Method for quickly preparing rutile phase nano titanium dioxide

A technology of nano-titanium dioxide and rutile phase, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of inconvenient large-scale production by microwave radiation method, long hydrolysis reaction time, poor production environment, etc., and achieve easy large-scale production Large-scale industrial production, low cost, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

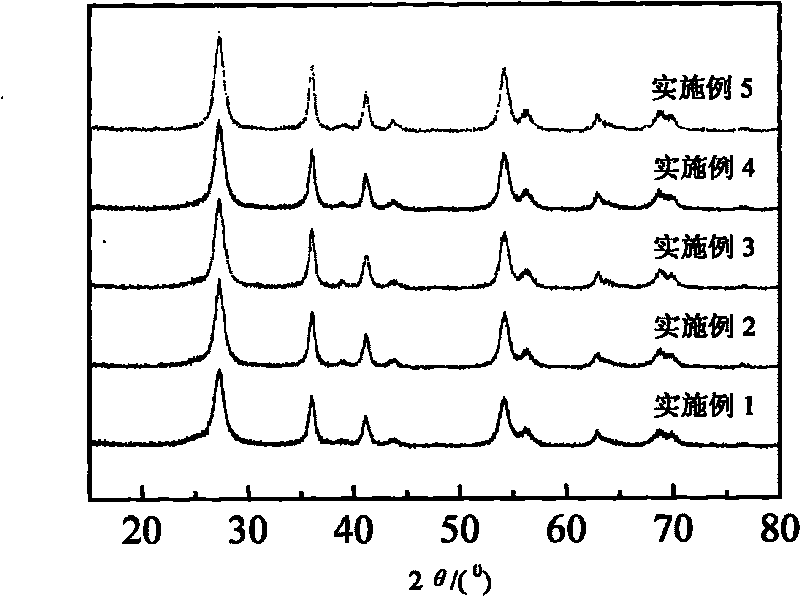

Embodiment 1

[0017] Weigh a certain amount of sodium hydroxide and titanium tetrachloride, add deionized water respectively to prepare 1.4mol / L sodium hydroxide aqueous solution and 2mol / L titanium tetrachloride aqueous solution, and measure 1.4mol / L hydrogen Put 400mL of sodium oxide solution in a 1000mL three-necked flask, heat up to 80°C, and while stirring, add 126mL of 2mol / L titanium tetrachloride aqueous solution dropwise, after the titanium tetrachloride aqueous solution is added dropwise, continue at 80°C Heat preservation reaction 25min, obtain rutile phase nano-titanium dioxide suspension, with the sodium hydroxide solution of 1.4mol / L, the pH value of rutile phase nano-titanium dioxide suspension is adjusted to pH=8, filter, wash repeatedly until there is no chloride ion (1% in the filtrate). Silver nitrate test), the obtained filter cake is dried and pulverized, and the content of rutile in the obtained nano-titanium dioxide powder is 100%.

Embodiment 2

[0019] Weigh a certain amount of sodium hydroxide and titanium tetrachloride, add deionized water respectively to prepare 6mol / L sodium hydroxide aqueous solution and 3.6mol / L titanium tetrachloride aqueous solution, measure 6mol / L hydroxide Put 300mL of sodium solution in a 1000mL three-necked flask, heat up to 90°C, and while stirring, add 400mL of 3.6mol / L titanium tetrachloride aqueous solution dropwise, after the titanium tetrachloride aqueous solution is added dropwise, continue to keep warm at 90°C Reaction 10min, obtain rutile phase nano-titanium dioxide suspension, add solid sodium carbonate to adjust the pH value of rutile phase nano-titanium dioxide suspension to pH=6, filter, repeatedly wash to no chloride ion (1% silver nitrate test) in the filtrate, will The obtained filter cake is dried and pulverized, and the content of rutile in the obtained nano titanium dioxide powder is 100%.

Embodiment 3

[0021] Weigh a certain amount of sodium hydroxide and titanium tetrachloride, add deionized water respectively to prepare 2mol / L sodium hydroxide aqueous solution and 2.5mol / L titanium tetrachloride aqueous solution, measure 2mol / L hydroxide Put 300mL of sodium solution in a 1000mL three-necked flask, heat up to 100°C, and while stirring, add 300mL of 2.5mol / L titanium tetrachloride aqueous solution dropwise, after the titanium tetrachloride aqueous solution is added dropwise, continue to keep warm at 100°C Reaction 20min, obtain rutile phase nano-titanium dioxide suspension, add solid ammonium carbonate and adjust the pH value of rutile phase nano-titanium dioxide suspension to pH=6.5, filter, repeatedly wash to no chloride ion (1% silver nitrate test) in the filtrate, will The obtained filter cake is dried and pulverized, and the content of rutile in the obtained nano titanium dioxide powder is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com