Platform type horizontal plane planar motion mechanism

A plane motion mechanism, the technology of the horizontal plane, applied in the directions of transportation and packaging, ship parts, ships, etc., can solve the problems of difficult control, large hydraulic drive volume, low precision, etc., and achieve the effects of high measurement accuracy, convenient operation and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

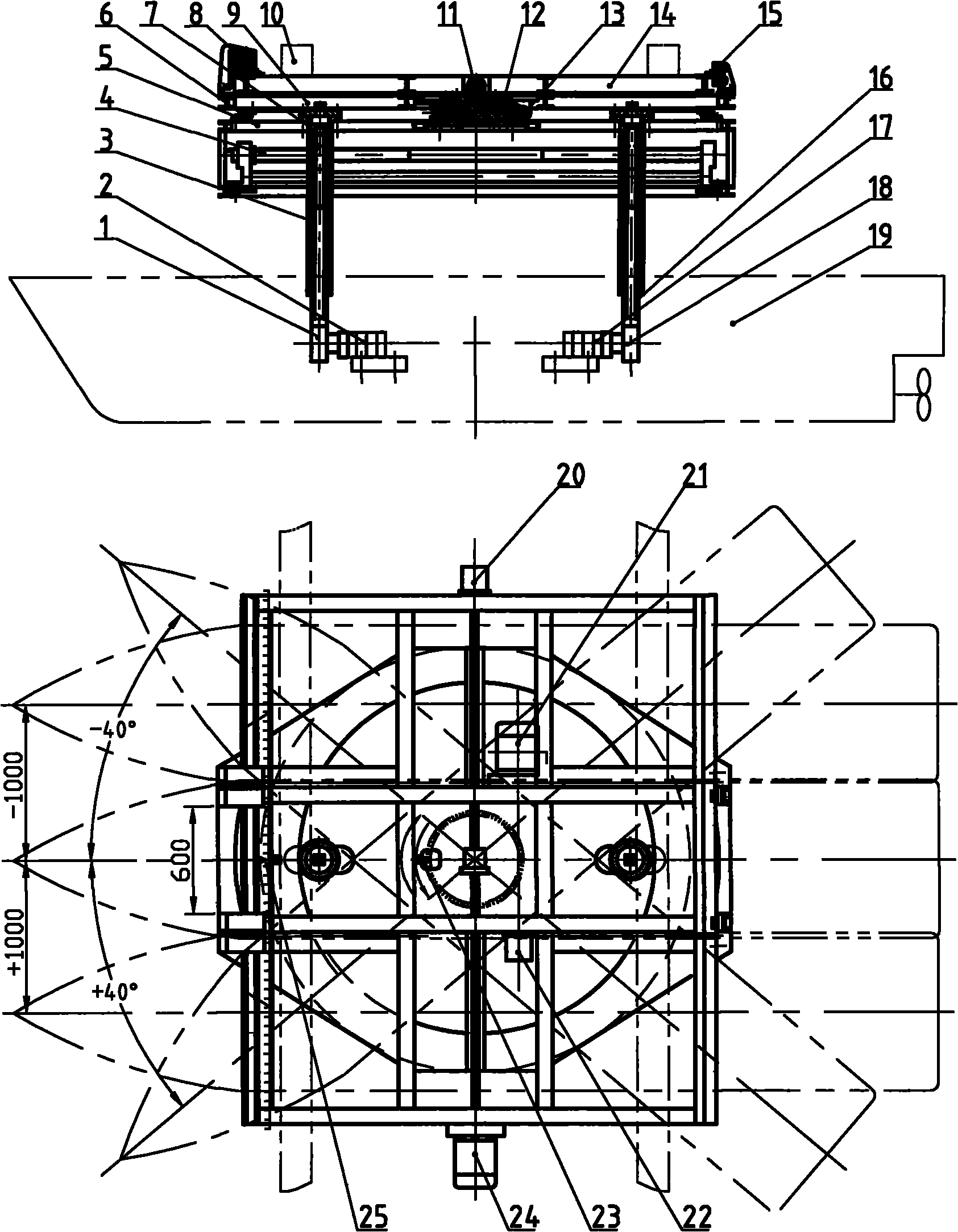

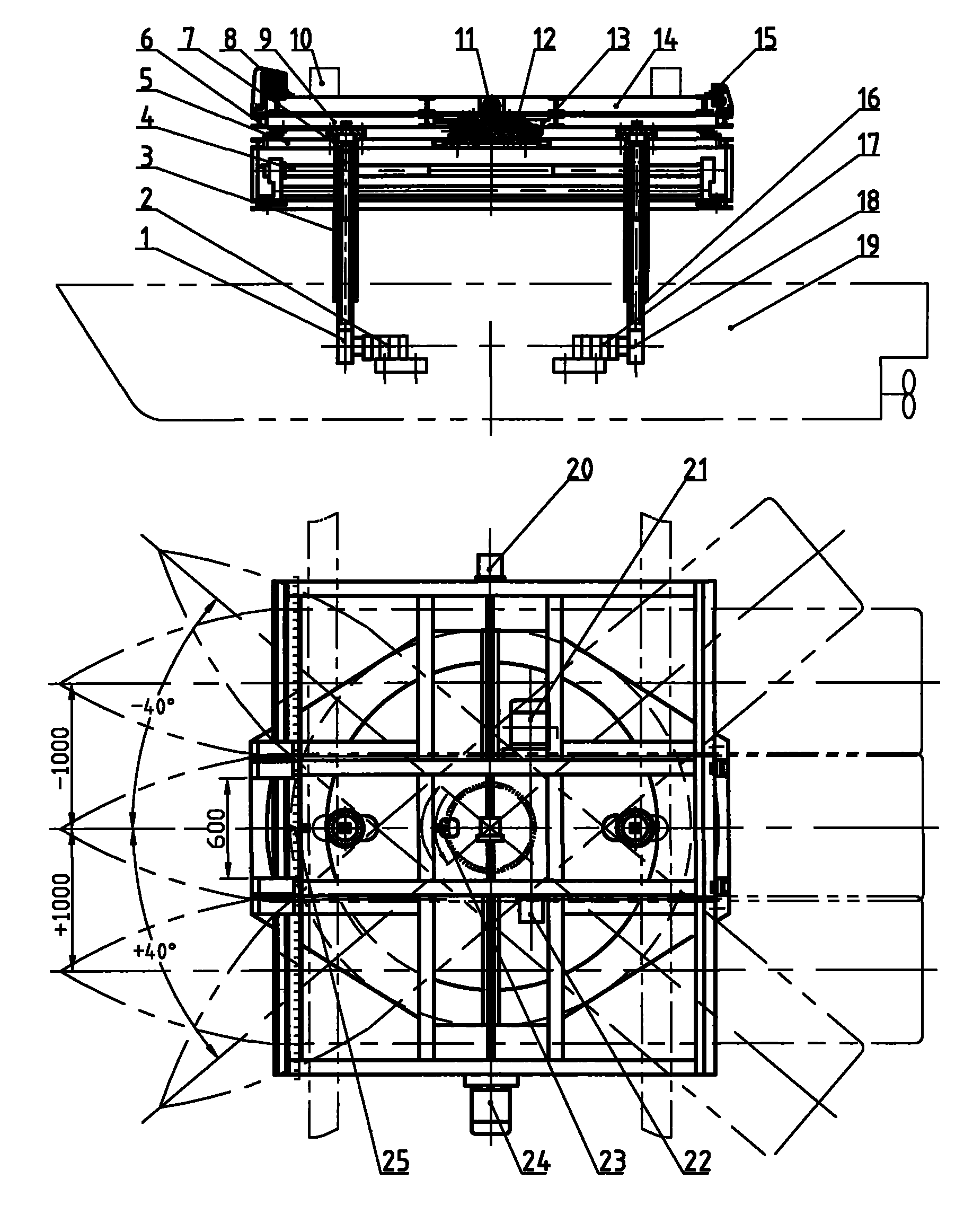

[0011] The platform-type horizontal plane motion mechanism of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] Such as figure 1 As shown, the platform-type horizontal plane motion mechanism of the present invention includes a mechanism frame 14 connected to the auxiliary trailer 10, a linear bearing 8, a roller bearing 15, a ball screw 11, a sway servo motor 24, an encoder 20, and a sway frame 9 is connected with the mechanism frame 14 through the linear bearing 8 and the roller bearing 15 to form a swaying moving part. Composite bearing 12, worm gear 13, circumferential guide rail 6, yaw servo motor 21, encoder 22, connecting plate 5 are connected with sway motion frame 9 through worm gear 13 to form yaw motion parts. The positive and negative screw rod 4 for adjusting the distance between the front and rear connecting rods 3, the length of the adjusting rod 16 on the connecting rod 3 is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com