A kind of preparation method of rare earth doped anatase titanium dioxide micro-nanosphere

An anatase type, titanium dioxide technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of unfavorable industrial production, complicated operation steps, high risk factor, and avoid high temperature calcination steps. , The preparation process is simple and the crystallinity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of rare earth-doped anatase titanium dioxide micro-nanospheres, comprising the steps of:

[0027] a. Disperse three kinds of powders of 1.8g yttrium oxide, 0.79g ytterbium oxide and 0.038g erbium oxide in deionized water to obtain an aqueous solution of rare earth metal oxides;

[0028] b. Adding 40ml of an aqueous solution of trifluoroacetic acid with a mass concentration of 99.0% dropwise into an aqueous solution of a rare earth metal oxide to obtain a mixed solution;

[0029] c. Dissolve 9.3g of titanyl sulfate powder in the mixed solution, and conduct a hydrothermal reaction at 180°C for 12 hours;

[0030] d. After the reaction is completed, the powder product is centrifugally washed and freeze-dried to obtain rare earth-doped anatase titanium dioxide micro-nanospheres. The freeze-drying conditions are as follows: the condensation temperature is 45° C., and the vacuum degree is 40 MPa.

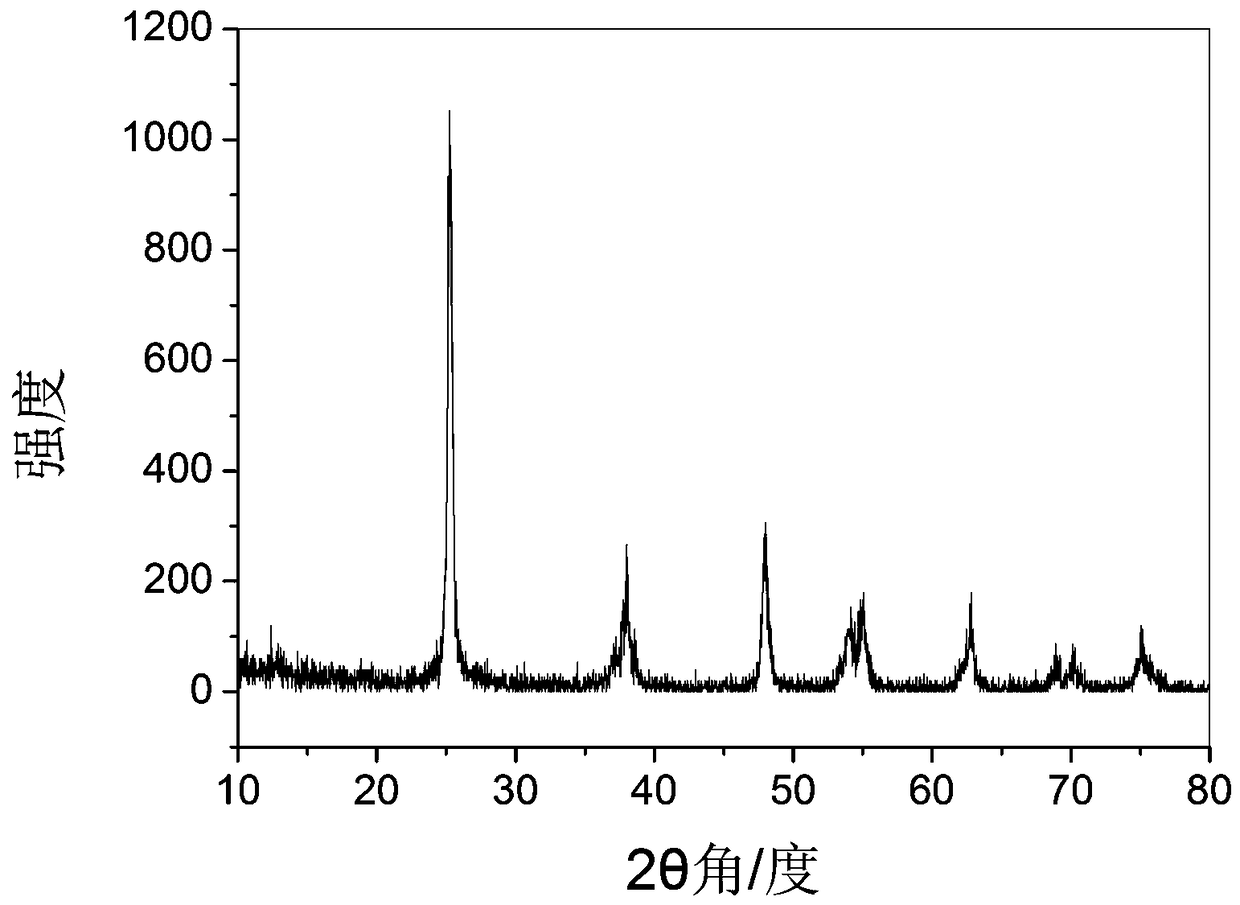

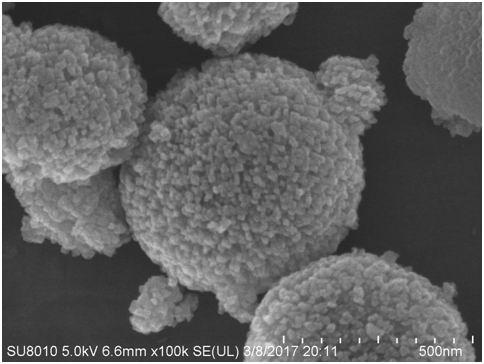

[0031] The results of X-ray diffraction analysis showed t...

Embodiment 2

[0033] A preparation method of rare earth-doped anatase titanium dioxide micro-nanospheres, comprising the steps of:

[0034] a. Disperse three kinds of powders of 1.14 yttrium oxide, 0.57g ytterbium oxide and 0.038g erbium oxide in deionized water to obtain an aqueous solution of rare earth metal oxides;

[0035] b. Adding 40ml of an aqueous solution of trifluoroacetic acid with a mass concentration of 98.0% dropwise into an aqueous solution of a rare earth metal oxide to obtain a mixed solution;

[0036] c. Dissolve 15.2g of titanyl sulfate powder in the mixed solution, and conduct a hydrothermal reaction at 180°C for 20 hours;

[0037] d. After the reaction is completed, the powder product is centrifugally washed and freeze-dried to obtain rare earth-doped anatase titanium dioxide micro-nanospheres. The freeze-drying conditions are as follows: the condensation temperature is 42° C., and the vacuum degree is 35 MPa.

[0038] The obtained rare earth-doped anatase titanium di...

Embodiment 3

[0040] A preparation method of rare earth-doped anatase titanium dioxide micro-nanospheres, comprising the steps of:

[0041] a. Disperse three kinds of powders of 2.20g yttrium oxide, 0.90g ytterbium oxide and 0.038g erbium oxide in deionized water to obtain an aqueous solution of rare earth metal oxides;

[0042] b. Adding 40ml of an aqueous solution of trifluoroacetic acid with a mass concentration of 97.0% dropwise into an aqueous solution of a rare earth metal oxide to obtain a mixed solution;

[0043] c. Dissolve 8.0 g of titanyl sulfate powder in the mixed solution, and conduct a hydrothermal reaction at 180° C. for 12 hours;

[0044] d. After the reaction is completed, the powder product is centrifugally washed and freeze-dried to obtain rare earth-doped anatase titanium dioxide micro-nanospheres. The freeze-drying conditions are as follows: the condensation temperature is 43° C., and the vacuum degree is 45 MPa.

[0045] The obtained rare earth-doped anatase titanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com