Process for preparing rutile phase spherical nano titania

A nano-titanium dioxide, rutile phase technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of complex process, high preparation cost, application limitation, etc., and achieves simplified preparation process, simple preparation process, good monodispersity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

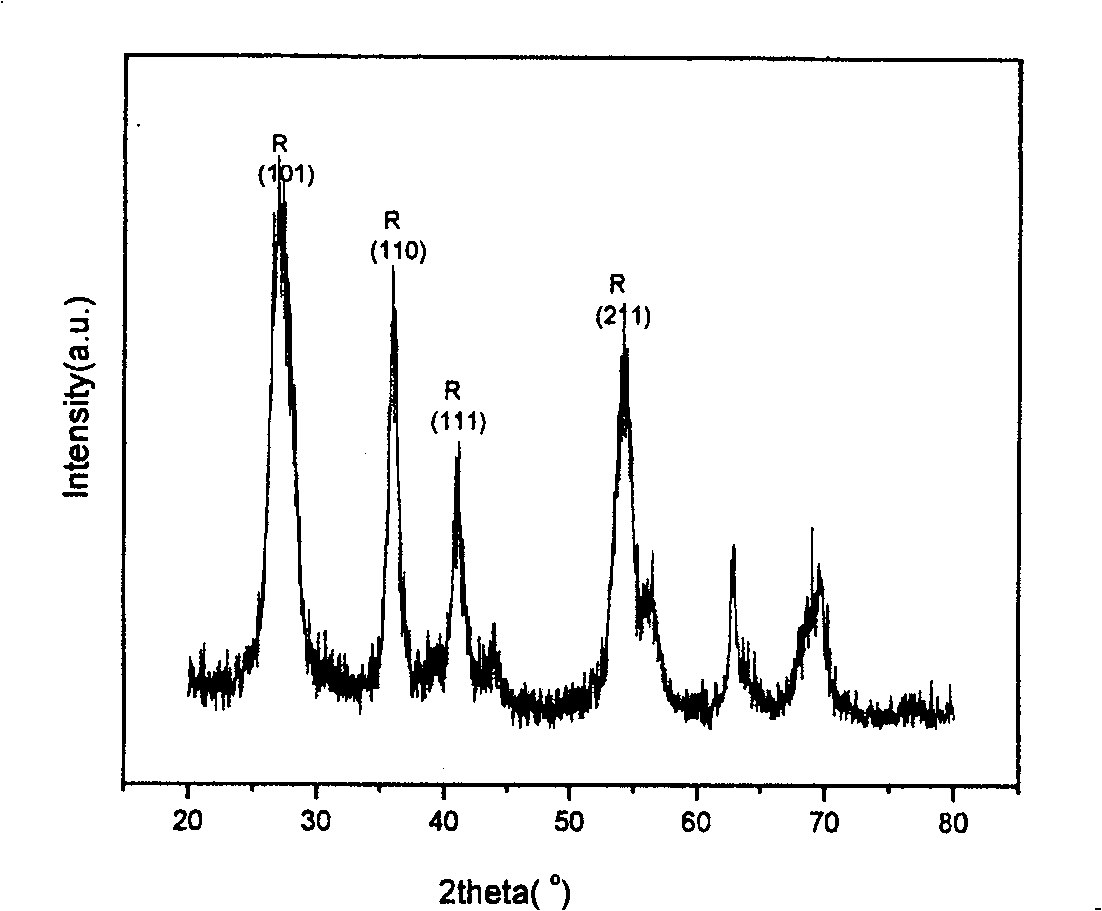

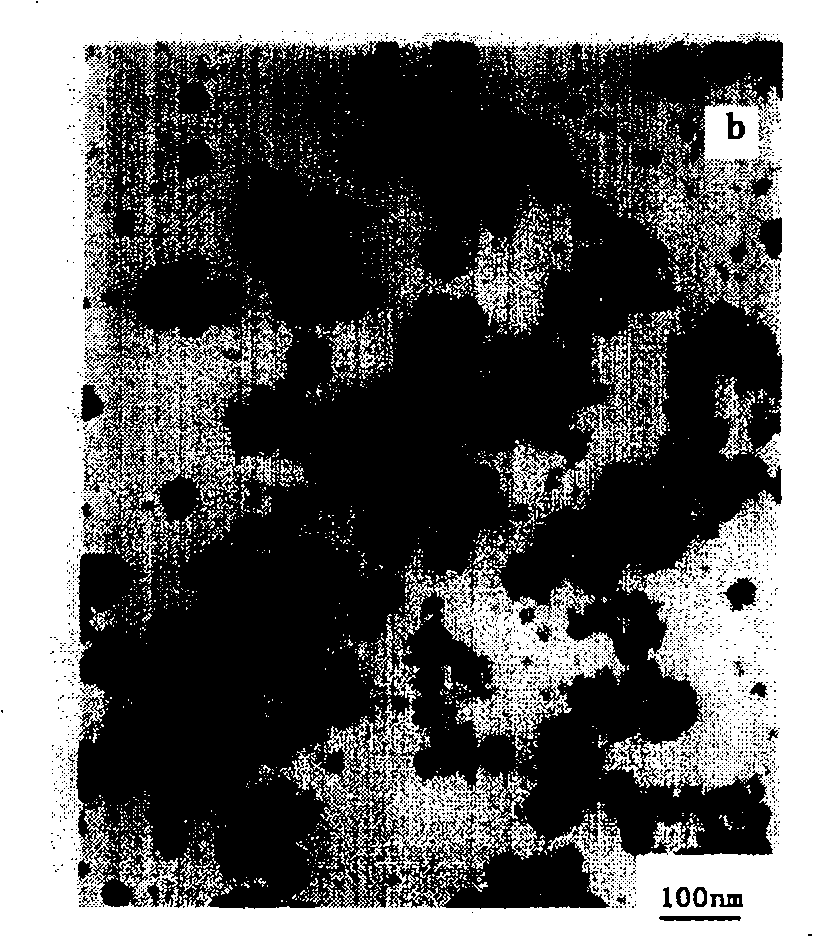

[0013] Add 5.5mL TiCl to the reaction kettle 4 , distilled water 95.5mL, TiCl 4 The concentration is 0.5 mol / L, a condensing device is installed on the reaction kettle, the temperature is raised to 100°C, and the temperature rise rate of the reactant is heated to boiling at 5°C / min. The reaction was continued for 5 hours. After the reaction, it was lowered to room temperature, filtered, washed several times with distilled water, dried at 80°C for 12 hours, and the obtained powder was calcined at 200°C for 5 hours to obtain 3.9g of the product. The X-ray diffraction results show that the powder is a rutile phase, and there is no anatase diffraction peak (such as figure 1 shown), the particle size of the powder is 25nm (such as figure 2 shown).

Embodiment 2

[0015] Add 8.8mL TiCl to the reaction kettle 4 , distilled water 91mL, TiCl 4 The concentration is 0.8mol / L, and a condensing device is installed on the reactor, and the temperature is raised to 80°C, and the heating rate of the reactants to boiling is 2.5°C / min. The reaction was continued for 5 hours. After the reaction was completed, it was lowered to room temperature, filtered, washed several times with distilled water, dried at 60°C for 24 hours, and the obtained powder was calcined at 600°C for 2 hours to obtain 6.3g of the product. X-ray diffraction results show that the powder is in rutile phase, no anatase diffraction peak appears, and the particle size of the powder is 70nm.

Embodiment 3

[0017] Add 11ml TiCl to the reaction kettle 4 , distilled water 89mL, TiCl 4 The concentration is 1.0mol / L, and a condensing device is installed on the reactor, and the temperature is raised to 100°C, and the heating rate of the reactant to boiling is 3.5°C / min. The reaction was continued for 5 hours. After the reaction was completed, it was lowered to room temperature, filtered, washed several times with distilled water, dried at 80°C for 12 hours, and the obtained powder was calcined at 600°C for 3 hours to obtain 7.8g of the product. X-ray diffraction results show that the powder is in rutile phase, no anatase diffraction peak appears, and the particle size of the powder is 90nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com