800 MPa-grade low-carbon hot-galvanized dual-phase steel and preparation method thereof

A dual-phase steel and hot-dip galvanizing technology, which is applied in the field of high-strength steel preparation, can solve the problems of not comprehensively considering production cost, formability, galvanizing performance and welding performance, and achieves the effect of ensuring strength and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

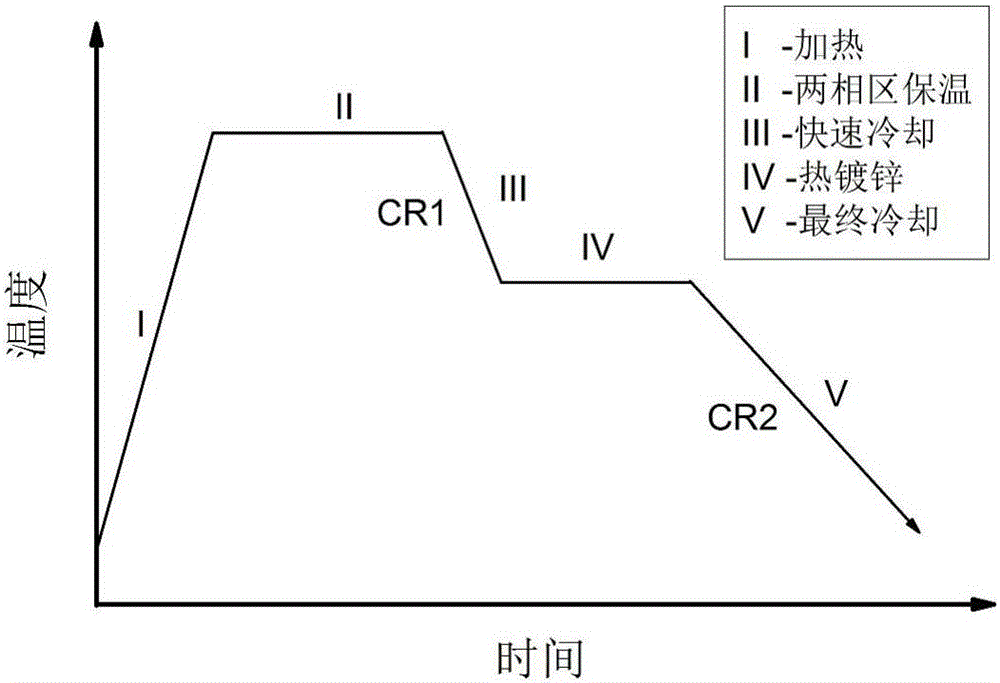

[0040] The preparation method of above-mentioned a kind of 800MPa level low-carbon hot-dip galvanized dual-phase steel comprises the following steps:

[0041] a. Smelting process: smelting according to the weight percentage composition of the above-mentioned 800MPa grade low-carbon hot-dip galvanized dual-phase steel, and controlling the vanadium content in the converter (that is, by controlling the vanadium content in the original molten iron instead of adding additional vanadium-iron alloy, reducing production costs), cast into slabs;

[0042] b. Hot rolling process: hot-rolled coils are obtained after the slab is heated, dephosphorized, hot-rolled and laminar cooling; wherein, the starting temperature of the finish rolling is 1000-1100°C, and the finishing rolling temperature is 850-950°C. Take the temperature as 600~700℃;

[0043] c. Pickling process: hot-rolled coils are pickled and then cold-rolled to obtain cold-rolled thin strip steel; wherein, the cold-rolled reducti...

Embodiment 1

[0052] The preparation method of 800MPa grade low-carbon hot-dip galvanized dual-phase steel provided by the present invention has the following processes:

[0053] (1) Through the smelting process, a dual-phase steel slab with the chemical composition shown in Table 1 is prepared:

[0054] Table 1 Chemical Composition of Duplex Steel (wt.%)

[0055] Numbering

C

Si

mn

P

S

als

Cr

Mo

V

N

DP1

0.08

0.30

1.70

0.012

0.002

0.050

0.50

0.25

0.07

0.004

DP2

0.09

0.25

1.60

0.011

0.002

0.030

0.45

0.30

0.10

0.005

[0056] (2) After heating, dephosphorization, hot rolling and laminar cooling to obtain hot rolled coils, the starting temperature of finish rolling is 1000-1100°C, the finishing rolling temperature is 850-950°C, and the coiling temperature is 600°C ~700°C; the specific hot rolling process parameters are shown in Table 2 below:

[0057] Table 2 Main process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com