Reciprocating compressor valve set structure with rapidly-opened-closed air discharge valve plate

An exhaust valve plate, reciprocating technology, applied in the field of compressors, can solve problems such as obstruction of smooth exhaust, reciprocating vibration of valve plates, frequent opening and closing of valve plates, etc., so as to improve gas transmission efficiency and efficiency, and reduce flow resistance loss. , The effect of prolonging the life of the valve plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

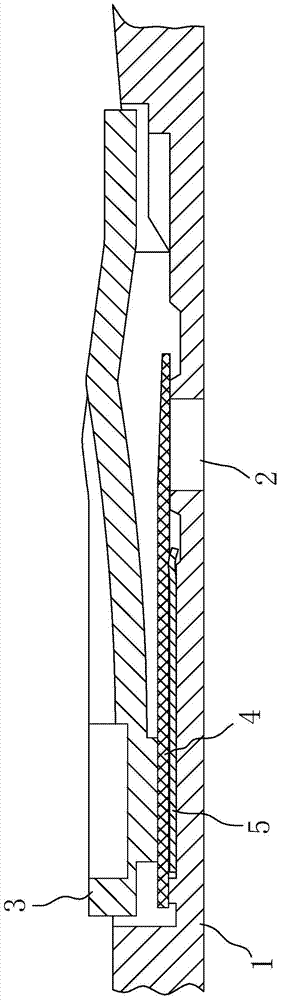

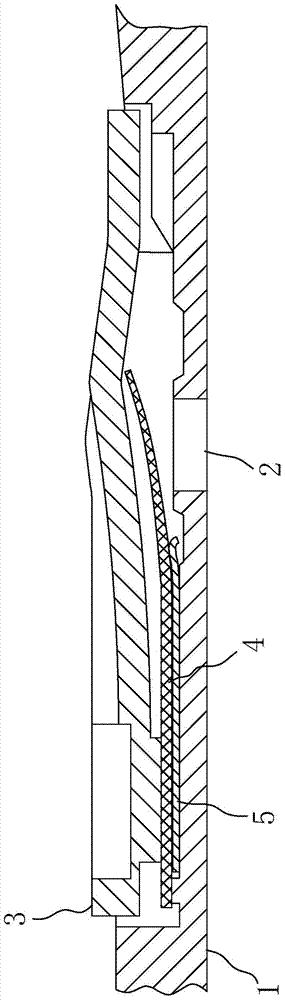

[0023] refer to Figure 1 ~ Figure 2 , a reciprocating compressor valve group structure with rapid opening and closing of the exhaust valve plate, including a valve plate 1 with a valve seat on the plate surface and an exhaust hole 2 in the valve seat, and a lift limiter on the valve seat A positioner 3, an exhaust valve plate 4 is arranged between the lift limiter 3 and the valve seat, and the exhaust valve plate 4 has a fixed end pressed by the lift limiter 3 and covers the exhaust hole 2 movable end; between the exhaust valve plate 4 and the valve seat, there is a spring plate 5 with a pretightening force towards the opening direction of the exhaust valve plate 4, and the spring plate 5 also has a fixed end and a movable end, and the spring plate The fixed end of 5 is fixed relative to the valve plate 1; the stiffness of the exhaust valve plate 4 is not less than 600 N*mm2.

[0024] Further as a preferred embodiment, the fixed end of the spring leaf 5 and the fixed end of ...

Embodiment 2

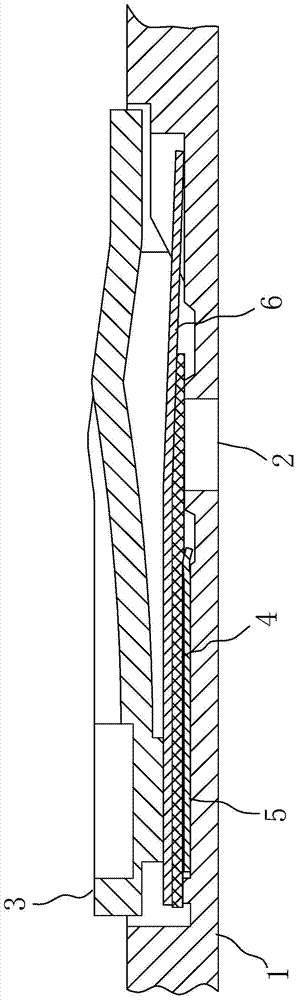

[0028] refer to Figure 4 , Figure 5 , the rest of the structure of Embodiment 2 is basically the same as that of Embodiment 1, but between the exhaust valve plate 4 and the lift limiter 3, an exhaust valve reed 6 is provided. The discharge valve reed 6 is also mainly used to reduce chattering, and there are such accessories in larger compressors.

[0029] Table 1:

[0030]

[0031] Table 1 further illustrates the rigidity of the exhaust valve plate 4, wherein the number in brackets in the first row of the table indicates the thickness of the exhaust valve plate 4, and the sampling rule of the measurement point is that when the valve plate is closed, the arc center of the movable end of the valve plate Coincident with the center of the vent hole, take the center point of this coincidence. The first vertical numbers such as 0.01mm, 0.02mm indicate different ejection heights of the same test point.

[0032]The bending stiffness of the exhaust valve is EI. According to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com