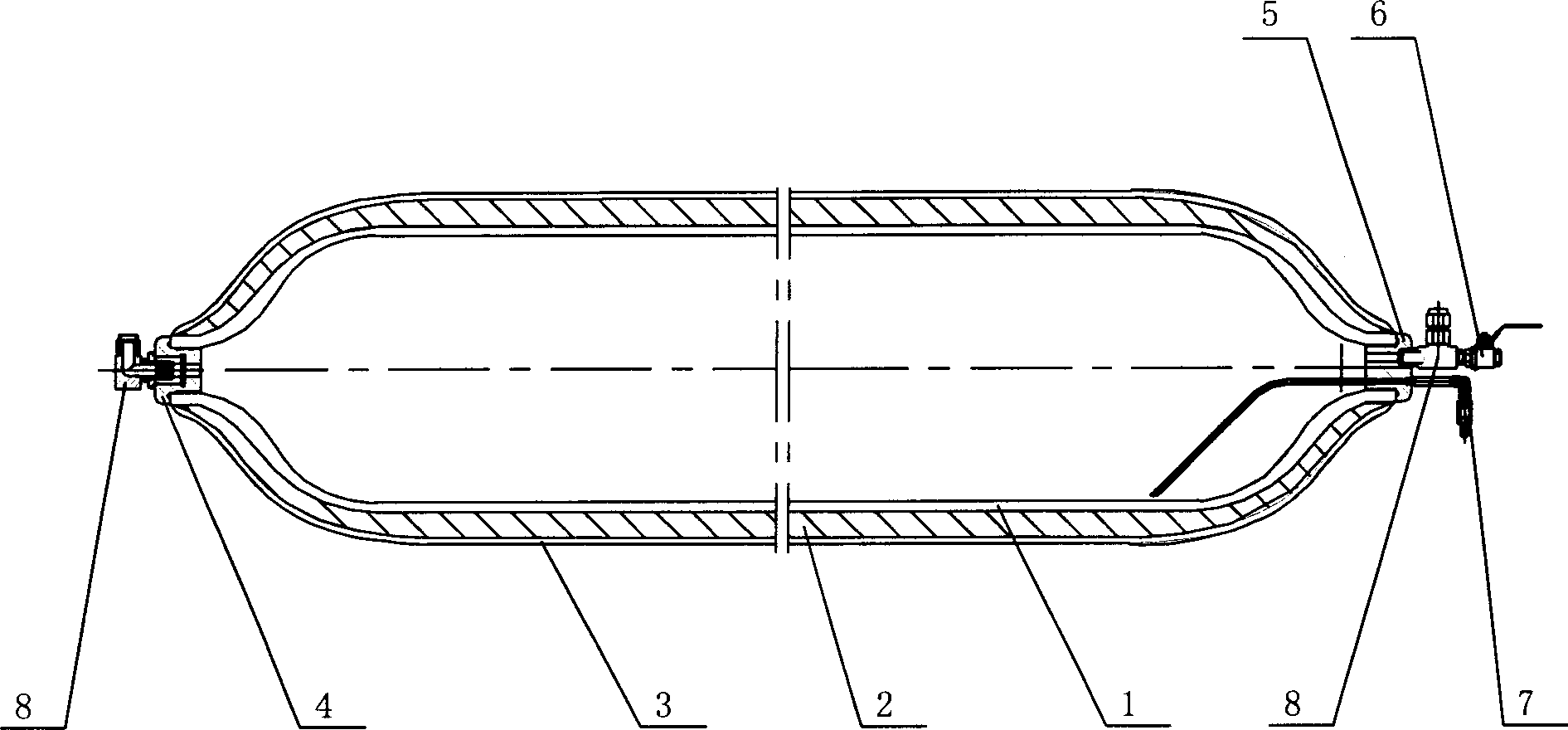

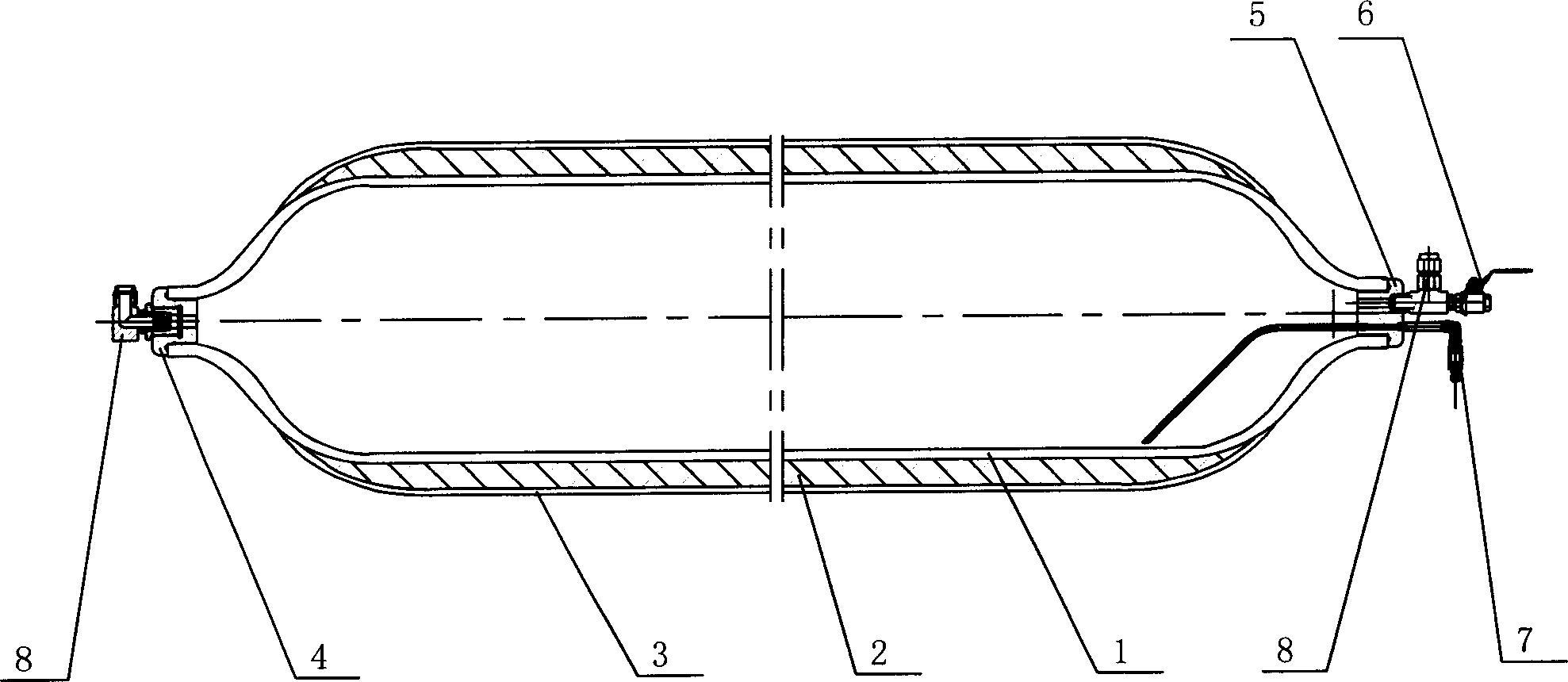

Steel inner container big capacity high pressure tank and its preparation

A technology for winding gas cylinders and manufacturing methods, which can be applied in fixed-capacity gas storage tanks, pressure vessels, gas/liquid distribution and storage, etc. Enhanced safety and reliability, improved fatigue resistance, and good anti-leakage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Said high-strength fibers in the above-mentioned manufacturing method of large-capacity high-pressure wound gas cylinders in steel are glass fibers, or polyacrylonitrile pre-oxidized fibers, or carbon fibers, or graphite fibers, or any of the above fibers. into strips or cloth. The tensile strength and elastic modulus of various fibers are quite different, but the price is also quite different. Generally, carbon fiber is selected to make the reinforced composite shell (2).

[0023] The properties and pressure resistance of high-pressure seamless steel pipes are also quite different. The choice is often made according to the technical requirements. The seamless steel pipe with the model number 4130X, or 30CrMo, or 35CrMo, or 4142, or 4145, or SA372 is used, and the thickness selection range is 8 -25mm matches the design cylinder and the working pressure.

[0024] In order to achieve a gap-free fit between the fully cured reinforced composite shell (2) and the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com