Method for preparing iminodibenzyl

A technology of adding phosphoric acid to iminodibenzyl and diaminobibenzyl, which is applied in the field of preparation of pharmaceutical intermediates, can solve the problems of difficult further improvement of product quality and complicated post-treatment process, and achieve good crystal form, high product yield and high product quality. The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

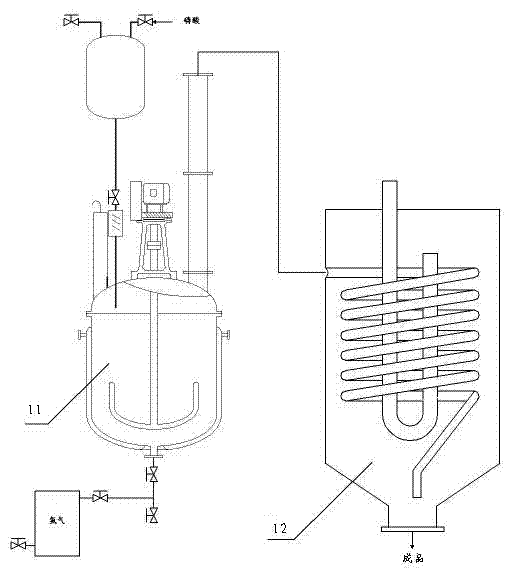

[0045] refer to figure 1 , figure 2 Shown technological process and equipment, prepare iminodibenzyl according to the method of the present invention.

[0046] Take 135kg2,2 , - Diaminobibenzyl is heated to 260°C in a 300L reaction kettle, and 135 kg of industrial phosphoric acid (85% mass fraction) is added dropwise for one hour, then the temperature is raised to 260°C to 300°C, and the temperature is kept for 1 hour. After the reaction is completed, the phosphoric acid waste solution is divided.

[0047] Turn on the vacuum, introduce industrial nitrogen (nitrogen flow rate at 80L / min), and carry out vacuum distillation, that is, iminodibenzyl powder will be evaporated. The vacuum degree of the whole system is -0.080MPa, and the liquid phase temperature in the reactor is kept at 200 ℃~240℃. The powdery product is collected by a cyclone separator and settles at the bottom of the collection tank. The distillation time was 2 hours, and when there was no obvious material to...

Embodiment 2

[0050] Take 135kg2,2 , - Diaminobibenzyl is heated to 260°C in a 300L reaction kettle, and 135 kg of industrial phosphoric acid (85% mass fraction) is added dropwise for one hour, then the temperature is raised to 260°C to 300°C, and the temperature is kept for 1 hour. After the reaction is completed, the phosphoric acid waste solution is divided.

[0051]Turn on the vacuum, introduce industrial nitrogen gas (nitrogen flow rate 120 L / min), and carry out vacuum distillation, that is, iminodibenzyl powder will be evaporated, and the vacuum degree of the whole system will be kept at -0.095 MPa, and the liquid phase temperature in the reactor will be kept at 200 ℃~240℃. The powdery product is collected by a cyclone separator and settles at the bottom of the collection tank. The distillation time was 1.5 hours. When the sight glass showed that there was no obvious material to evaporate, and the temperature of the gas phase dropped to 150°C, the distillation was stopped after exte...

Embodiment 3

[0053] Take 135kg2,2 , - Diaminobibenzyl is heated to 260°C in a 300L reaction kettle, and 135 kg of industrial phosphoric acid (85% mass fraction) is added dropwise for one hour, then the temperature is raised to 260°C to 300°C, and the temperature is kept for 1 hour. After the reaction is completed, the phosphoric acid waste solution is divided.

[0054] Turn on the vacuum, introduce industrial nitrogen gas (nitrogen flow rate 100 L / min), and carry out vacuum distillation, that is, iminodibenzyl powder will be evaporated, and the vacuum degree of the whole system will be kept at -0.090 MPa, and the liquid phase temperature in the reactor will be kept at 200 ℃~240℃. The powdery product is collected by a cyclone separator and settles at the bottom of the collection tank. The distillation time was 1.5 hours. When the sight glass showed that there was no obvious material to evaporate, and the temperature of the gas phase dropped to 150°C, the distillation was stopped after ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com