Tool for strengthening blade through laser cladding technology

A laser cladding and technology technology, applied in metal material coating process, metal processing, coating, etc., can solve the problems of high requirements for cladding powder and production powder that does not meet the requirements, and achieve low cost, corrosion resistance and corrosion resistance. Improved abrasion resistance and fine and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

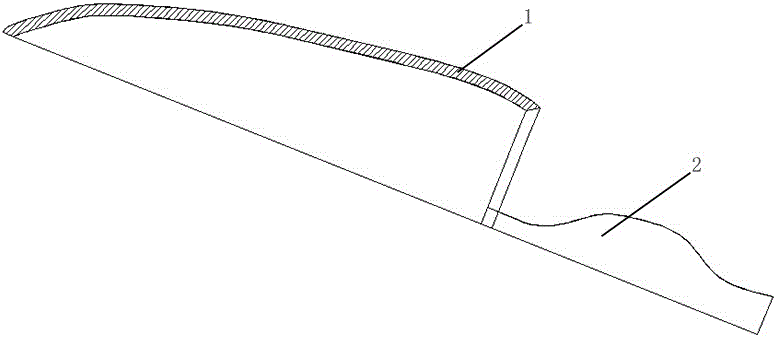

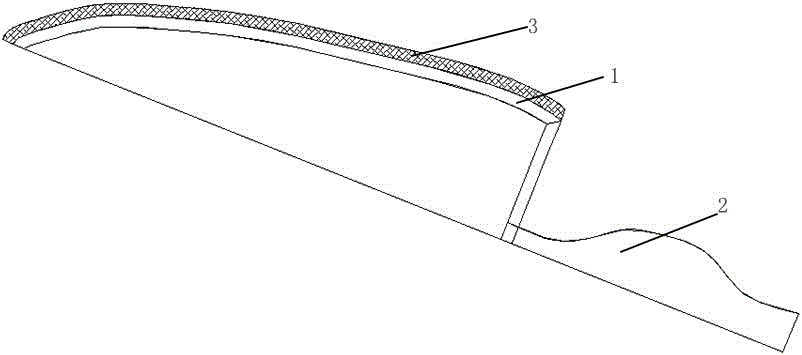

[0020] The cemented carbide mixed powder is a mixture of nickel-based alloy powder and tungsten carbide powder. The nickel-based alloy powder accounts for 70% by mass, and the tungsten carbide powder accounts for 30% by mass. The nickel-based alloy powder is composed of Cr : 18%, Fe: 5%, Nb: 2%, Mo: 8%, Al: 0.2%, Ti: 1.5%, C: 0.4%, Si: 0.2%, Mn: 0.2%, V: 1.5%, remaining The amount is Ni. The material of the cutter body to be clad is 3Cr13 and the thickness is 2.5mm; the cutter body is pretreated and polished with sandpaper to remove the oxide skin or rust spots on the cutting edge line 1, and the cladding part of the cutter body is cleaned with acetone to remove the surface dust and Oil stains, etc.; choose equipment and parameters for laser cladding on the blade: the laser is a semiconductor laser, coaxial powder feeding, laser cladding parameters: laser power 1300W, defocusing distance 10mm, cladding speed 5mm / s, The protective gas pressure is 0.1Mpa, the laser spot diamete...

Embodiment 2

[0023] The cemented carbide mixed powder is a mixture of nickel-based alloy powder and tungsten carbide powder. The nickel-based alloy powder accounts for 60% by mass, and the tungsten carbide powder accounts for 40% by mass. The nickel-based alloy powder is composed of Cr : 20%, Fe: 5%, Nb: 3%, Mo: 9.5%, Al: 0.3%, Ti: 2.0%, C: 0.5%, Si: 0.3%, Mn: 0.4%, V: 2.0%, remaining The amount is Ni. The material of the cutter body to be clad is 4Cr13 and the thickness is 3.0 mm; the cutter body is pretreated and polished with sandpaper to remove the oxide skin or rust spots on the cutting edge line 1, and the cladding part of the cutter body is cleaned with acetone to remove the surface dust and Oil stains, etc.; choose equipment and parameters for laser cladding on the blade: the laser is a fiber laser, using lateral powder feeding laser cladding, the laser cladding parameters are: laser power 1500W, defocusing distance 12mm, cladding speed 6 ㎜ / s, the protective gas pressure is 0.1Mpa...

Embodiment 3

[0026] The cemented carbide mixed powder is a mixture of nickel-based alloy powder and tungsten carbide powder. The nickel-based alloy powder accounts for 40% by mass, and the tungsten carbide powder accounts for 60% by mass. The nickel-based alloy powder is composed of Cr : 23%, Fe: 6%, Nb: 4.5%, Mo: 11%, Al: 0.4%, Ti: 2.5%, C: 0.6%, Si: 0.5%, Mn: 0.6%, V: 2.5%, remaining The amount is Ni. The material of the knife body to be clad is 4Cr13, and the thickness is 3.0mm; the knife body is pretreated and polished with sandpaper to remove the oxide skin or rust spots on the edge line 1, and the cladding part of the knife edge is cleaned with acetone to remove the dust and oil on the surface etc.; select the equipment and parameters for laser cladding on the blade: the laser is a fiber laser, using side-feeding laser cladding, the laser cladding parameters are: laser power 1800W, defocus distance 12mm, cladding speed 8mm / s, the protective gas pressure is 0.1Mpa, the laser spot di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com