Square high-load air spring

An air spring, high load-bearing technology, applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., can solve the problems of unscientific sealing connection method and structure, unreasonable shape and size of air spring, limited pressure bearing capacity, etc. , to achieve the effect of strong pressure bearing capacity, improved bending moment resistance, and improved pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] Such as figure 2 , Figure 5 As shown, a square high-load air spring includes a capsule body 6 and a capsule body seal, and the feature is that the capsule body 6 is square.

[0026] Further, the skeleton layer of the capsule body 6 is an aramid cord skeleton layer.

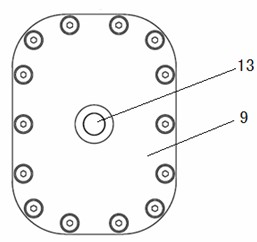

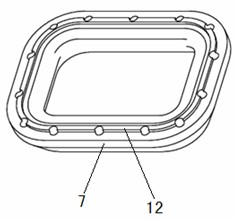

[0027] Such as figure 1 , figure 2 As shown, a square high-load air spring of the present invention has a specific structure consisting of an upper cover plate 9, a lower cover plate 1, an upper buckle ring 7, a lower buckle ring 3, a capsule body 6, an upper limit member 10, and a lower limit member 11. most of the composition.

[0028] The capsule 6 is formed by vulcanizing capsule rubber, a skeleton layer, an upper sub-mouth steel ring, and a lower sub-mouth steel ring. The grooves of the upper and lower mouth steel rings are matched in shape, and the capsule bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com