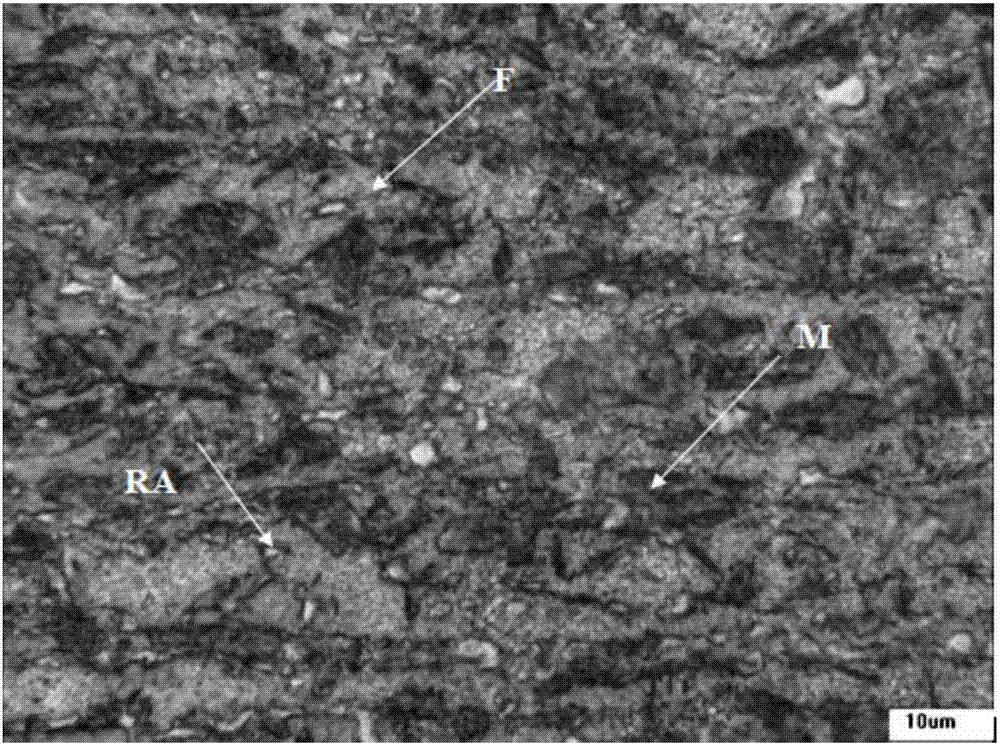

Ultralow yield ratio 980 MPa-grade cold rolling two-phase steel and manufacturing method thereof

A manufacturing method and technology of 980mpa, applied in the field of dual-phase steel, can solve the problems of decreased plasticity and formability, difficulty in meeting processing and forming, increase in yield strength, etc., and achieve good formability, high n value, and good elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

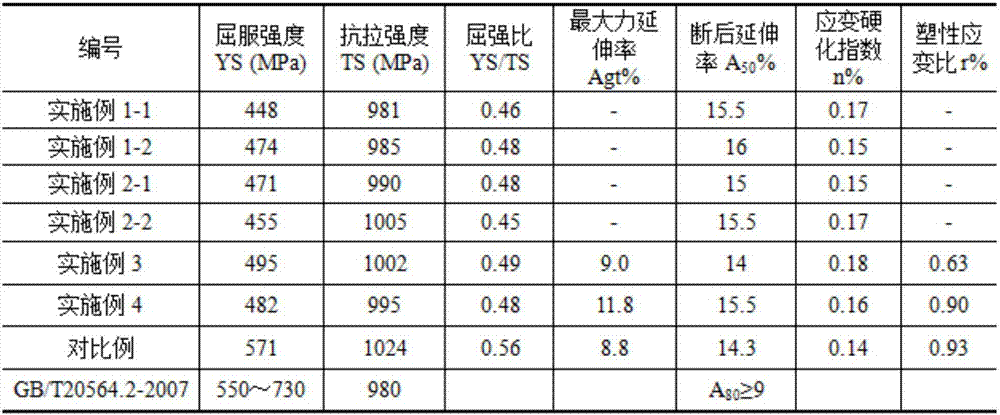

Embodiment 1

[0019] A 980MPa low process sensitivity, low yield ratio cold-rolled dual-phase steel, its components and weight percentage content: C: 0.17%, Mn: 1.76%, Als: 0.04%, Si: 0.5%, P: 0.010 %, S: 0.005%, Cr: 0.4, and the balance is Fe and unavoidable impurities. The manufacturing process is as follows:

[0020] 1) Smelting and continuous casting into billets;

[0021] 2) Heat the cast slab to 1250°C, keep it warm for 2.5 hours, then carry out hot rolling, start rolling at 1150°C, and control the final rolling temperature at 900°C:

[0022] 3) Carry out coiling, control coiling temperature at 650 ℃;

[0023] 4) Carry out conventional pickling;

[0024] 5) Carry out cold rolling, and control the cumulative reduction rate of cold rolling to 66.7%;

[0025] 6) Carry out continuous annealing, control the annealing temperature at 780°C, and annealing time 120s;

[0026] 7) Cool to 720°C at a slow cooling rate of 3°C / s;

[0027] 8) Perform rapid cooling, the cooling rate is controll...

Embodiment 2

[0030] 980MPa low process sensitivity, low yield ratio cold-rolled dual-phase steel, its components and weight percentage content: C: 0.17%, Mn: 1.76%, Als: 0.04%, Si: 0.5%, P: 0.010%, S: 0.005%, Cr: 0.4, and the balance is Fe and unavoidable impurities. The manufacturing process is as follows:

[0031] 1) Smelting and continuous casting into billets;

[0032] 2) Heat the cast slab to 1250°C, keep it warm for 2.5 hours, then carry out hot rolling, start rolling at 1150°C, and control the final rolling temperature at 900°C:

[0033] 3) Carry out coiling, control coiling temperature at 650 ℃;

[0034] 4) Carry out conventional pickling;

[0035] 5) Carry out cold rolling, and control the cumulative reduction rate of cold rolling to 66.7%;

[0036] 6) Carry out continuous annealing, control the annealing temperature at 800°C, and annealing time 120s;

[0037] 7) Cool to 710°C at a slow cooling rate of 3°C / s;

[0038] 8) Perform rapid cooling, the cooling rate is controlled ...

Embodiment 3

[0041] 980MPa low process sensitivity, low yield ratio cold-rolled dual-phase steel, its components and weight percentage content: C: 0.14%, Mn: 2.0%, Als: 0.04%, Si: 0.5%, P: 0.010%, S: 0.005%, Nb: 0.03%, Cr: 0.3%, and the balance is Fe and unavoidable impurities. The manufacturing process is as follows:

[0042] 1) Smelting and continuous casting into billets;

[0043] 2) Heat the cast slab to 1250°C, keep it warm for 2.5 hours, then carry out hot rolling, start rolling at 1150°C, and control the final rolling temperature at 920°C:

[0044] 3) Carry out coiling, control coiling temperature at 680 ℃;

[0045] 4) Carry out conventional pickling;

[0046] 5) Carry out cold rolling, and control the cumulative reduction rate of cold rolling to 66.7%;

[0047] 6) Carry out continuous annealing, control the annealing temperature at 790°C, and annealing time 120s;

[0048] 7) Cool to 700°C at a slow cooling rate of 3°C / s;

[0049] 8) Perform rapid cooling, the cooling speed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com