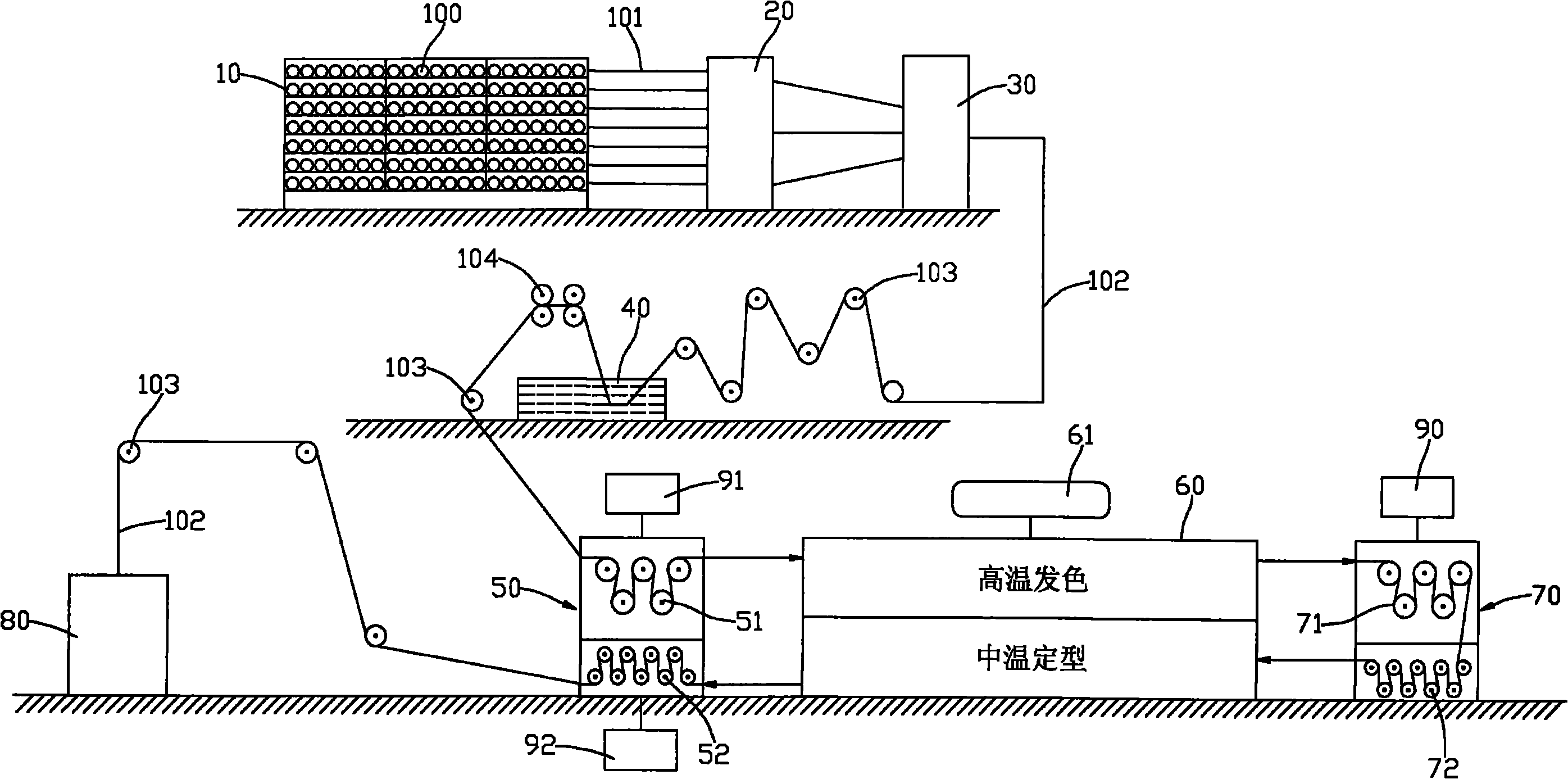

Efficient and environment-friendly webbing production system

ActiveCN102182009AHigh tensile strengthCompact structureOrnamental textile articlesHeating/cooling textile fabricsYarnAutomation

The invention discloses an efficient and environment-friendly webbing production system, which comprises a yarn stand, a webbing loom, a dye groove, an oven, a first drafting device, a second drafting device and a plurality of intermediate rollers, wherein the upper layer of the oven is used for performing color development on webbing at a high temperature, and the lower layer of the oven is used for forming the webbing at an intermediate temperature; an upper group of rollers and a lower group of rollers are arranged inside the first drafting device, the upper group of rollers connected with a damping device is used for delivering the webbing to the upper layer of the oven for color development at the high temperature, and the lower group of rollers connected with an electric motor is used for drawing the webbing out of the oven; and an upper group of rollers and a lower group of rollers are also arranged inside the second drafting device, the upper group of rollers connected with the electric motor is used for pushing the webbing into the upper layer of the oven for color development at the high temperature, and the lower group of rollers is used for delivering the webbing into the lower layer of the oven for forming at the intermediate temperature. The system has a compact structure, simple production process and high automation and production efficiency. Moreover, by the system, a washing process can be eliminated, the tensile strength of the webbing is increased, and good environment-friendly effect is achieved.

Owner:东莞方皓汽车配件有限公司

Process for preparing wool fat aklaline earth metal soap

InactiveCN1408832AAvoid emissionsQuick responseFatty acid esterificationOrganic solventAlkaline earth metal

The preparation process of wool fat alkaline earth metal soap includes the saponification between wool fat and alkali of alkaline earth metal at 0.1-0.5 MPa and 70-170 deg.c in the presence of water or water and organic solvent. The saponificatino reaction has controlled reaction pressure and proper solvent, and thus fast reaction speed, high conversion rate and no introduction of strong alkali and strong acid salt can omit the water washing process and avoid exhaust of sewage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for quickly preparing rutile phase nano titanium dioxide

ActiveCN101698507AAvoid high temperature calcination stepSave energyNanostructure manufactureTitanium dioxideAqueous sodium hydroxideTitanium tetrachloride

The invention discloses a method for quickly preparing rutile phase nano titanium dioxide, comprising: first, preparing 1.4-6.0mol / L of sodium hydroxide water solution and 1-3.6mol / L of titanium tetrachloride water solution; heating the sodium hydroxide water solution to be 80-100 DEG C, and adding the titanium tetrachloride water solution into the sodium hydroxide water solution while stirring; after the titanium tetrachloride water solution is completely added, continuously carrying out heat preservation reaction for 10-25min, and obtaining rutile phase nano titanium dioxide suspending liquid; and finally, using alkali to adjust the pH of the suspending liquid to be 6-8, filtering and washing to remove foreign ions, drying and grinding the obtained filter cake, and obtaining the rutile phase nano titanium dioxide powder. The method can be used for quickly synthesizing the nano titanium dioxide with the rutile content of 100% under the mild condition, avoids the steps of high temperature calcination adopted by the traditional method, saves the energy, and has the characteristics of short process flow, low cost, convenient operation and easy realization of large-scale industrialized production.

Owner:江苏河海纳米科技股份有限公司 +1

Method for preparing aluminum tobermorite adsorbing material by using fire coal ash wastes

ActiveCN104107676AImprove use valueImprove adsorption capacityOther chemical processesSilicon compoundsRoom temperatureAdditional values

The invention discloses a method for preparing an aluminum tobermorite adsorbing material by using fire coal ash wastes. The method comprises the following steps: calcining fire coal ash in an electric heating furnace, cooling to room temperature and grinding to obtain fine ash powder; subsequently leaching the fine ash powder by using diluted hydrochloric acid and then filtering, washing and drying to obtain a precursor ash powder body; grinding and mixing the ash powder body and Ca(OH)2, then adding NaOH into the mixture and grinding and mixing to be uniform to obtain a mixture; spraying a water glass solution to the mixture and rotationally rolling to form a spherical granular aluminum tobermorite reactant precursor; putting the aluminum tobermorite reactant precursor into a stainless steel wire cage drawer of a reaction kettle, performing a hydrothermal water-proof stilling reaction for 16-20 hours at the temperature of 170-190 DEG C; cooling and releasing the pressure after the reaction ends, and then separating out reaction products and drying to obtain the aluminum tobermorite adsorbing material. The material prepared by the method disclosed by the invention has good adsorption and decontamination effects and achieves the aim of preparing an environmental material with a relatively high additional value by using the fire coal ash.

Owner:SHAANXI UNIV OF SCI & TECH

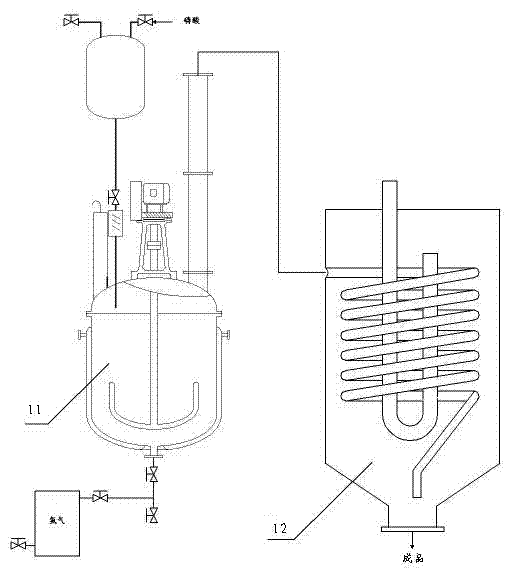

Fischer-Tropsch synthesized Co-based fluidized bed catalyst and preparation method thereof

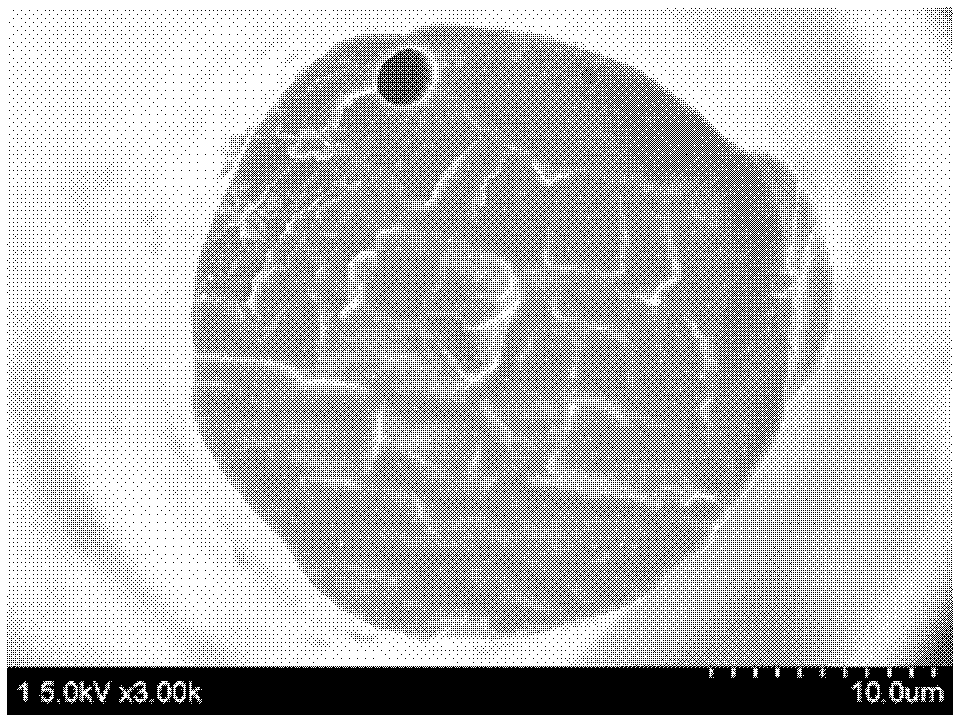

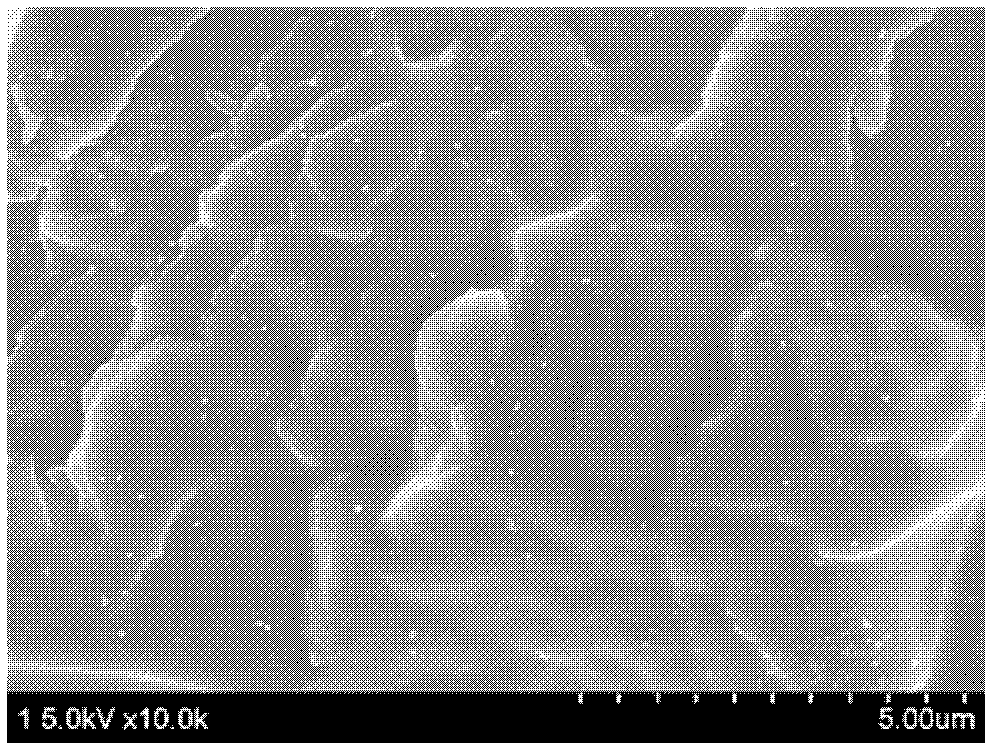

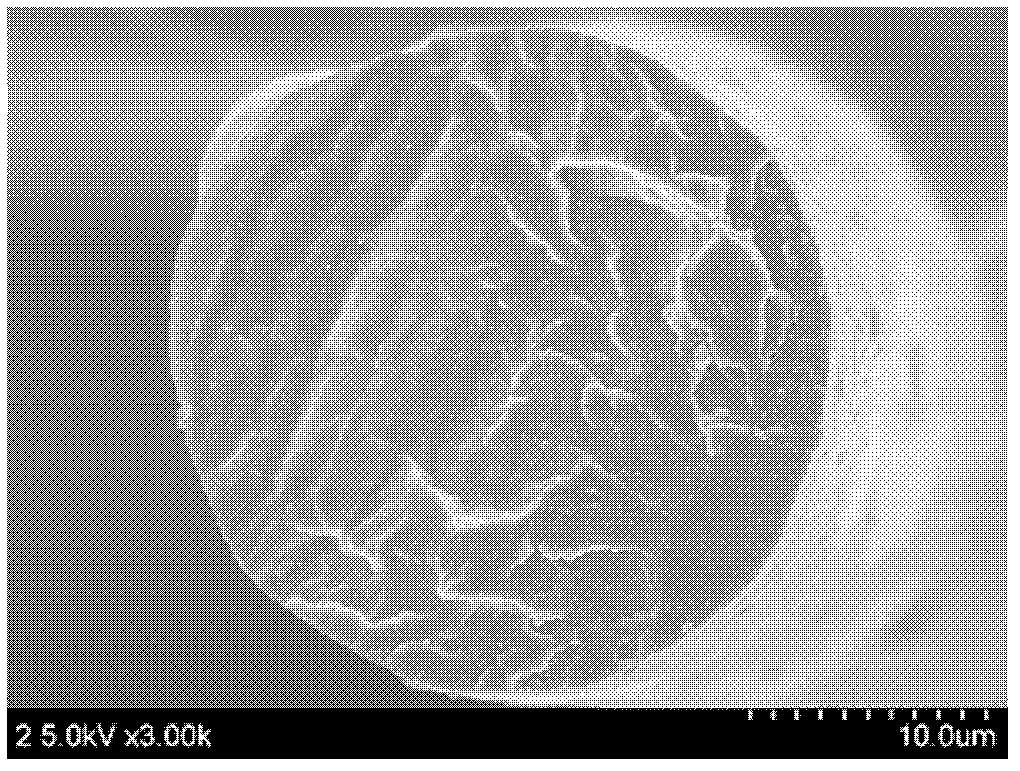

ActiveCN102039133AHigh mechanical strengthReduce wear rateCatalyst activation/preparationLiquid hydrocarbon mixture productionAlkaline earth metalFluidized bed

The invention relates to a Fischer-Tropsch synthesized Co-based fluidized bed catalyst and a preparation method thereof, mainly solving the problems existing in the prior art because an Fischer-Tropsch synthesis reaction is a strong exothermic reaction which causes thermal withdrawal difficulty in a reactor, temperature runaway and easy catalyst inactivation in case of using a fixed bed, and relatively low selectivity of heavy hydrocarbon in case of using a fluidized bed. By adopting the preparation method and the technical scheme that at least one of oxides of Si or Al or a mixture of the at least one oxide and ZrO2 is selected as a carrier, and the active constituent contains the following composition with a chemical formula in the atomic ratio of Co100AaBbOx, wherein A is selected from at least one of alkali metal or alkaline earth metal, B is selected from at least one of Cr, Ni, Cu and Zn to be combined into a catalyst, the invention favorably solves the problems and can be used in the industrial production of the Fischer-Tropsch synthesis reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing iminodibenzyl

The invention discloses a method for preparing iminodibenzyl. In the method, phosphoric acid is added into 2,2,-diamido-bibenzyl to form salt, and the salt is subjected to cyclization reaction to prepare the iminodibenzyl. The method is characterized in that after the phosphoric acid is separated from a product formed by the cyclization reaction of the 2,2,-diamido-bibenzyl, nitrogen is introduced to perform reduced pressure distillation, and the distilled iminodibenzyl is collected by a cyclone separator. The method for preparing the iminodibenzyl comprises the following steps of: adding the phosphoric acid into the 2,2,-diamido-bibenzyl to form the salt, performing the cyclization reaction to obtain iminodibenzyl, introducing the nitrogen directly, distilling under reduced pressure, and collecting the iminodibenzyl by the cyclone separator, wherein the product formed by the cyclization reaction is subjected to the steps of elutriation, recrystallization and the like. The method has a simple process, the yield of the product is improved, and the purity of the iminodibenzyl is over 99.0 percent.

Owner:JIANGSU TOHOPE PHARMA

Method for preparing fluidized bed cobalt-based Fisher-Tropsch synthesis catalyst

ActiveCN101992088AHigh mechanical strengthReduce wear rateHydrocarbon from carbon oxidesCatalyst activation/preparationFluidized bedRare earth

The invention relates to a method for preparing a fluidized bed cobalt-based Fisher-Tropsch synthesis catalyst, which mainly solves the problem of complex catalyst preparation process in the prior art. For solving the problem, the invention adopts the technical scheme that: in the catalyst, Co is used as a main active ingredient, alkali metal and rare-earth metal La or Ce are used as cocatalysts,and a mixture of SiO2 or Al2O3 and ZrO2 is used as a carrier; and the method comprises the following steps of: mixing salt solution of the main catalyst and the cocatalysts and the sol solution of the carrier to obtain catalyst slurry containing 10 to 50 weight percent of solid, adjusting the pH value of the slurry to between 0.1 and 7 by using acid or alkali, performing spray drying molding on the slurry, and baking the molded product to obtain the catalyst. The method is applied in industrial preparation of the fluidized bed cobalt-based Fisher-Tropsch synthesis catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

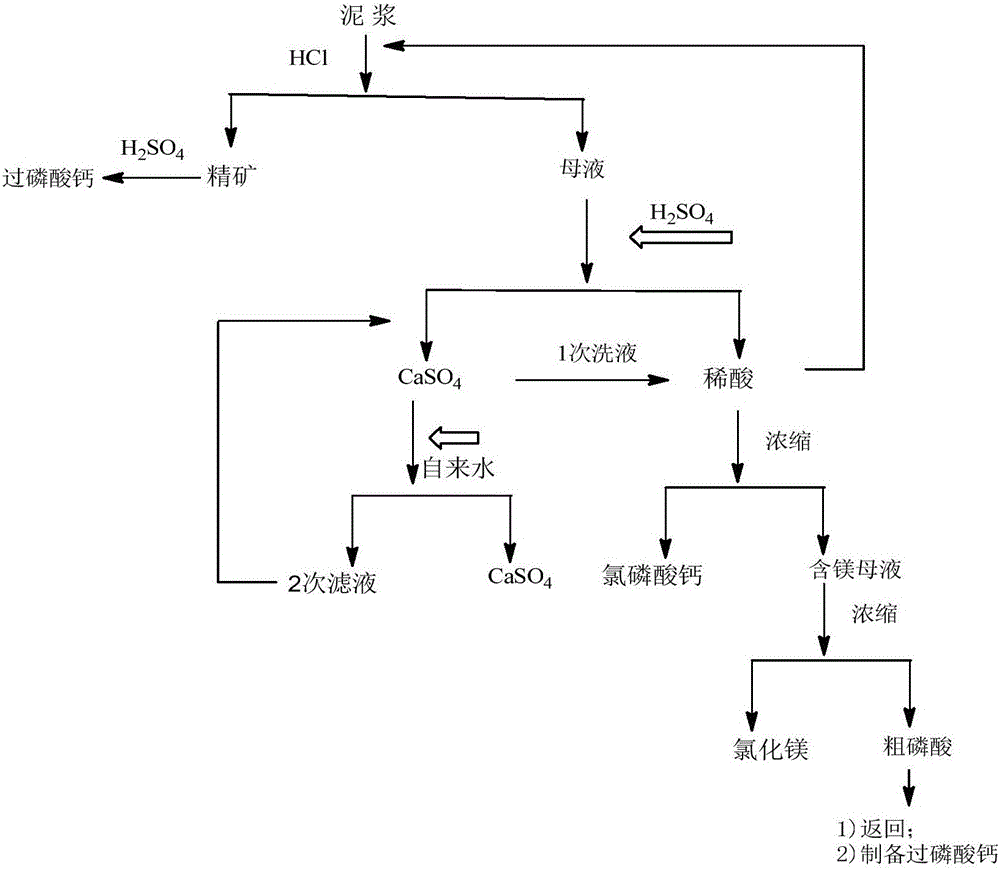

Method for green-producing high-quality calcium superphosphate co-generated magnesium chloride by low-level collophanite

InactiveCN106517124AReduce contentSolve problems such as poor qualitySuperphosphatesMagnesium chloridesDecompositionCarbonate

The invention relates to a method for green-producing high-quality calcium superphosphate co-generated magnesium chloride by low-level collophanite, comprising steps of a, performing acid splitting on carbonate in the phosphorite by hydrochloric acid and preparing phosphorus concentrate; b, preparing high-purity calcium sulfate; c, preparing magnesium chloride; after concentrating the filter fluid to a certain volume, preparing magnesium chloride. The invention has the advantages that the method is applicable to prepare high-efficient phosphatic fertilizer by directly producing high-quality low-magnesium phosphorite in hydrochloric acid decomposition, carbonate of low-level phosphorite and in particular to high-magnesium phosphorite; no waste discharges during the whole technical flow; by applying the invention, the phosphorus pentoxide content of phosphorite is promoted through one acidolysis while content of magnesium oxide in the phosphorite is also reduced; thus the problem of agglomeration and poor phosphatic fertilizer quality caused by high magnesium content during the ordinary calcium production can be solved; the phosphorite therefrom is directly reacted with sulfuric acid, thus high-quality phosphatic fertilizer of which available phosphorus is improved to 16-18% P2O5 can be obtained.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Catalyst for hydrogen production from methanol reforming as well as preparation method and application of catalyst

ActiveCN102688759AEasy to makeEfficient preparationHydrogenMetal/metal-oxides/metal-hydroxide catalystsOxalateReaction temperature

The invention relates to a catalyst for hydrogen production from methanol reforming as well as a preparation method and an application of the catalyst. The catalyst comprises the following components in percentage by mass: 35.0-55.0% of CuO, 35.0-55.0% of ZnO, 5.0-15.0% of Al2O3, and 3.0-10.0% of graphite. The method comprises the steps as follows: precursors of Cu, Zn and Al and oxalic acid solid are added into water solution at the same time and stirred, wherein the molar weight of oxalic acid is 1.2-1.6 times of the total molar weight of Cu, Zn and Al, the reaction temperature is 50-90 DEG C, and the reaction time is 5-9 hours; after the reaction, the mixture is separated and dried for 10-15 hours at 100-120 DEG C; the mixture is calcinated for 3-8 hours at 350-550 DEG C and with air or nitrogen as calcination atmosphere; after calcination, graphite is added for beating into pieces and molding, and then the finished catalyst is obtained. The preparation method has the advantages of simple preparation process and high efficiency, and reduces the cost greatly; and the catalyst has good catalytic performance on hydrogen production from methanol reforming.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Non-drying preparation method of ethylene glycol antimony

ActiveCN102060666AAvoid destructionEliminate drying processPreparation of metal alcoholatesHydroxy compound separation/purificationPolyesterActivated carbon

The invention provides a non-drying preparation method of ethylene glycol antimony, and relates to a preparation method of antimony-containing compound catalyst which is used in polyester polycondensation reaction. The preparation method is characterized by comprising the following steps: adding antimony trioxide and ethylene glycol in a reaction tank to be subjected to esterification dehydrationreaction, wherein the weight ratio of the antimony trioxide to ethylene glycol is 1:(6-7), the temperature in the reaction tank is 135-150 DEG C and the pressure ranges from minus 0.10MPa to minus 0.08MPa; after the reaction, adding a single activated carbon decolouring impurity-removing reagent in the reaction tank for decolouring and impurity removal, then performing circulating filtration, andthen filtering again; and then conveying filtrate to a crystallizing tank, crystallizing the filtrate, performing centrifuge dripping, and then directly performing inspection and packaging. In the method provided by the invention, washing and drying are not required, and the chelate structure of the product is not damaged; and the single activated carbon decolouring impurity-removing reagent is used, thus the effects of decolouring and impurity removal are good, the hue value of the product is high, the loss of ethylene glycol is less, the stability of the product quality is good, the operation is simple, and the production cost is low.

Owner:益阳市华昌锑业催化剂有限公司

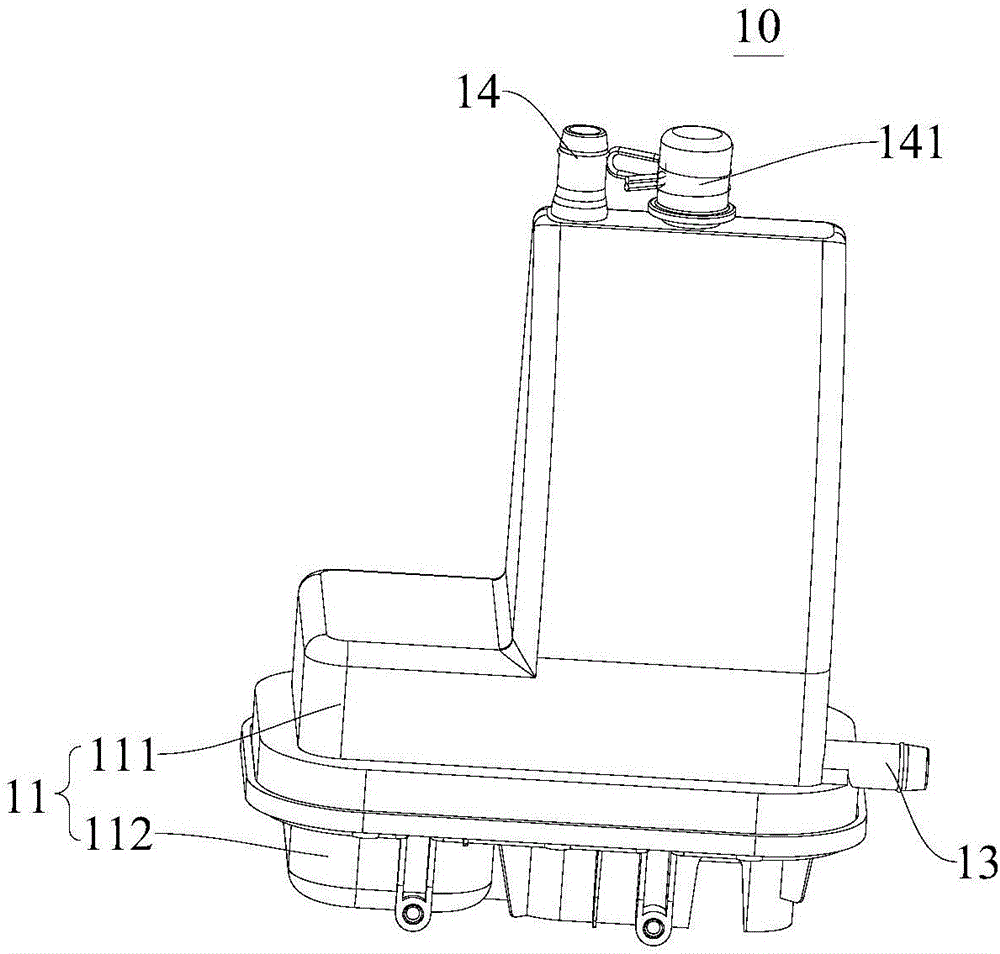

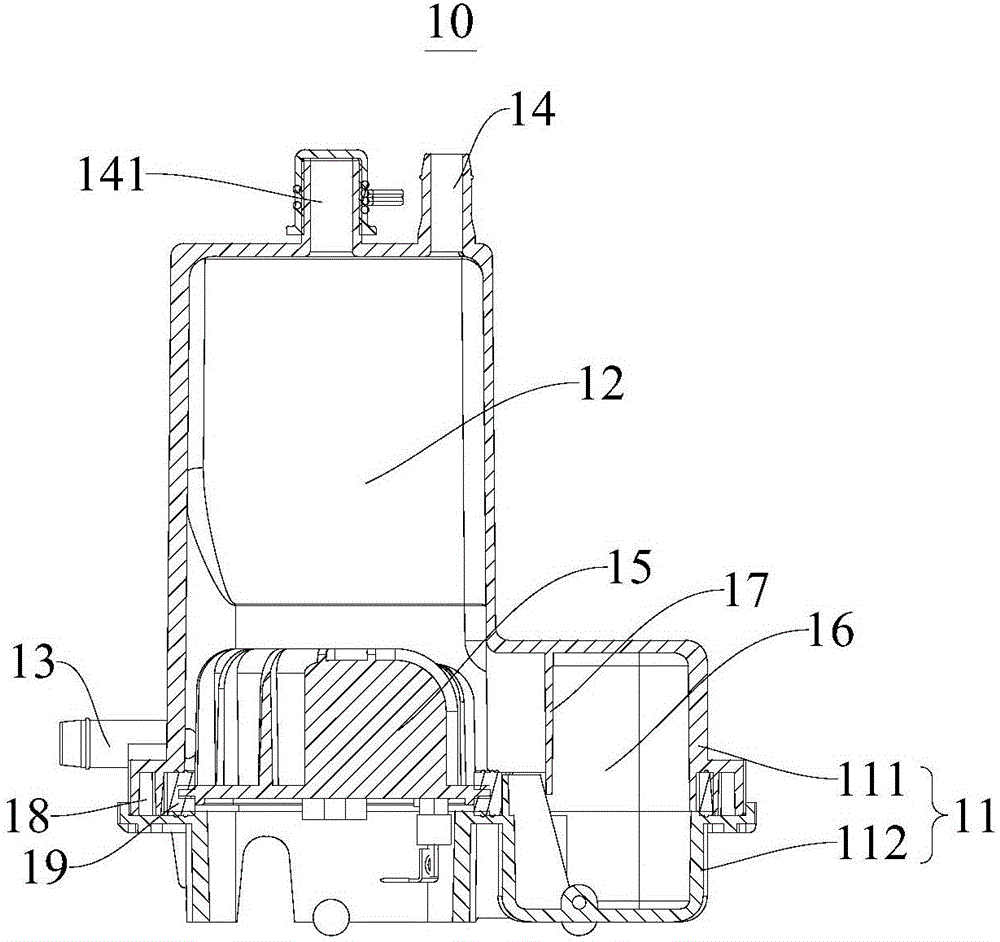

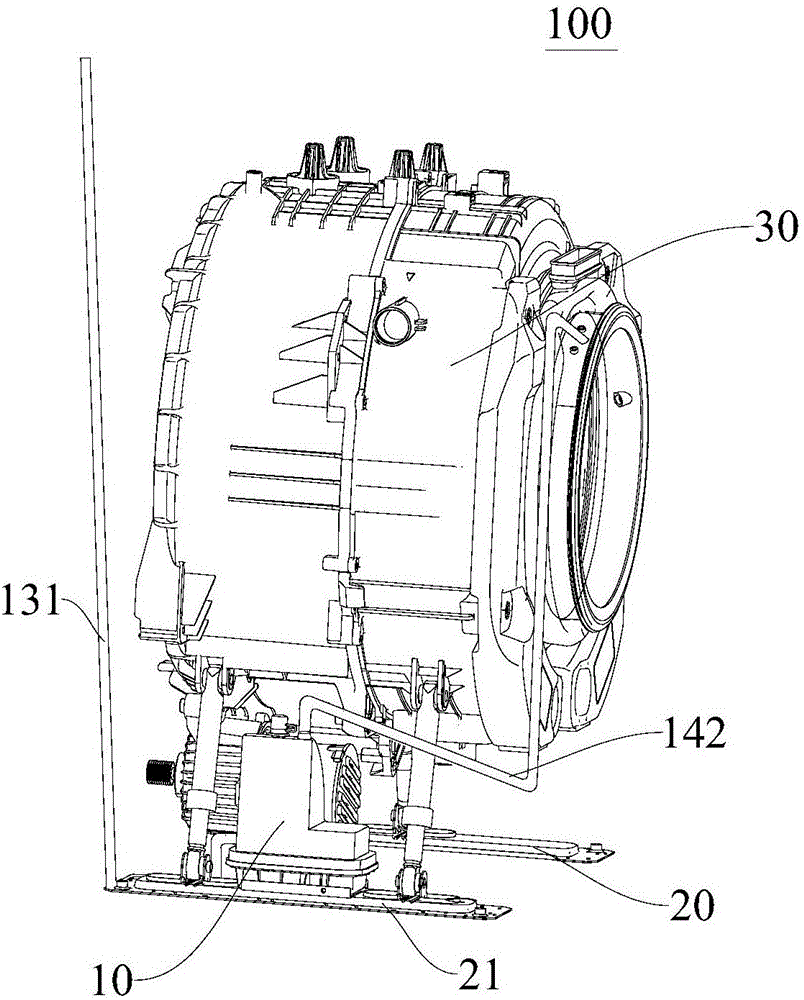

Steam generator and clothes dryer with same

InactiveCN106049011AImprove work performanceExtended service lifeTextiles and paperLaundry driersWork performanceEngineering

The invention discloses a steam generator and a clothes dryer with the same. The steam generator comprises a machine shell, a heating piece and a temperature controller. A steam generation cavity is defined in the machine shell, the machine shell is provided with a water inlet and a steam outlet communicated with the steam generation cavity, the heating piece is arranged in the steam generation cavity, the temperature controller is arranged in the steam generation cavity and connected with the heating piece, the temperature controller detects the temperature of the heating piece, controls the heating piece to be heated when the heating piece is lower than the preset temperature and closes the water inlet and controls the heating piece to stop being heated when the heating piece reaches the preset temperature and opens the water inlet. By means of the steam generator, the heating piece and the water inlet are controlled to work through the temperature controller, the water level in the steam generation cavity is controlled within a reasonable range, it can be guaranteed that the steam generator provides steam for the clothes dryer continuously, work performance of the clothes dryer can also be improved, and the service life of the clothes dryer is prolonged.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Method for synthesizing titanium silicalite molecular sieve

InactiveCN104692409AReduce dosageSynthetic operation is simpleCrystalline aluminosilicate zeolitesSolvent freeSilicon oxide

The invention relates to a method for synthesizing a titanium silicalite molecular sieve, which comprises the following steps: mixing, stirring and hydrolyzing a titanium-containing compound, a TPAOH aqueous solution and a silicon raw material, and putting the obtained mixture into a high-pressure reaction kettle to heat for reacting; and mixing an obtained reaction mixture with solid silica gel, drying the obtained object so as to obtain a solid mixture, carrying out heating reaction on the solid mixture in an airtight reaction kettle, after the solid mixture is cooled, taking out and then roasting the solid mixture so as to remove organic matters, so that a TS-1 molecular sieve is obtained. In the technical scheme above, by reducing the application amount of a guiding agent tetrapropylammonium hydroxide (TPAOH), taking inorganic silicon oxide for replacing organosilicone as a raw material, and taking a solid-phase solvent-free crystallization method, the steps of filtering, washing and the like are omitted, thereby simplifying the synthesis operation of the TS-1 molecular sieve and reducing the synthetic cost.

Owner:QUFU NORMAL UNIV

Hydrogenation catalyst and preparation method thereof

ActiveCN111375418AHigh mechanical strengthImprove wear resistanceCatalyst carriersHeterogenous catalyst chemical elementsPtru catalystActive agent

The invention discloses a hydrogenation catalyst and a preparation method thereof; the catalyst comprises an active metal component and a carrier, wherein the carrier is phosphorus-containing alumina.The preparation method of the hydrogenation catalyst comprises the following steps: adding bottom water into a reactor; then adding a sodium metaaluminate solution, a phosphate surfactant solution and a cation exchange resin turbid liquid for reaction; aging the obtained slurry, adding cation exchange resin, separating the slurry, filtering and drying the separated slurry to obtain pseudo-boehmite, uniformly mixing the obtained pseudo-boehmite raw material with deionized water; molding, drying and roasting the material to obtain a carrier, and further introducing an active metal component toobtain the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

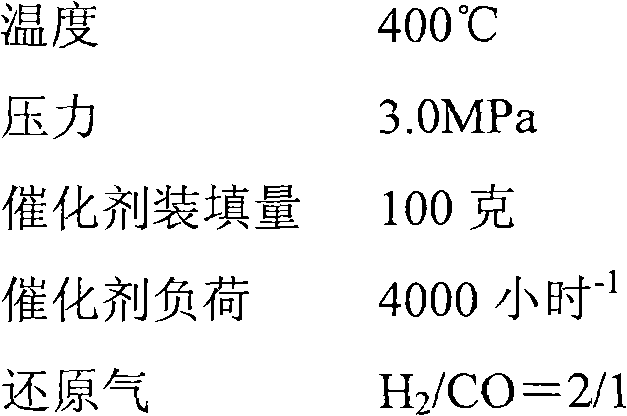

Supported catalyst for hydrogen production by methanol reforming as well as preparation method and application thereof

ActiveCN102716751AEasy to controlSave the washing processHydrogenMetal/metal-oxides/metal-hydroxide catalystsNitrogenCopper

The invention discloses a supported catalyst for hydrogen production by methanol reforming as well as a preparation method and application thereof. The supported catalyst for hydrogen production by methanol reforming comprises the following components in percentage by mass: 15.0-25.0 percent of CuO, 10.0-20.0 percent of assistants, and 60.0-75.0 percent of complex carriers.. The preparation method comprises the steps of: preparing the complex carriers from SiO2 and Al2O3 by virtue of extrusion formation, impregnating the complex carriers in an impregnating solution which is a soluble precursor water solution of copper and the assistants by using an isometric impregnating method, drying at the temperature of 100-120 DEG C for 10-15 hours, and roasting for 3-8 hours under the condition that the roasting atmosphere is nitrogen or air and the roasting temperature is between 350 and 550 DEG C to obtain a catalyst finished product. The supported catalyst for hydrogen production by methanol reforming has the advantages that because the catalyst is prepared by using the impregnating method, the process is simple and easy to control, the cost is greatly reduced, and the performance of the catalyst is good.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of metal surface chemical conversion film for polyurea anticorrosive coating

InactiveCN102808173AHigh bonding strengthReduce energy consumptionMetallic material coating processesInositol pentakisphosphateInositol pentaphosphate

The invention belongs to the field of metal anticorrosion and protection and relates to a preparation method of a metal surface chemical conversion film for polyurea anticorrosive coating. Metal surface treatment solution consists of inositol phosphate and composite additives, wherein the volume concentration of the inositol phosphate is 15.0-30.0g / L and the volume concentration of the composite additives is 3.0-5.0g / L; the inositol phosphate consists of two or three of inositol tetraphosphate, inositol pentaphosphate and inositol hexaphosphate; and the composite additives consist of at least three of sodium nitrate, benzotrizaole, sodium molybdate, sodium tungstate, citric acid, tartaric acid, sodium 3-nitrobenzene sulfonate, sodium fluoborate and hexafluorozirconic acid. A dipping, coating or spray treatment method is adopted. The preparation method is suitable for metal materials such as steel and iron, aluminum alloy, and galvanized steel and iron. After surface treatment is conducted, polyurea coating is sprayed. The bonding strength of the polyurea coating is larger than 10MPa.

Owner:SHANDONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com