Method for preparing nano hydroxyapatite powder

A nano-hydroxyapatite and powder technology, applied in the field of biomedical materials, can solve the problems of long production cycle, cumbersome procedures, low output, etc., and achieve the effect of reducing manpower and material resources, overcoming low output and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

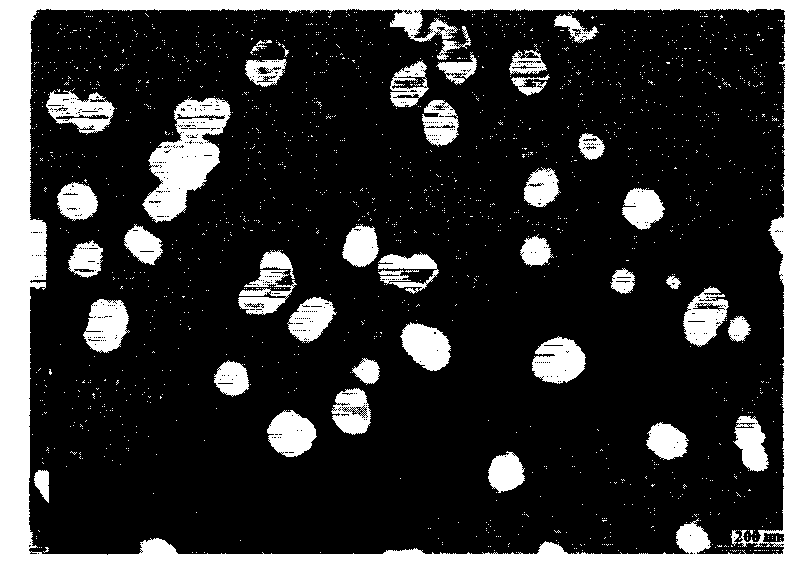

Image

Examples

Embodiment 1

[0030] At room temperature, weigh 11.80g calcium nitrate (Ca(NO 3 ) 2 4H 2 (2) Polyethylene Glycol 15.00g with molecular weight 6000, they are dissolved with deionized water and transferred to 50ml volumetric flask and constant volume to scale, get the composite solution of calcium nitrate and Polyethylene Glycol; Wherein said calcium nitrate and The concentration of calcium nitrate in the polyethylene glycol composite solution is 1.00mol / L, and the polyethylene glycol mass fraction is 30%; then 50.00ml of the composite solution is transferred to a 250ml four-necked bottle and continuously stirred in a water bath at 10°C ; After the temperature of the composite solution reaches 10°C, use 0.1ml ammonia water (NH 3 ·H 2 O) Adjust its pH to 10.0. Then at room temperature, weigh 3.96g diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ), was dissolved in deionized water and transferred to a 50ml volumetric flask and fixed to the mark to prepare diammonium hydrogen phosphate ((N...

Embodiment 2

[0032] At room temperature, weigh 1.18g of calcium nitrate and 5.00g of polyethylene glycol with a molecular weight of 2000, dissolve them with deionized water and transfer them to a 50ml volumetric flask and set the volume to the mark to obtain calcium nitrate and polyethylene glycol. Composite solution; Calcium nitrate concentration is 0.10mol / L in wherein said calcium nitrate and polyethylene glycol composite solution, and described polyethylene glycol mass fraction is 10%; Then this composite solution of 40.00ml is transferred to 250ml four-neck bottle and keep stirring in a water bath at 25°C; when the temperature of the composite solution reaches 25°C, adjust its pH to 11.0 with 2.0ml of ammonia water. Then at room temperature, take by weighing 0.40g diammonium hydrogen phosphate, dissolve it with deionized water and transfer it to a 50ml volumetric flask and settle to the mark to prepare diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) solution, the concentration of w...

Embodiment 3

[0034] At room temperature, take by weighing 59.04g of calcium nitrate and 10.00g of polyethylene glycol with a molecular weight of 10000, dissolve them with deionized water and transfer to a 50ml volumetric flask and settle to the mark to obtain calcium nitrate and polyethylene glycol Composite solution; Calcium nitrate concentration is 5.00mol / L in wherein said calcium nitrate and polyethylene glycol composite solution, and described polyethylene glycol mass fraction is 20%; Then this composite solution of 45.00ml is transferred to 250ml four-neck bottle and keep stirring in a water bath at 15°C; when the temperature of the composite solution reaches 15°C, adjust its pH to 11.0 with 1.0ml of ammonia water. Then at room temperature, take by weighing 19.82g of diammonium hydrogen phosphate, dissolve it with deionized water and transfer to a 50ml volumetric flask and settle to the mark to prepare diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) solution, the concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com