Multi-hole continuous-casting submersed nozzle for square and round billets

An immersion and nozzle technology, applied in the field of continuous casting of steel, can solve problems such as the molten steel that cannot be well distributed at the outlet, and achieve the effects of preventing thermal stress cracks, avoiding violent fluctuations, and reducing impact speed and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

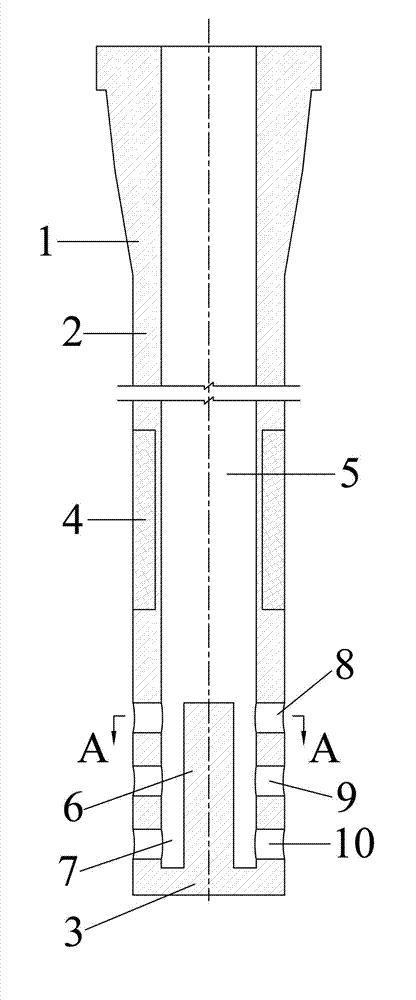

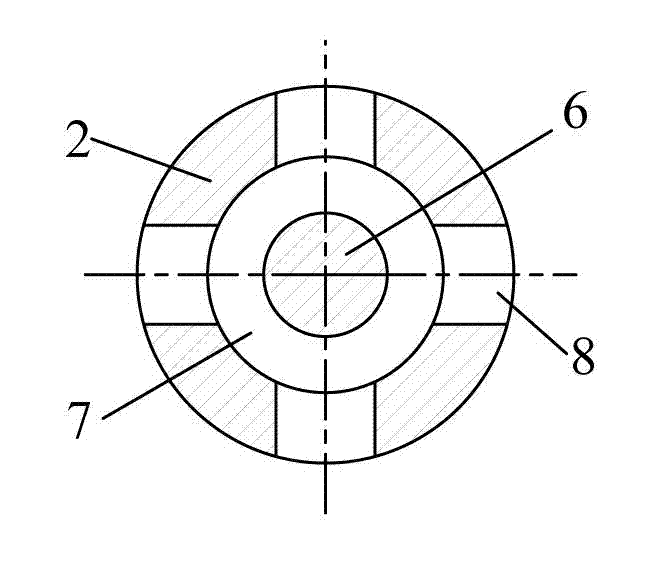

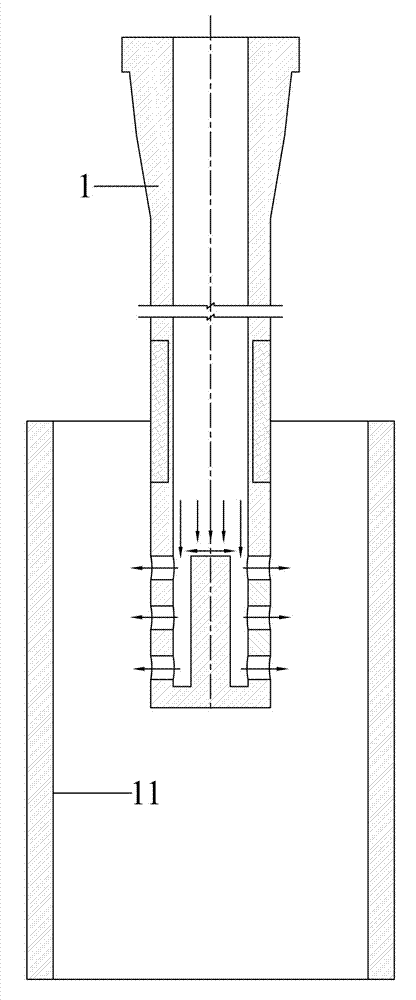

[0025] See attached Figure 1~3 , a porous continuous casting submerged nozzle for square and round billets according to the present invention, mainly composed of a nozzle body 1, the nozzle body 1 includes a side wall 2 and a bottom plate 3, and a circle of slag lines 4 is arranged on the outer surface of the nozzle side wall 2, The depth of the slag line 4 is 15 mm, the height is 120 mm, and the distance between the lower end of the slag line 4 and the lower surface of the nozzle bottom plate 3 is 120 mm. In practical application, the nozzle side wall 2 and bottom plate 3 are generally formed by isostatic pressing of aluminum carbon or quartz refractory materials, and the slag line 4 is made of zirconia composite material with good slag erosion resistance. The side wall 2 is connected to the bottom plate 3 and encloses a hollow inner cavity 5 in the vertical direction. The upper end of the inner cavity 5 is open, and the lower end is the closed bottom plate 3 . The cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com