Automatic hot-dip galvanizing method and intelligent processing system

An intelligent processing system, hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of high labor intensity, substandard emission, poor working environment, etc., to improve protection performance, reducing time, improving the effect of galvanizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

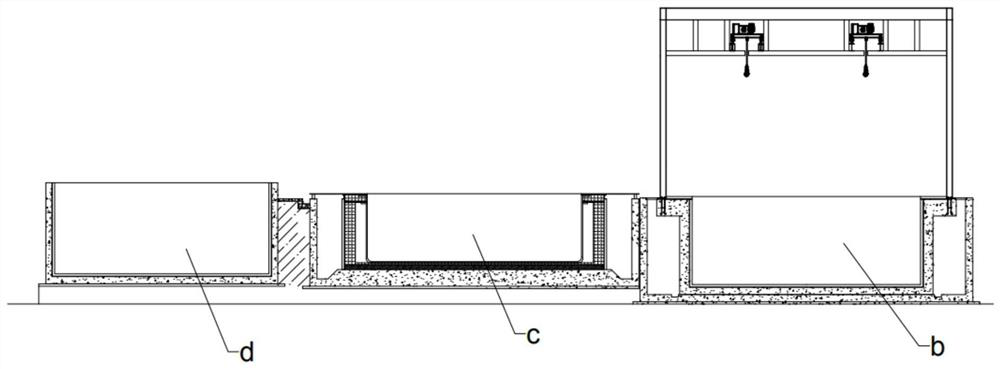

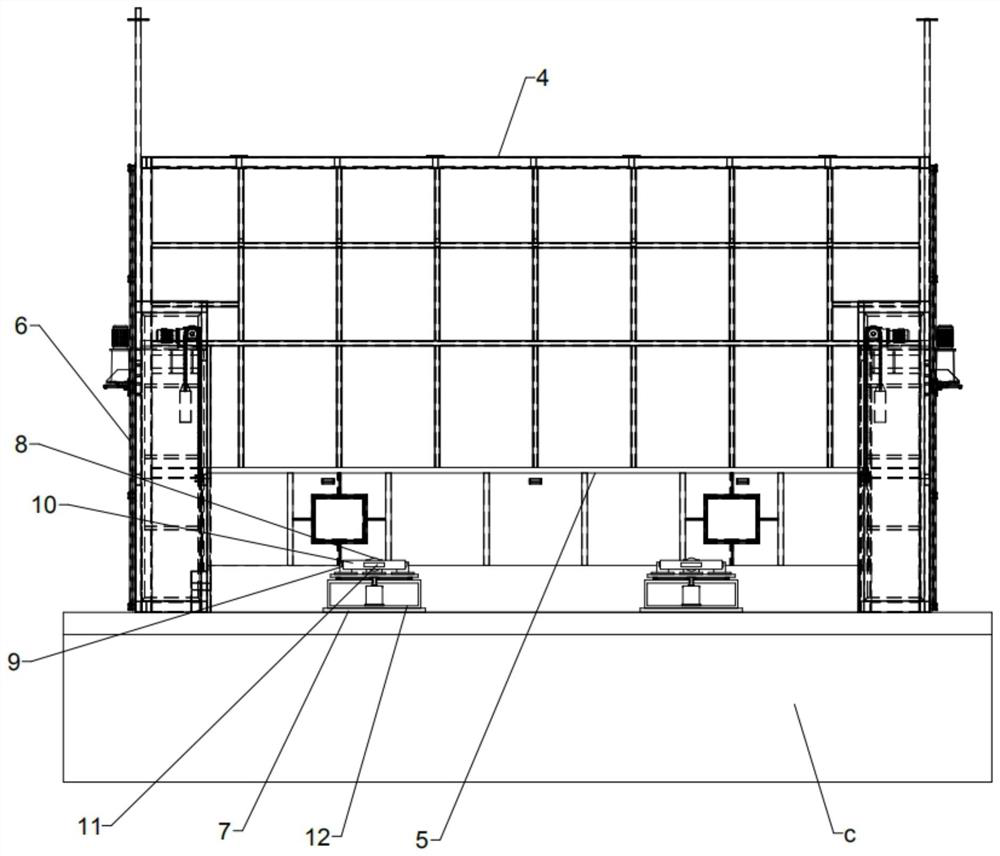

[0035] The present invention will be specifically described below with reference to the drawings. Figure 1-9 As shown, in the art, all electrical parts in this case are connected to its adapted power source through a wire, and should select a suitable controller according to the actual situation, to meet the control requirements, concrete connection, and control order, should be referenced In the working principle, the electrical components are completed in the order of the electrical components, and the detailed connection means is well known in the art, and the following mainly introduces the working principle and the process, not in terms of electrical control.

[0036] EXAMPLE: Attached Figure 1-9 It can be seen that during the specific implementation process, an automatic hot dip galvanizing method includes the following steps:

[0037] Step S1, the workpiece is hung: the hooks to be plated on the front treatment area A of the placement table;

[0038] Step S2, the moving feed:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com