X70 large deformation resisting pipeline steel and manufacturing method

A technology of anti-large deformation and pipeline steel, which is applied in the field of pipeline steel, can solve the problems of large difference in performance between the same plate and high level of banded structure, and achieve low phase transition point, precise control of steel plate structure ratio, and high cooling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

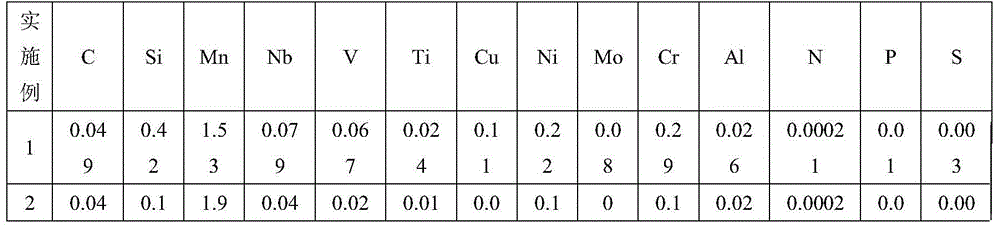

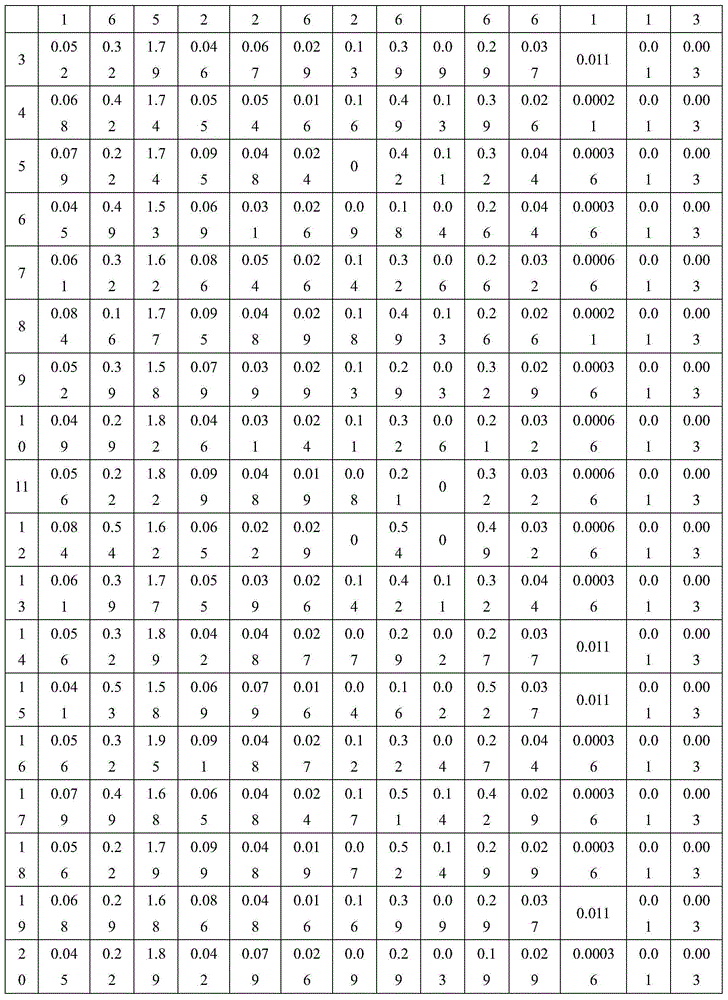

[0045]A kind of X70 anti-large deformation pipeline steel of the present invention, the mass percent of chemical composition in this steel is C 0.04%-0.09%, Si 0.15%-0.55%, Mn 1.45%-1.75%, Nb 0.04%-0.10%, V 0.02%-0.08%, Ti 0.01%-0.03%, Cu 0%-0.20%, Ni 0.15-0.55%, Mo 0-0.15%, Cr 0.15%-0.45%, Al 0.025%-0.045%, N 0.0002% -0.011%, P≤0.015%, S≤0.005%, the rest is Fe and other unavoidable impurity elements.

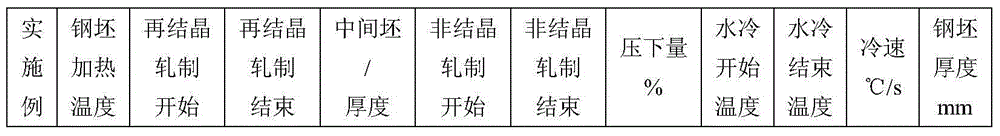

[0046] In the present invention, the TMCP hot-rolled steel plate used for the X70 large-deformation-resistant pipeline steel is produced using the following process route: material preparation→converter or electric furnace smelting→external refining→casting→slab reheating→controlled rolling→controlled cooling.

[0047] The TMCP process temperature and cooling rate are controlled according to the following parameters: slab heating temperature 1050-1250°C; recrystallization zone controls rolling start temperature 950-1150°C, recrystallization zone controls rolling end temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com