Device and method for counter-gravity casting of solidification process controlled titanium-based alloy

A technology of anti-gravity casting and titanium-based alloys, which is applied in the field of anti-gravity casting methods and suction casting systems for titanium-based alloys. Inhomogeneity, thermal stress reduction, and excellent structure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

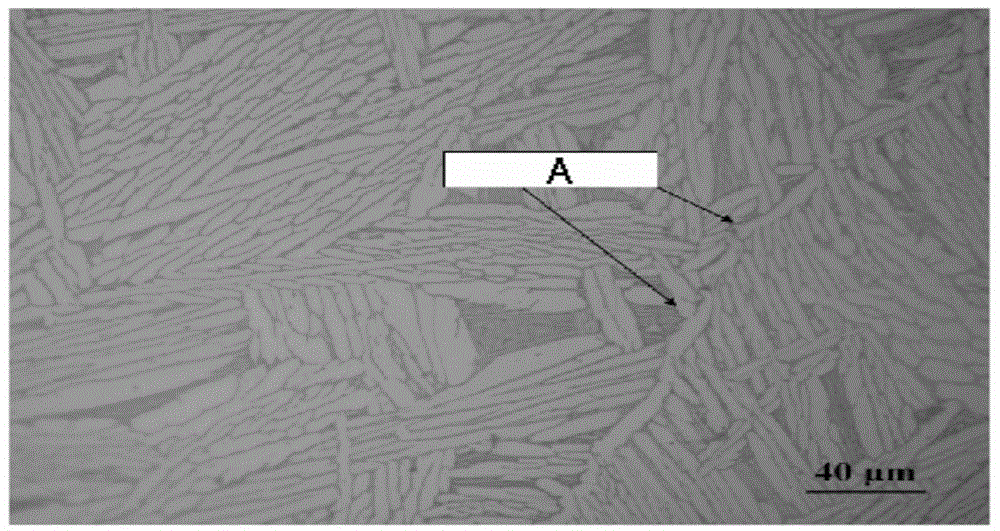

Examples

Embodiment 1

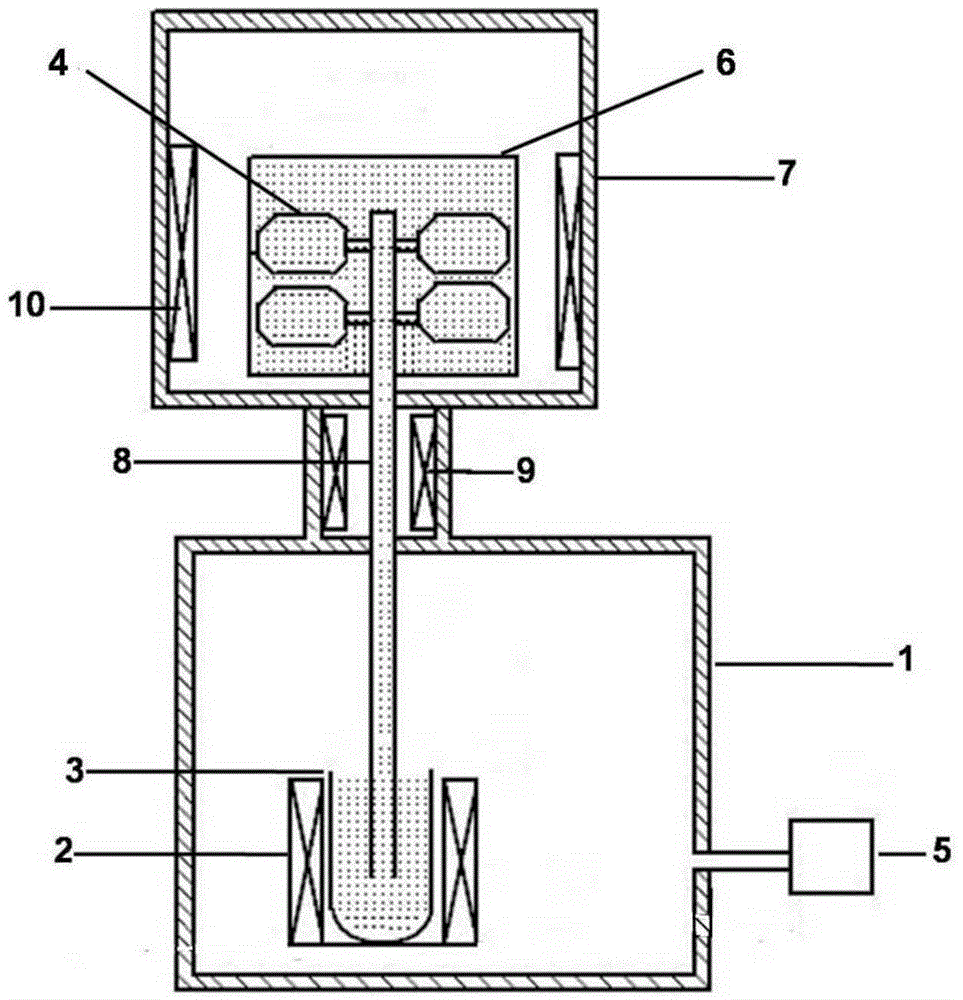

[0027] This embodiment is a titanium-based alloy anti-gravity casting device with controllable solidification process, which consists of two parts: a melting system and a suction casting system. This embodiment is obtained by improving the anti-gravity casting device in the prior art.

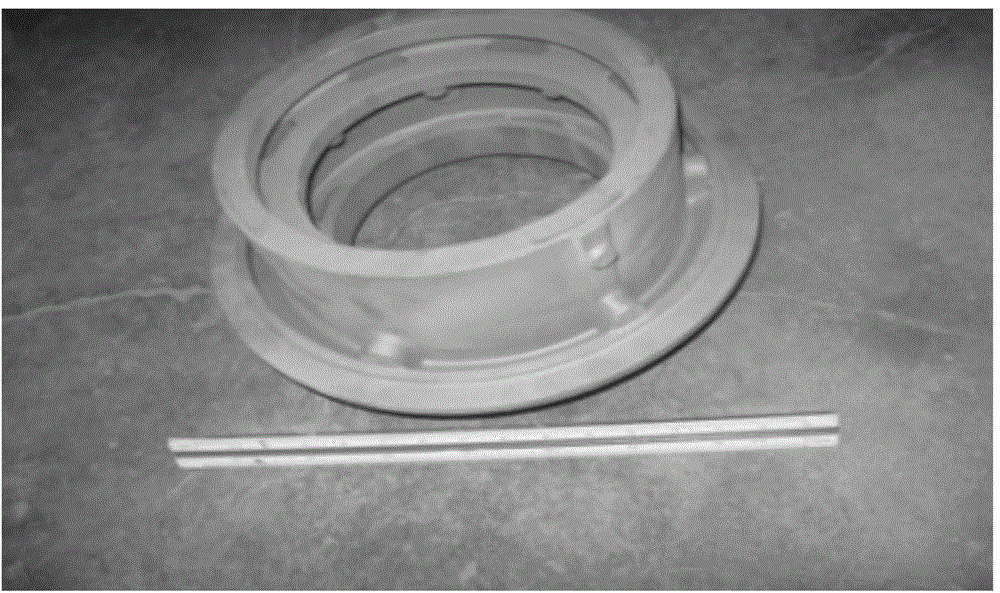

[0028] The smelting system is the same as the prior art, including a lower furnace body 1, an induction heater 2, a water-cooled copper crucible 3, a crucible lifting mechanism 4, an inert gas storage bottle 5 and a vacuum pipeline 6. Wherein, the induction heater is a water-cooled copper coil wound on the outside of the water-cooled copper crucible, and the crucible lifting mechanism is located below the water-cooled copper crucible and controlled by a motor, which can realize the lifting of the water-cooled copper crucible. Suction casting system is made up of upper furnace body 7, riser pipe 8, riser pipe heater 9, mold heater 10, mold fixing sleeve 6, and ceramic mold 12. The mold fixing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com