Smelting technique of novel nickel-iron-base high-temperature alloy GH4169D

A technology of GH4169D and GH4169, which is applied in the smelting process of the new nickel-iron-based superalloy GH4169D, can solve problems such as scrapping of steel ingots, fluctuations in the content of Al and Ti in steel ingots, unqualified, etc., and achieve high welding performance, improved metallurgical quality, and good The effect of thermal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] ⑴ Vacuum induction melting

[0035] a) Full melting temperature: 1535°C;

[0036] b) Refining temperature: 1535°C;

[0037] c) Tapping temperature: 1475°C;

[0038] d) Vacuum degree during full melting period: 30Pa;

[0039] e) Vacuum degree during refining period: 2Pa, keep for 90min.

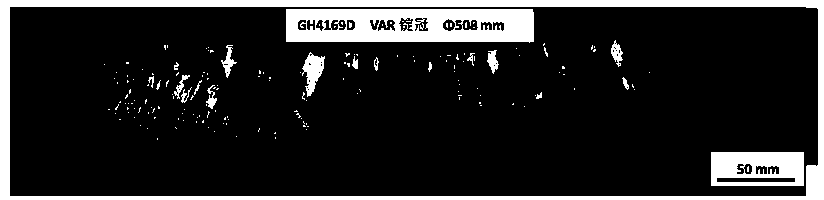

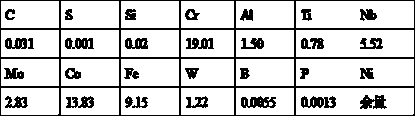

[0040] The chemical composition of the sensing electrode is shown in Table 1;

[0041] Table 1 %

[0042] C S Si Cr Al Ti Nb 0.031 0.001 0.02 19.01 1.50 0.78 5.52 Mo co Fe W B P Ni 2.83 13.83 9.15 1.22 0.0055 0.0013 margin

[0043] ⑵ Protective atmosphere electroslag remelting

[0044] The slag ratio is CaF 2 :Al 2 o 3 :CaO:TiO 2 =65%: 15%: 15%: 5%;

[0045] Melting speed: 4.0kg / min;

[0046] The chemical composition of the electroslag ingot is shown in Table 2;

[0047] Table 2 %

[0048] Ingot part ...

Embodiment 2

[0057] ⑴ Vacuum induction melting

[0058] a) Full melting temperature: 1540°C;

[0059] b) Refining temperature: 1540°C;

[0060] c) Tapping temperature: 1480°C;

[0061] d) Vacuum degree during full melting period: 30Pa;

[0062] e) Vacuum degree during refining period: 2Pa, keep for 90 min.

[0063] The chemical composition of the sensing electrode is shown in Table 4;

[0064] Table 4 %

[0065] C S Si Cr Al Ti Nb 0.028 0.001 0.03 18.91 1.53 0.75 5.49 Mo co Fe W B P Ni 2.81 13.79 9.18 1.20 0.0060 0.0012 margin

[0066] ⑵ Protective atmosphere electroslag remelting

[0067] The slag ratio is CaF 2 :Al 2 o 3 :CaO:TiO 2 =65%: 15%: 15%: 5%;

[0068] Melting speed: 3.9kg / min;

[0069] The chemical composition of the electroslag ingot is shown in Table 5;

[0070] table 5 %

[0071] Ingot part C S S...

Embodiment 3

[0080] ⑴ Vacuum induction melting

[0081] a) Full melting temperature: 1555°C;

[0082] b) Refining temperature: 1560°C;

[0083] c) Tapping temperature: 1485°C;

[0084] d) Vacuum degree during full melting period: 30Pa;

[0085] e) Vacuum degree during refining period: 2Pa, keep for 90 min.

[0086] The chemical composition of the sensing electrode is shown in Table 7;

[0087] Table 7%

[0088] C S Si Cr Al Ti Nb 0.033 0.001 0.01 19.08 1.50 0.74 5.55 Mo co Fe W B P Ni 2.80 13.75 9.20 1.21 0.0060 0.0013 margin

[0089] ⑵ Protective atmosphere electroslag remelting

[0090] The slag ratio is CaF 2 :Al 2 o 3 :CaO:TiO 2 =65%: 15%: 15%: 5%;

[0091] Melting rate: 3.9kg / min.

[0092] The chemical composition of the electroslag ingot is shown in Table 8;

[0093] table 8%

[0094] Ingot part C S Si Al Ti head 0.032 0.0008 0.04 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com