Preparation technique of phase transformation induced plasticity hot galvanizing steel plate

A phase transformation-induced plasticity, hot-dip galvanized steel sheet technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problem of good coating phase structure and its control method, poor wettability, no adhesion performance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

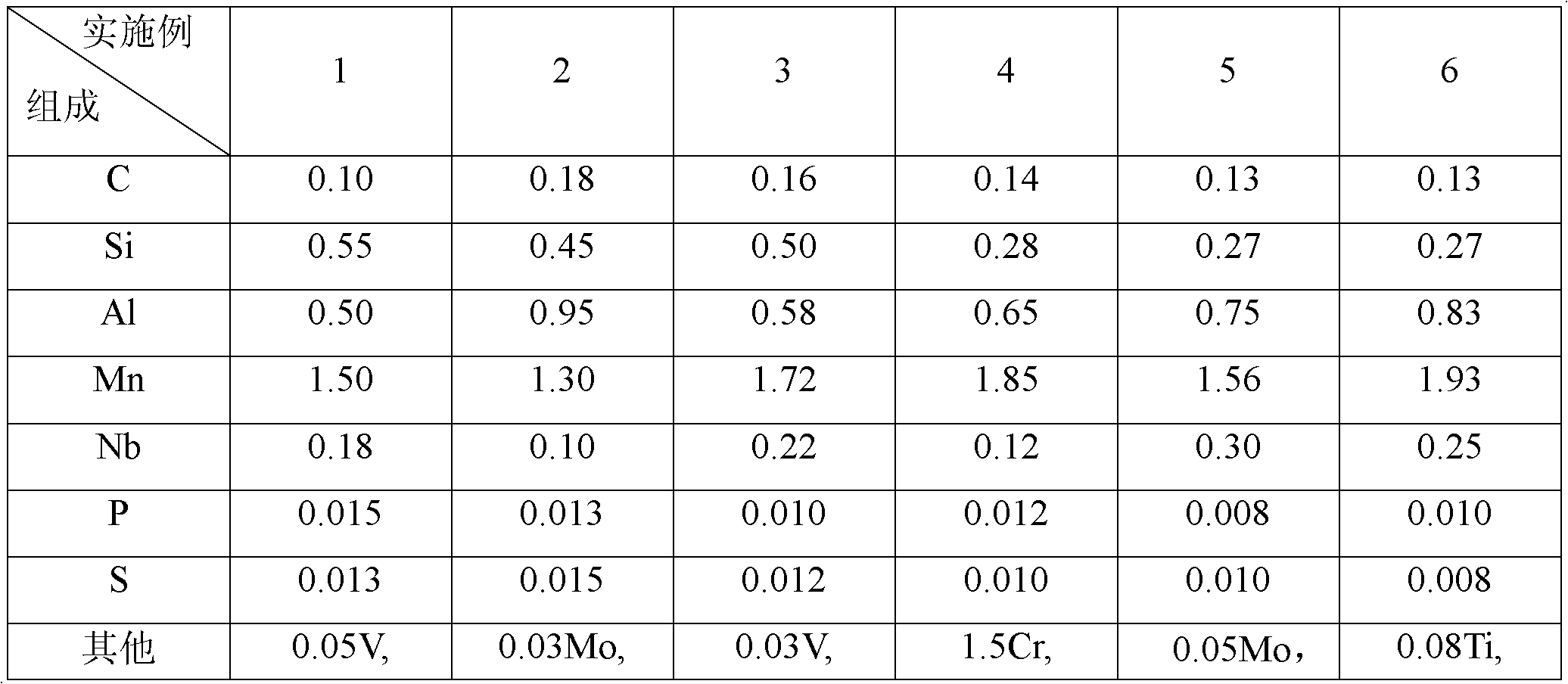

Embodiment 1-6

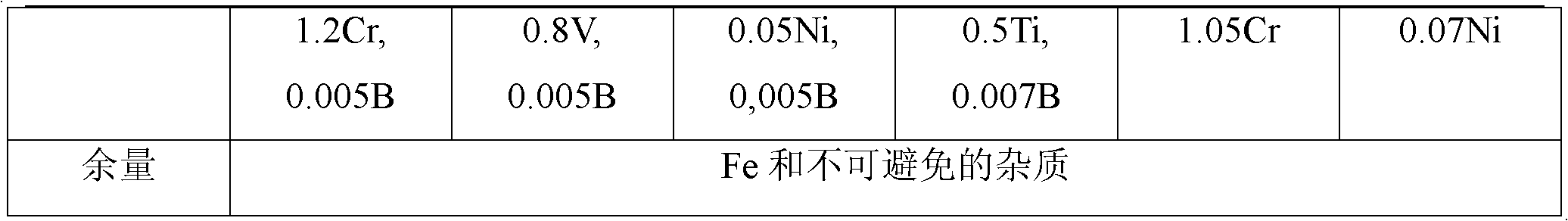

[0040] Use the zinc solution in Table 3 for the steel plate in Table 1, and adopt the existing improved Sendzimir method or the United States Steel United method galvanizing production line galvanizing according to the hot-dip galvanizing process conditions in Table 2: specifically: cold-rolled The thin steel plate is cooled to a set temperature, put into a galvanizing pot, and then hot-dip galvanized in a hot-dip galvanizing solution within a certain temperature range to obtain a phase-change-induced plasticity hot-dip galvanized steel plate.

[0041] The steel plate can be prepared according to the process conditions in Table 2. The specific steps are: vacuum smelting, casting to obtain a billet; sending the billet into a billet heating furnace for reheating; and then performing hot rolling at the set hot rolling finishing temperature to obtain Hot-rolled billet: Coil the hot-rolled billet to obtain a hot-rolled steel plate with a thickness specification of 2.5-6.0 mm; cold-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com