Method for preparing CNT (carbon nano tube)-polyacrylonitrile fibre by melting spinning

A polyacrylonitrile fiber and carbon nanotube technology, which is applied in the directions of melt spinning, stretch spinning, fiber chemical characteristics, etc., can solve the problems of corrosive chemical solvents, lack of research, and high production costs, and achieves a high production cost. The method is simple, the strength of the raw silk is improved, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

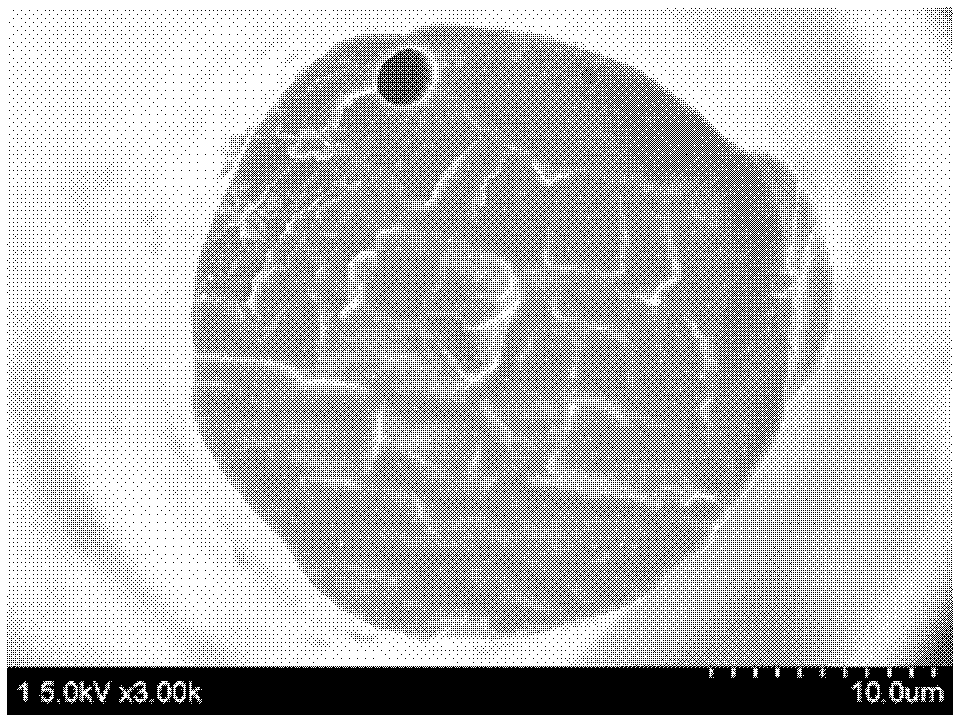

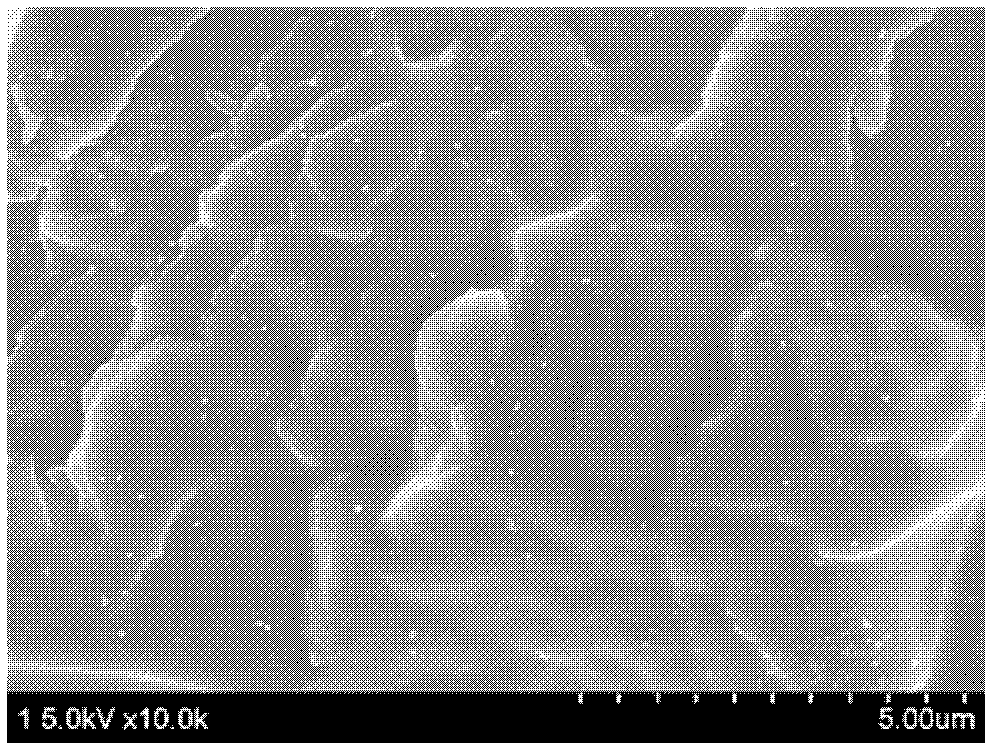

[0027] First, single-walled carbon nanotubes and ionic liquid [BMIM]Cl were mixed evenly in an ultrasonic cell pulverizer with a mass ratio of 1:10, and then mixed with polyacrylonitrile powder (the mass ratio of polyacrylonitrile powder to carbon nanotubes was 10: 2) Mix evenly in a high-speed mixer, and put the mixture into the hopper of a twin-screw spinning machine for melt spinning. The melt spinning temperature is 180°C, the aspect ratio of the spinneret is 3:1, the hole diameter is 0.3mm, and the winding speed is 25m / min; then the as-spun yarn is subjected to primary dry heat stretching and secondary dry heat stretching; After stretching, the plasticizer was removed in acetone solvent at 40°C; finally, PAN / CNT composite fibers were obtained by heat setting. The PAN fiber strength is 3.5cN / dtex, and the elongation at break is 19.0%. Figure 1(a) and Figure 1(b) are SEM cross-sectional views of PAN / CNT composite fibers with different magnifications when the mass ratio of ...

Embodiment 2

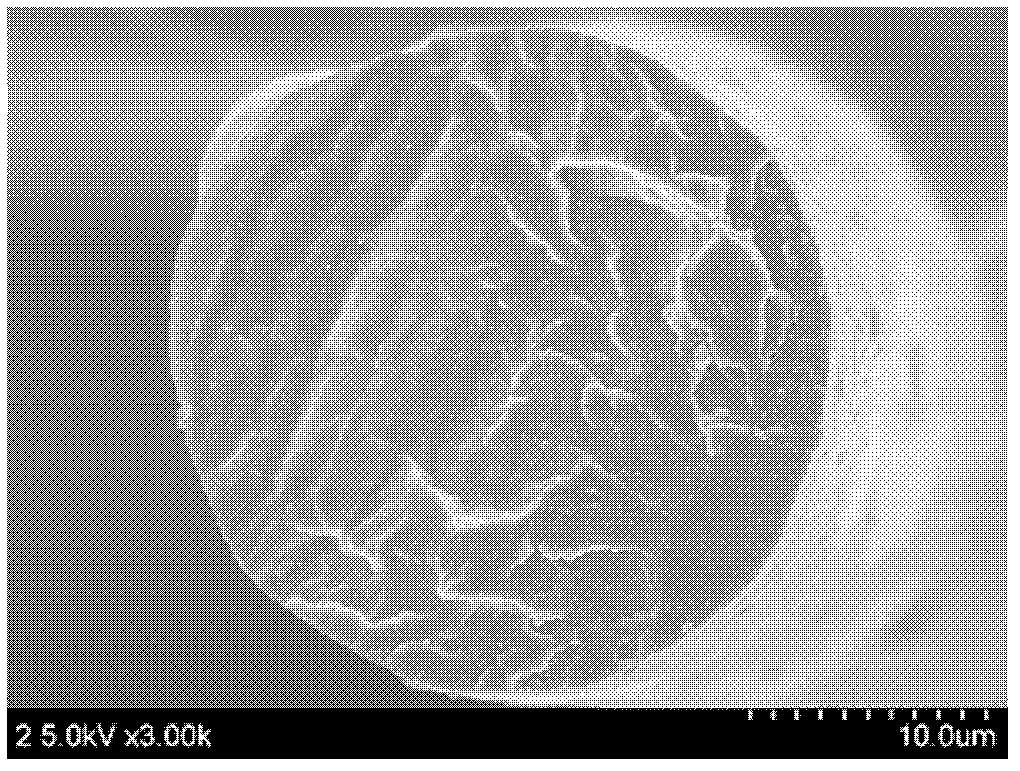

[0029] First, single-walled carbon nanotubes and ionic liquid [BMIM]BF 4 Disperse the carbon nanotubes uniformly in an ultrasonic cell pulverizer with a mass ratio of 1:10, and then mix the above homogeneous solution with polyacrylonitrile powder (the mass ratio of polyacrylonitrile powder to carbon nanotubes is 8:2) in a high-speed mixer Mix evenly, and then transfer the above-mentioned homogeneous mixture to a twin-screw spinning machine for melt spinning. The melt spinning temperature is 190°C, the aspect ratio of the spinneret is 5:1, the aperture is 0.3mm, and the winding speed is 150m / min, and the as-spun silk is drawn through the secondary heat pipe; Removal of plasticizer in solvent; heat setting to obtain PAN / CNT composite fiber. The PAN fiber strength is 3.8cN / dtex, and the elongation at break is 17.0%. Figure 2(a) and Figure 2(b) are SEM cross-sectional views of PAN / CNT composite fibers with different magnifications when the mass ratio of PAN / CNT is 8:2.

Embodiment 3

[0031] First, multi-walled carbon nanotubes and ionic liquid [BMIM]BF 4 Disperse the carbon nanotubes uniformly in an ultrasonic cell pulverizer with a mass ratio of 1:50, then mix the above homogeneous solution with polyacrylonitrile powder (the mass ratio of polyacrylonitrile powder to carbon nanotubes is 6:2) in a high-speed mixer Mix evenly, and then transfer the above-mentioned homogeneous mixture to a twin-screw spinning machine for melt spinning. The melt spinning temperature is 195°C, the aspect ratio of the spinneret is 3:1, the hole diameter is 0.5mm, and the winding speed is 100m / min. Removal of plasticizer in acetone solvent; heat setting to obtain PAN / CNT composite fiber. The PAN fiber strength is 4.8cN / dtex, and the elongation at break is 15.0%. Figure 3(a) and Figure 3(b) are SEM cross-sectional views of PAN / CNT composite fibers with different magnifications when the mass ratio of PAN / CNT is 6:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com