Controllable magnesium-containing hydrogen storage alloy preparation method

A hydrogen storage alloy and alloy technology, which is applied in the field of preparation of controllable magnesium-containing hydrogen storage alloys, can solve the problems of burning loss and intensified oxidation, complicated process, and high equipment requirements, so as to improve the absorption rate of alloy elements and ensure uniformity and precision , Reduce burning loss and volatilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

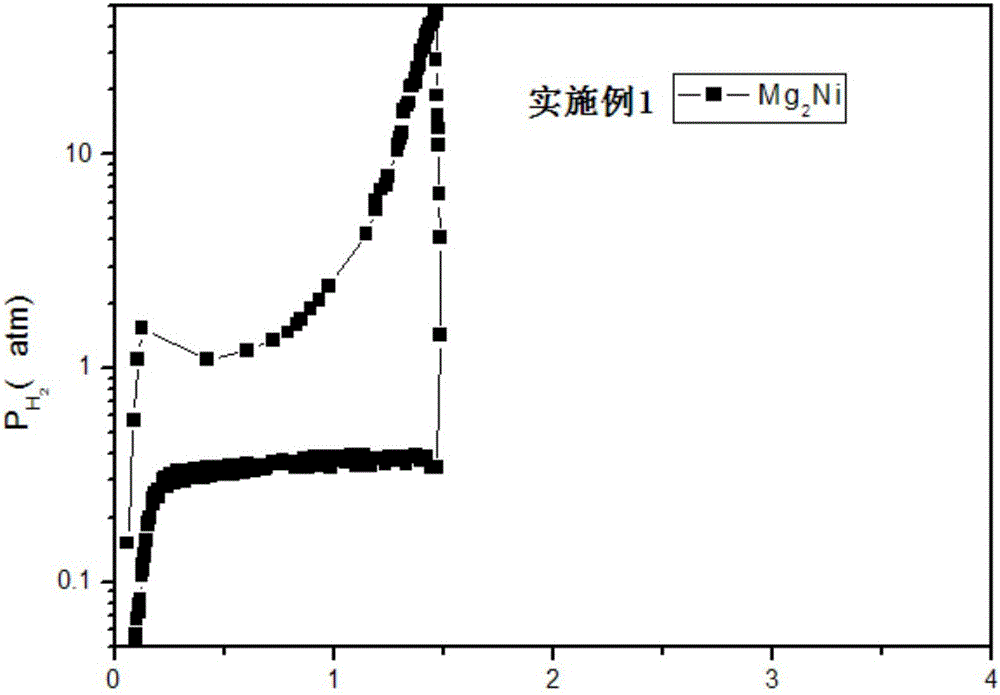

Embodiment 1

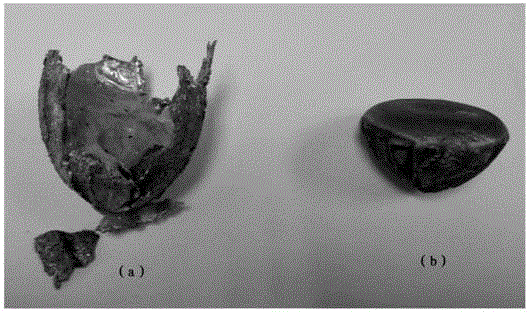

[0040] To prepare 20gMg by traditional smelting method 2 The preparation process of Ni (Mg excess 15%) alloy is:

[0041] 1. Ingredients: According to 20gMg 2 The Ni alloy will be calculated. The Mg content is 9.06g, Ni is 10.94g, and the magnesium excess is 15%. The total magnesium is 10.42g. The total weight of magnesium and nickel is 21.36g. Both magnesium and nickel are in powder form. Mix the magnesium powder and nickel powder. Piece.

[0042] 2 Put the pressed block sample into the crucible of the water-cooled suspension melting furnace.

[0043] 3. After washing the furnace 1 to 4 times, usually after 3 times, turn on the power and adjust the power of the melting furnace to raise the temperature in the crucible to about 100°C, then turn off the power and continue vacuuming below 0.5Pa, and finally pass in 0.05MPa The Ar gas is protected to complete the smelting preparations.

[0044] 4. Melting: Turn on the power, the power will rise to 38KW in about 45 seconds, and the nickel...

Embodiment 2

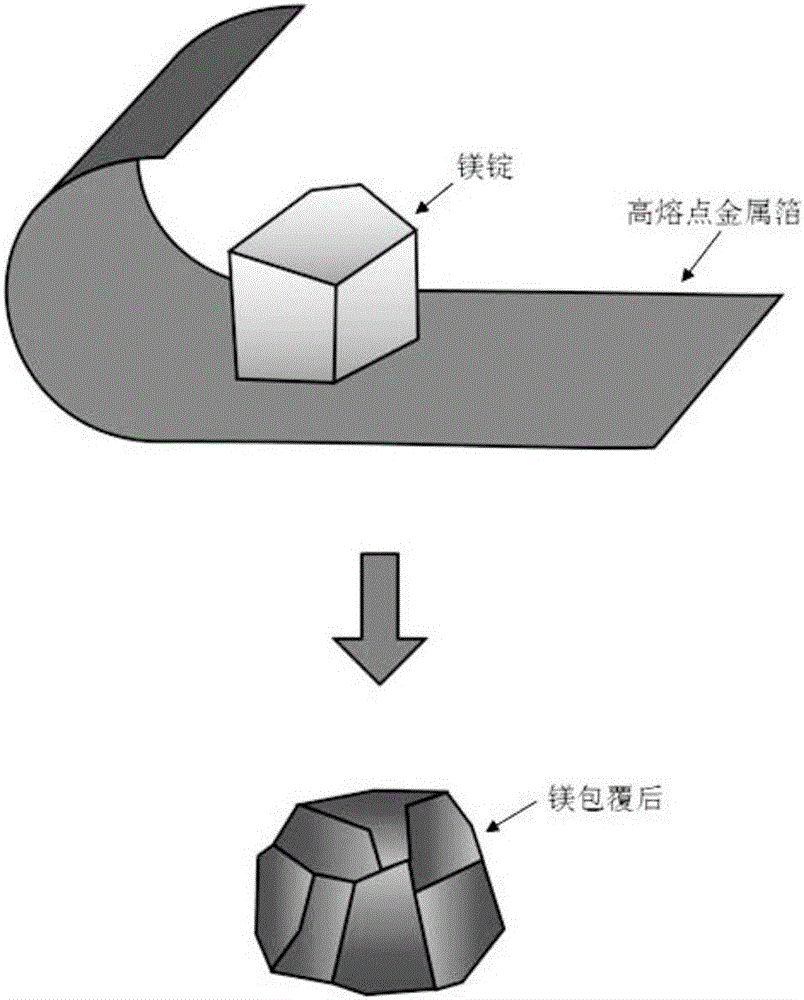

[0047] 20gMg prepared by the preparation method provided by the invention 2 Ni alloy, the specific production process is:

[0048] 1. Ingredients: According to 20gMg 2 The Ni alloy will be calculated. The Mg content is 9.06g, the Ni is 10.94g, the magnesium excess is 15%, the total magnesium is 10.42g, the total weight of magnesium and nickel is 21.36g, the magnesium is a cut piece of pure magnesium ingot, and the nickel used for coating is 0.2 mm thick nickel foil.

[0049] 2. Press the magnesium figure 1 After being coated by the method shown, it is put into a crucible of a water-cooled suspension melting furnace.

[0050] 3. After washing the furnace 1 to 4 times, usually 4 times, turn on the power supply, adjust the power of the melting furnace to raise the temperature in the crucible to about 100℃, then turn off the power supply and continue to vacuum to below 0.5Pa, and finally pass in 0.05MPa The Ar gas is protected to complete the smelting preparations.

[0051] 4. Melting: ...

Embodiment 3

[0056] 20gMg prepared by the preparation method provided by the invention 2 Cu alloy, its specific preparation process is:

[0057] 1. Ingredients: According to 20gMg 2 Cu alloy will be calculated, which contains 8.67g of Mg, 11.33g of Cu, 10% excess of magnesium, a total of 9.537g of magnesium, and a total weight of 20.867g of magnesium and copper. Magnesium is a cut piece of pure magnesium ingot, and copper used for coating magnesium ingot It is a 0.1mm thick copper foil.

[0058] 2. Put the magnesium ingot as figure 1 After being coated by the method shown, it is put into a crucible of a water-cooled suspension melting furnace.

[0059] 3. Wash the furnace 1 to 4 times, usually 4 times, turn on the power, adjust the power of the smelting furnace, so that the temperature in the crucible rises to about 100℃, then turn off the power and continue to evacuate to below 0.5Pa, and finally pass the 0.05MPa Ar gas protects and completes the smelting preparations.

[0060] 4. Melting: Turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com