Method for rolling magnesium-aluminum layered laminated plate by drum-shaped corrugated roller

A technology of corrugated rolls and laminated plates, applied in metal rolling and other directions, can solve problems such as poor mechanical properties, low interface bonding strength, edge cracking, etc., and achieve the effect of promoting bonding and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

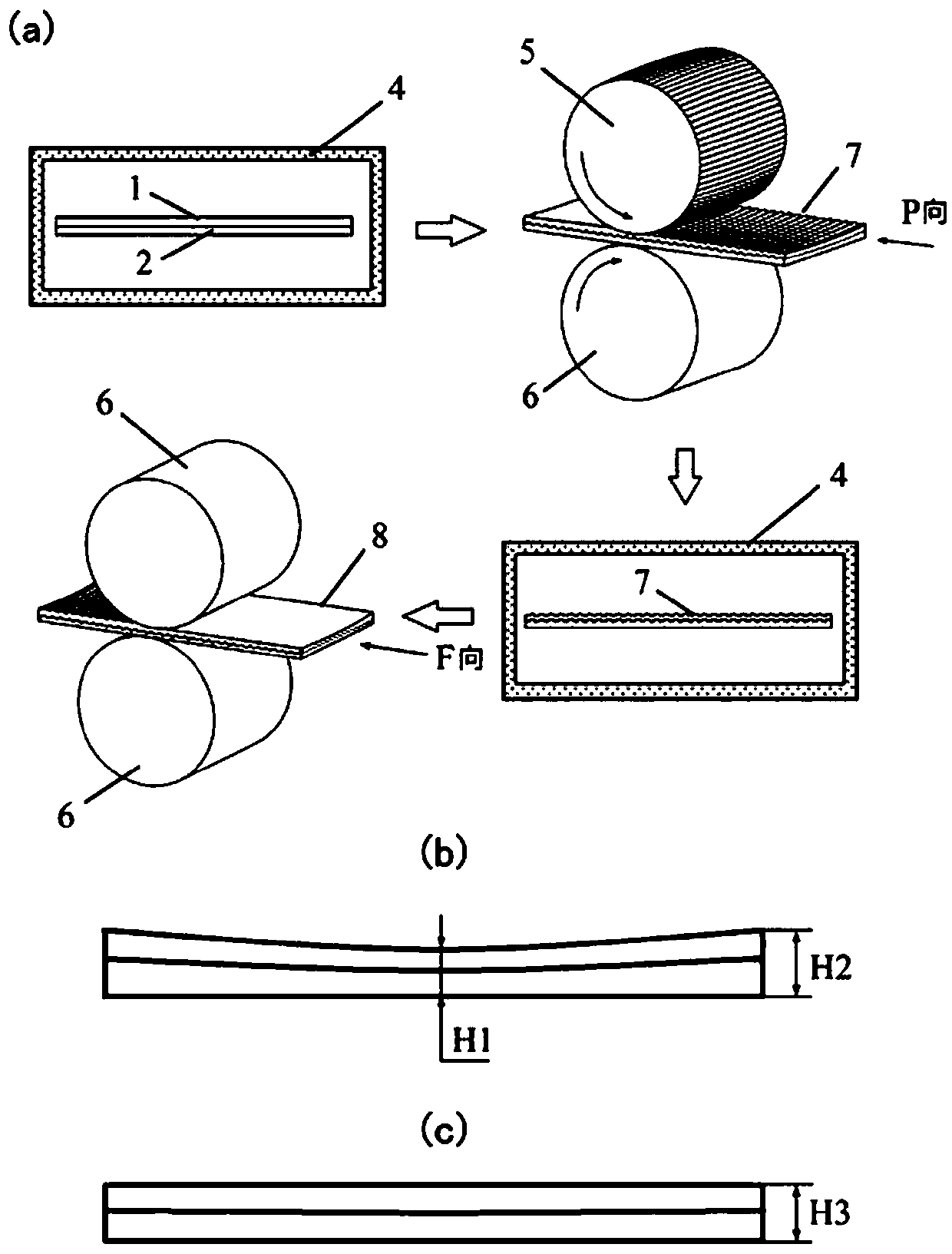

[0060] Attached image 3 Magnesium / aluminum laminates were prepared by the method shown:

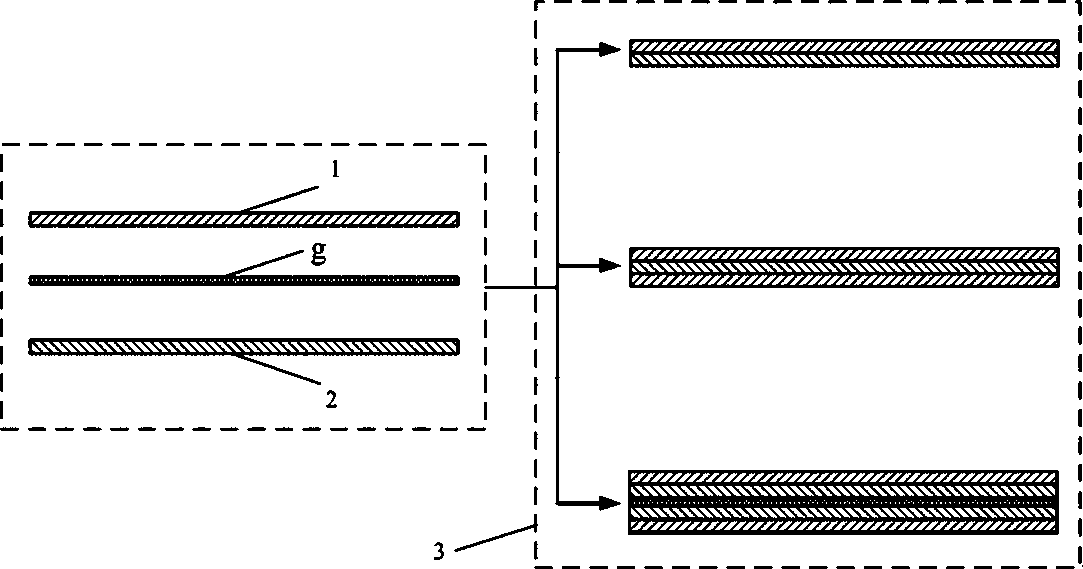

[0061] 1) Billet: AZ31 magnesium alloy plate with length and width of 200mm (length) × 50mm (width) × 2mm (height) is selected as double plate 1 and 1060 of 200mm (length) × 50mm (width) × 2mm (height). The aluminum plate is used as the base plate 2, and the surface of the metal plate is polished and cleaned with a steel wire brush with a diameter of 0.3mm. riveting;

[0062] 2) Heating: heating the assembled slab 3 in an argon atmosphere protection environment for 20 minutes, and the heating temperature is 350°C;

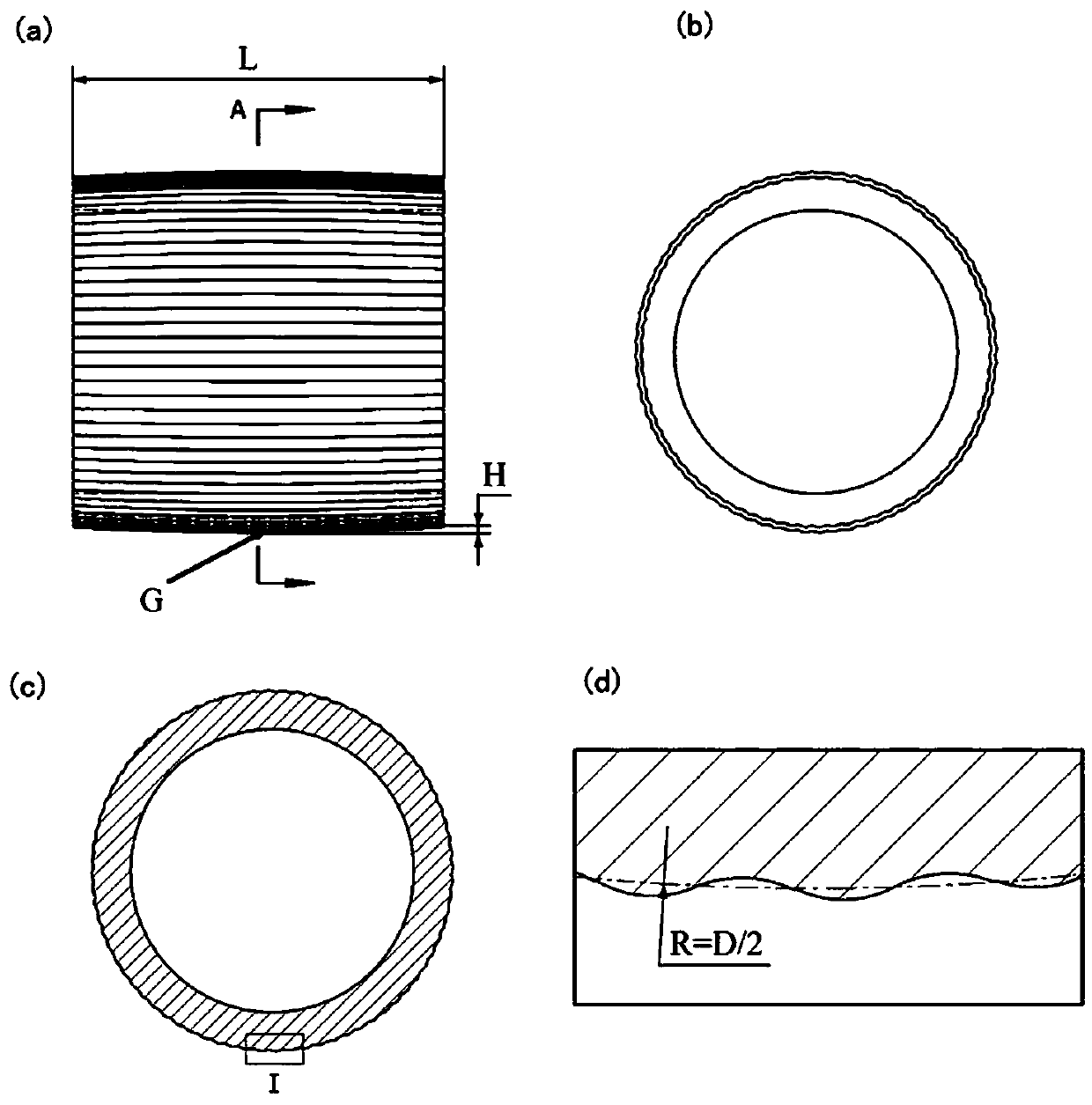

[0063] 3) Drum-shaped corrugated roll rolling: the slab 3 is rolled and compounded by using a two-roll mill equipped with an upper roll that is a drum-shaped corrugated roll 5 and a lower roll that is an ordinary flat roll 6. The average diameter of the upper and lower rolls is: D= 150mm, drum height H and roll body length L were 2mm and 150mm respectively, rolling reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com