Efficient and environment-friendly webbing production system

A production system and webbing technology, applied in the elongation of fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of low tensile strength, high production cost, heavy webbing weight, etc., to increase tensile strength, save The effect of eliminating the washing process and reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

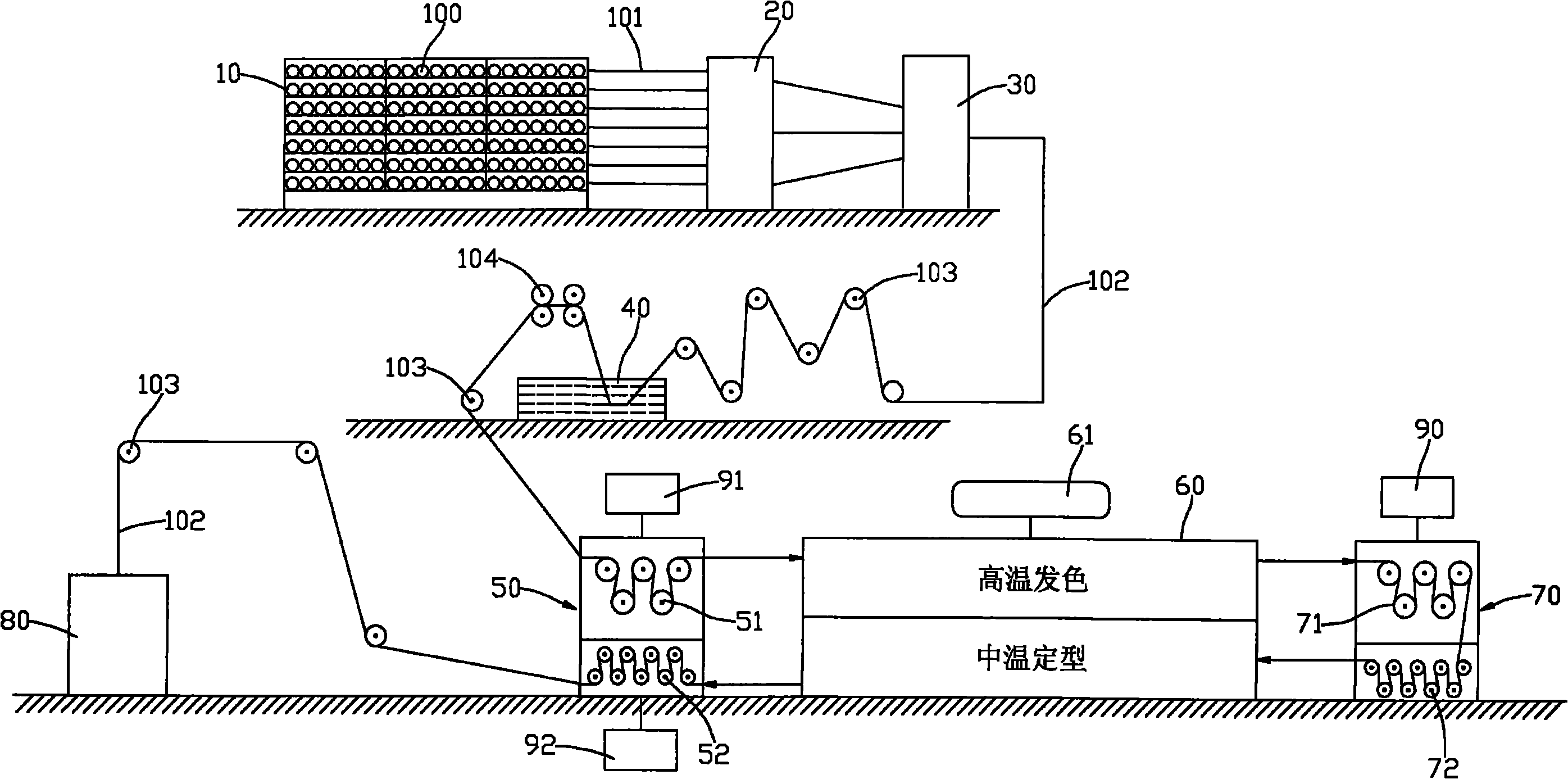

[0021] See figure 1 and figure 2 Shown: the highly efficient and environment-friendly webbing production system of the present invention mainly includes the following parts:

[0022] The creel 10 is located at the forefront of the system and is a multi-layer and multi-row structure in which a large number of yarn discs 100 can be placed to continuously supply the yarn 101 to the ribbon loom 30;

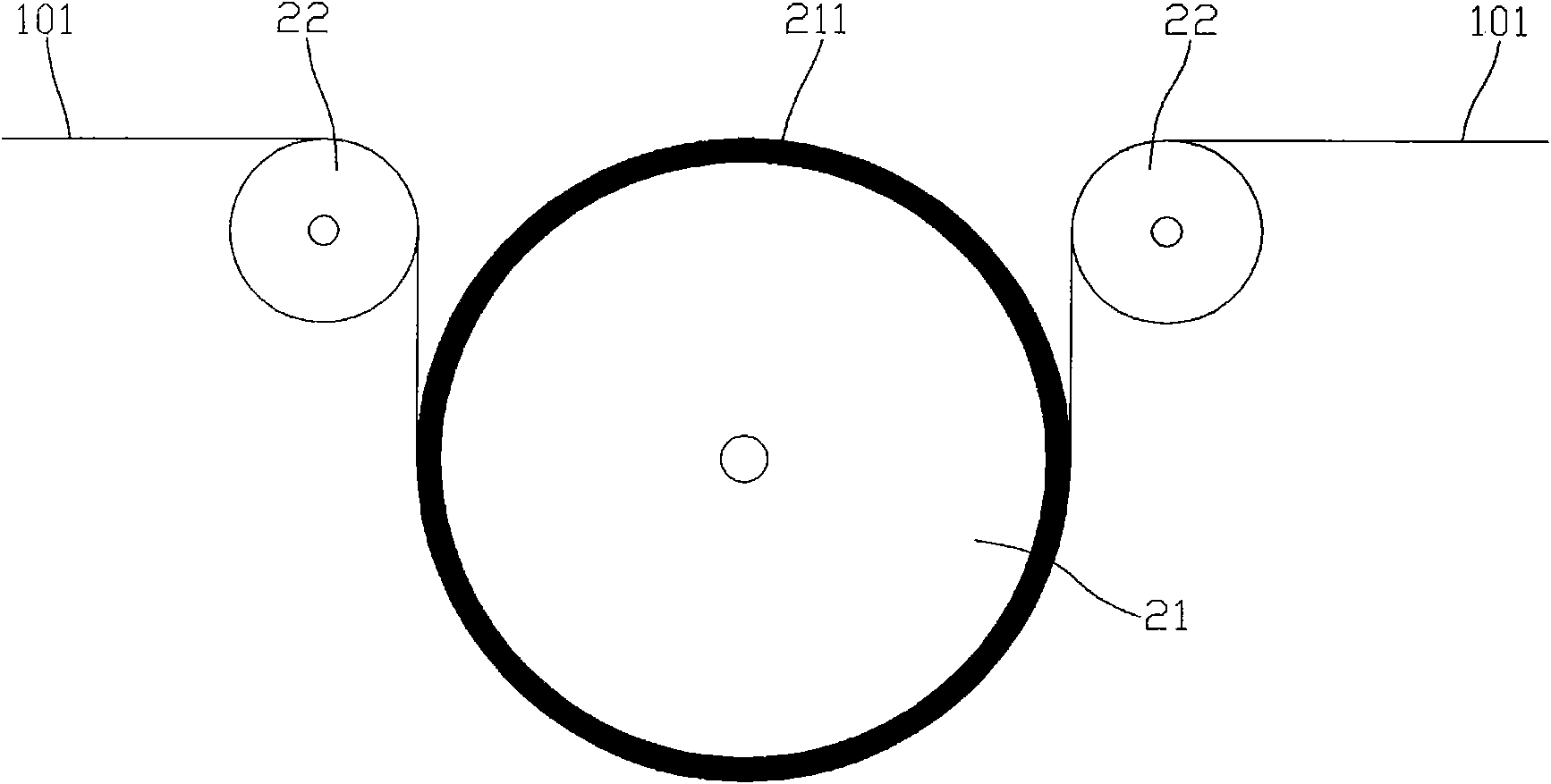

[0023] The yarn correcting device 20 is located between the creel 10 and the ribbon loom 30, and has a plurality of main correcting rollers 21 with rubber layers 211 on the inside. The secondary correction roller 22 that enters and exits the main correction roller 21; through this structure, when the yarns of different lengths pass through the main correction roller 21, they will have different linear speeds due to the friction of the rubber layer 211, and will eventually be supplied to the webbing The yarn 101 of the machine 30 is adjusted to be consistent in length, avoiding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com