Sn-S-based thermoelectric compound and preparation method thereof

A compound and thermoelectric technology, which is applied in the manufacture/processing of thermoelectric devices, and the material of thermoelectric device junction leads, etc., can solve problems that have not been reported by anyone, and achieve the effects of less time-consuming, fine and uniform structure, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

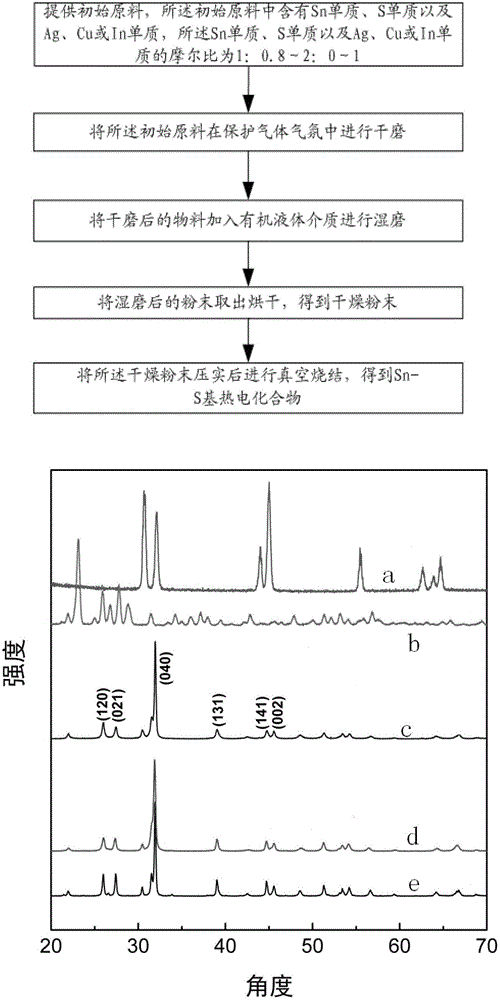

[0040] Specifically, the preparation method of the Sn-S based thermoelectric compound according to the embodiment of the present invention includes the following steps:

[0041] a) Provide initial raw materials, the initial raw materials contain Sn simple substance, S simple substance and Ag, Cu or In simple substance, the molar ratio of Sn simple substance, S simple substance and Ag, Cu or In simple substance is 1:0.8~2:0 ~1;

[0042] b) Dry grinding the initial raw material in a protective gas atmosphere;

[0043] c) adding the dry-milled material to an organic liquid medium for wet milling;

[0044] d) taking out and drying the wet-milled powder to obtain dry powder;

[0045] e) vacuum sintering the dry powder after compaction to obtain a Sn—S based thermoelectric compound.

[0046] Therefore, according to the method for preparing Sn—S-based thermoelectric compounds according to the embodiment of the present invention, the initial raw materials used are non-toxic and non...

Embodiment 1

[0060] Using tin (Sn) powder and sulfur (S) powder as the initial raw materials, weigh a total of 20g of powder according to the SnS chemical formula, put it into a stainless steel ball mill tank (volume 250mL), and add stainless steel grinding balls (grinding balls) of different diameters The weight ratio to powder is about 20:1). The ball mill tank was filled with high-purity argon as a protective gas, and dry-milled on a planetary ball mill (QM-2, Nanjing University Instrument Factory) at a speed of 450r / min for 15h. After dry grinding, absolute ethanol was added as the medium, and wet grinding was carried out at a speed of 350r / min for 90 min. The powder after wet grinding was taken out and dried, and the intermediate compound powder was formed through mechanical alloying (MA) reaction of dry grinding and wet grinding.

[0061] The intermediate compound powders were sintered in a spark plasma sintering furnace (SPS) at temperatures of 823K and 973K, respectively, to obtain...

Embodiment 2

[0064] Using tin (Sn) powder and sulfur (S) powder as initial raw materials, a total of 20 g of powder was weighed according to the chemical formula of SnS, and the intermediate compound powder was prepared according to the method described in Example 1.

[0065] The intermediate compound powder is sintered in a spark plasma sintering furnace at temperatures of 823K, 853K, 893K and 973K respectively to obtain a Sn-S-based thermoelectric compound block.

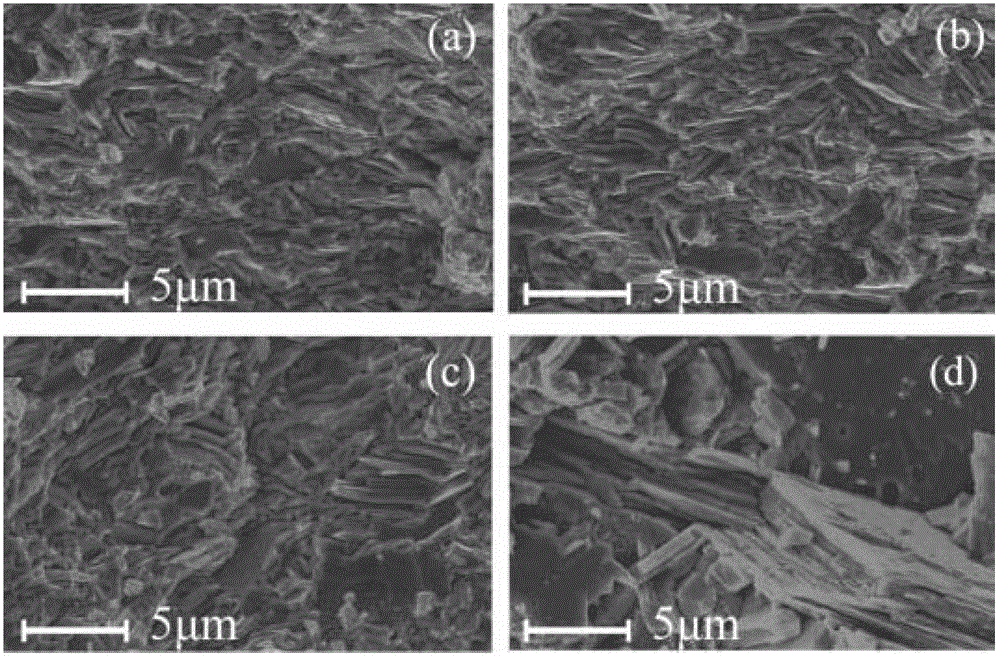

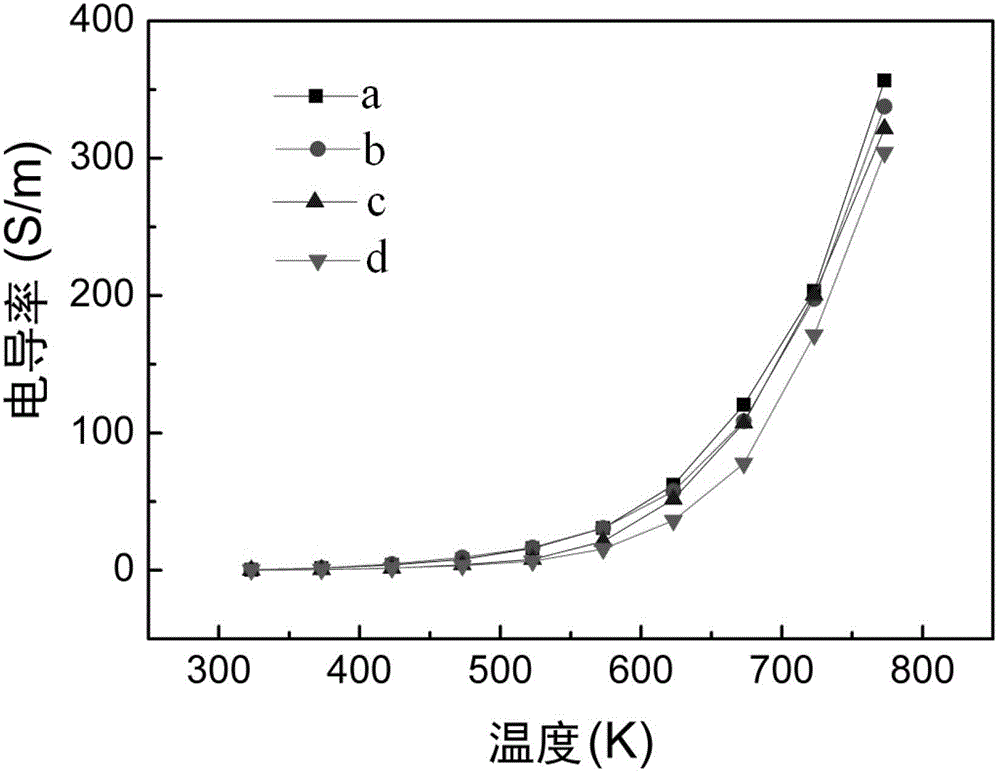

[0066] image 3 Scanning electron microscope (SEM) photos showing the cross-section of Sn-S-based thermoelectric compound bulk samples sintered by SPS at different temperatures, Figure 4-Figure 7 Respectively represent the electrical conductivity, Seebeck coefficient, thermal conductivity, and ZT value of Sn-S-based thermoelectric compound bulk samples sintered by SPS at different temperatures as a function of temperature, where a represents the sintering temperature of 823K, and b represents the sintering temperature is 853...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com