Semi-high speed steel copper soldering inlaid steel cutting blade and manufacturing method thereof

A semi-high-speed steel and copper brazing technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of poor sharpness, low sharpness, and reduce the cost of blade steel alloy content, and achieve low cost and improve smoothness. , the effect of reducing material cost and process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

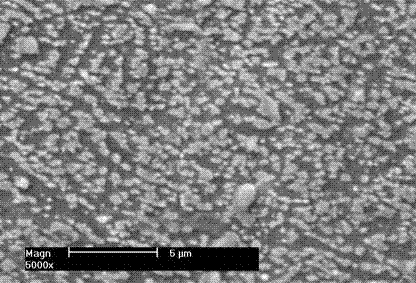

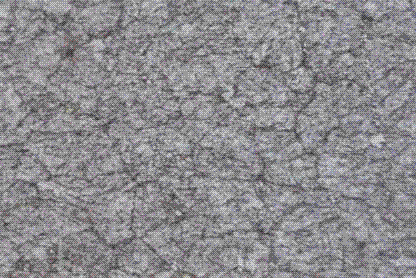

[0044] A semi-high-speed steel copper-brazed paper-cutting blade inlaid with steel in this embodiment, the paper-cutting blade is made of semi-high-speed steel blade steel 1 welded on the cutter body 3 through copper brazing, and the composition of the semi-high-speed steel blade steel 1 As shown in Table 1. Its concrete preparation method is as follows:

[0045] (1) Production of semi-high-speed steel blade steel:

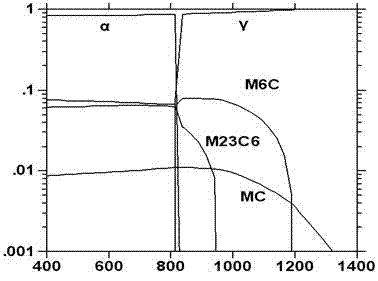

[0046] First prepare the semi-high-speed steel blade steel, adopt induction electric furnace or induction electric furnace+electroslag remelting to smelt the semi-high-speed steel blade steel, and the semi-high-speed steel blade steel satisfying the present invention is composed of the following chemical elements in weight percentage: C: 0.56~ 0.65%, Si: 0.40-0.60%, Mn: 0.25-0.40%, Cr: 6.0-6.8%, W: 1.6-2.5%, Mo: 4.2-5.2%, V: 0.7-0.9%, Nb: 0.1-0.2 %, one of Co or Ni: 0.3-0.4%, S≤0.02%, P≤0.025%, the rest is Fe and unavoidable impurities; the composition design of...

Embodiment 2

[0063] A semi-high-speed steel copper-brazed paper-cutting blade inlaid with steel in this embodiment, the paper-cutting blade is made of semi-high-speed steel blade steel 1 welded on the cutter body 3 through copper brazing, and the composition of the semi-high-speed steel blade steel 1 As shown in Table 1. Its concrete preparation method is as follows:

[0064] (1) Production of semi-high-speed steel blade steel:

[0065] First, the semi-high-speed steel blade steel is prepared, and the semi-high-speed steel blade steel is smelted by induction electric furnace or induction furnace + electroslag remelting. The composition of the semi-high-speed steel blade steel is shown in Table 1.

[0066] (2) Forging and rolling process:

[0067] The semi-high-speed steel blade steel smelted in step (1) is forged and rolled, and the forging and rolling temperature is 870°C to 930°C.

[0068] (3) Annealing:

[0069] Heat the semi-high-speed steel blade steel forged and rolled in step (2...

Embodiment 3

[0078] A semi-high-speed steel copper-brazed paper-cutting blade inlaid with steel in this embodiment, the paper-cutting blade is made of semi-high-speed steel blade steel 1 welded on the cutter body 3 through copper brazing, and the composition of the semi-high-speed steel blade steel 1 As shown in Table 1. Its concrete preparation method is as follows:

[0079] (1) Production of semi-high-speed steel blade steel:

[0080] First, the semi-high-speed steel blade steel is prepared, and the semi-high-speed steel blade steel is smelted by induction electric furnace or induction furnace + electroslag remelting. The composition of the semi-high-speed steel blade steel is shown in Table 1.

[0081] (2) Forging and rolling process:

[0082] The semi-high-speed steel blade steel smelted in step (1) is forged and rolled at a forging temperature of 940°C to 990°C.

[0083] (3) Annealing:

[0084] Heat the semi-high-speed steel blade steel forged in step (2) to 850°C, keep it warm fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com