Production method capable of reducing fatigue crack growth rate of bainite steel rail

A technology of fatigue crack growth and production method, which is applied in the production field of reducing the fatigue crack growth rate of bainitic rails, can solve the problems of long production cycle, unsatisfactory production rhythm, high production cost, etc., and achieve high tensile strength and reduce fatigue Crack growth rate, effect of reducing center segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

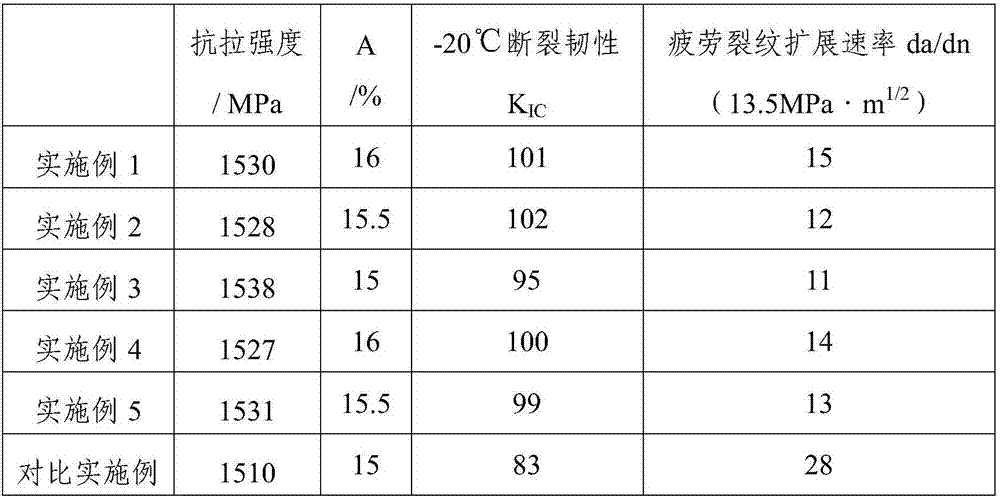

Examples

Embodiment 1

[0016] A production method for reducing the fatigue crack growth rate of a bainite rail, comprising the following steps:

[0017] 1) When smelting and deoxidizing, the basicity of the slag refined outside the LF furnace is controlled at 1.87, and the slag inclusions are controlled at calcium plagioclase (CaO·Al 2 o 3 2SiO2 2 ) plastic region;

[0018] 2) During continuous casting, the temperature of the tundish is controlled at 12°C above the liquidus line, and the casting speed is controlled at 0.5m / min; the 280*380mm bloom is continuously cast by liquid core pressing and electromagnetic stirring technology, and the current intensity is 750A , frequency 8Hz; the terminal liquid core is lightly pressed down by 10mm, the equiaxed grain rate of the cast slab is 98%, and the cast slab is stacked in the slow cooling pit and the heat preservation cover for 48 hours.

[0019] In the rolling step, the heating process is 1087°C for slab heating zone I, 1242°C for slab heating zone ...

Embodiment 2

[0022] A production method for reducing the fatigue crack growth rate of a bainite rail, comprising the following steps:

[0023] 1) When smelting and deoxidizing, the basicity of the slag refined outside the LF furnace is controlled at 2.2, and the slag inclusions are controlled at calcium plagioclase (CaO·Al 2 o 3 2SiO2 2 ) plastic region;

[0024] 2) During continuous casting, the temperature of the tundish is controlled at 18°C above the liquidus line, and the casting speed is controlled at 0.3m / min; the 280*380mm bloom is continuously cast by liquid core pressing and electromagnetic stirring technology, and the current intensity is 600A , frequency 8Hz; the terminal liquid core is lightly pressed down by 10mm, the equiaxed grain rate of the slab is 96%, and the slab is stacked in the slow cooling pit and the heat preservation cover for 48 hours.

[0025] In the rolling step, the heating process is 1052°C for slab heating zone I, 1211°C for slab heating zone II, 1229°...

Embodiment 3

[0028] A production method for reducing the fatigue crack growth rate of a bainite rail, comprising the following steps:

[0029] 1) When smelting and deoxidizing, the basicity of the slag refined outside the LF furnace is controlled within the range of 2.0, and the slag inclusions are controlled within the calcium plagioclase (CaO·Al 2 o 3 2SiO2 2 ) plastic region;

[0030] 2) During continuous casting, the temperature of the tundish is controlled at 15°C above the liquidus line, and the casting speed is controlled at 0.3m / min; the 280*380mm bloom is continuously cast by liquid core pressing and electromagnetic stirring technology, and the current intensity is 600A , frequency 8Hz; the terminal liquid core is lightly pressed down by 10mm, the equiaxed grain rate of the cast slab is 98%, and the cast slab is stacked in the slow cooling pit and the heat preservation cover for 48 hours.

[0031] In the rolling step, the heating process is 1132°C for slab heating zone I, 1243°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com