A height-limited solder preform

A preformed solder sheet and solder sheet technology, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem of difficulty in controlling the thickness of the metal alloy layer with uniform size, poor uniformity of solder layer thickness, and different degrees of dissolution and other problems, to achieve the effect of simple and easy welding conditions, fast welding speed and less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

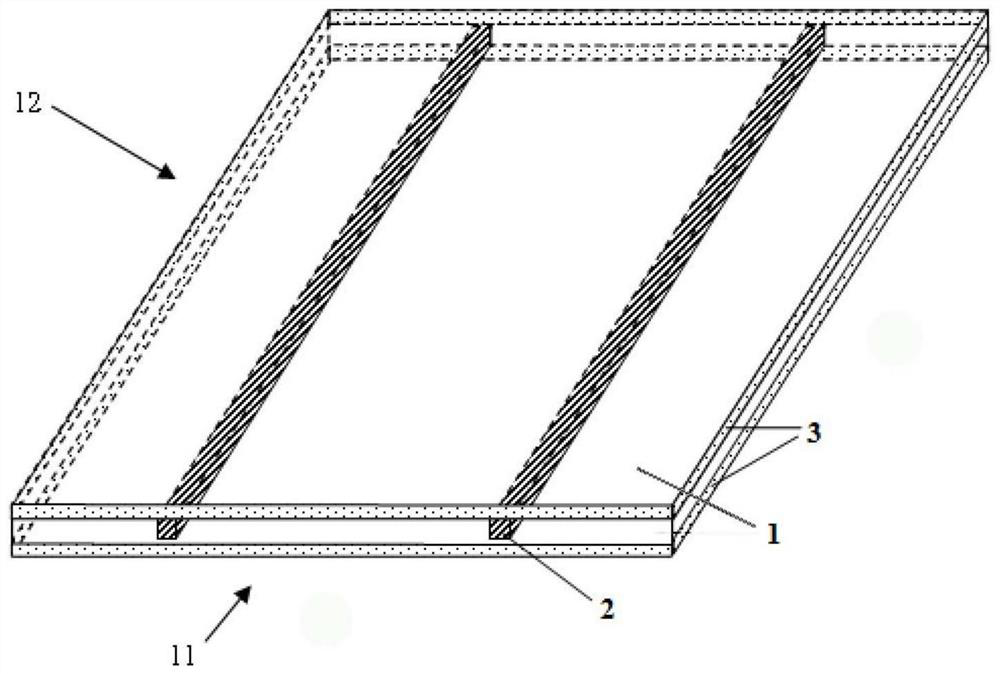

[0036] Such as figure 1 As shown, the solder preform with limited high performance of the present invention includes a solder base 1, a metal wire 2 and a flux layer 3;

[0037] The solder lug base 1 is a cuboid with length×width×thickness=6mm×6mm×0.2mm; one length×width surface of the solder lug base 1 is provided with two grooves parallel to the wide side 12, the concave The cross section of the groove is square, the length, width and depth of the groove are 6mm, 0.1mm and 0.1mm respectively, the metal wire is copper wire, the size of the metal wire 2 is the same as the groove, and it can just be embedded in the groove Fixed.

[0038] A layer of flux layer 3 with a thickness of 0.01-0.02 mm is coated on the surface of the solder chip substrate 1 embedded with the metal wire 2 .

[0039] Specifically, the flux composition of the flux layer 3 is: 1.5-2.5 parts of succinic acid, 1-2 parts of malonic acid, 1.5-3 parts of dibromobutenediol, 0.5-3 parts of triethanolamine hydroc...

Embodiment 2

[0043] Such as figure 1 As shown, the solder preform with limited high performance of the present invention includes a solder base 1, a metal wire 2 and a flux layer 3;

[0044] The solder lug base 1 is a cuboid with length×width×thickness=15mm×15mm×0.5mm; two grooves parallel to the wide side 12 are opened on a length×width surface of the solder lug base 1, and the concave The cross section of the groove is square, the length, width and depth of the groove are 15mm, 0.35mm and 0.35mm respectively, the metal wire is silver wire, and the size of the metal wire 2 is the same as that of the big and small grooves, which can just fit into the groove Fixed.

[0045] A layer of flux layer 3 with a thickness of 0.005-0.01 mm is coated on the surface of the solder chip substrate 1 embedded with the metal wire 2 .

[0046] Specifically, the composition of the flux layer 3 is: 1.5-2.5 parts of succinic anhydride, 3.8-4.5 parts of glutaric acid, 2.5-3 parts of dibromobutenediol, 0.8-1 p...

Embodiment 3

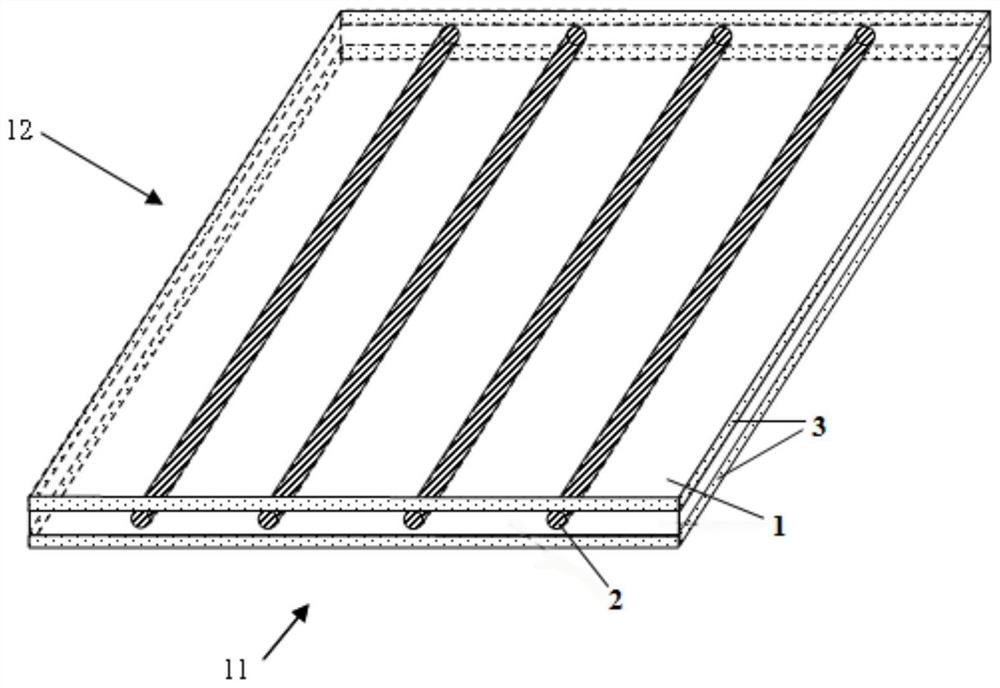

[0049] Such as figure 2 As shown, the solder preform with limited high performance of the present invention includes a solder base 1, a metal wire 2 and a flux layer 3;

[0050] The solder lug base 1 is a cuboid with length×width×thickness=20mm×20mm×0.3mm; one length×width surface of the solder lug base 1 is provided with four grooves parallel to the wide side 12, the concave The cross section of the groove is circular, the length, width and depth of the groove are 10mm, 0.15mm and 0.15mm respectively, the metal wire is a copper-silver alloy wire, the diameter of the metal wire 2 is 0.15mm, and the length is 10mm, and Embedded in the groove fixed.

[0051] A layer of flux layer 3 with a thickness of 0.02-0.03 mm is coated on the surface of the solder chip substrate 1 embedded with the metal wire 2 .

[0052] Specifically, the composition of the flux layer 3 is: 2.5-3 parts of glutaric acid, 4-5 parts of suberic acid, 1-1.5 parts of dibromosuccinic acid, 0.5-1 part of dietha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com