Shock-resistant high-abrasion-resistant steel ball steel and preparation method thereof

An impact-resistant, steel ball technology, applied in the field of steel, can solve the problem that the impact toughness and wear resistance of wear-resistant steel balls cannot well meet user requirements, etc., to improve the uniformity of the rolled structure, improve the surface quality, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

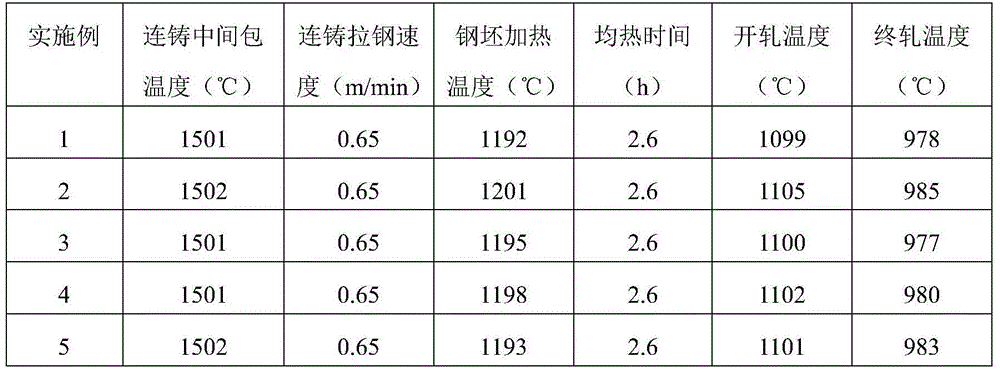

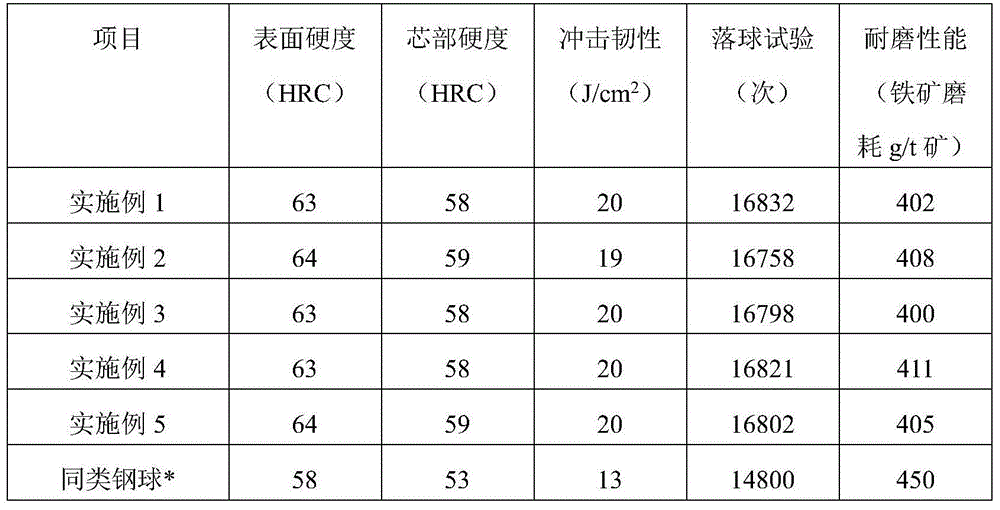

[0023] The steel for impact-resistant and wear-resistant steel balls of the present invention preferably adopts UHP ultra-high-power electric furnace, LF refining outside furnace, VD vacuum degassing treatment, continuous casting casting slabs, and rolling into lumber processes to produce steel products. EXAMPLES The implementation process of the present invention is specifically illustrated by the production process of Φ125mm steel.

[0024] The production process is as follows:

[0025] (1) Rough refining

[0026] Smelted in an electric furnace, the ladle baking temperature is ≥800°C, the end point [C]≥0.40%, [P]≤0.012%, the content of residual elements meets the design requirements, and the tapping temperature of molten steel is 1630-1670°C;

[0027] (2) Refining

[0028] The refining furnace adopts LF furnace. After rough smelting, the molten steel enters the LF furnace for deoxidation and desulfurization. After the LF furnace, it enters the VD vacuum treatment. Before e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com