Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Appropriate quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In-mould labelled container

InactiveUS20130139700A1Promote wettingEasy disposalWrappersFlexible elementsEngineeringMechanical engineering

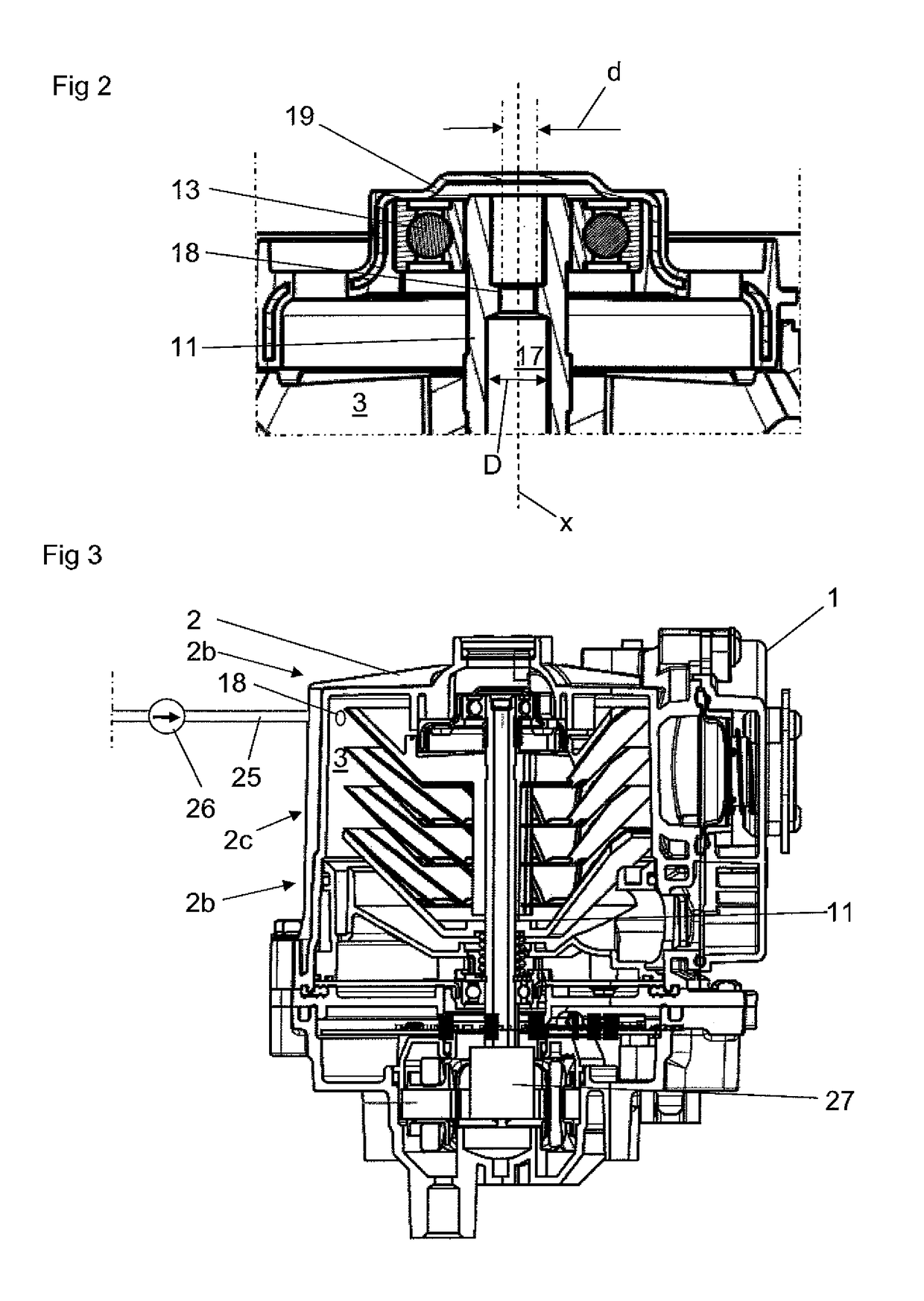

The present invention concerns a container, preferably a capsule for use in a food preparation machine, comprising: (i) a structure with a lower side, at least one substantially vertical pillar extending from the lower side, said pillar being linked to a circular upper frame, said circular upper frame having a substantially L-shaped cross-section with a first circular portion disposed vertically to which the pillar is linked, said vertical portion being linked at its upper side to a second horizontal circular portion forming a peripheral edge, said first vertical portion having a height a and a thickness x, said second horizontal portion having a width b and a thickness y, (ii) a label attached to the lower side, pillar and outer surface of the upper circular frame's vertical portion, thus forming an envelope that defines capsule side walls. According to the invention, x is superior to y, and xa is superior to yb.

Owner:NESTEC SA

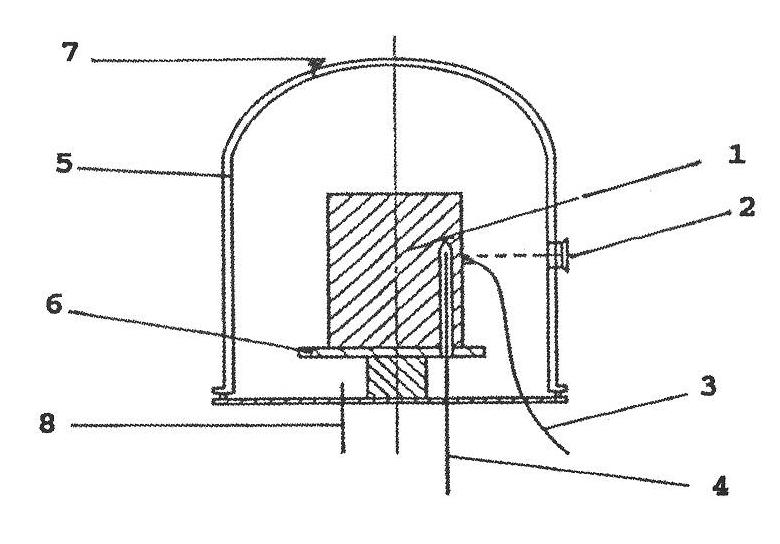

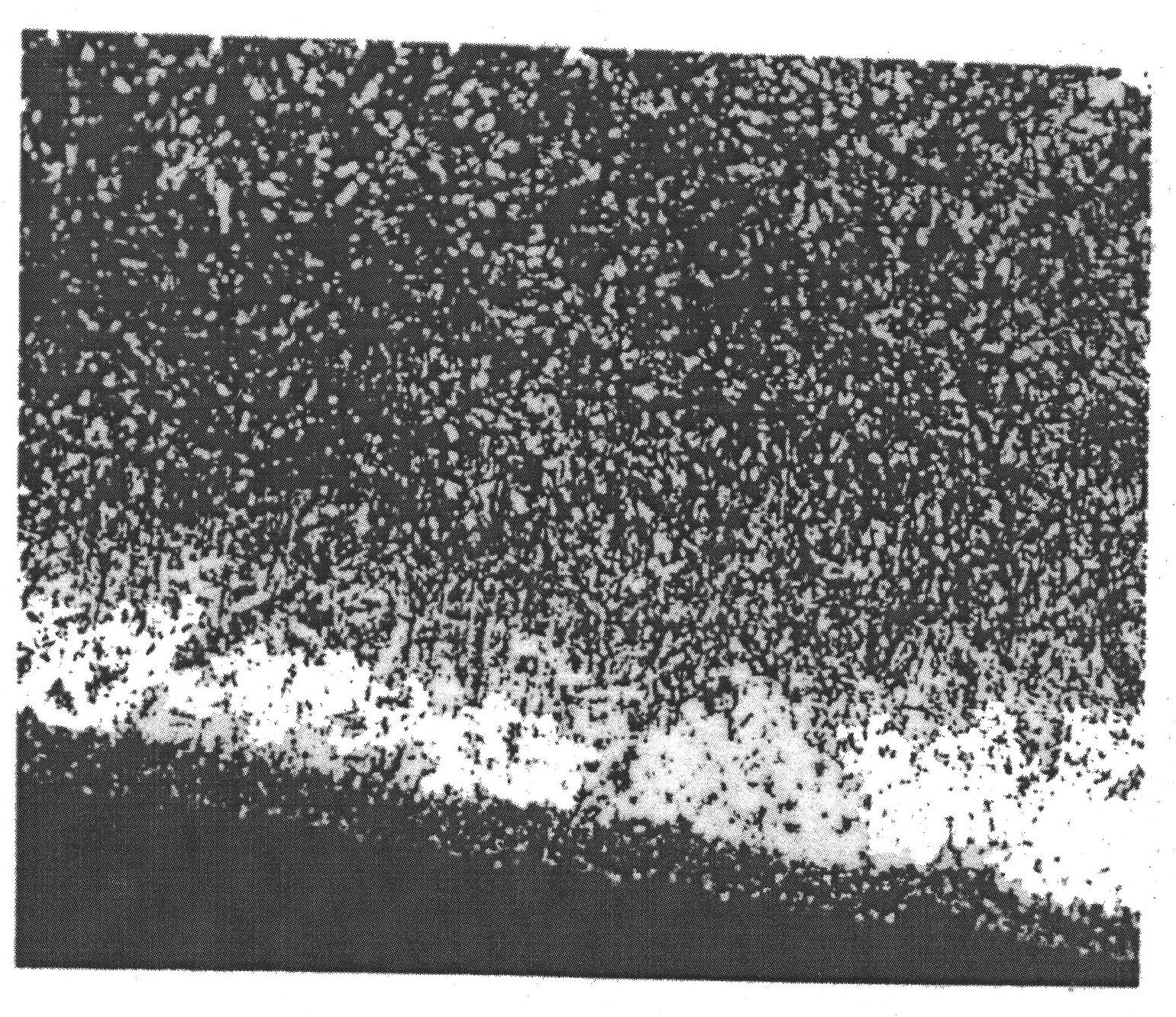

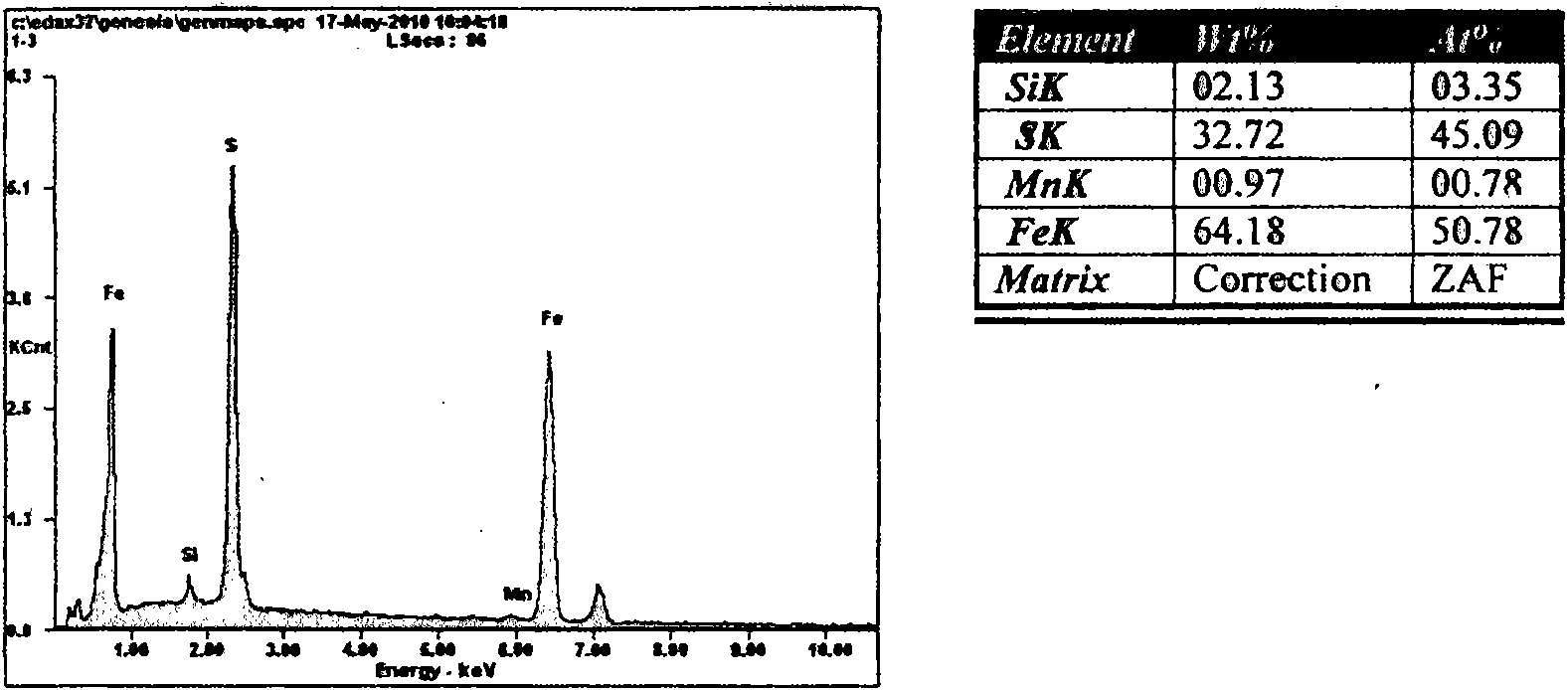

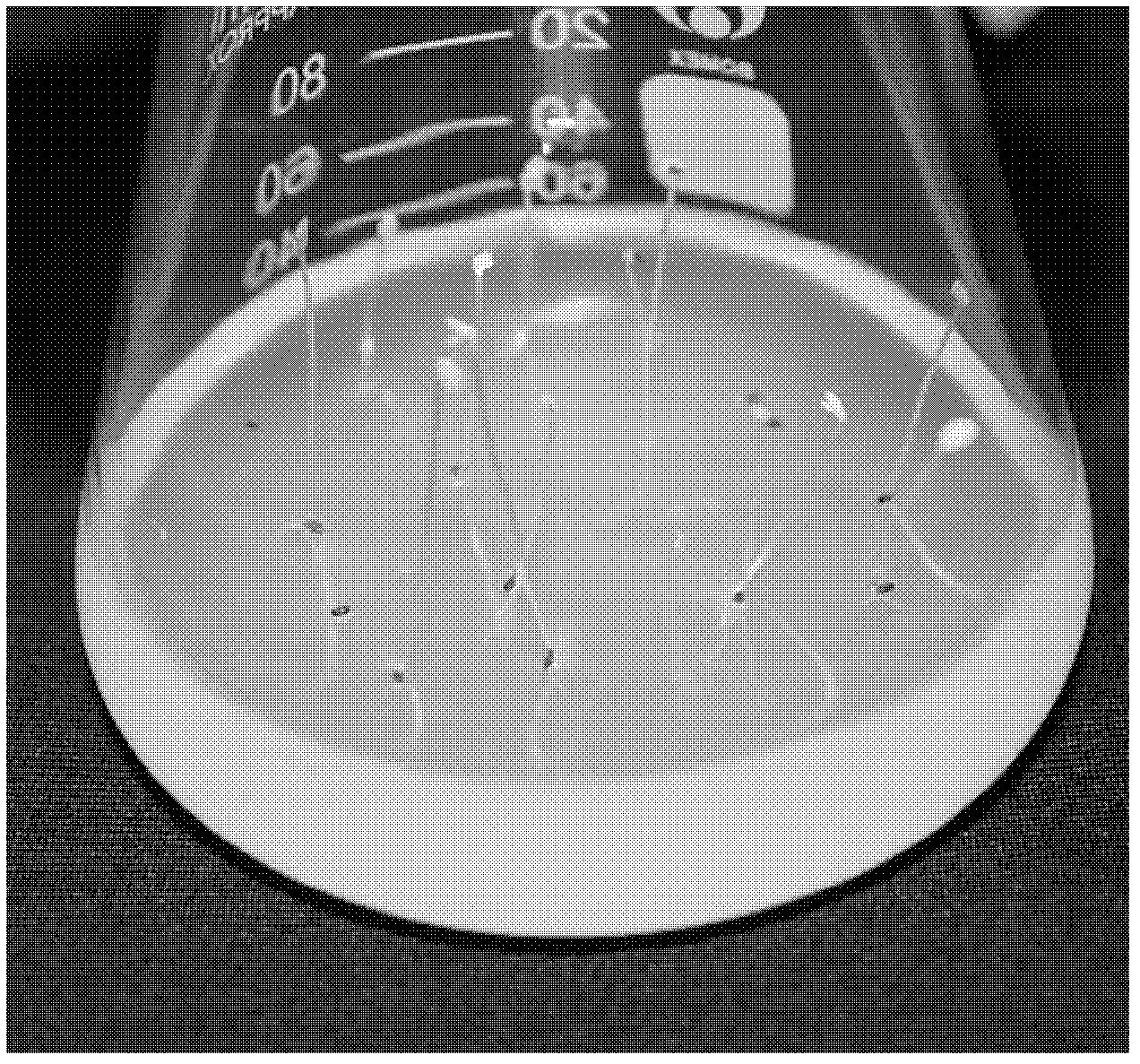

Gas plasma sulfurizing process

InactiveCN101956155AMeet technical quality requirementsEvenly distributedSolid state diffusion coatingWind drivenElectrolysis

The invention discloses a gas plasma sulfurizing process, which belongs to the technical field of surface heat treatment. In the process, a steel workpiece is placed in a sealed sulfurizing furnace with direct-current high voltage and high vacuum, then an appropriate amount of carrier gasses such as hydrogen gas, argon gas, ammonia gas and the like, and hydrogen sulfide are introduced into the furnace to form a sulfurizing atmosphere. Those gases are split into plasma states of nitrogen, hydrogen, argon and sulfur after entering the sulfurizing furnace and dash against the surface of the steel workpiece positioned on a negative plate to ensure that the temperature of the workpiece is raised, wherein sulfur ions infiltrate into the surface of a component to form ferrous sulfide which covers the whole surface of the component to fulfill the aim of sulfurizing. The process has the advantages of no pollution, low cost and high sulfurizing quality, overcomes the defects of serious pollution and high cost of the conventional electrolytic sulfurizing, and also overcomes the defect of low quality of plasma sulfurizing performed by using solid sulfur on the market at present. Through sulfurizing treatment, the mechanical life of a mechanical workpiece can be improved by 2 to 3 times, and the process has obvious economical and social benefits and extensive development prospect when applied to an automobiles, a train, a wind-driven generators, a petroleum machinery and a rolling machine.

Owner:BEIJING TIANMA BEARING CO LTD

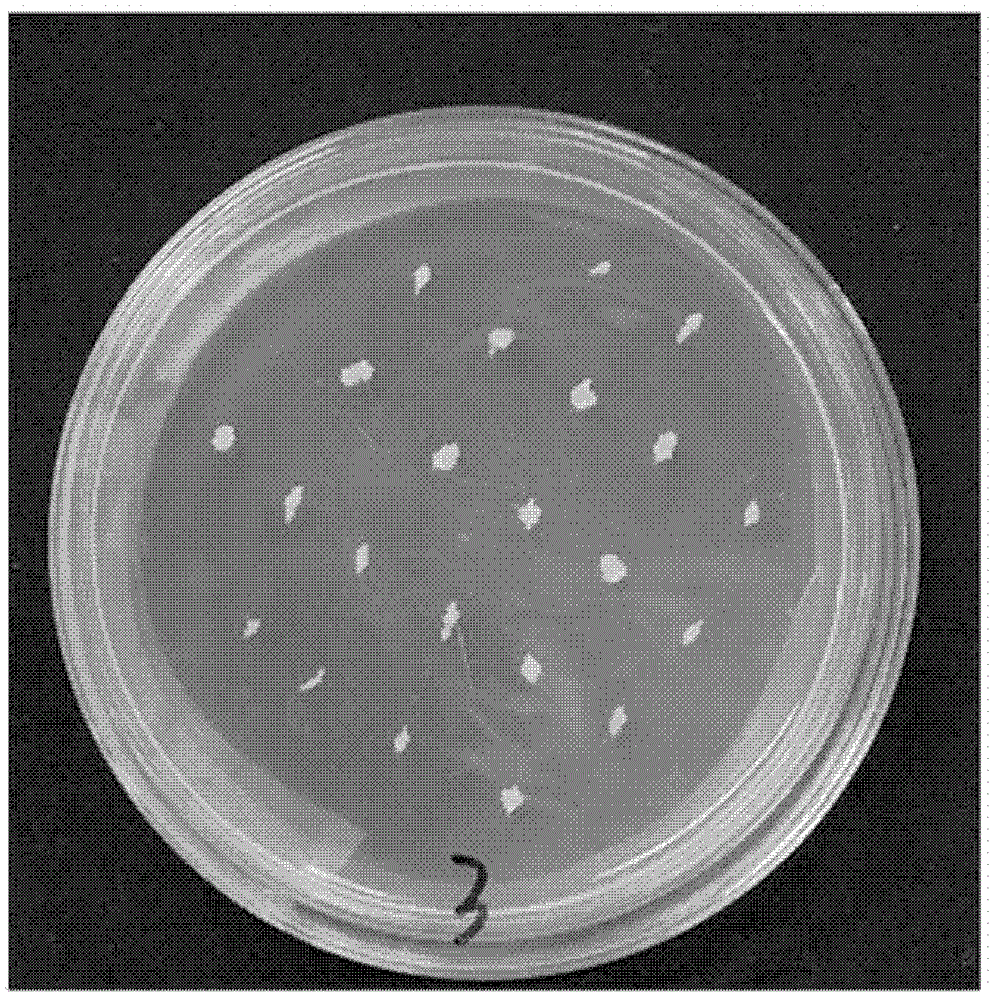

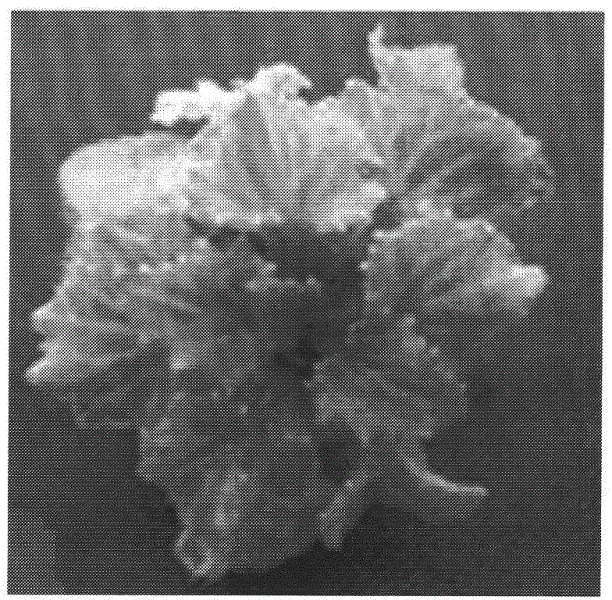

Method for breeding chamomile

InactiveCN102301952AHigh Inorganic Salt ConcentrationIncrease contentPlant tissue cultureHorticulture methodsBudCell budding

The invention discloses a method for breeding chamomile. The method disclosed by the invention comprises the following steps: (1) inoculating chamomile seeds onto a seed germination culture medium to carry out sterile seedling cultivation so as to produce sterile seedlings; (2) taking hypocotyls of the sterile seedlings as explants, inoculating the explants onto a callus induction culture medium to carry out callus induction culture so as to generate calluses by virtue of induction; (3) inoculating the calluses generated by induction onto an adventitious bud differentiation culture medium to carry out adventitious bud induction differentiation culture so as to obtain adventitious buds; (4) inoculating the adventitious buds onto a rooting culture medium to carry out rooting culture and culturing adventitious roots by virtue of induction so as to obtain rooted seedlings; and (5) hardening and transplanting the rooted seedlings so as to finally obtain the chamomile. In a regeneration system established by the method disclosed by the invention, callus inductivity reaches up to 86.63%, differentiation rate of the adventitious buds reaches up to 25.5%, rooting rate reaches up to 100%, and transplanting survival rate reaches up to 100%, thus a large number of excellent chamomile test-tube plantlets can be obtained in short term so as to realize large-scale factory production.

Owner:BEIJING FORESTRY UNIVERSITY

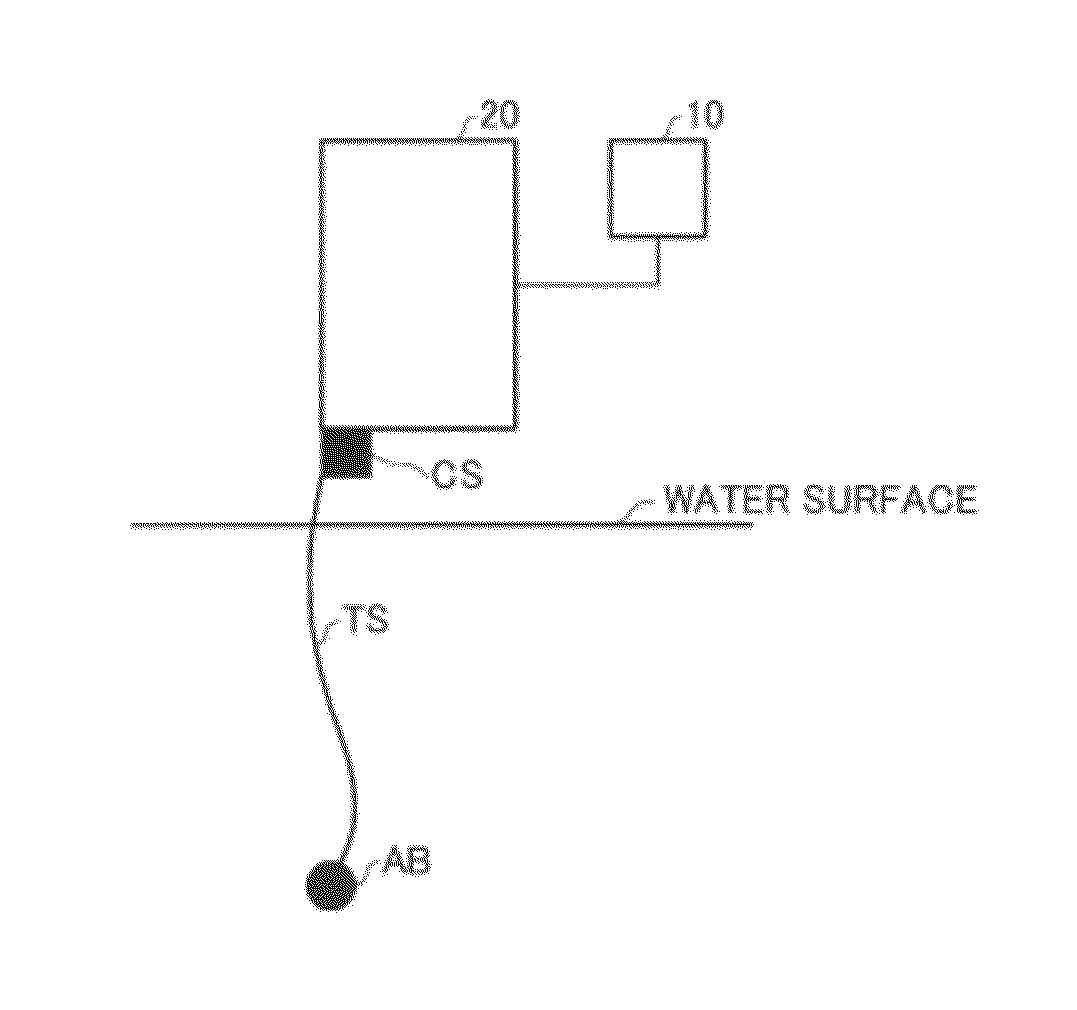

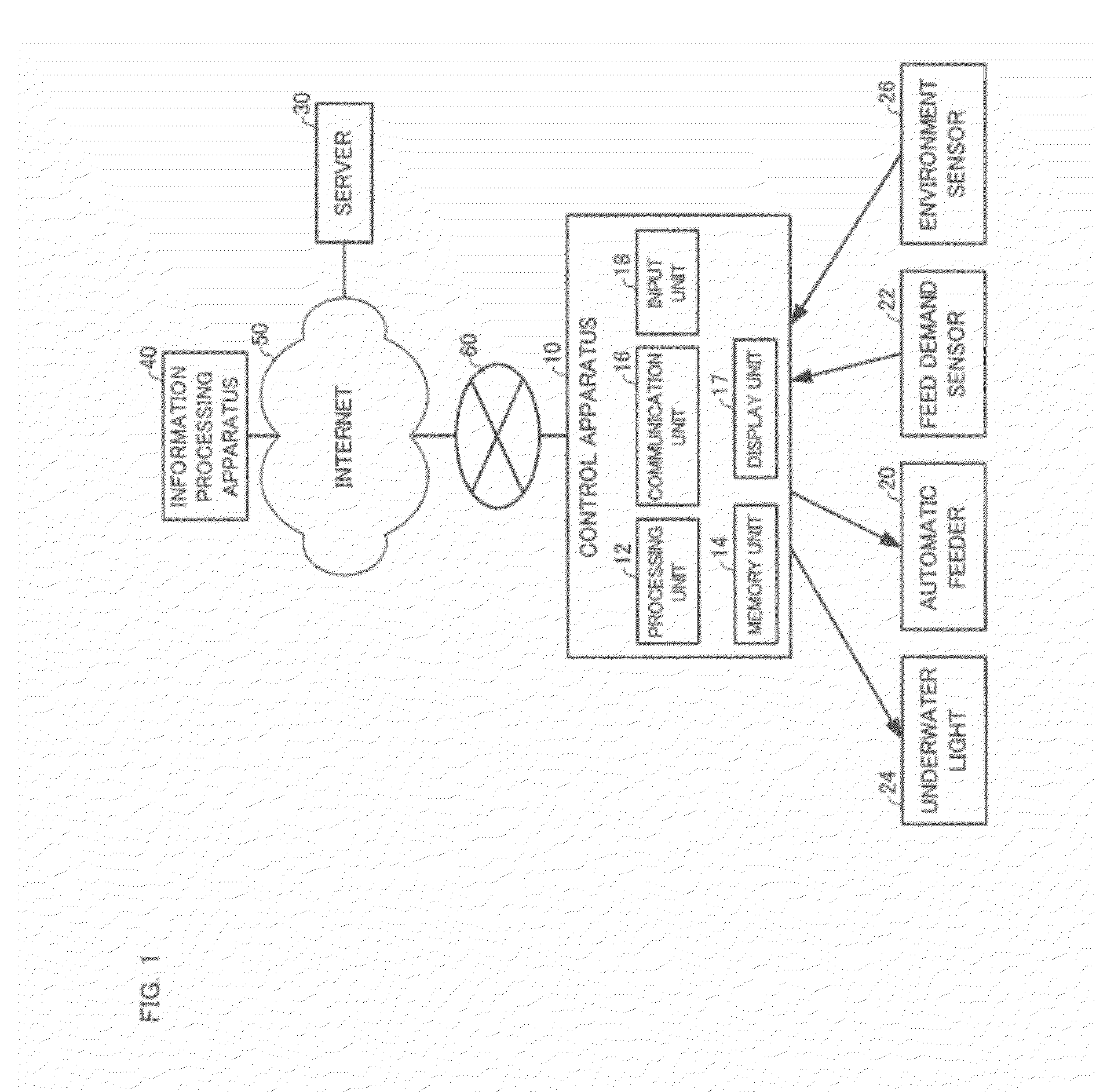

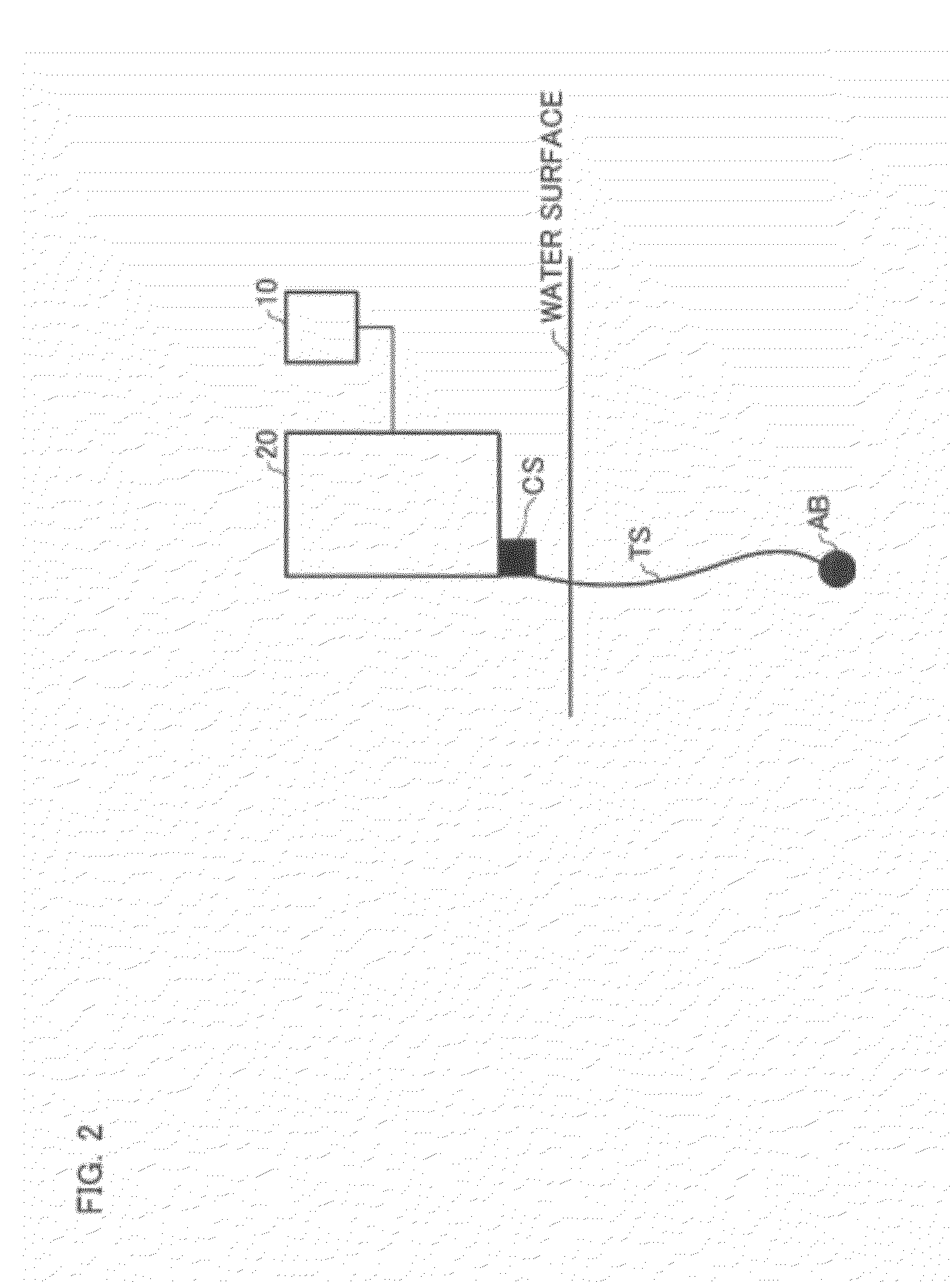

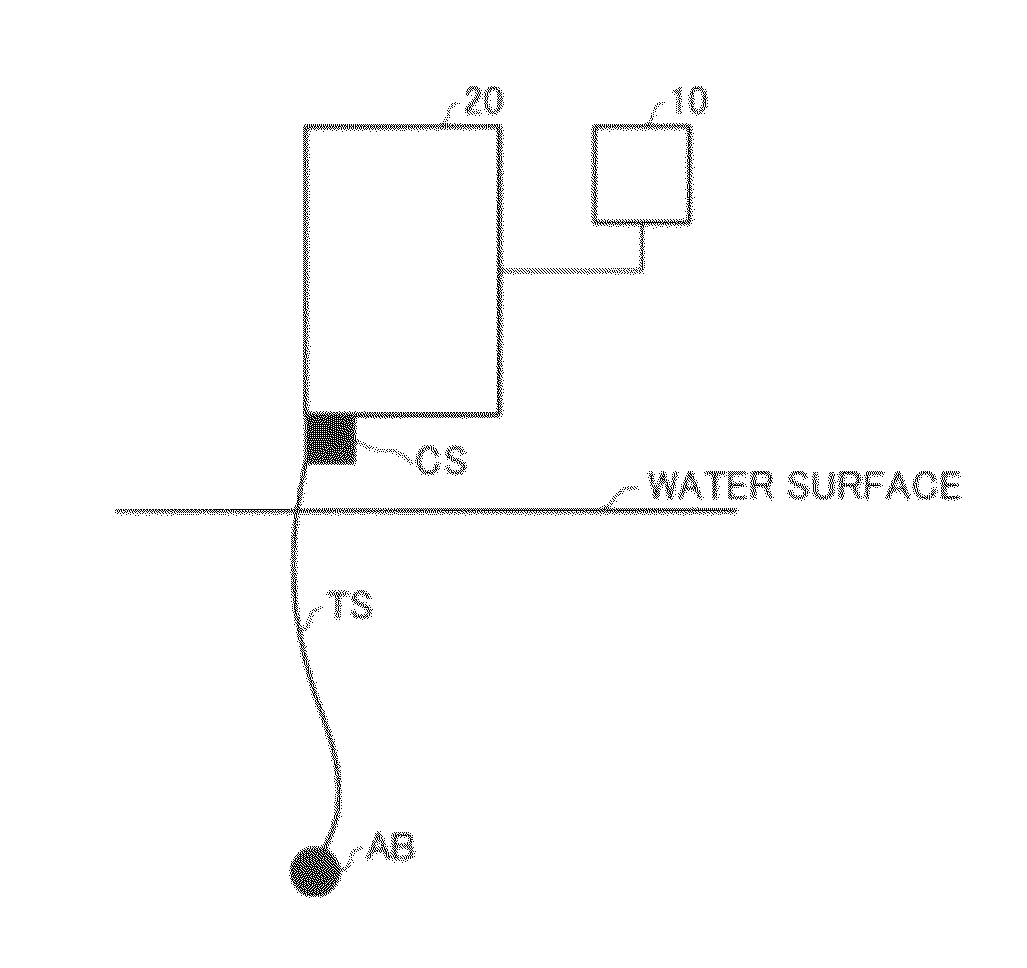

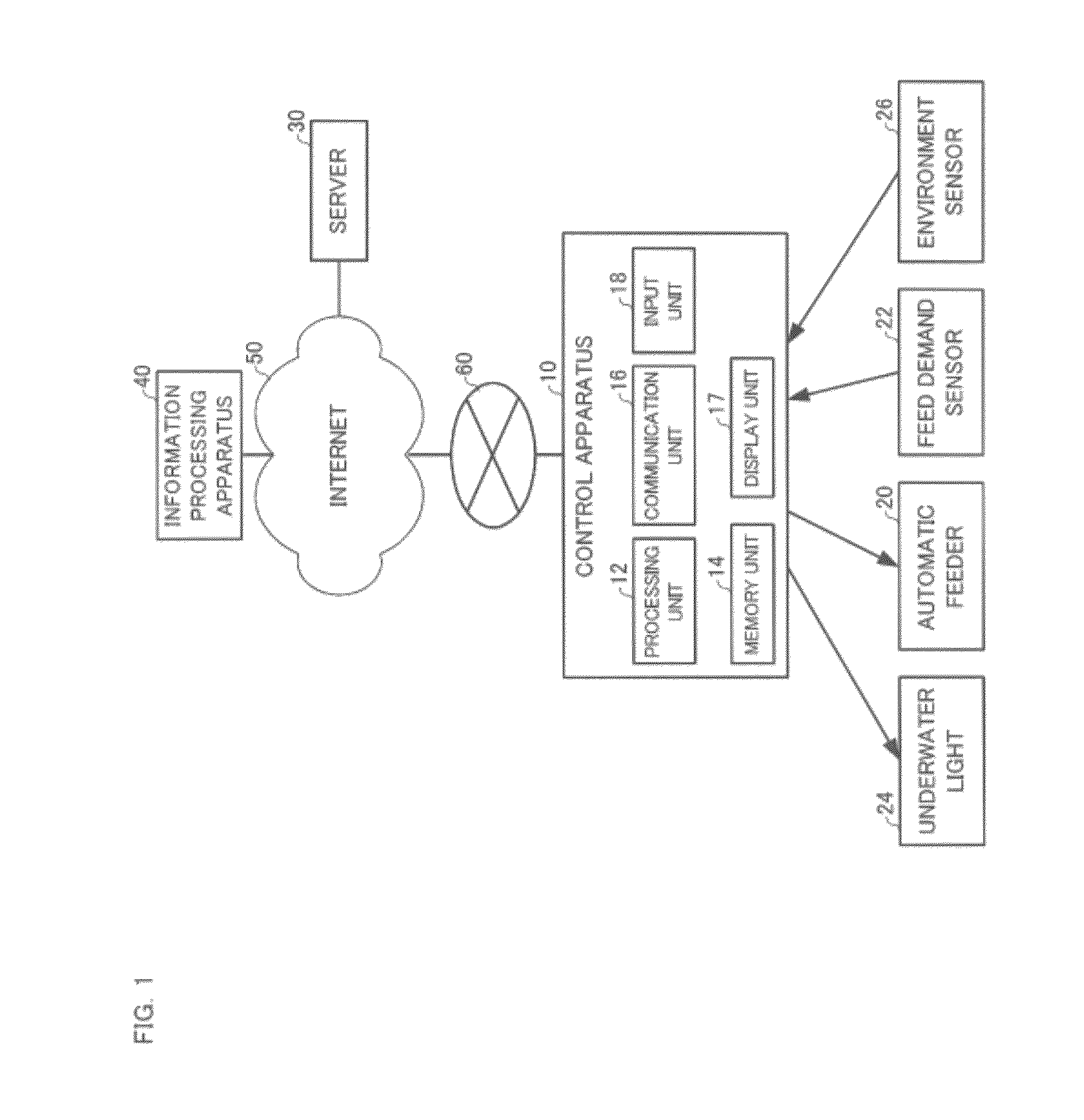

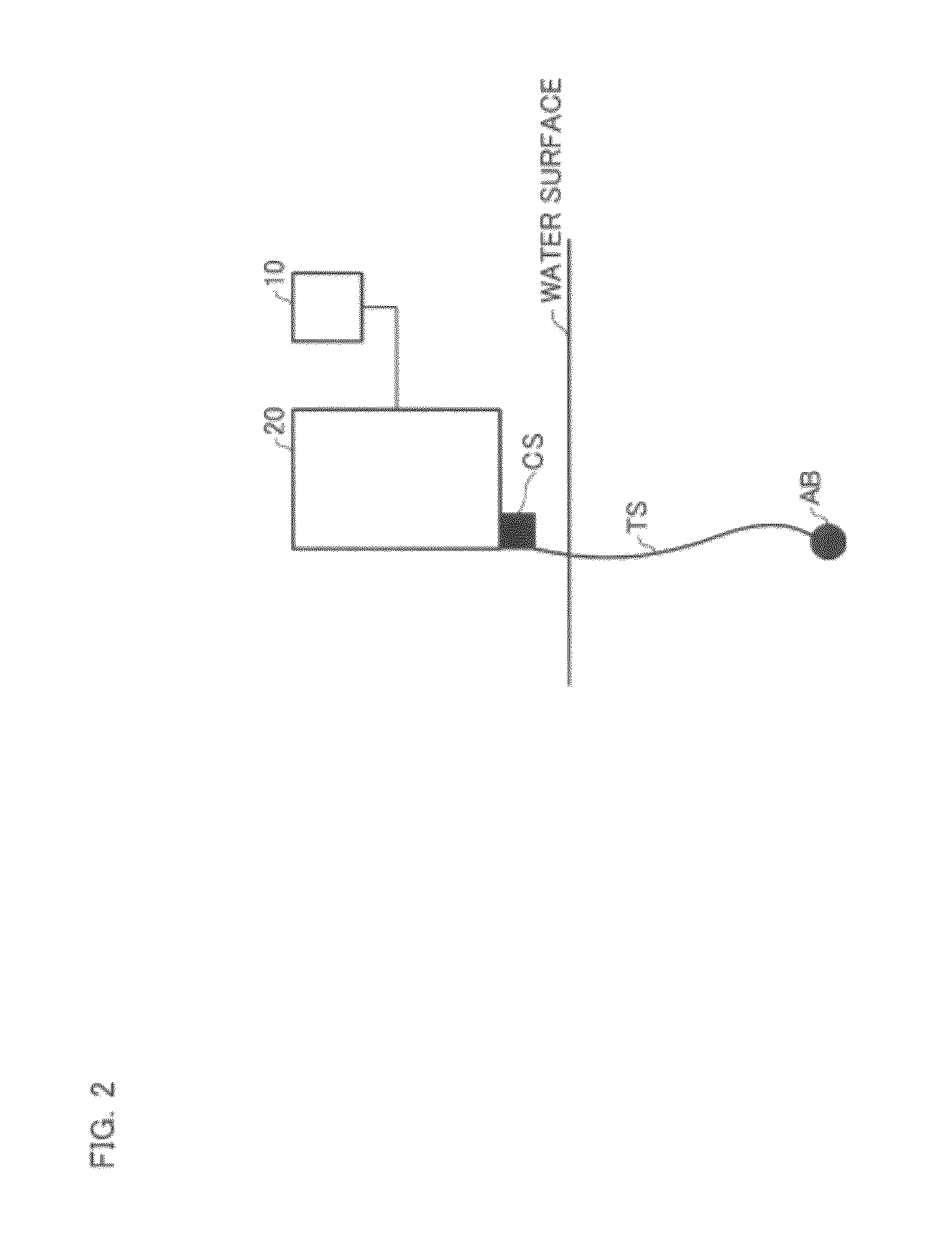

Feeding method and feeding system for farmed fish

InactiveUS20120055412A1Appropriate quantityClimate change adaptationPisciculture and aquariaFodderBiology

Owner:NIPPON SUISAN KAISHA LTD

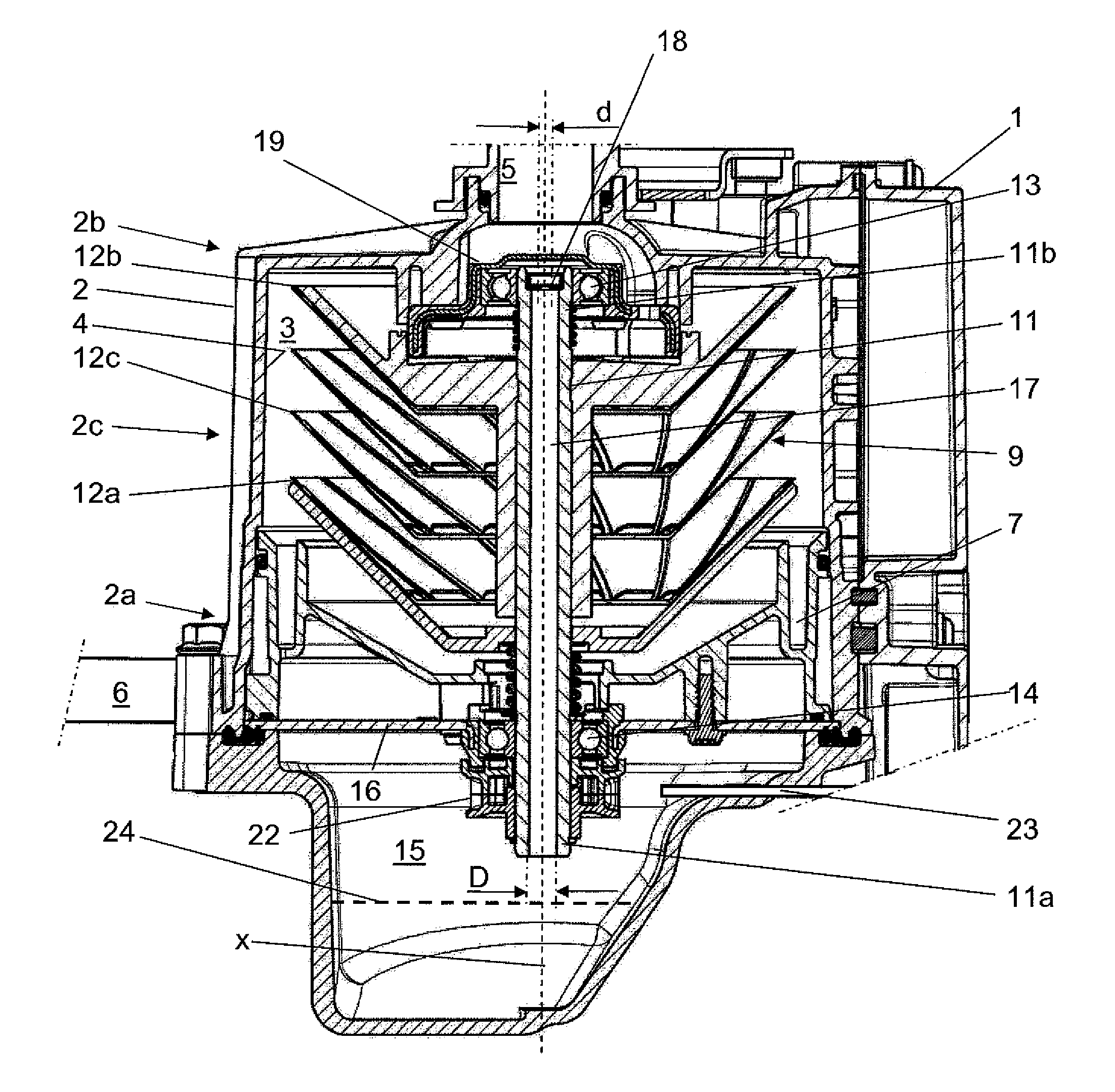

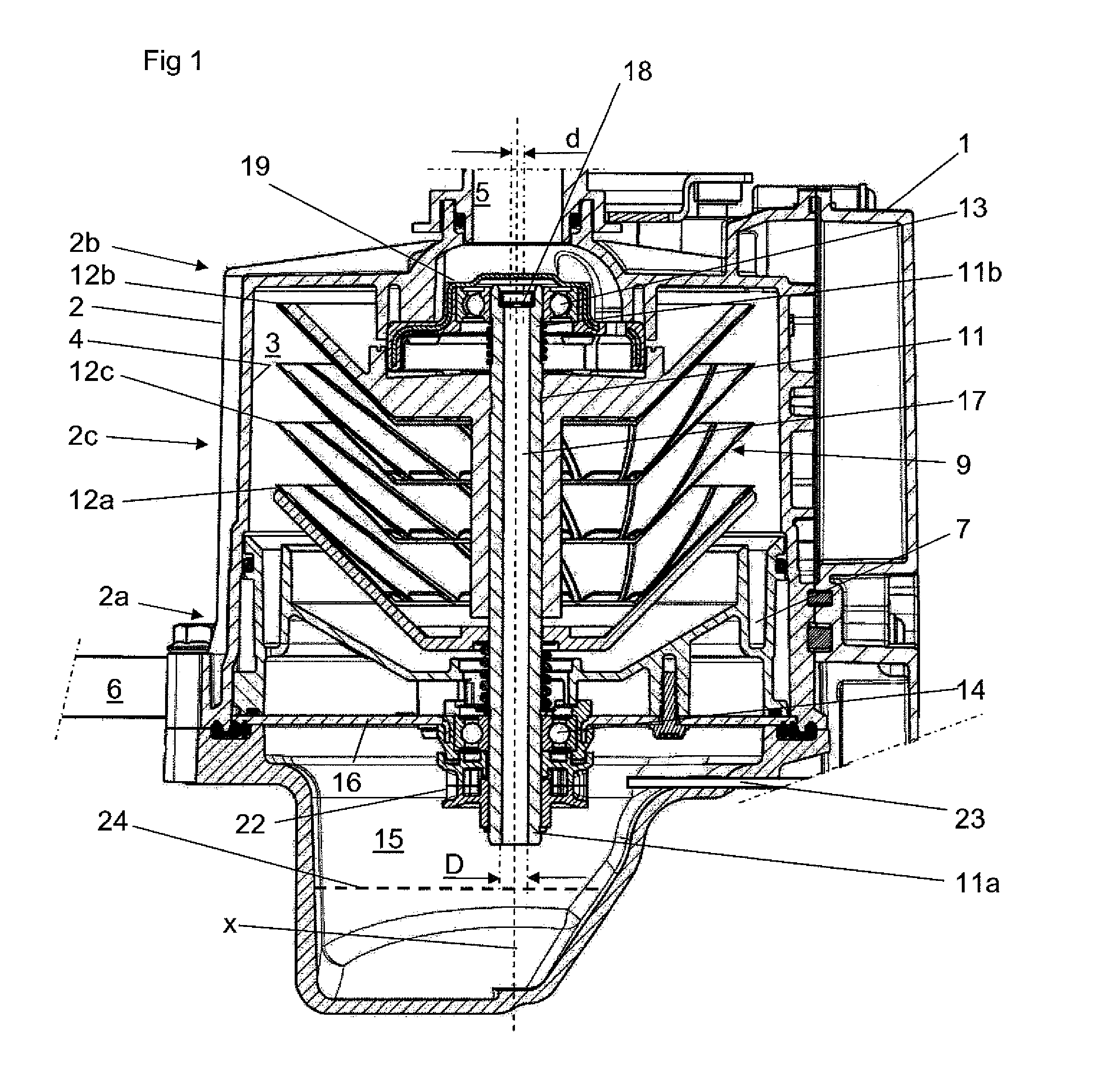

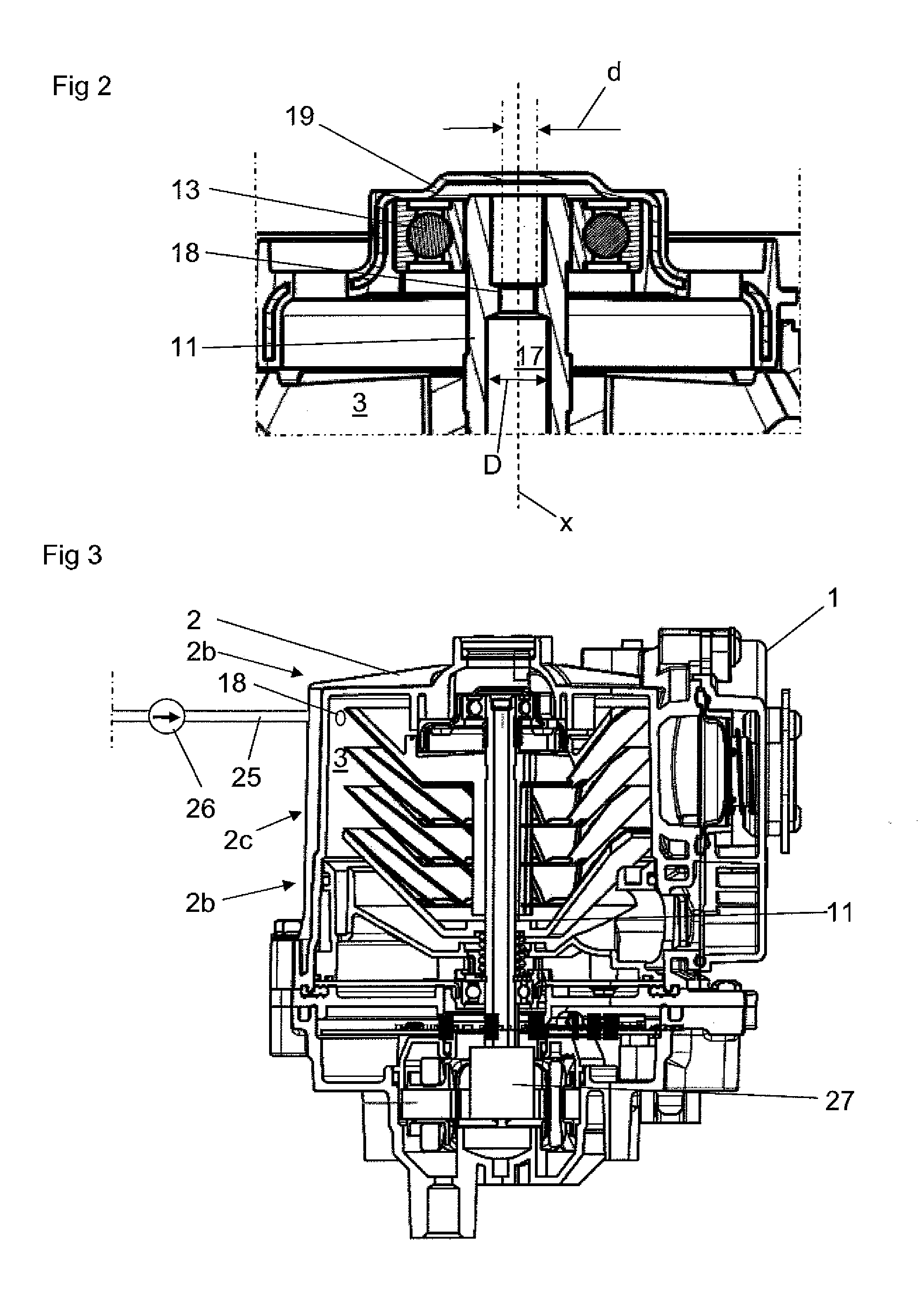

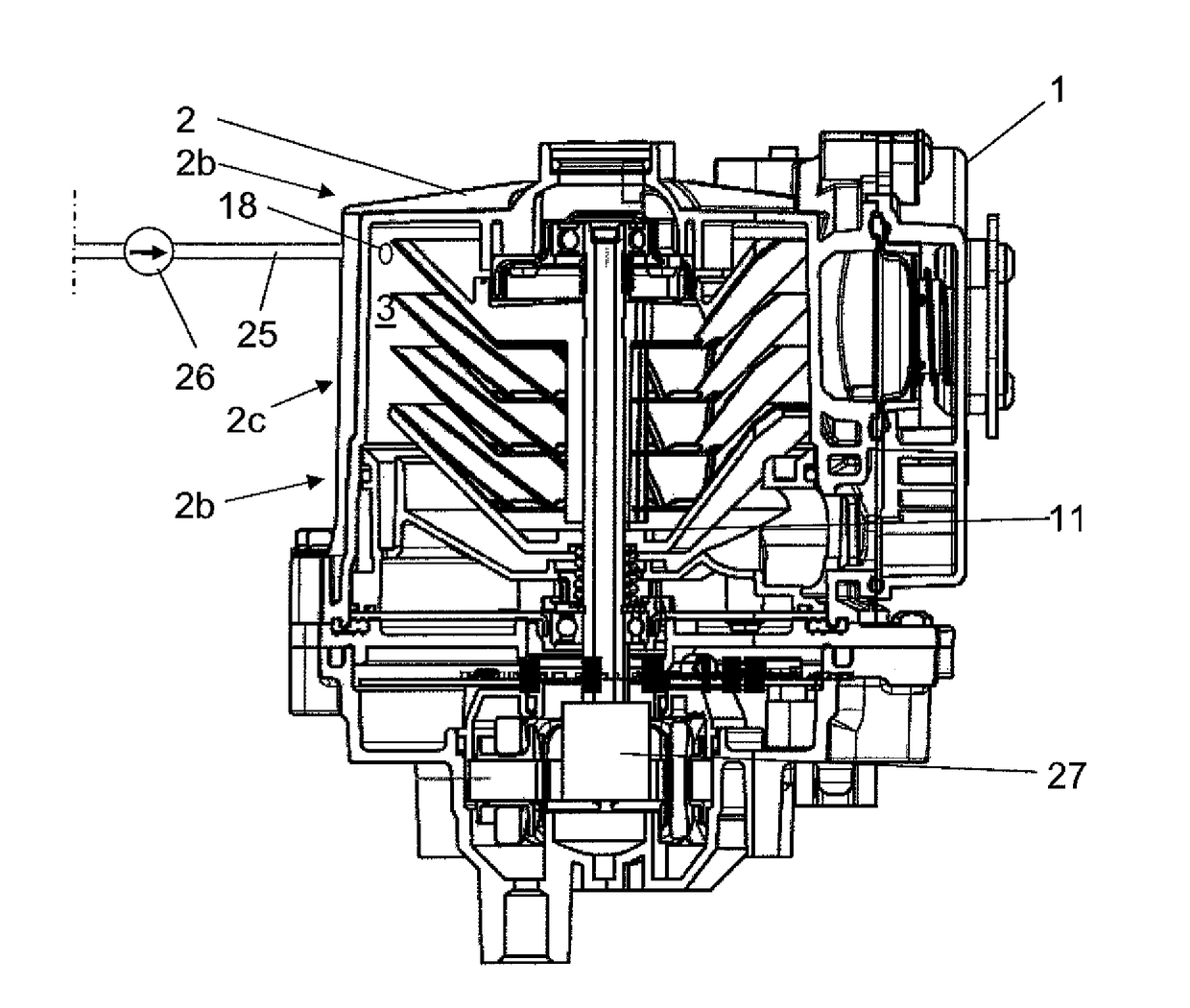

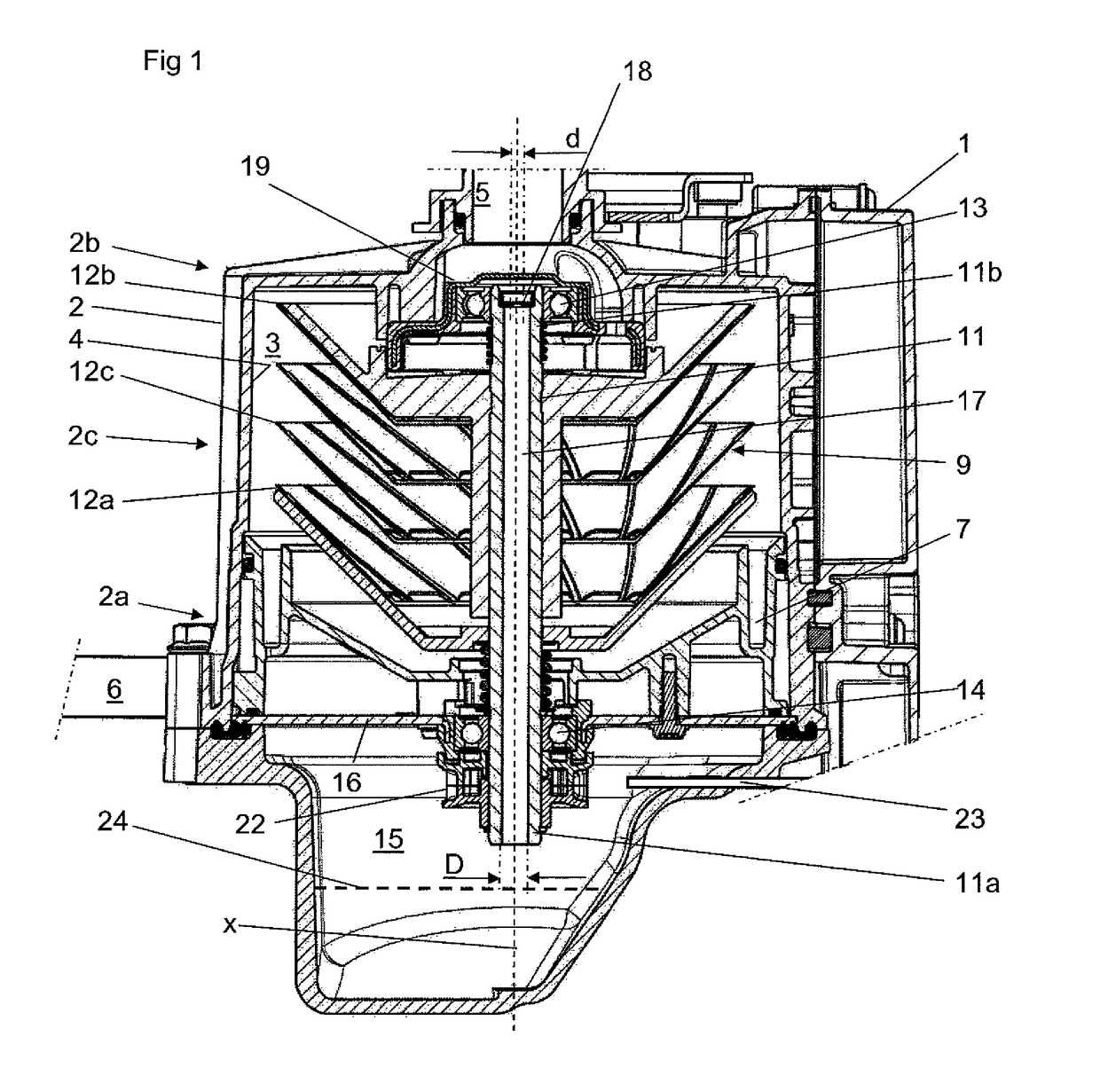

Centrifugal separator

ActiveUS20150119226A1Avoid and reduce agglomerationAvoid and reduce sticky agglomerationMachines/enginesCentrifugesCentrifuge rotorInlet channel

A centrifugal separator for cleaning crankcase gas, containing oil, from an internal combustion engine, includes a stationary casing defining a separation space and including a first end portion, an opposite second end portion and an inner wall surface facing the separation space. The separator also includes an inlet channel for the gas to be cleaned, a gas outlet channel for the cleaned gas and an oil outlet for the separated the oil. A centrifuge rotor is provided in the separation space and includes a spindle and a plurality of separation discs carried by the spindle. The centrifuge rotor is rotated to create a rotating gas volume. An oil supply device supplies such a quantity of oil to the separation space that a flowing oil film is created on the inner wall surface during operation of the centrifugal separator.

Owner:ALFA LAVAL CORP AB

In-mould labelled container

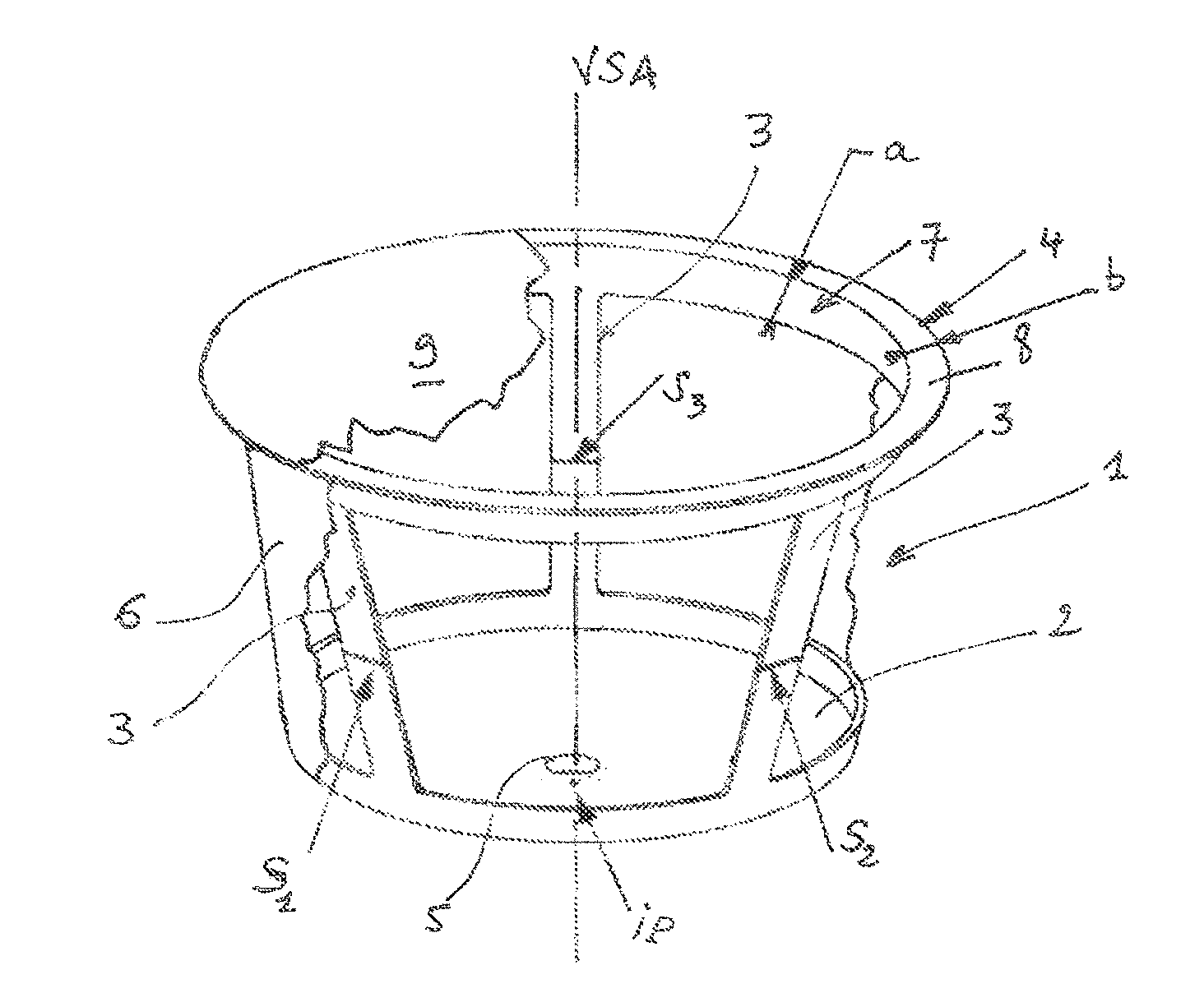

InactiveUS8833235B2Easy disposalEasy to recycleWrappersContainer/bottle contructionInjection pointBiomedical engineering

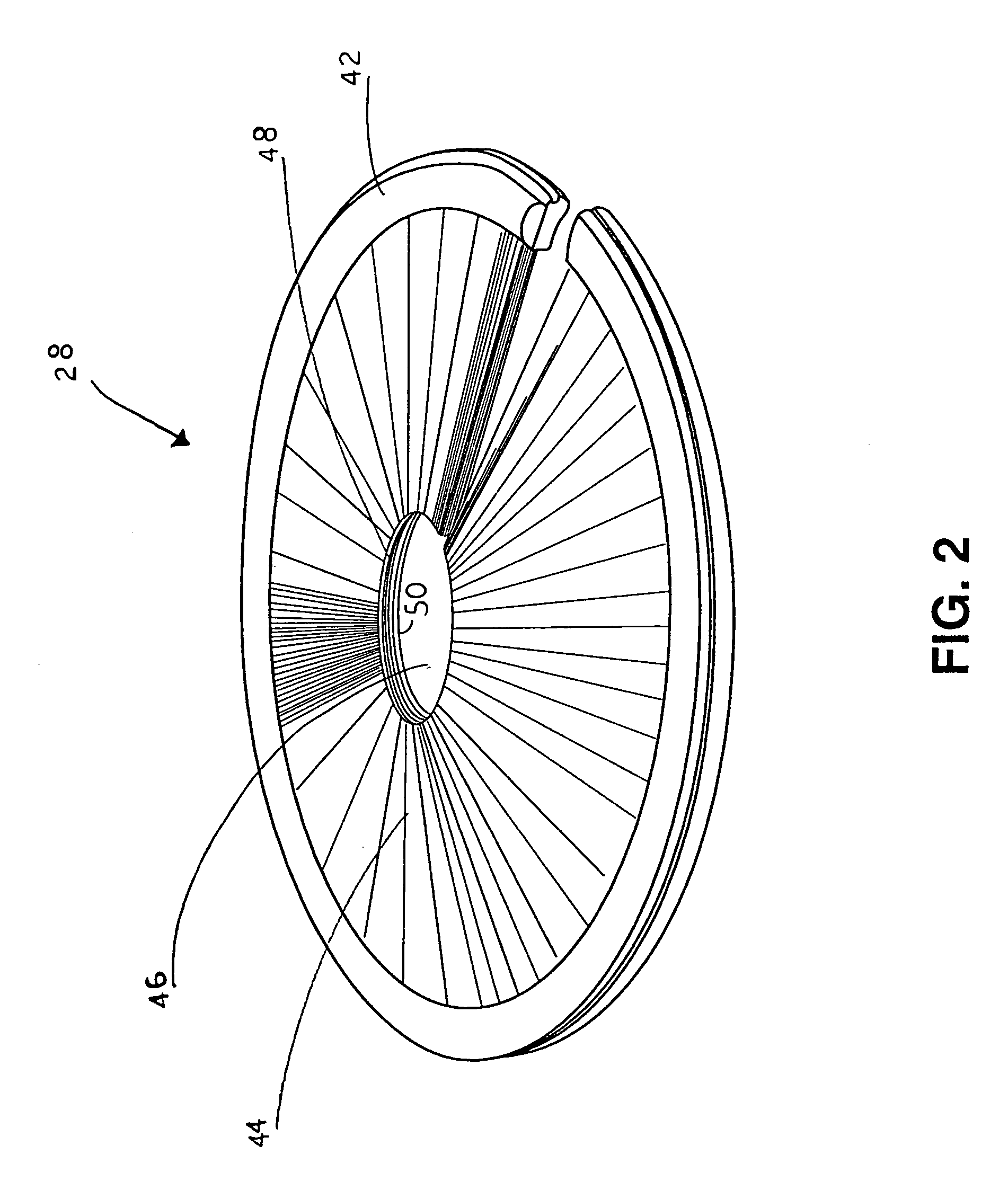

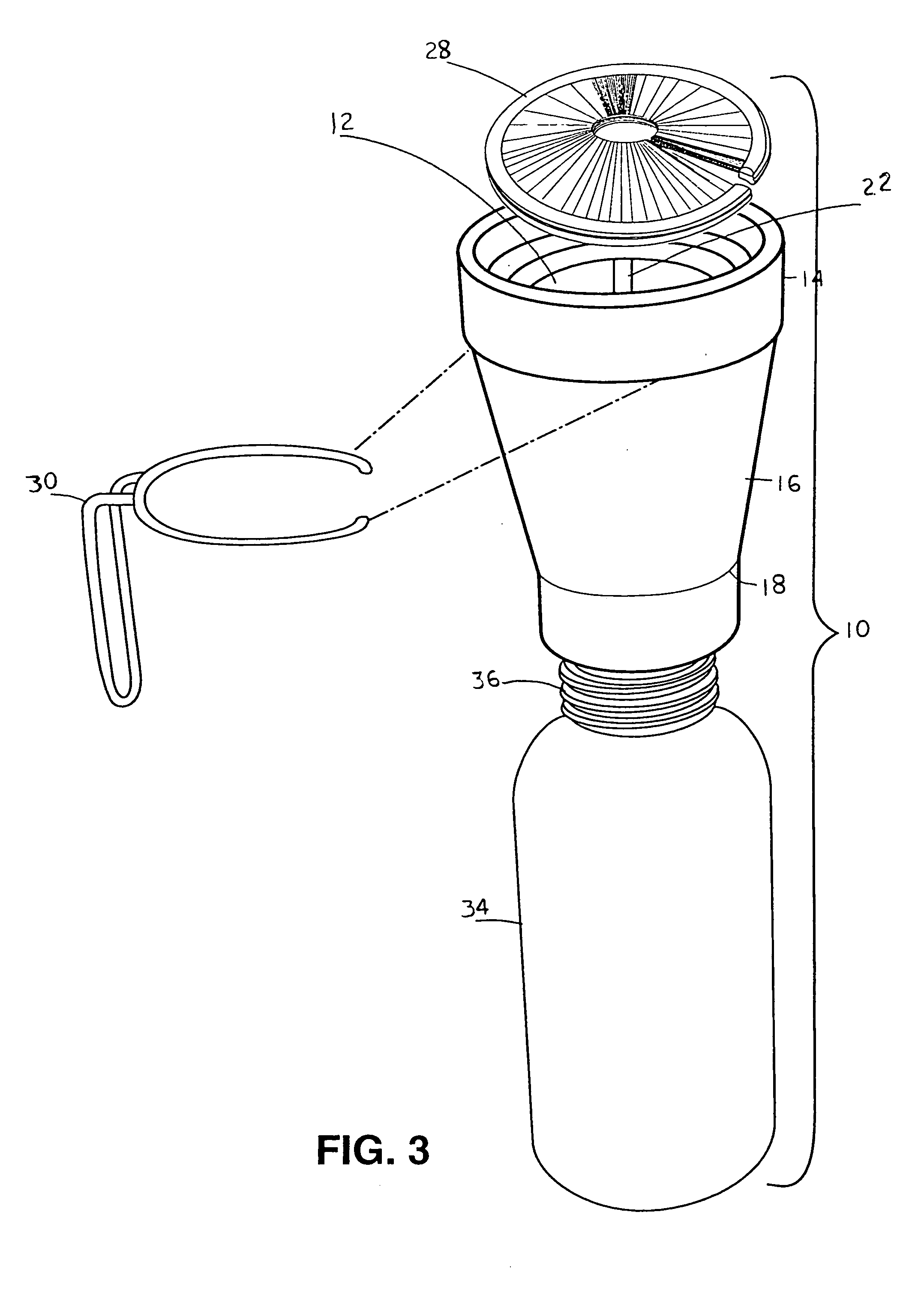

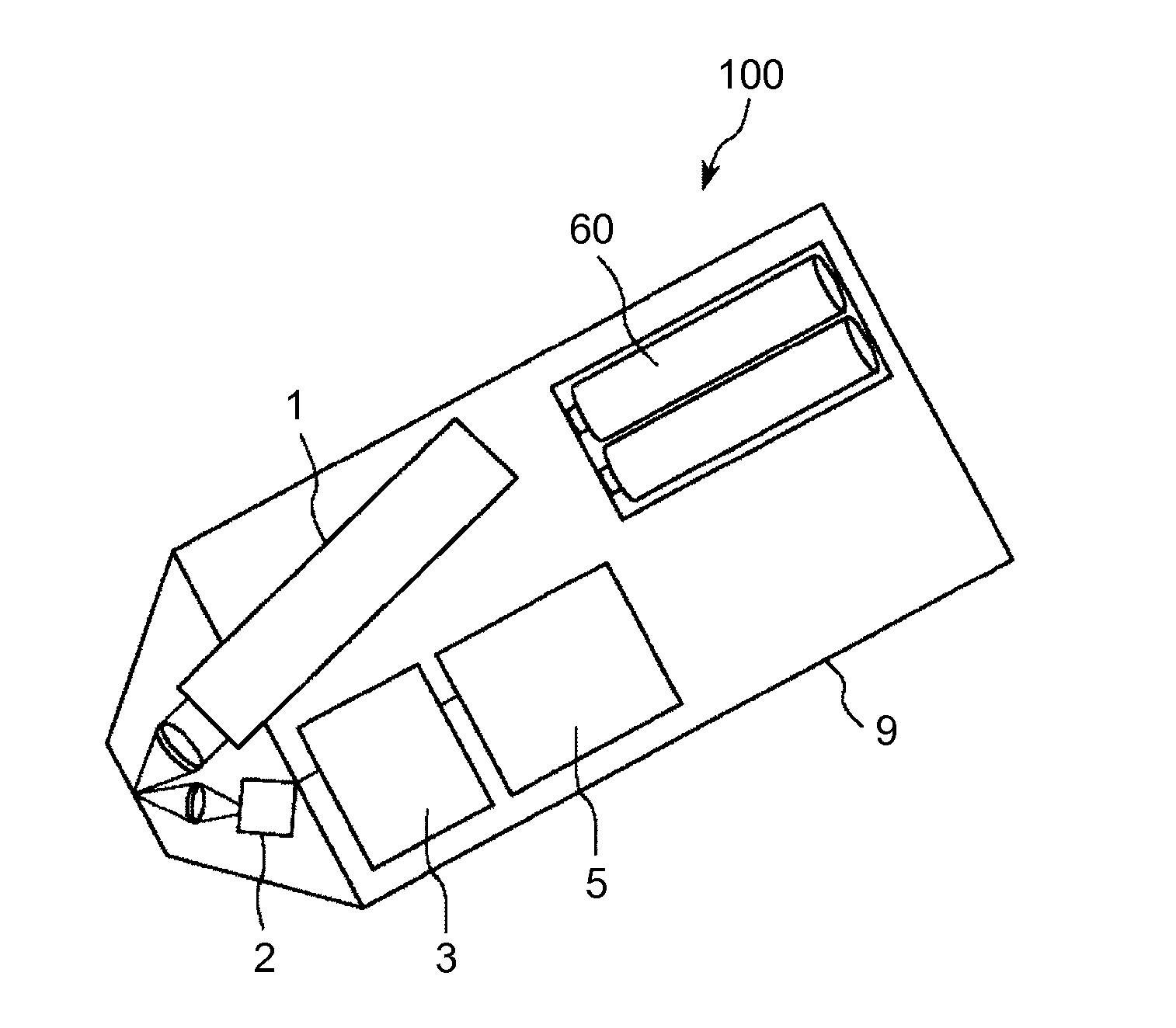

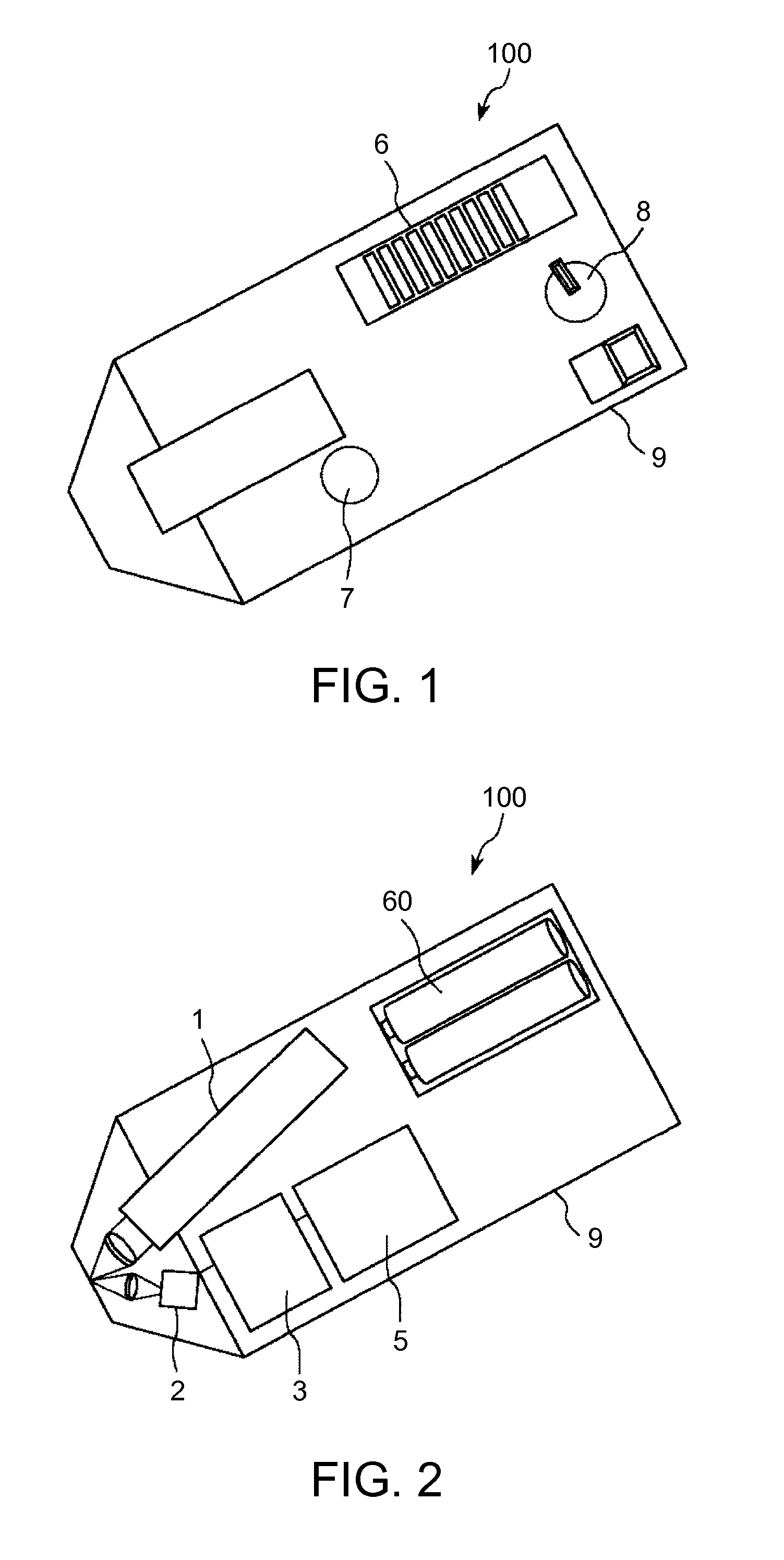

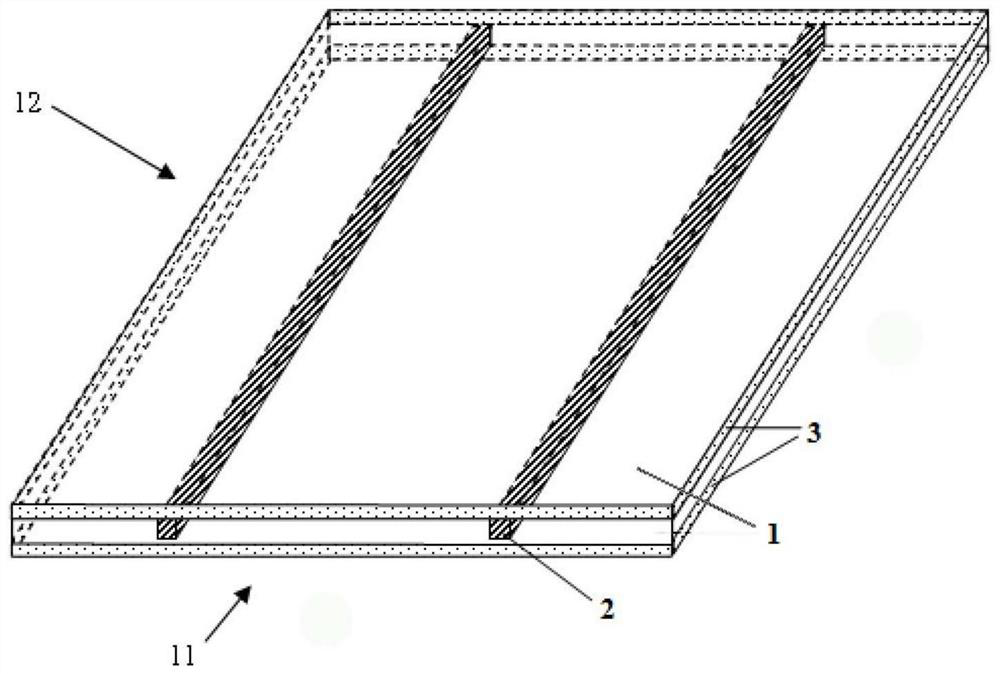

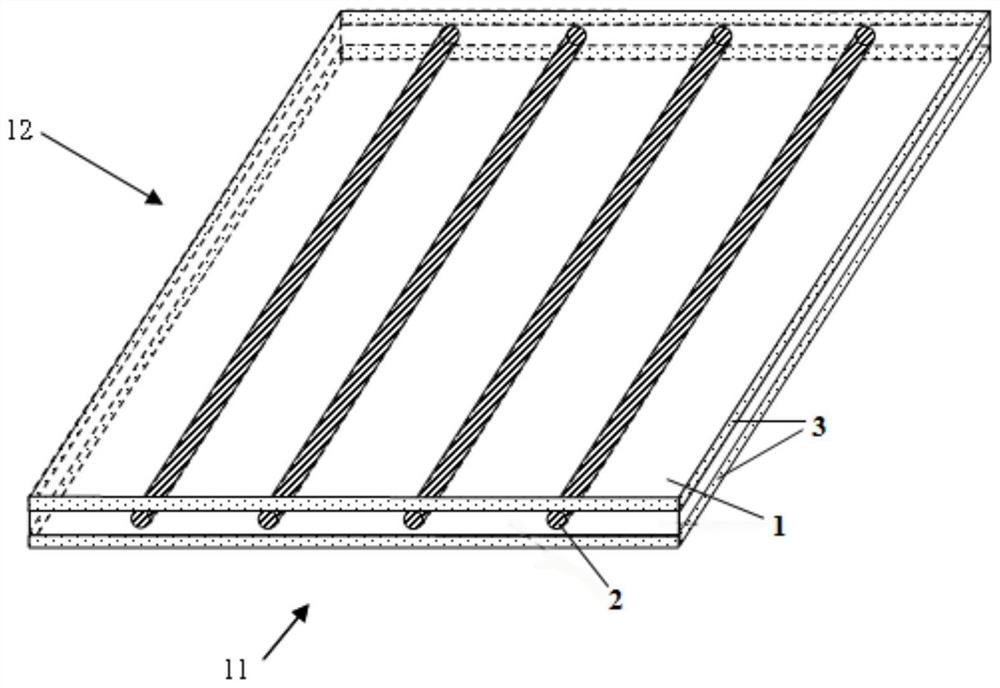

The present invention concerns an injection-molded capsule for use in a food preparation machine, said capsule for use in a food preparation machine comprising: (i) a structure (1) with a lower side (2), at least three pillars (3) extending from the lower side and linked to a circular upper frame (4) which defines the surroundings of the capsule top side, the pillars (3) having cross-sections S1, S2 and S3, the lower side (2) being a solid wall that comprises a dispensing opening (5) and is centered across the vertical symmetry axis VSA of said capsule, and (ii) a label (6) attached to the outer surface of the lower side (2), pillars (3) and upper circular frame (4), thus forming an envelope that defines capsule side walls, characterized in that the injection point IP of the capsule is off-centered in the vicinity of said dispensing opening (5), opposed the pillar (3) having a cross-section S3 relatively to the axis VSA, and in that S1=S2 and S3>S1.

Owner:SOC DES PROD NESTLE SA

In-mould labelled container

InactiveUS20130146495A1Promote wettingEasy disposalWrappersLaminationBiomedical engineeringFood preparation

The present invention concerns an injection-molded capsule for use in a food preparation machine, said capsule for use in a food preparation machine comprising: (i) a structure (1) with a lower side (2), at least three pillars (3) extending from the lower side and linked to a circular upper frame (4) which defines the surroundings of the capsule top side, the pillars (3) having cross-sections S1, S2 and S3, the lower side (2) being a solid wall that comprises a dispensing opening (5) and is centered across the vertical symmetry axis VSA of said capsule, and (ii) a label (6) attached to the outer surface of the lower side (2), pillars (3) and upper circular frame (4), thus forming an envelope that defines capsule side walls, characterized in that the injection point IP of the capsule is off-centered in the vicinity of said dispensing opening (5), opposed the pillar (3) having a cross-section S3 relatively to the axis VSA, and in that S1=S2 and S3>S1.

Owner:SOC DES PROD NESTLE SA

Feeding method and feeding system for farmed fish

InactiveUS8955457B2Appropriate quantityClimate change adaptationAnimal feeding devicesFodderFeeding Methods

Owner:NIPPON SUISAN KAISHA LTD

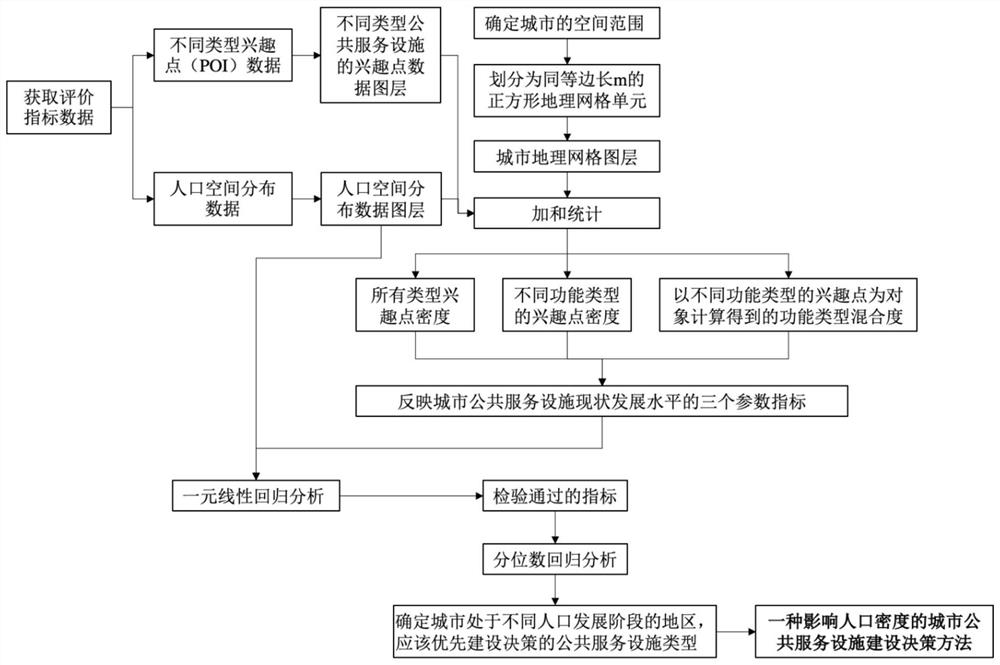

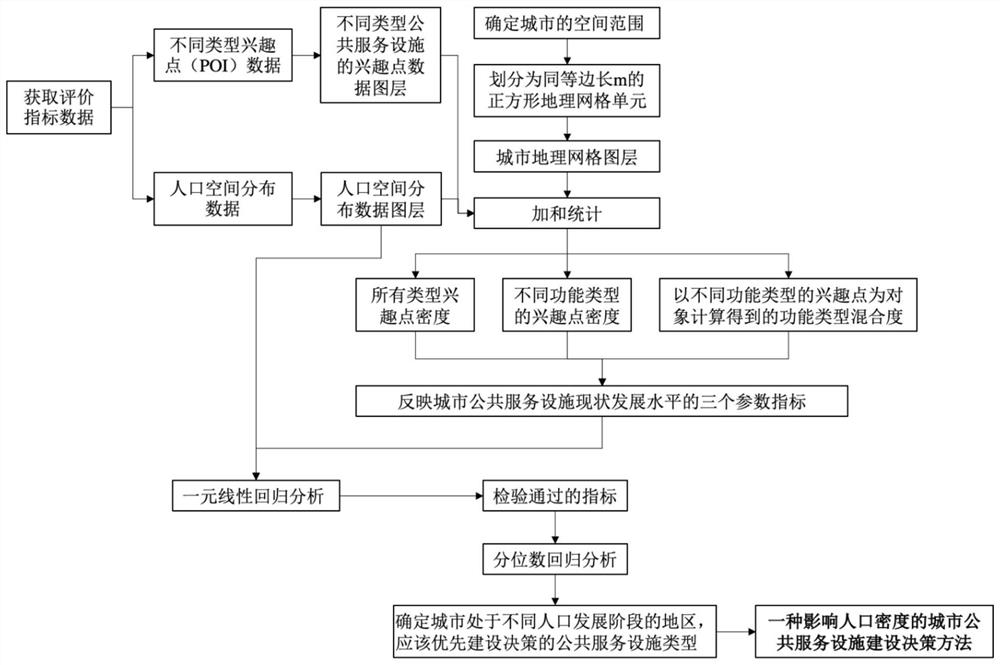

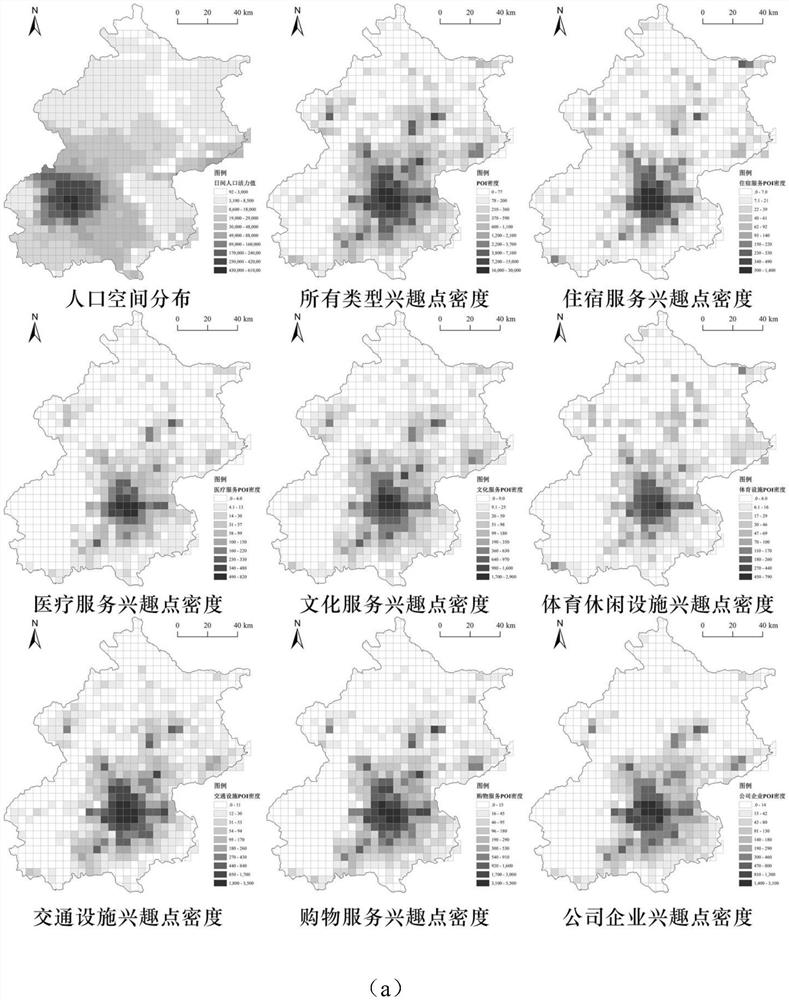

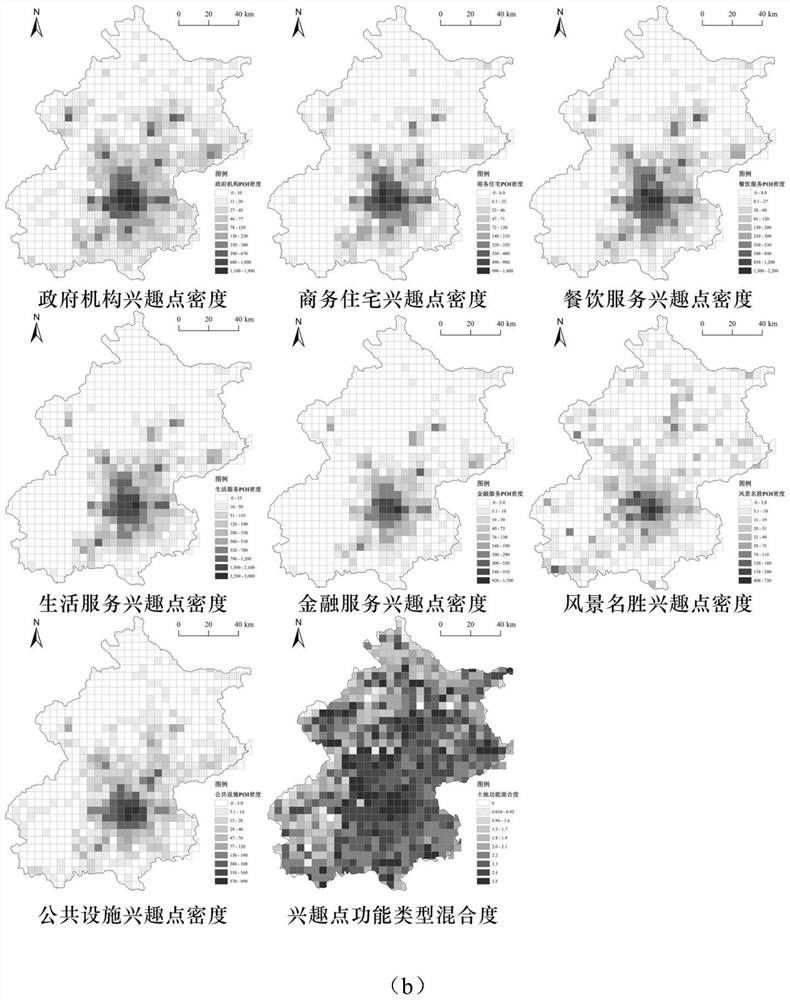

Urban public service facility construction decision-making method influencing population density

The invention discloses an urban public service facility construction decision-making method influencing population density, and the method comprises the steps: dividing an urban space into square geographic grid units with the same side length; performing unary linear regression analysis among different indexes by combining three parameter indexes, namely the density of interest points of all types, the density of interest points of different function types and the mixing degree of the function types of the interest points, which reflect the current development level of urban public service facilities; and further performing quantile regression analysis on the parameter indexes passing the regression model test, constructing a correlation and an influence process between population distribution data in the geographic grid units and public service facility indexes, and comprehensively judging the influence strength of the public service facilities on regions in different population development stages. According to the method, the public service facility types which should be preferentially built in regions with different population development levels in a city are accurately reflected, so that the population density improvement efficiency is improved, and the use efficiency of public service facility configuration is optimized.

Owner:PEKING UNIV

Bovine germicide application device

ActiveUS20050095274A1Reduce the amount of wasteReduce the amount of solutionCannulasLiquid flow controllersEngineering

Owner:HAKES DENNIS LEE

Drug application device, detection device, drug application method, and detection method

InactiveUS20160361000A1Appropriate quantityVaccination/ovulation diagnosticsMedical applicatorsMedicineDrug application

A drug application device irradiates terahertz light onto skin, outputs information concerning detection target cytokine determined from reflected rays of the terahertz light, and supplies a drug on the basis of the output information. A detection device irradiates terahertz light onto a patch attached to skin, and outputs information concerning detection target cytokine determined from reflected rays of the terahertz light.

Owner:SEIKO EPSON CORP

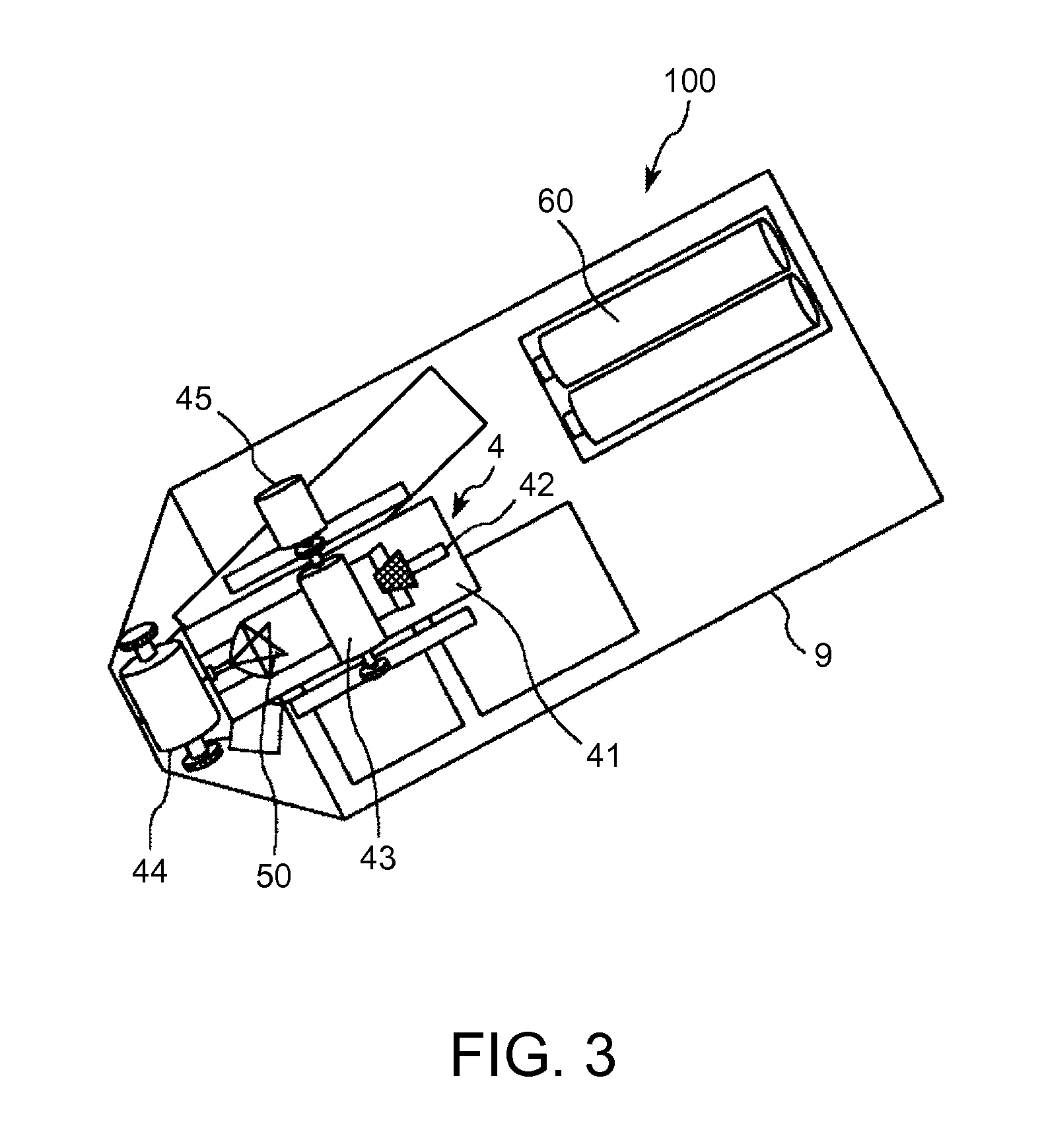

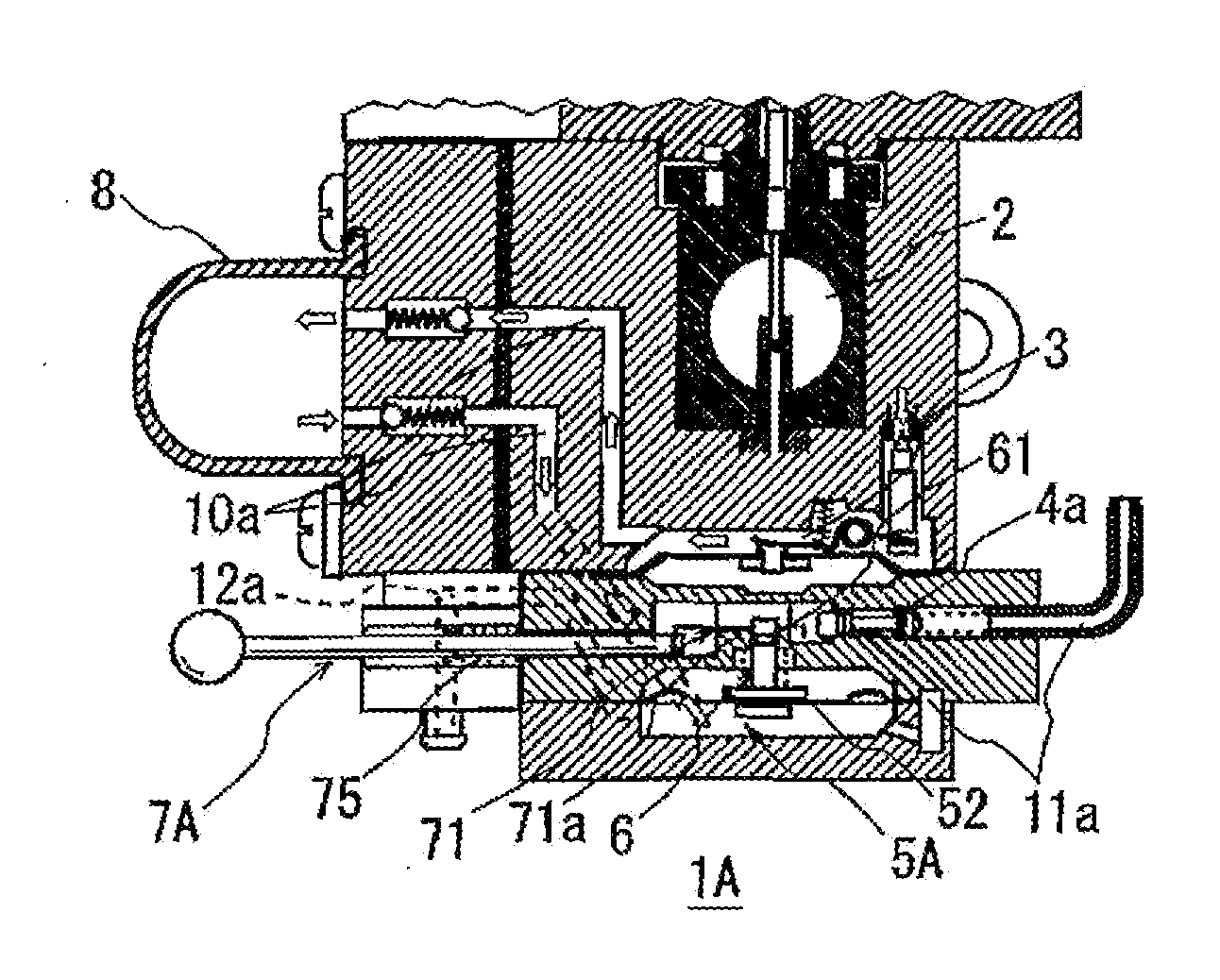

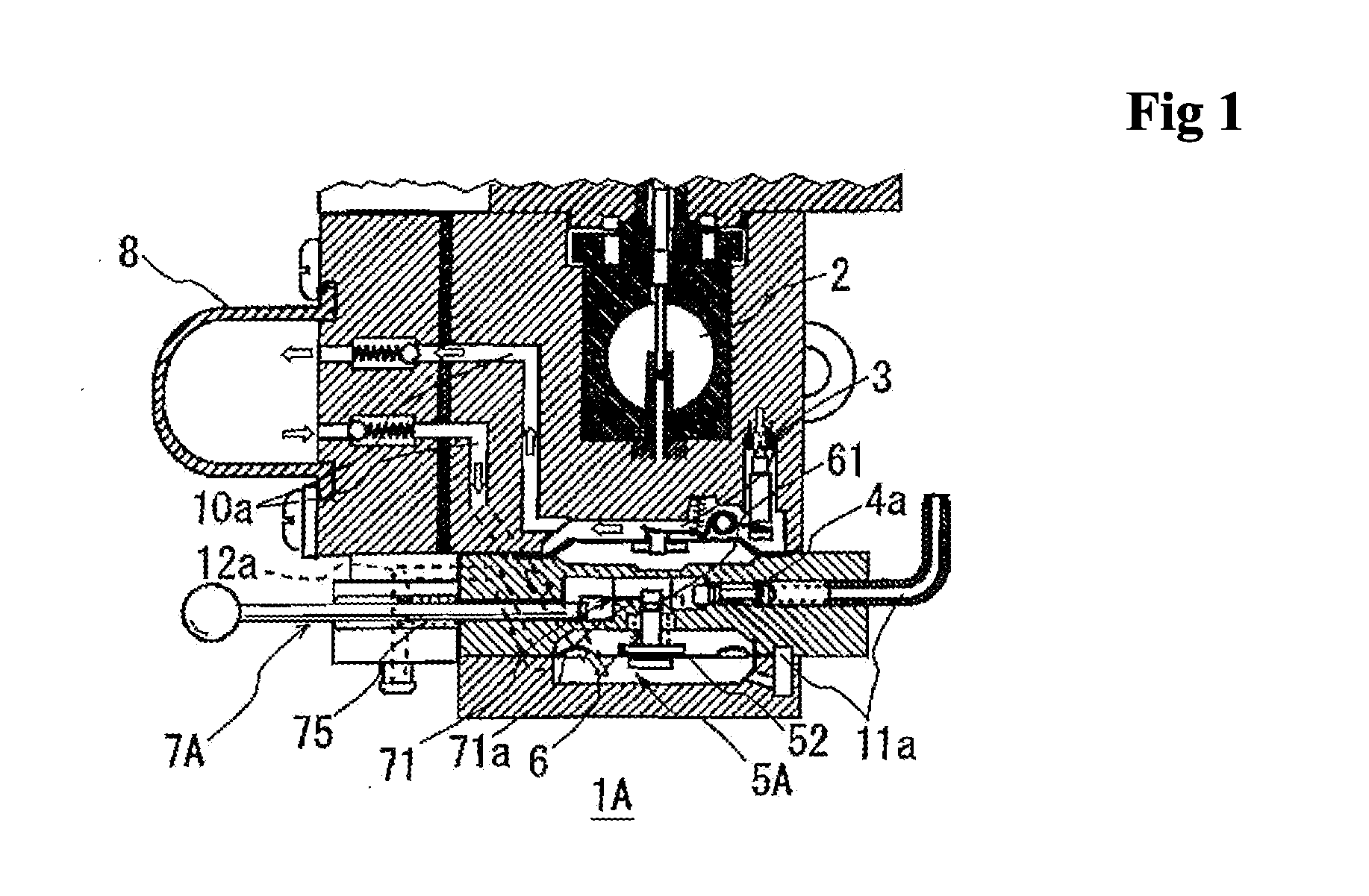

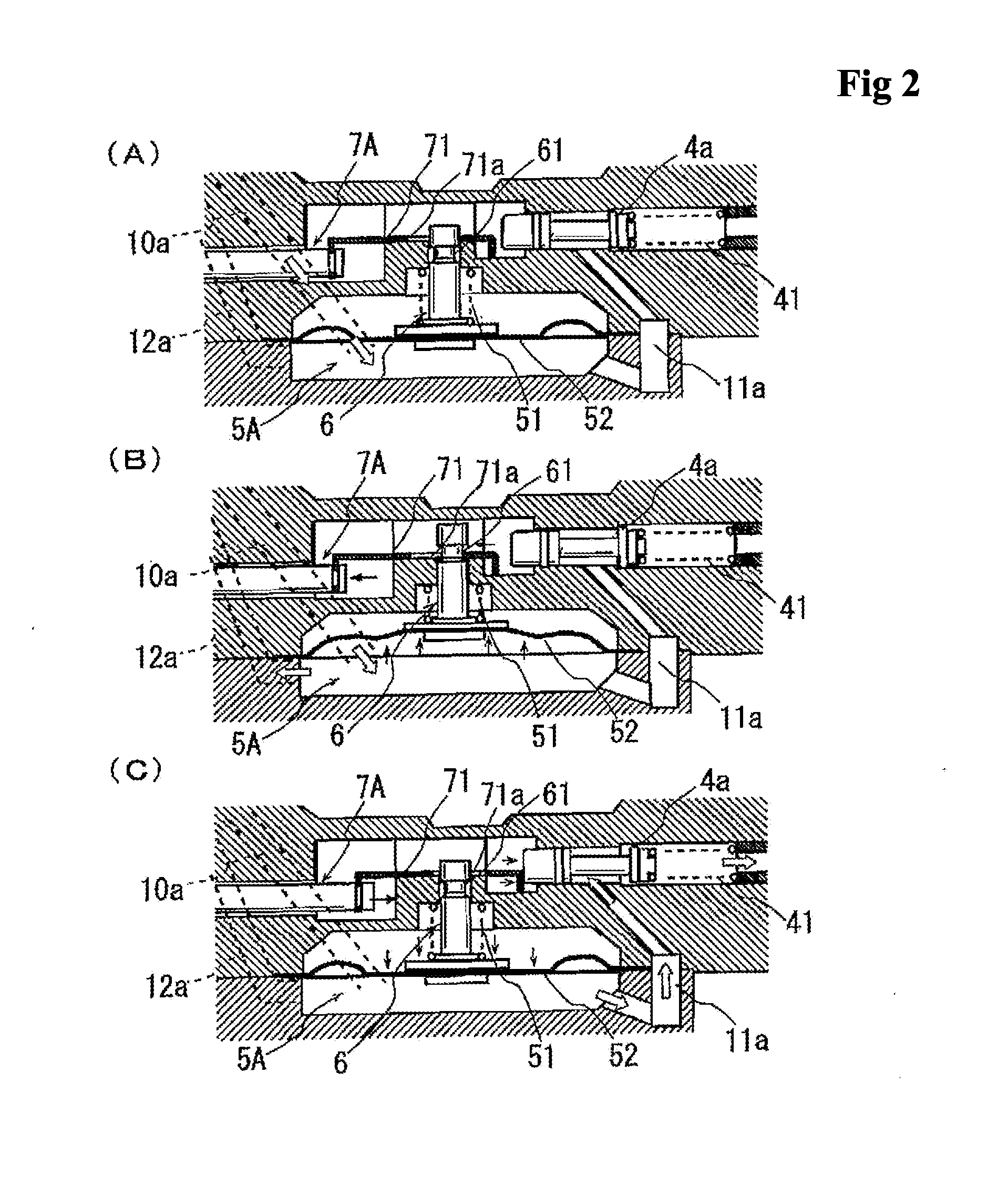

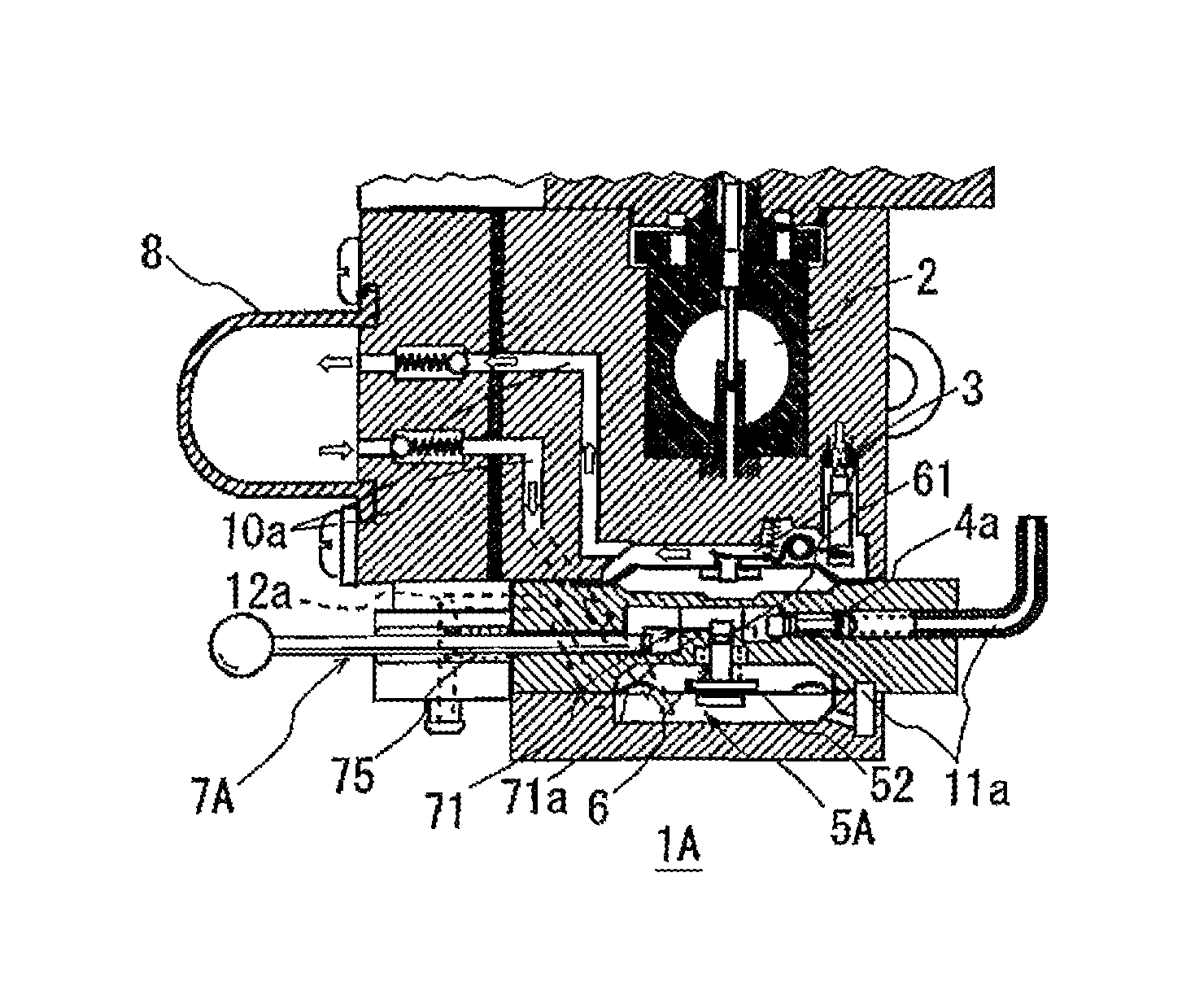

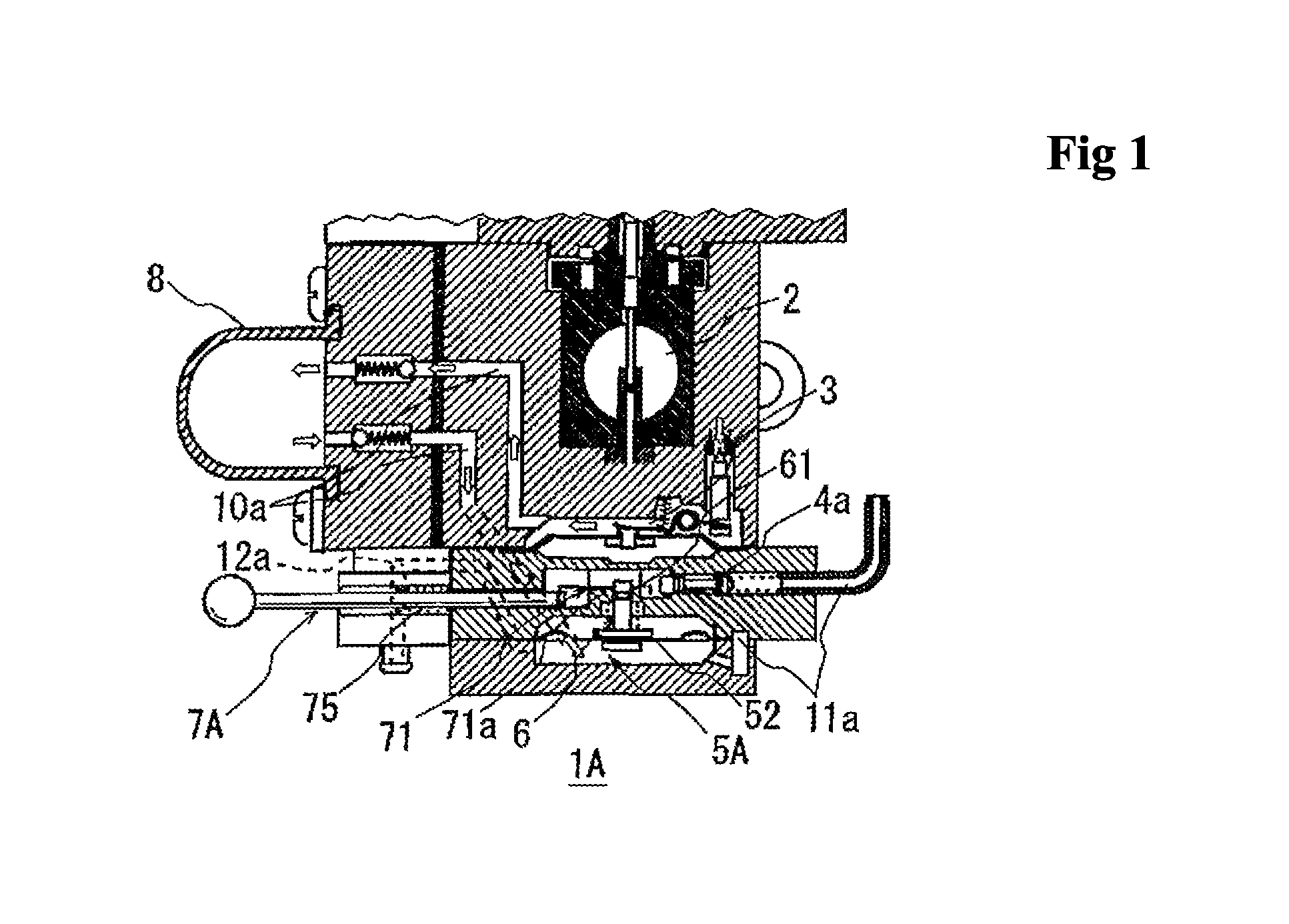

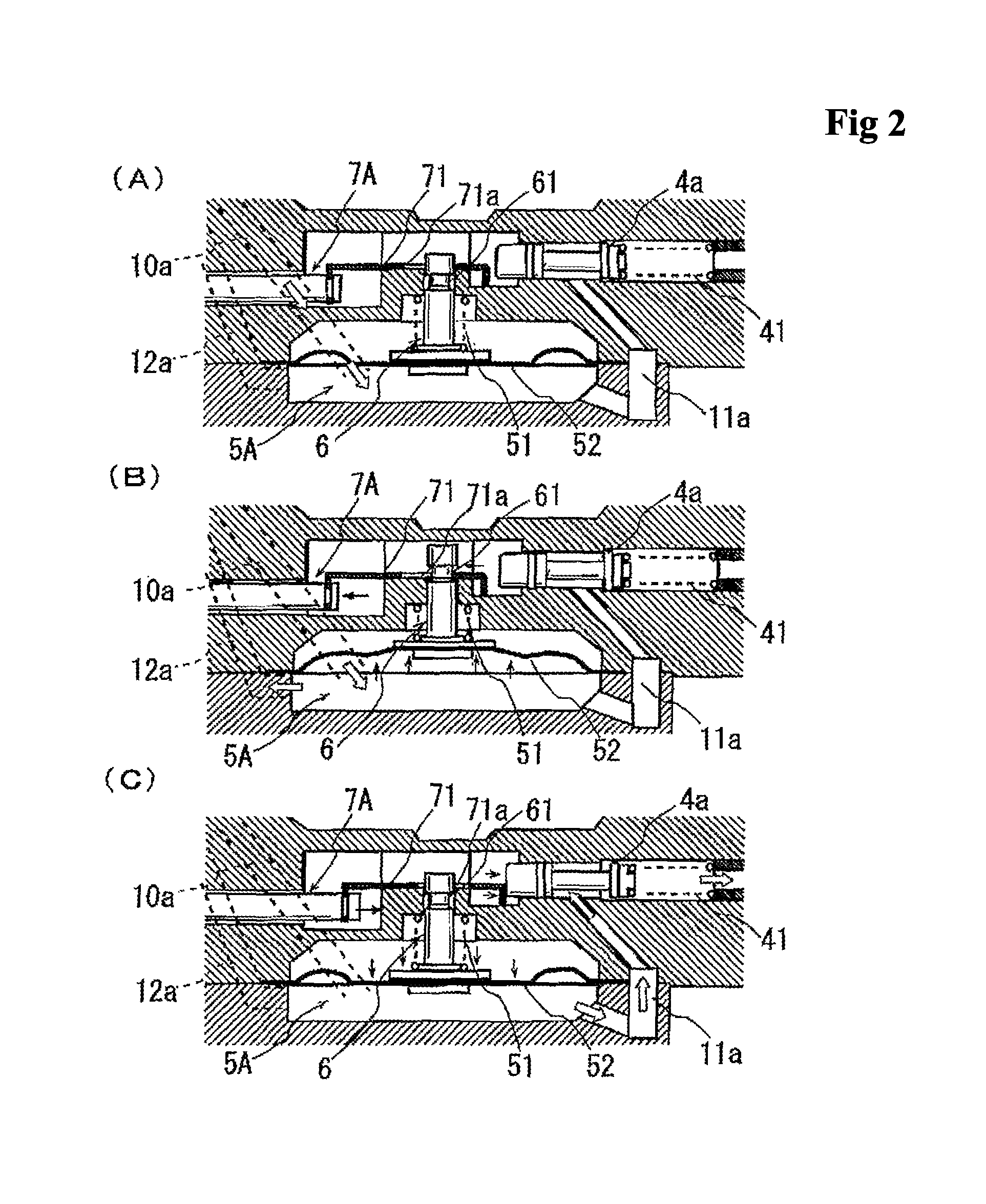

Starting device and carburetor using same

ActiveUS20120055450A1Easy to operateSatisfactory performanceMachines/enginesLiquid fuel feedersNuclear engineeringCarburetor

A starting device for feeding a quantity of fuel from the fixed-quantity fuel chamber to an intake passage during start-up having a manually operated primary pump for suctioning / pumping fuel and arranged on a fuel introduction path connected along a fuel-feeding path; and a fixed-quantity fuel chamber for temporarily storing fuel delivered from the primary pump. An internal wall of the fixed-quantity fuel chamber undergoes elastic displacement, allowing its internal capacity to expand / shrink within a predetermined range; the fixed-quantity fuel chamber is connected to a fuel delivery path that communicates with the intake passage side and has a manually operated open / close valve; the valve is opened in a state in which, due to the primary pump being operated, the fixed-quantity fuel chamber is filled with a predetermined quantity of fuel while enlarging its internal capacity, whereby it shrinks due to an elastic contraction force and the fuel.

Owner:ZAMA JAPAN

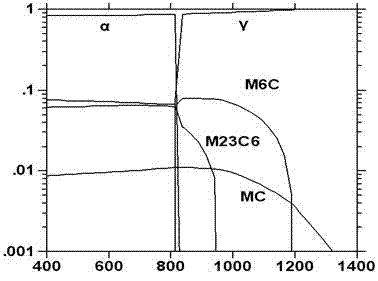

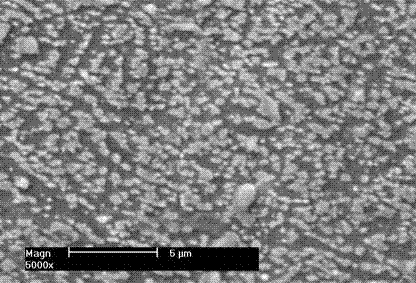

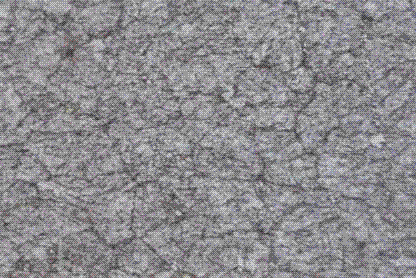

Semi-high speed steel copper soldering inlaid steel cutting blade and manufacturing method thereof

ActiveCN102776446BImprove sharpnessImprove impact toughnessFurnace typesMetal working apparatusTemperingSoldering

The invention discloses a semi-high speed steel copper soldering inlaid steel cutting blade and a manufacturing method thereof, which belong to the field of mechanical blades. The cutting blade is manufactured by welding a semi-high speed shear steel on a cutter body through copper soldering, wherein the semi-high speed shear steel comprises the following chemical elements by weight percent: 0.56-0.65% of C, 0.40-0.60% of Si, 0.25-0.40% of Mn, 6.0-6.8% of Cr, 1.6-2.5% of W, 4.2-5.2% of Mo, 0.7-0.9% of V, 0.1-0.2% of Nb, 0.3-0.4% of one of Co or Ni, no more than 0.02% of S, no more than 0.025% of P and the balance of Fe. The method for preparing comprises: smelting the semi-high speed shear steel, carrying out forging rolling at 870 DEG C-1080 DEG C, and then annealing; secondarily, heating to 1160 DEG C-1180 DEG C, carrying out copper soldering to inlay steel, and quenching at the same time; and finally, tempering. The cutting blade has the same hardness as the original high speed steel copper soldering inlaid steel cutting blade, but has higher sharpness, and is easy for cutter sharpening, and the material cost and the technological cost are lowered.

Owner:ANHUI JIALONG KNIVES MFG

Preparation method for semi-high speed steel

The invention discloses a preparation method for semi-high speed steel. The method includes the steps of (1) smelting, (2) forging and rolling, (3) annealing, (4) simultaneous copper brazing and quenching, and (5) tempering. In the step of smelting, smelting is conducted through an electric induction furnace, or electroslag remelting is conducted after smelting through the electric induction furnace; the semi-high speed shear steel is composed of, by weight percentage, 0.56%-0.65% of C, 0.40%-0.60% of Si, 0.25%-0.40% of Mn, 6.0%-6.8% of Cr, 1.6%-2.5% of W, 4.2%-5.2% of Mo, 0.7%-0.9% of V, 0.1%-0.2% of Nb, 0.3%-0.4% of Co or Ni, 0-0.02% of S, 0-0.025% of P, and the balance Fe. The hardness of a paper cutting blade made of the semi-high speed steel is identical with that of an original paper cutting blade which is manufactured through copper brazing and high-speed steel inlaying, but the sharpness is higher, blade sharpening is easy, and material cost and process cost are reduced.

Owner:CHONGQING CHUNGU MACHINERY MFG CO LTD

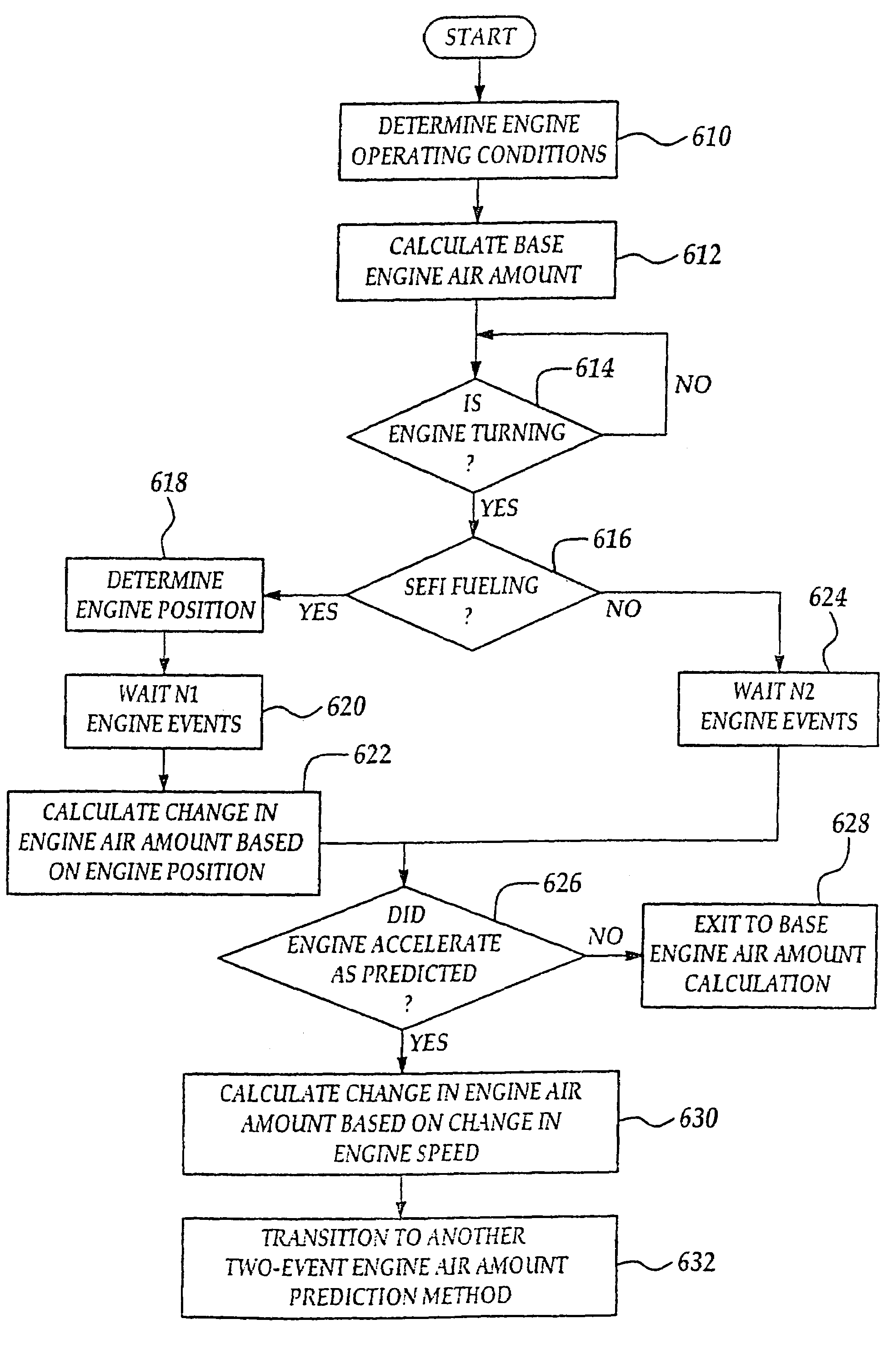

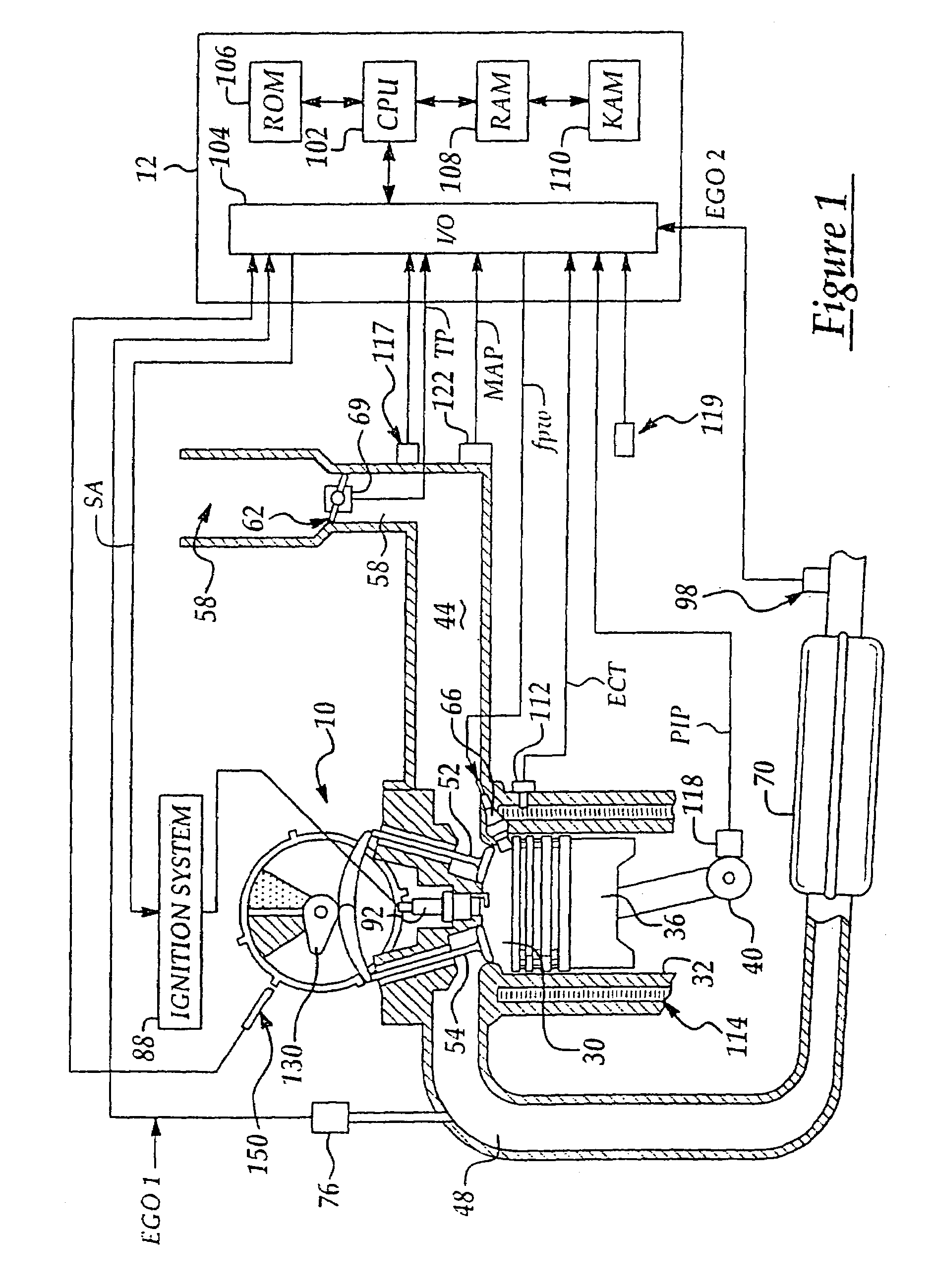

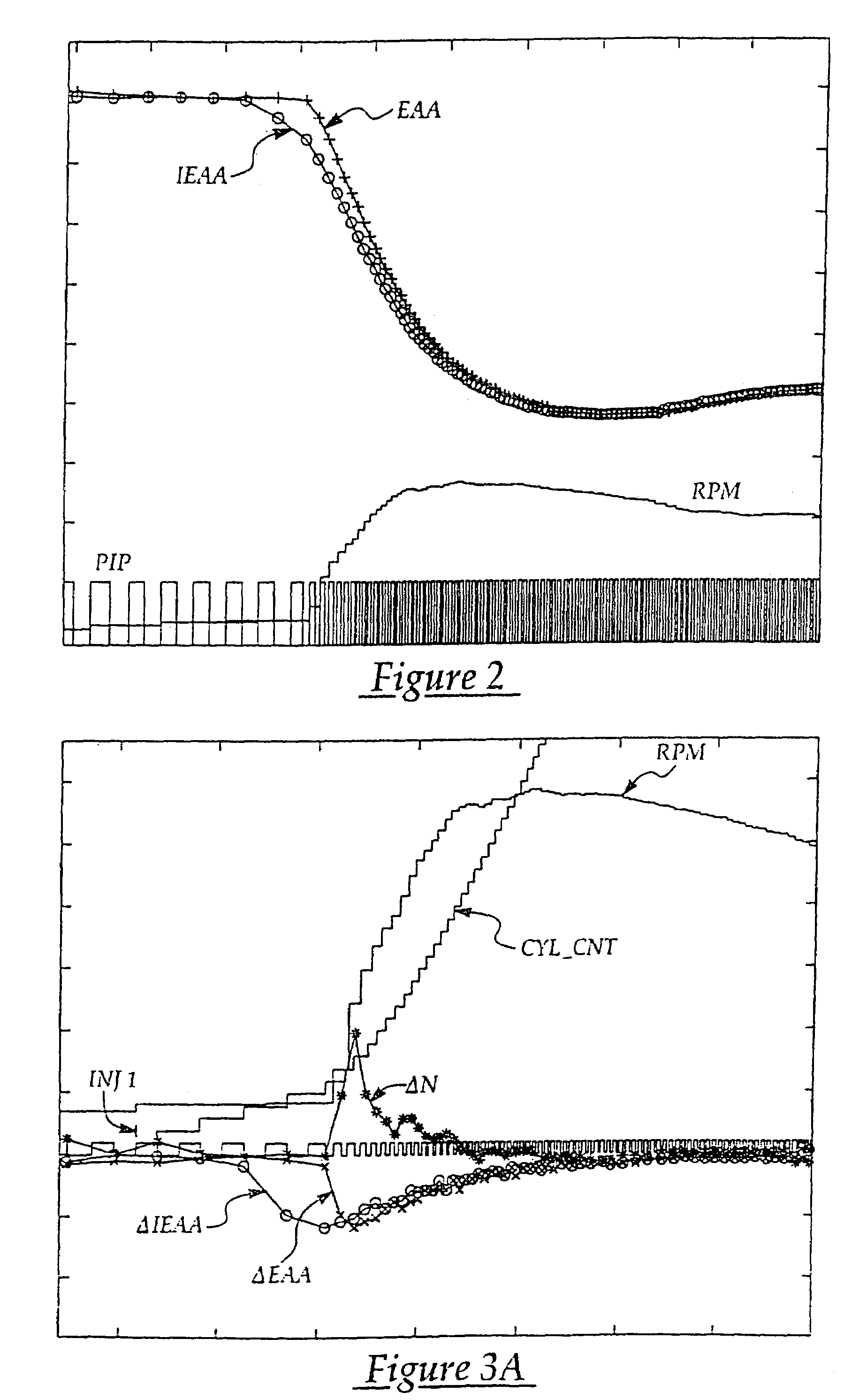

Engine air amount prediction based on engine position

InactiveUS6990960B2Accurate predictionReduce restrictionsElectrical controlFuel injection apparatusAir volumeInternal combustion engine

A system and method to predict engine air amount for an internal combustion engine is described. Included is a method to predict a change in engine air amount based on engine position. This method especially suited to engine starts, where engine air amount is difficult to predict due to low engine speed and limited sensor information. The system and method provides the prediction of engine air amount without extensive models or calibration. Fuel is supplied based on the predicted engine air amount.

Owner:FORD GLOBAL TECH LLC

Method for cultivating potatoes

InactiveCN107278601AIncrease productionGuaranteed water storage and moisturizing abilityFertilising methodsSeed immunisationSolanum tuberosumLand preparation

The invention relates to a method for cultivating crops, in particular to a method for cultivating potatoes. The invention includes methods such as soil preparation, base fertilizer application, seed potato treatment, ridging and sowing, field management and the like, and the potato can be cultivated through the cultivation method of the invention, which can effectively increase yield.

Owner:徐州腾丰食用菌科技有限公司

Centrifugal separator having oil coating on sidewalls

ActiveUS9863296B2Avoid and reduce sticky agglomerationReliable and efficient separation of gasMachines/enginesCentrifugesCentrifuge rotorInlet channel

A centrifugal separator for cleaning crankcase gas, containing oil, from an internal combustion engine, includes a stationary casing defining a separation space and including a first end portion, an opposite second end portion and an inner wall surface facing the separation space. The separator also includes an inlet channel for the gas to be cleaned, a gas outlet channel for the cleaned gas and an oil outlet for the separated the oil. A centrifuge rotor is provided in the separation space and includes a spindle and a plurality of separation discs carried by the spindle. The centrifuge rotor is rotated to create a rotating gas volume. An oil supply device supplies such a quantity of oil to the separation space that a flowing oil film is created on the inner wall surface during operation of the centrifugal separator.

Owner:ALFA LAVAL CORP AB

Water purifier

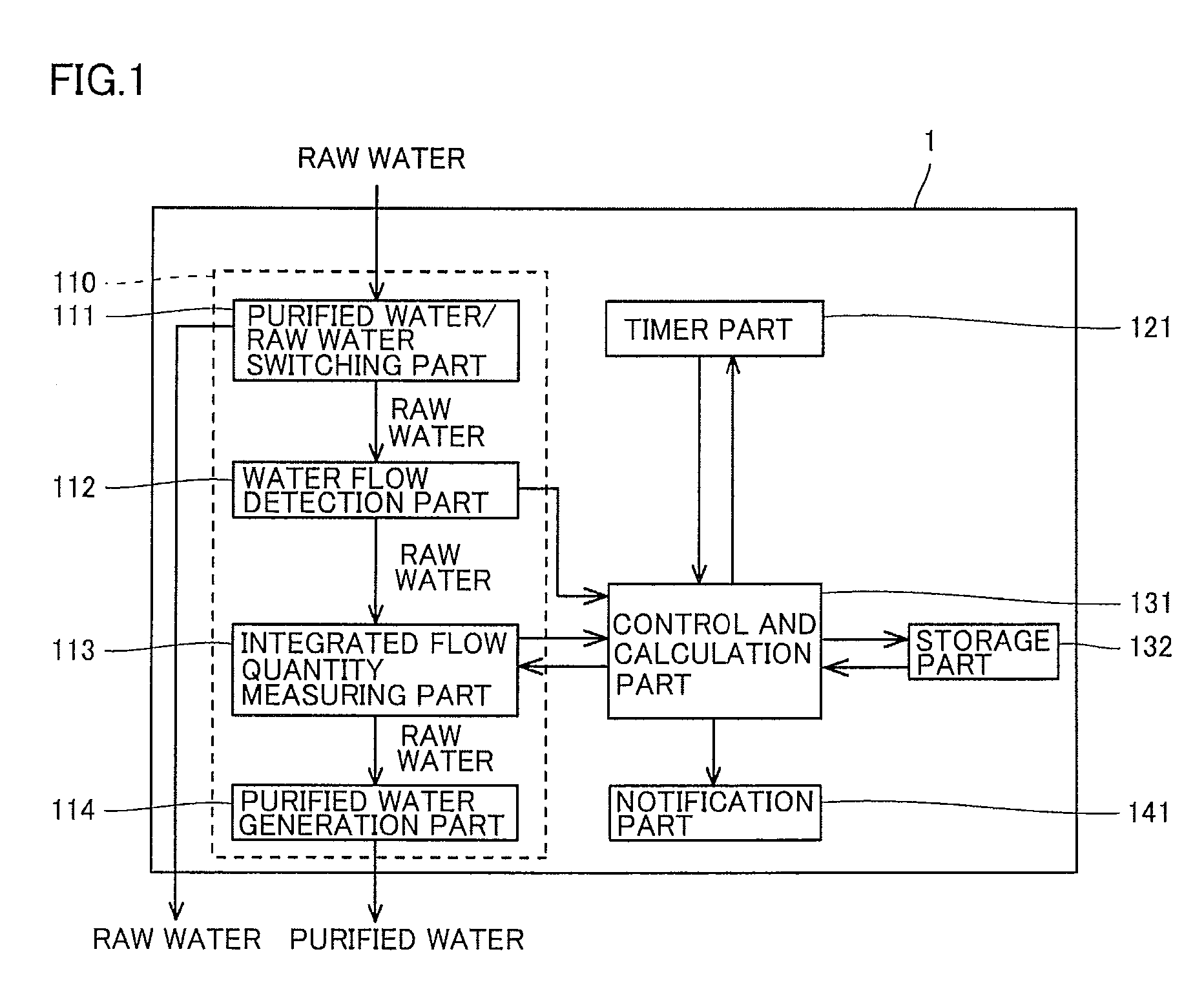

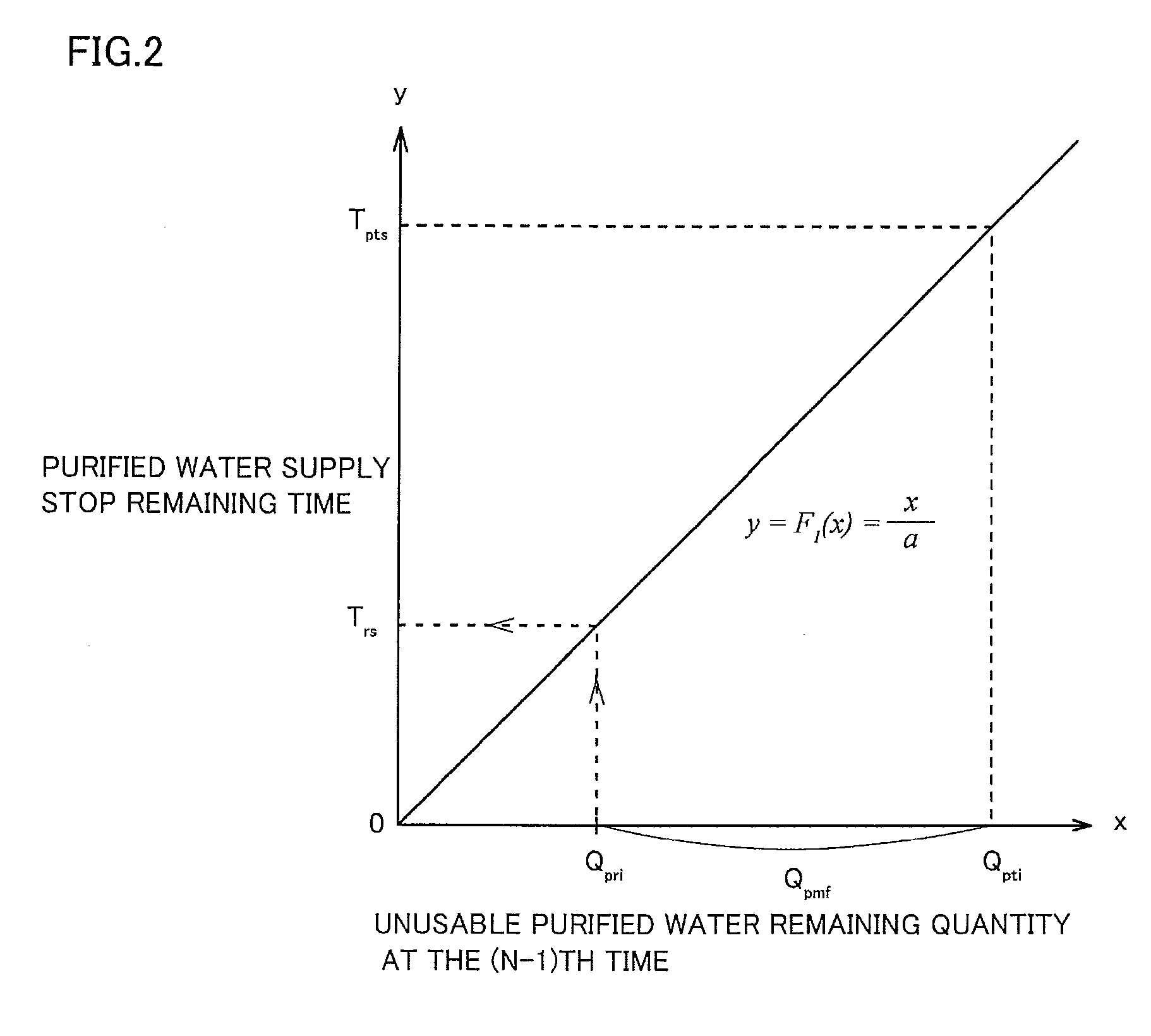

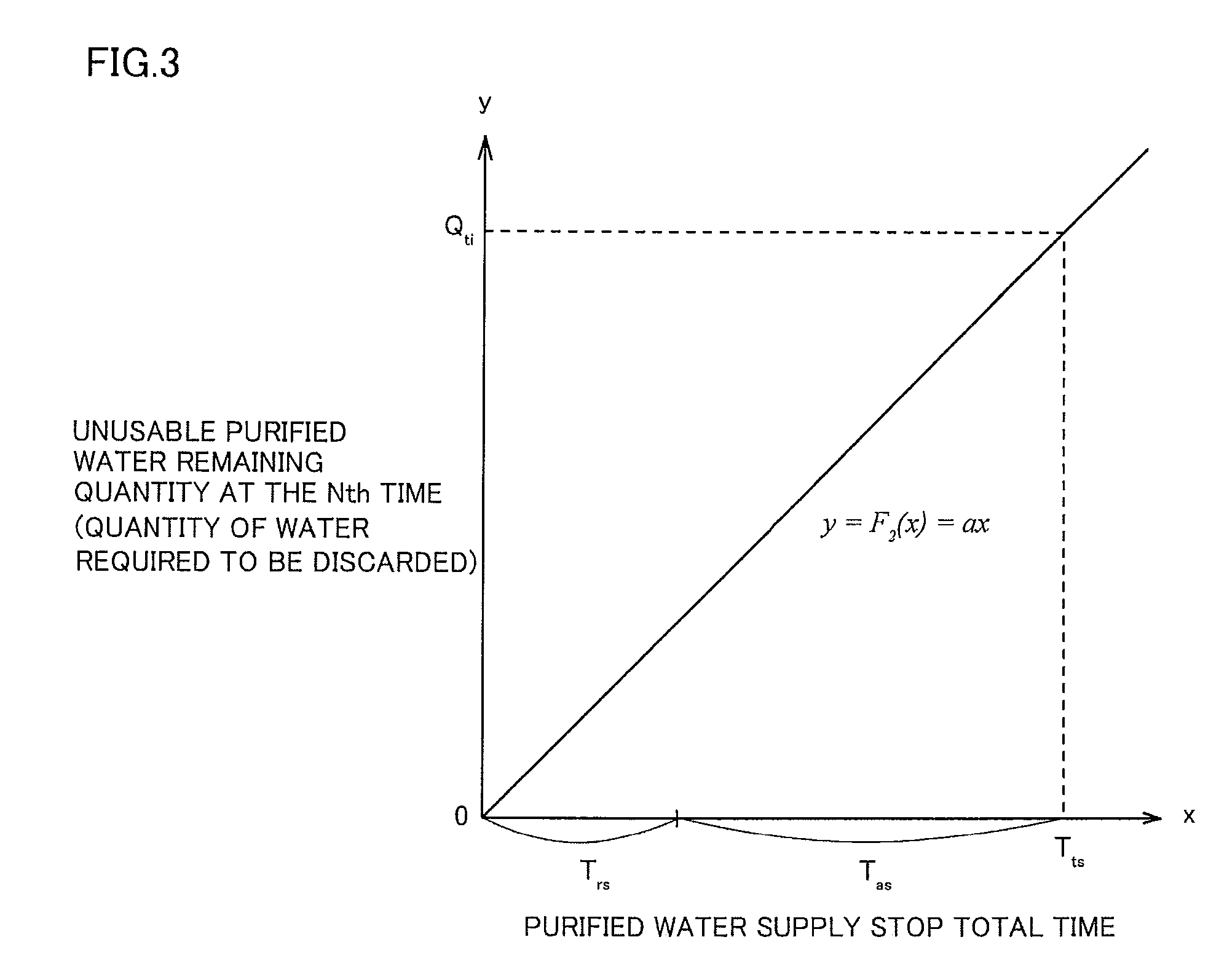

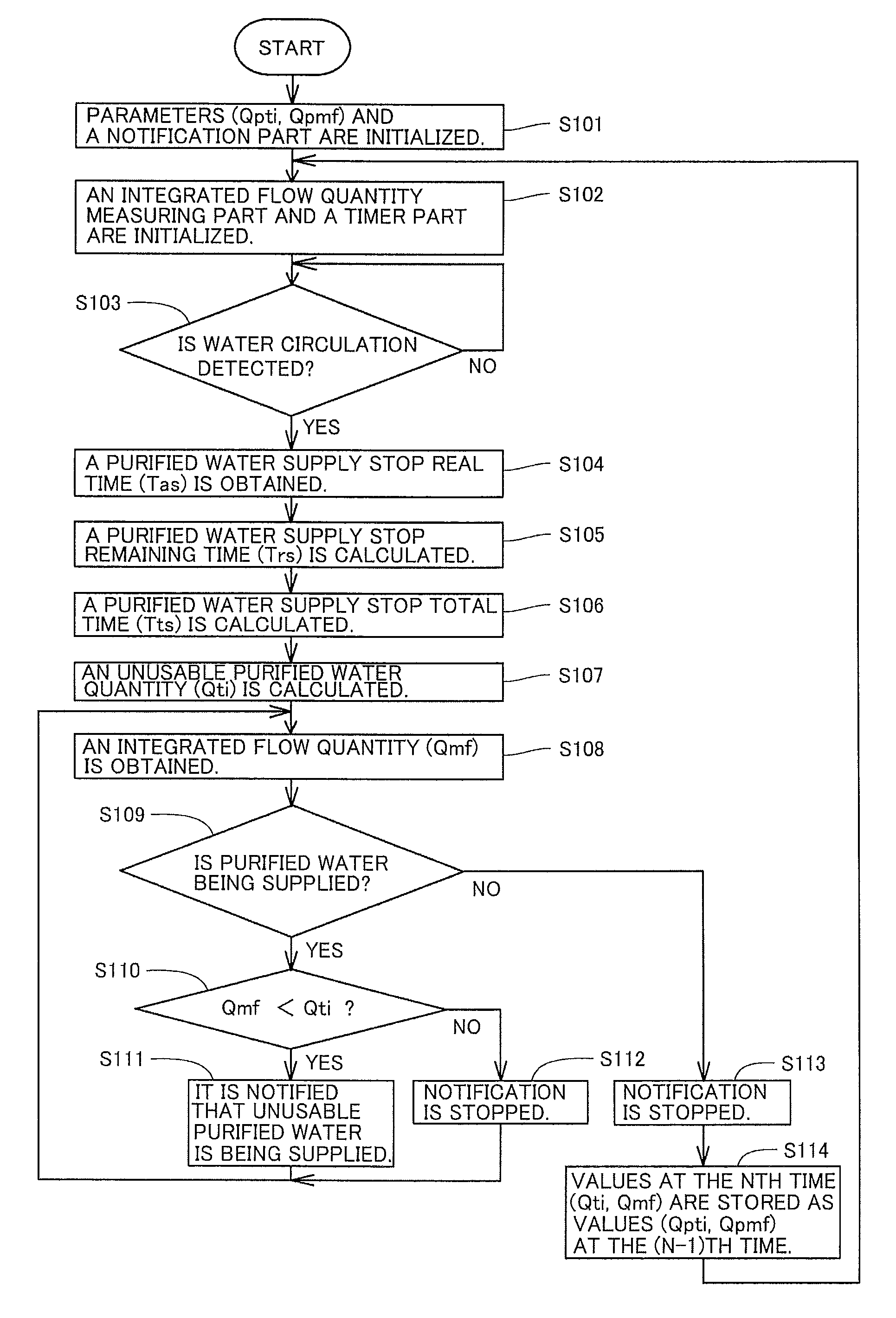

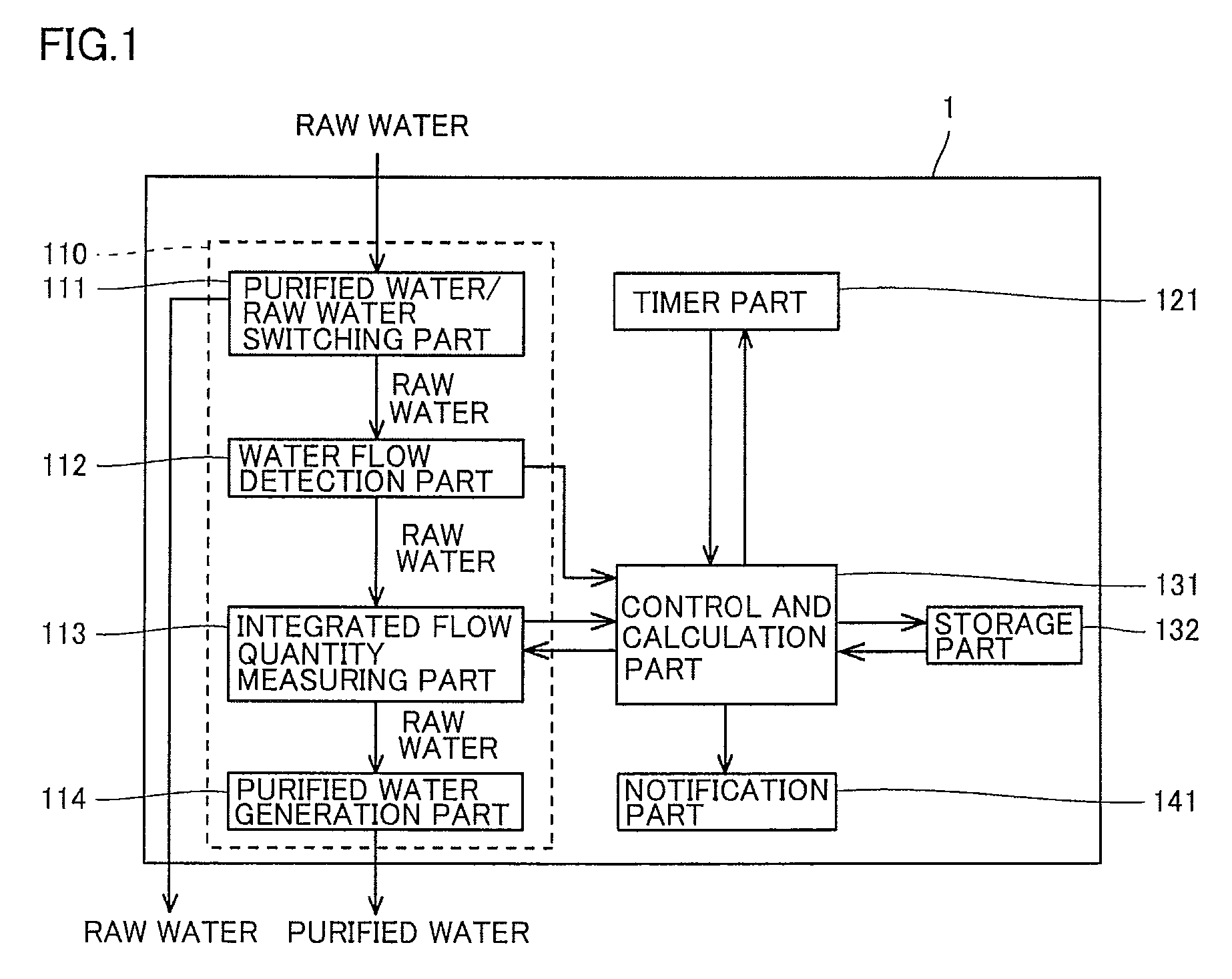

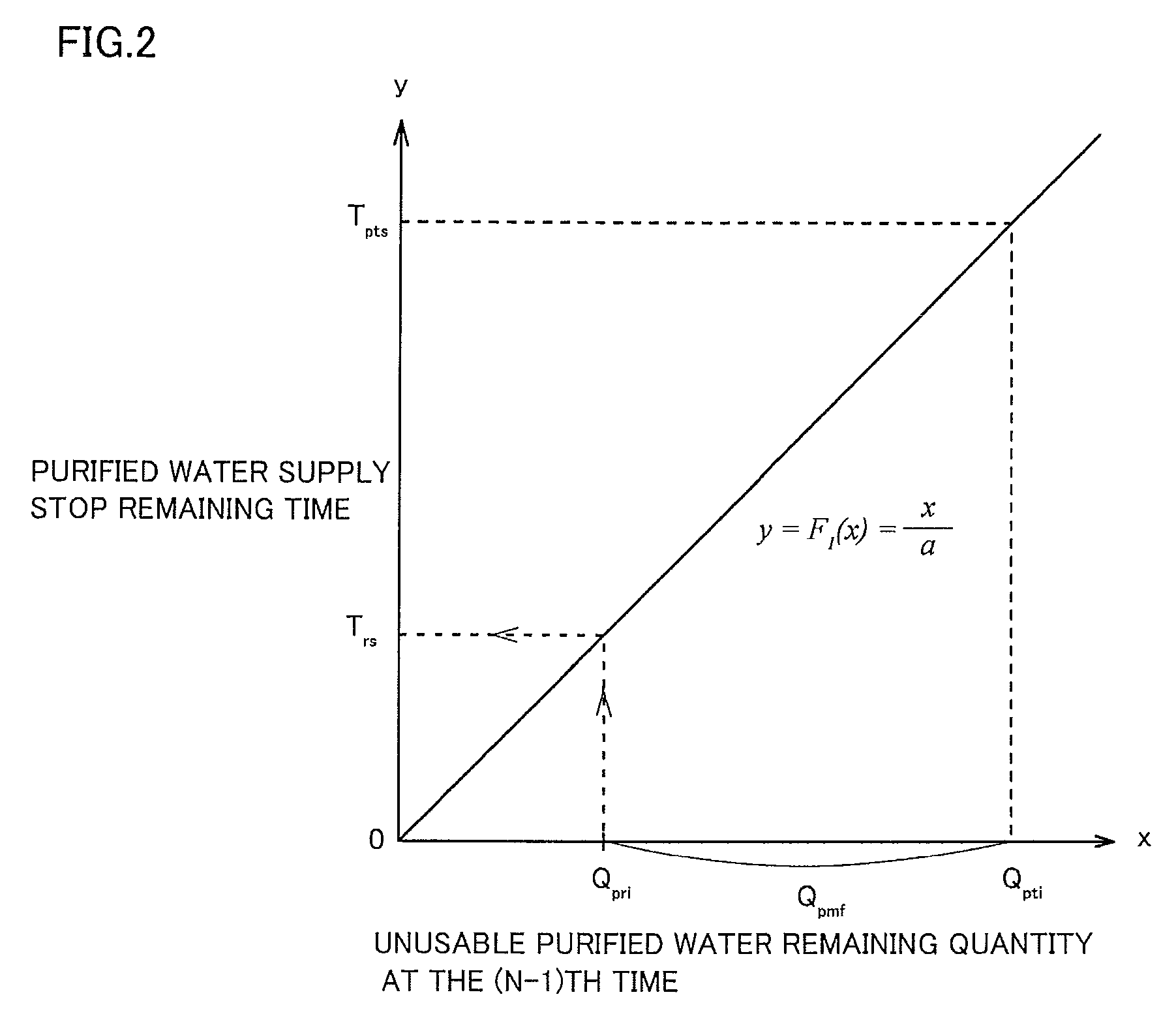

InactiveUS20120298567A1Increase the number ofAppropriate quantityWater treatment parameter controlTreatment involving filtrationEngineeringDischarge measurements

A water purifier determining an appropriate discarded water quantity includes: a purified water supply; an integrated flow quantity measuring part; and a control and calculation part. The control and calculation part is configured to determine whether purified water is unsuitable for use based upon the integrated flow quantity measured for a period of time from when the supply is started. A value of water quantity Qti at the Nth time is determined based on a length of time from when the purified water supply stops the supply at the (N−1)th time up to when the purified water supply starts the supply at the the Nth time; and a difference between a quantity of water measured for a period of time from when the supply at the (N−1)th time is started to when the supply at the (N−1)th time is stopped and a value of Qti at the (N−1)th time.

Owner:SHARP KK

Semi-high-speed steel

The invention discloses a semi-high-speed steel. The semi-high-speed steel is prepared from the following chemical elements in percentage by weight: 0.58-0.62% of C, 0.48-0.52% of Si, 0.28-0.38% of Mn, 6.12-6.60% of Cr, 1.82-2.28% of W, 4.45-4.94% of Mo, 0.76-0.81% of V, 0.13-0.16% of Nb, 0.32-0.38% of Co or Ni, S which is less than or equal to 0.02%, P which is less than or equal to 0.025%, and the balance being Fe. According to the semi-high-speed steel disclosed by the invention, the hardness of a paper cutting blade made from the semi-high-speed steel is the same as that of an original copper-brazed steel-inlaid paper cutting blade made from high-speed steel, but the sharp degree of the paper cutting blade made from the semi-high-speed steel is higher, the paper cutting blade made from the semi-high-speed steel is easy to sharpen, and the material cost and the technology cost are reduced.

Owner:CHONGQING GUIKUN MACHINERY CO LTD

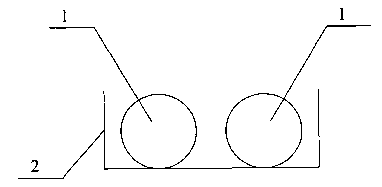

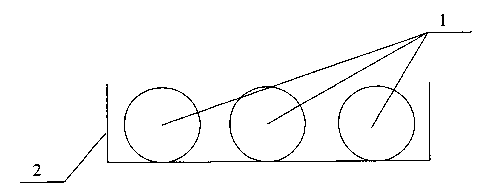

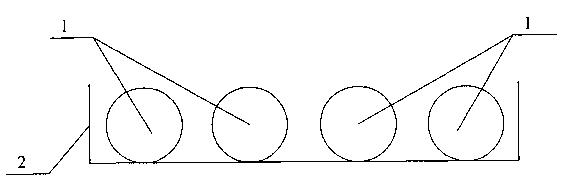

Spiral conveyer

InactiveCN103029965AImprove delivery capacityStrong conveying capacityPackagingSpiral bladeEngineering

The invention relates to a conveyer, in particular to a spiral conveyer. The spiral conveyer provided by the invention comprises spiral blades (1) and a material groove (2); and the spiral blades (1) are located inside the material groove (2). The quantity of the spiral blades (1) is more than or equal to two. Furthermore, the quantity of the spiral blades (1) is three to six. With the adoption of the technical scheme, the spiral conveyer provided by the invention has the following beneficial effects that (1) a plurality of the spiral blades are used, and are located in the material groove, the delivery capacity of the spiral conveyer can be effectively improved, the delivery capacity is strong, the delivery quantity is large, and the delivery efficiency is high; and (2) the quantity of the spiral blades is three to six, the quantity is suitable, and the spiral conveyer is convenient to machine and maintain.

Owner:溧阳市保珠建材厂

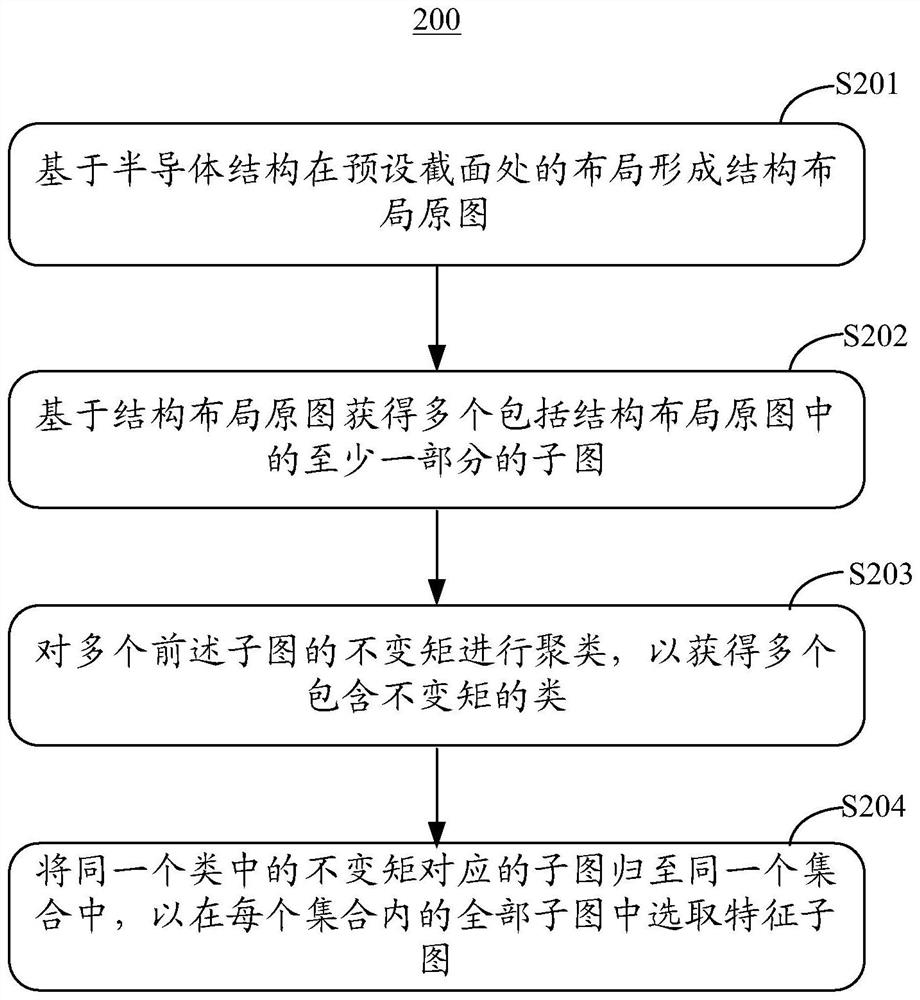

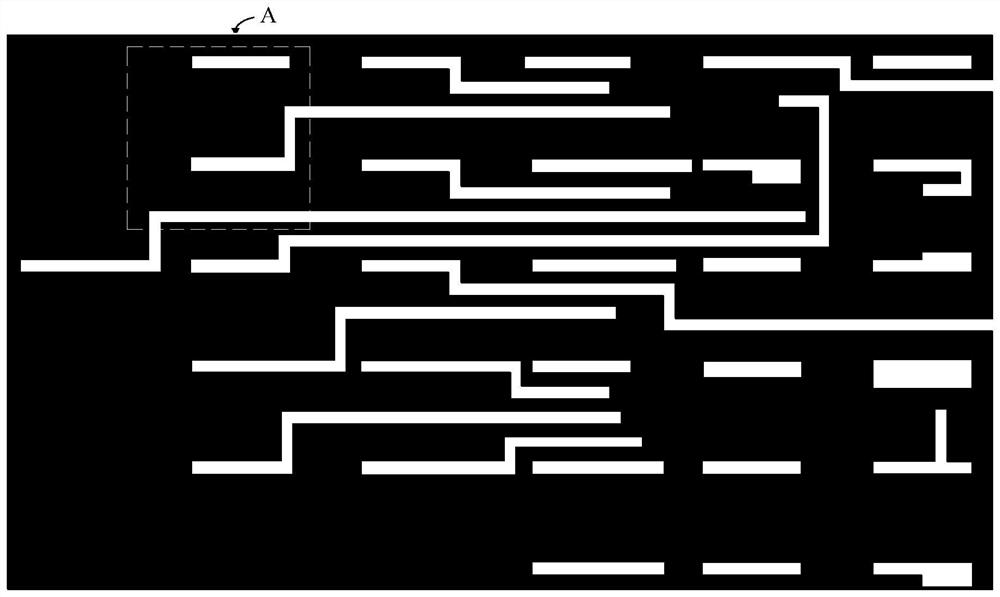

Method, device and system for decomposing layout of semiconductor structure and storage medium

ActiveCN113554091AAppropriate quantityGood representationCharacter and pattern recognitionComputer aided designGraph basedAlgorithm

The invention provides a method, a device and a system for decomposing the layout of a semiconductor structure and a storage medium. The method comprises the following steps: forming a to-be-decomposed structural layout original graph based on the layout of a semiconductor structure at a preset section; obtaining a plurality of sub-graphs comprising at least one part of the structural layout original graph based on the structural layout original graph; clustering the invariant moments of the plurality of sub-graphs to obtain a plurality of classes containing the invariant moments; and classifying the sub-graphs corresponding to the invariant moments in the same class into the same set so as to select feature sub-graphs from all the sub-graphs in each set.

Owner:YANGTZE MEMORY TECH CO LTD

A decision-making method for the construction of urban public service facilities that affects population density

ActiveCN112966899BEfficient determinationQuick fixData processing applicationsComplex mathematical operationsQuantile regressionRegression analysis

The invention discloses a decision-making method for the construction of urban public service facilities that affects population density. The urban space is divided into square geographic grid units with the same side length. On the basis of the urban population spatial distribution data, all types of interest point densities, different The density of interest points of functional type and the mixing degree of functional types of interest points are three parameter indicators that reflect the current development level of urban public service facilities, and a linear regression analysis between different indicators is carried out; the parameter indicators that pass the regression model test are further quantified Regression analysis, constructing the correlation and influence process between the population distribution data in the geographic grid unit and the public service facility indicators, and comprehensively judging the impact of public service facilities on regions with different population development stages. This method accurately reflects the types of public service facilities that should be prioritized in cities at different levels of population development, so as to improve the efficiency of population density and optimize the use efficiency of public service facilities.

Owner:PEKING UNIV

Starting device and carburetor supplying fixed amount of fuel

ActiveUS9194336B2Easy to operateSatisfactory performanceMachines/enginesLiquid fuel feedersCarburetorStart up

A starting device for feeding a quantity of fuel from the fixed-quantity fuel chamber to an intake passage during start-up having a manually operated primary pump for suctioning / pumping fuel and arranged on a fuel introduction path connected along a fuel-feeding path; and a fixed-quantity fuel chamber for temporarily storing fuel delivered from the primary pump. An internal wall of the fixed-quantity fuel chamber undergoes elastic displacement, allowing its internal capacity to expand / shrink within a predetermined range; the fixed-quantity fuel chamber is connected to a fuel delivery path that communicates with the intake passage side and has a manually operated open / close valve; the valve is opened in a state in which, due to the primary pump being operated, the fixed-quantity fuel chamber is filled with a predetermined quantity of fuel while enlarging its internal capacity, whereby it shrinks due to an elastic contraction force and the fuel.

Owner:ZAMA JAPAN

Method for breeding chamomile

InactiveCN102301952BHigh Inorganic Salt ConcentrationIncrease contentHorticulture methodsPlant tissue cultureBudCell budding

The invention discloses a method for breeding chamomile. The method disclosed by the invention comprises the following steps: (1) inoculating chamomile seeds onto a seed germination culture medium to carry out sterile seedling cultivation so as to produce sterile seedlings; (2) taking hypocotyls of the sterile seedlings as explants, inoculating the explants onto a callus induction culture medium to carry out callus induction culture so as to generate calluses by virtue of induction; (3) inoculating the calluses generated by induction onto an adventitious bud differentiation culture medium to carry out adventitious bud induction differentiation culture so as to obtain adventitious buds; (4) inoculating the adventitious buds onto a rooting culture medium to carry out rooting culture and culturing adventitious roots by virtue of induction so as to obtain rooted seedlings; and (5) hardening and transplanting the rooted seedlings so as to finally obtain the chamomile. In a regeneration system established by the method disclosed by the invention, callus inductivity reaches up to 86.63%, differentiation rate of the adventitious buds reaches up to 25.5%, rooting rate reaches up to 100%, and transplanting survival rate reaches up to 100%, thus a large number of excellent chamomile test-tube plantlets can be obtained in short term so as to realize large-scale factory production.

Owner:BEIJING FORESTRY UNIVERSITY

Rapid breeding method of senecio cruentus

InactiveCN101810144BHigh concentration of inorganic saltsIncrease contentPlant tissue cultureHorticulture methodsSenecioPlant tissue

The invention discloses a rapid breeding method of senecio cruentus, belonging to the cultivation field of plant tissues. The method comprises the following steps of: (1) serving senecio cruentus seeds as explants; (2) cultivating cluster buds by induction; (3) cultivating strong seedlings; (4) cultivating calluses by induction; (5) cultivating the calluses by enrichment; (6) cultivating adventitious buds by differentiation; (7) cultivating adventitious roots by induction; and (8) hardening and transplanting seedlings, wherein a minimal medium adopted in each cultivation stage is an MS medium, and a growth regulating agent added in each cultivation stage is selected with optimum dosage and proportioning ratio after being tested by a orthogonal design. The senecio cruentus bred by the method has the advantages of strongly grown test-tube seedlings, high breeding coefficient and scale and industrial production, the average induced rooting rate reaches 94.68%, and the survival rate of transplantation reaches 100%.

Owner:BEIJING FORESTRY UNIVERSITY

Water purifier

InactiveUS8845887B2Increase the number ofAppropriate quantityTime indicationVolume/mass flow measurementEngineeringStreamflow

Owner:SHARP KK

Semi-high-speed shear steel

The invention discloses semi-high-speed shear steel. The semi-high-speed shear steel is composed of following chemical elements including, by weight, 0.66-0.7% of C, 0.35-0.5% of Si, 0.3-0.42% of Mn, 5.5-7% of Cr, 1.5-2.7% of W, 4.5-5% of Mo, 1-1.2% of V, 0.13-0.21% of Nb, 0.5-0.55% of Co, 0-0.01% of S, 0-0.02% of P, and the balance Fe. A copper-brazed steel-inlaid paper cutting blade prepared from the semi-high-speed shear steel has the same hardness as an original copper-brazed steel-inlaid paper cutting blade prepared from high-speed steel, but is higher in sharpness and easy to sharpen. Besides, material cost and process cost are reduced.

Owner:CHONGQING LINGYUN TOOLS CO LTD

A height-limited solder preform

ActiveCN106475702BReasonable structureEasy to processWelding/cutting media/materialsSoldering mediaElectronic packagingSolder material

The invention relates to the technical field of soldering materials and particularly discloses a height-limited type solder preform. The height-limited type solder preform comprises a solder preform matrix and metal wires. The solder preform matrix is in a cuboid shape. One length*width surface of the solder preform matrix is provided with at least two grooves parallel to the width edge of the surface. The length of each groove is equal to that of the width edge of the surface. The depth of each groove is smaller than that of the solder preform. The dimensions of each metal wire are equal to that of each groove, and each metal wire can be just embedded into the corresponding groove to be fixed. The melting point of each metal wire is 300 DEG C or above higher than that of the solder preform matrix. The preparation process of the height-limited type solder preform is simple and easy to operate. The height-limited type solder preform is low in cost, stable in soldering thickness, high in uniformity, low in voidage, and particularly suitable for high-reliability soldering having a certain requirement for the height of a solder layer in the process of electronic packaging.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

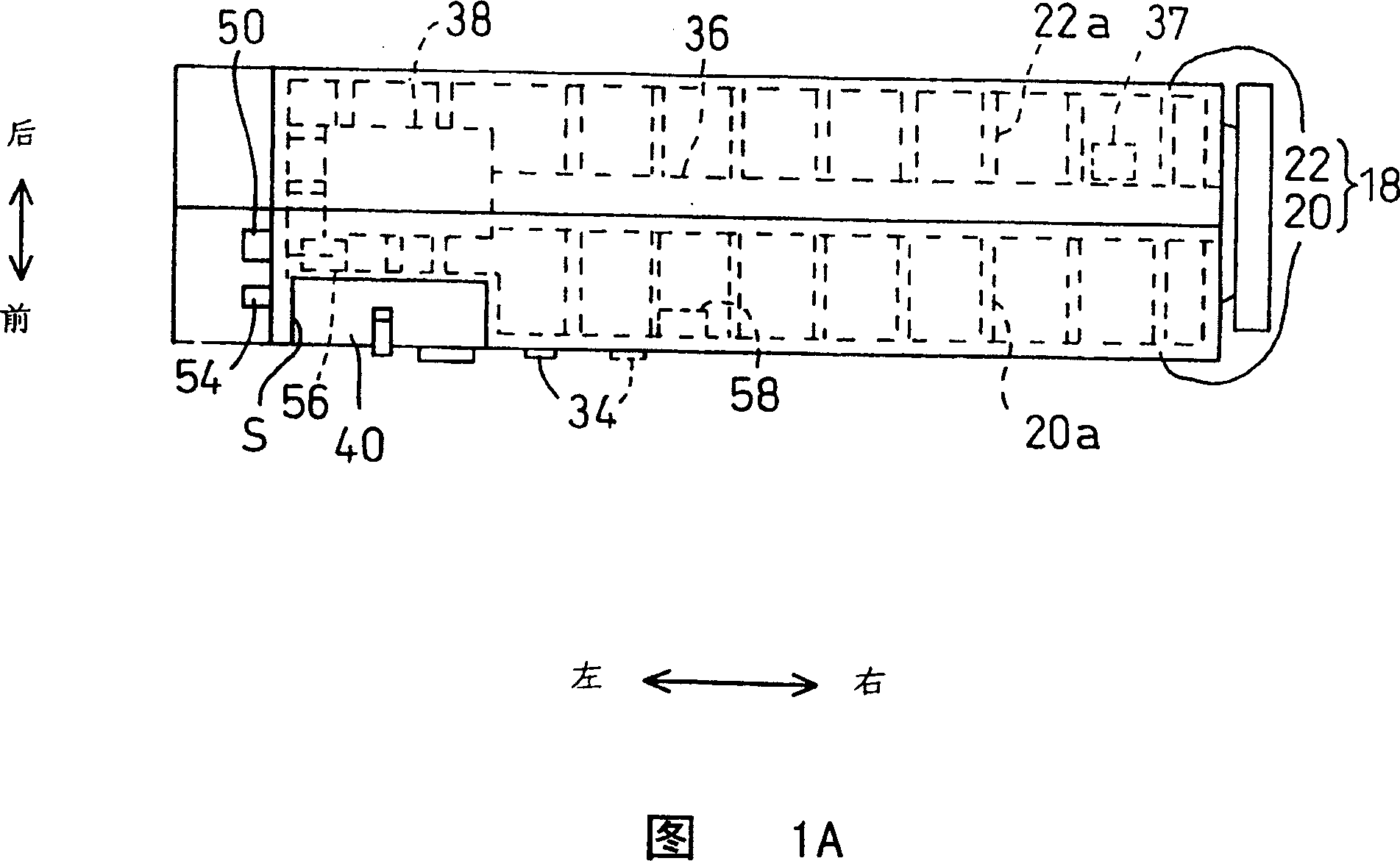

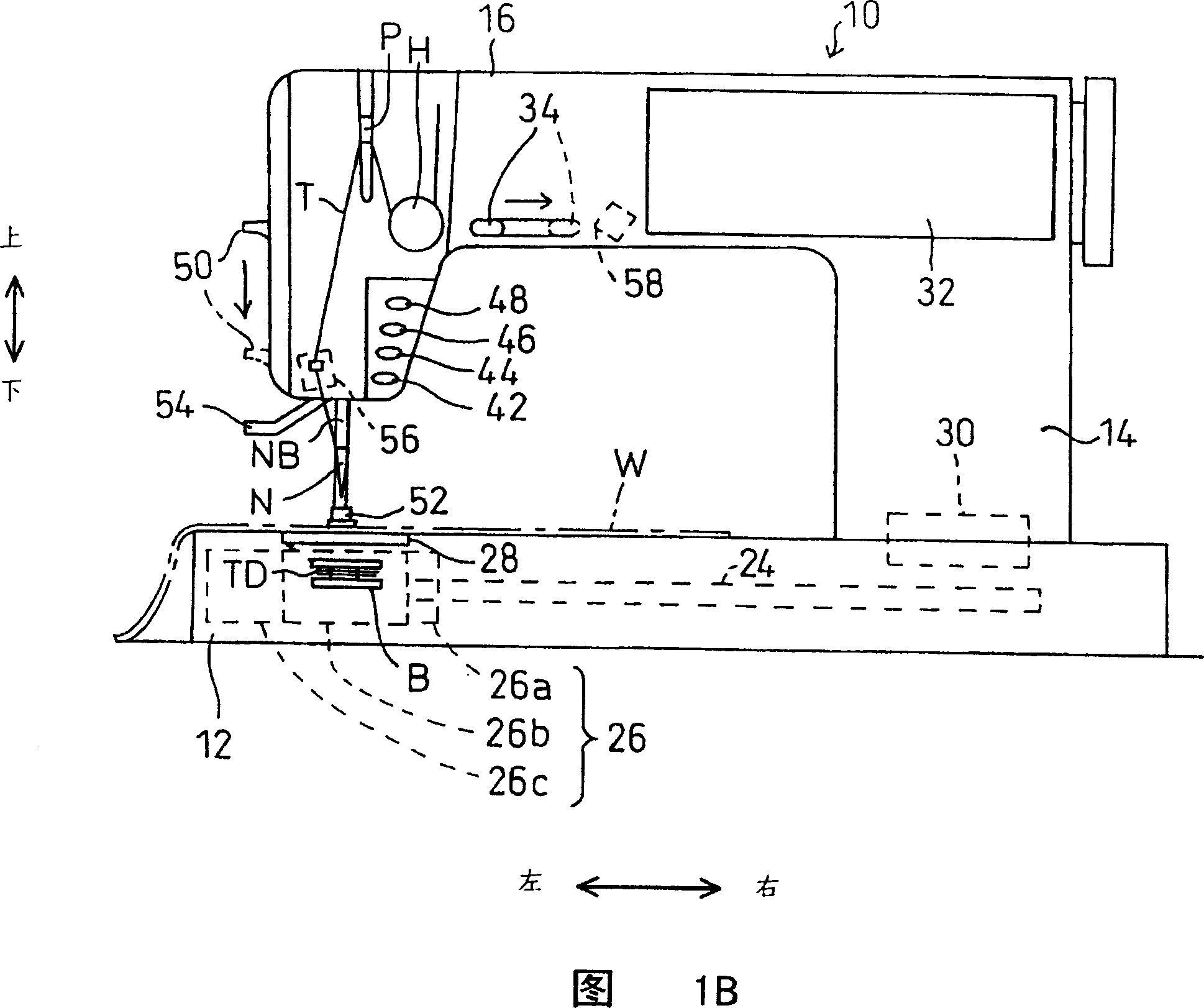

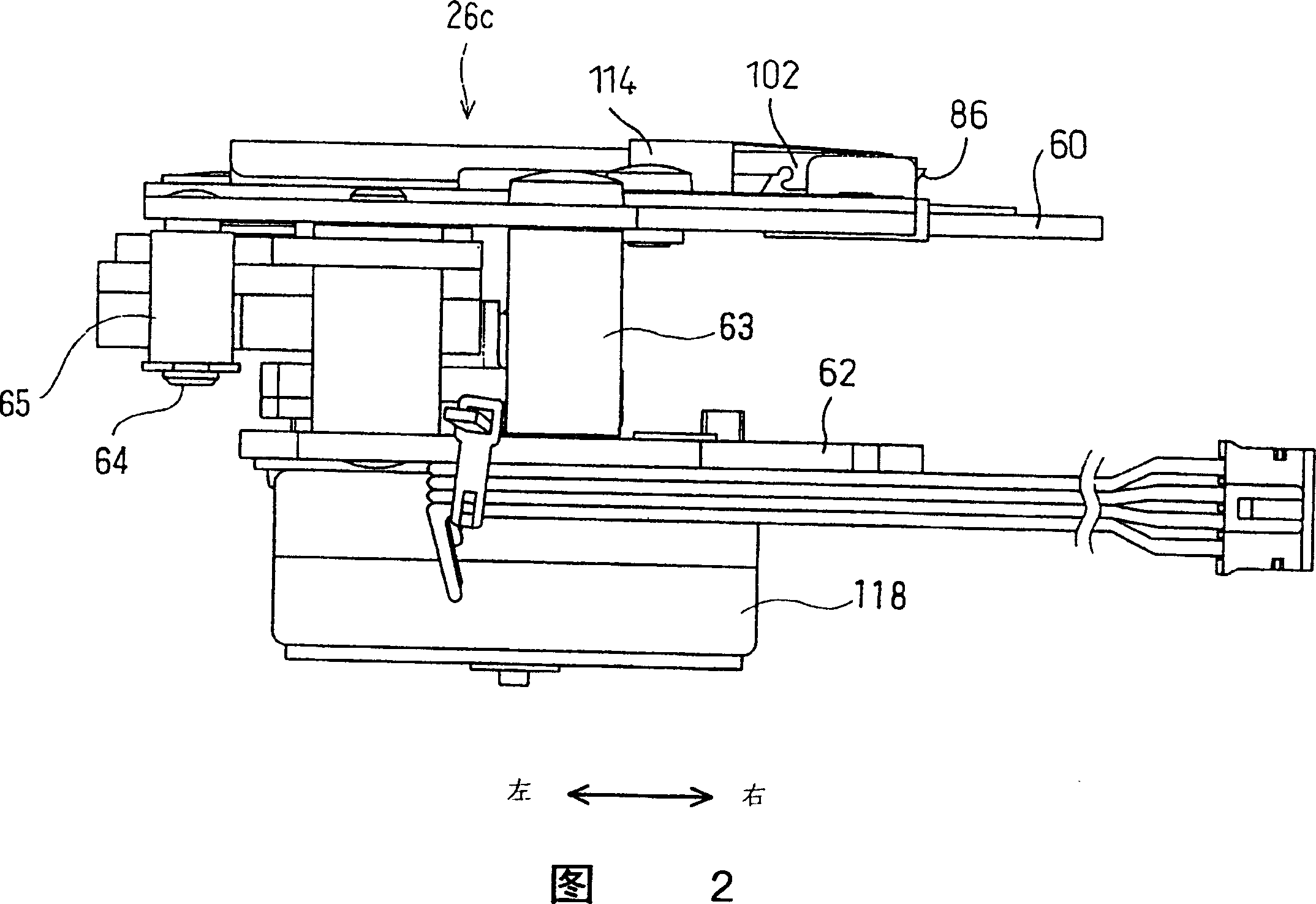

Sewing machine with improved thread cutting mechanism

InactiveCN100363548CAppropriate quantityProgramme-controlled sewing machinesNeedle severing devicesReciprocating motionSewing needle

A sewing machine includes a needle plate having a needle hole through which a sewing needle is allowed to pass, a thread catcher reciprocally moved forward and backward below the needle plate and being elongated in a moving direction, the thread catcher having a frontward end with respect to a direction of forward movement of the thread catcher and including first and second generally hook-shaped catching portions, and a cutting blade located between the first and second catching portions at least during backward movement of the thread catcher to cut a thread caught between the first and second catching portions. The first catching portion is located nearer to the frontward end of the thread catcher than the second catching portion with respect to the moving direction of the thread catcher during forward movement of the thread catcher. The first catching portion is further spaced from and located nearer to the needle hole of the needle plate than the second catching portion with respect to a direction perpendicular to the moving direction of the thread catcher. The thread catcher is moved backward so that the thread caught between the first and second catching portions intersects the cutting blade.

Owner:BROTHER KOGYO KK

Semi-high-speed steel

The invention discloses semi-high-speed steel. The semi-high-speed steel is composed of, by weight, 0.56%-0.65% of C, 0.40%-0.60% of Si, 0.25%-0.40% of Mn, 6.0%-6.8% of Cr, 1.6%-2.5% of W, 4.2%-5.2% of Mo, 0.7%-0.9% of V, 0.1%-0.2% of Nb, 0.3%-0.4% of Co, 0-0.02% of S, 0-0.025% of P, and the balance Fe. The strength of a paper cutting blade made from the semi-high-speed steel is identical with that of an original high-speed steel copper brazing steel plated paper cutting blade, but the paper cutting blade made from the semi-high-speed steel is higher in sharpness and easy to sharpen, and the material cost and process cost are reduced.

Owner:CHONGQING LINGYUN TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com