Sewing machine with improved thread cutting mechanism

A sewing machine and thread cutting technology, which is applied in the field of sewing machines, can solve the problems of shortening the thread quantity and unable to maintain the quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

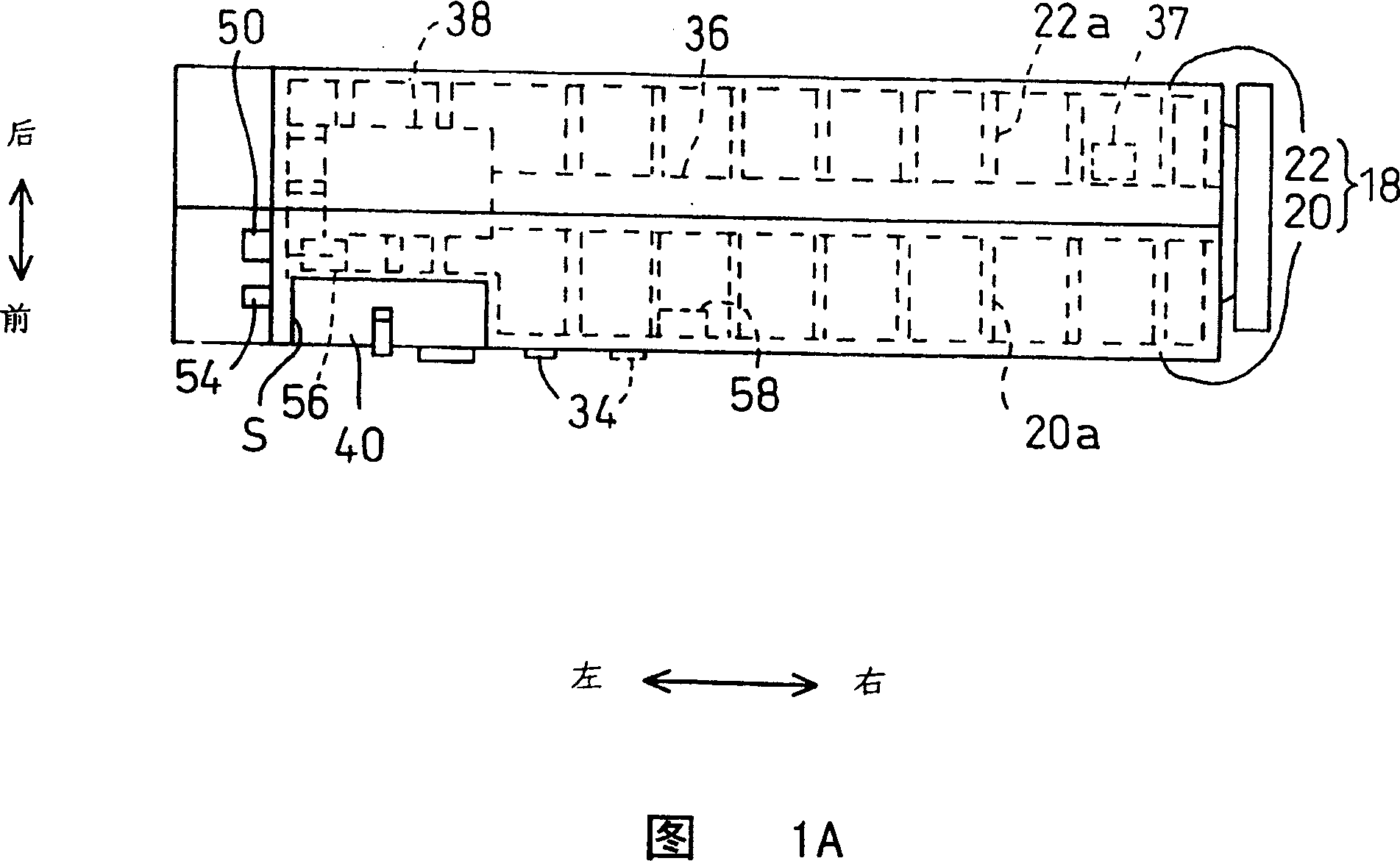

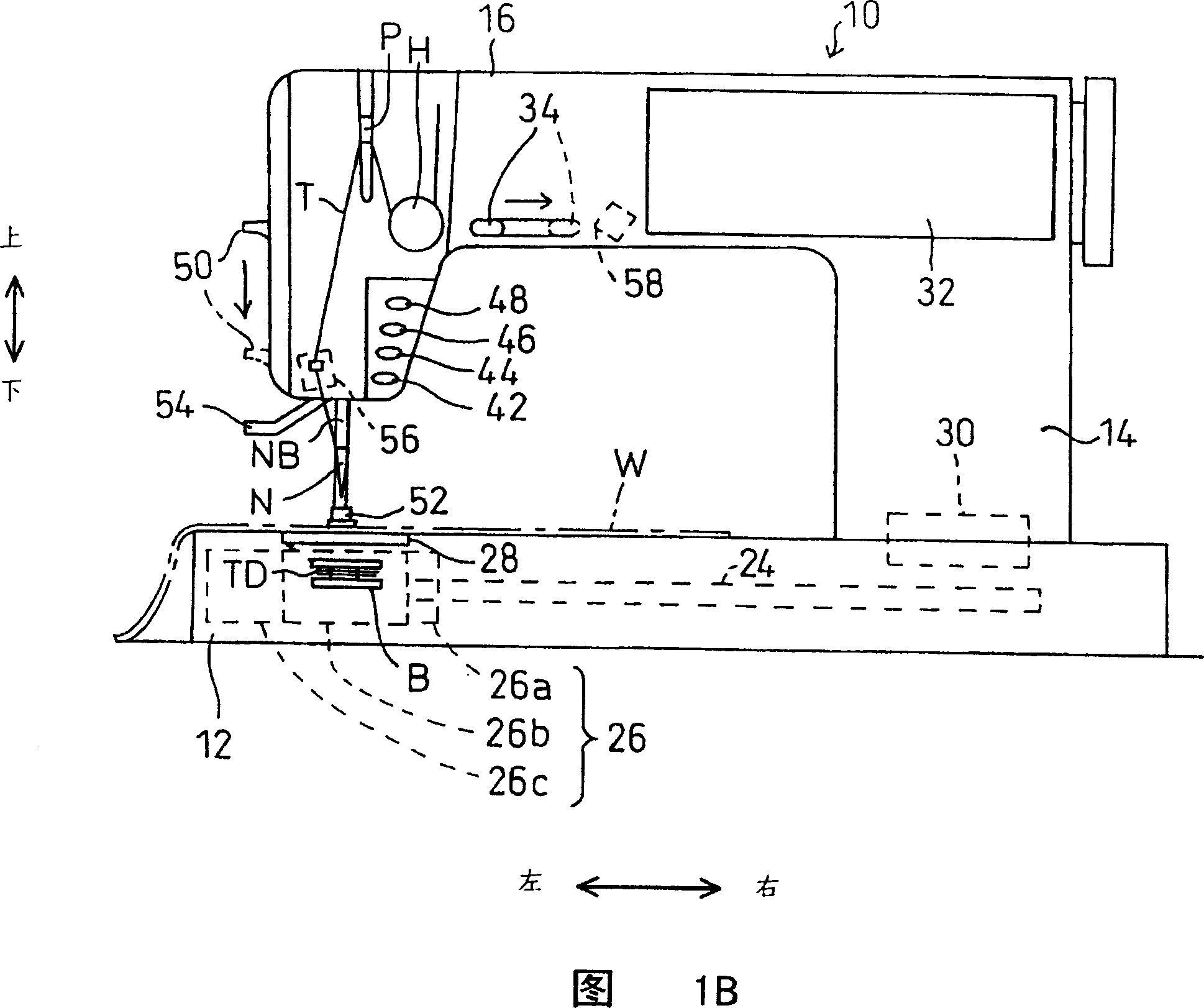

[0050] An embodiment of the present invention will be described in detail with reference to the accompanying drawings. Referring to Fig. 1A and 1B, sewing machine 10 of the present invention comprises: a sewing base plate 12 with horizontal plane; A post 14, this post extends upwards from the right-hand part of base plate 12; The right side extends horizontally so as to be opposite to or above the bottom plate 12 . The bottom plate 12 , the pillars 14 and the arms 16 are continuously formed on a resin cabinet 18 including a front cabinet 20 and a rear cabinet 22 . Japanese Patent Application No. 2001-295564 filed by the assignee of the present application discloses the cabinet as described above.

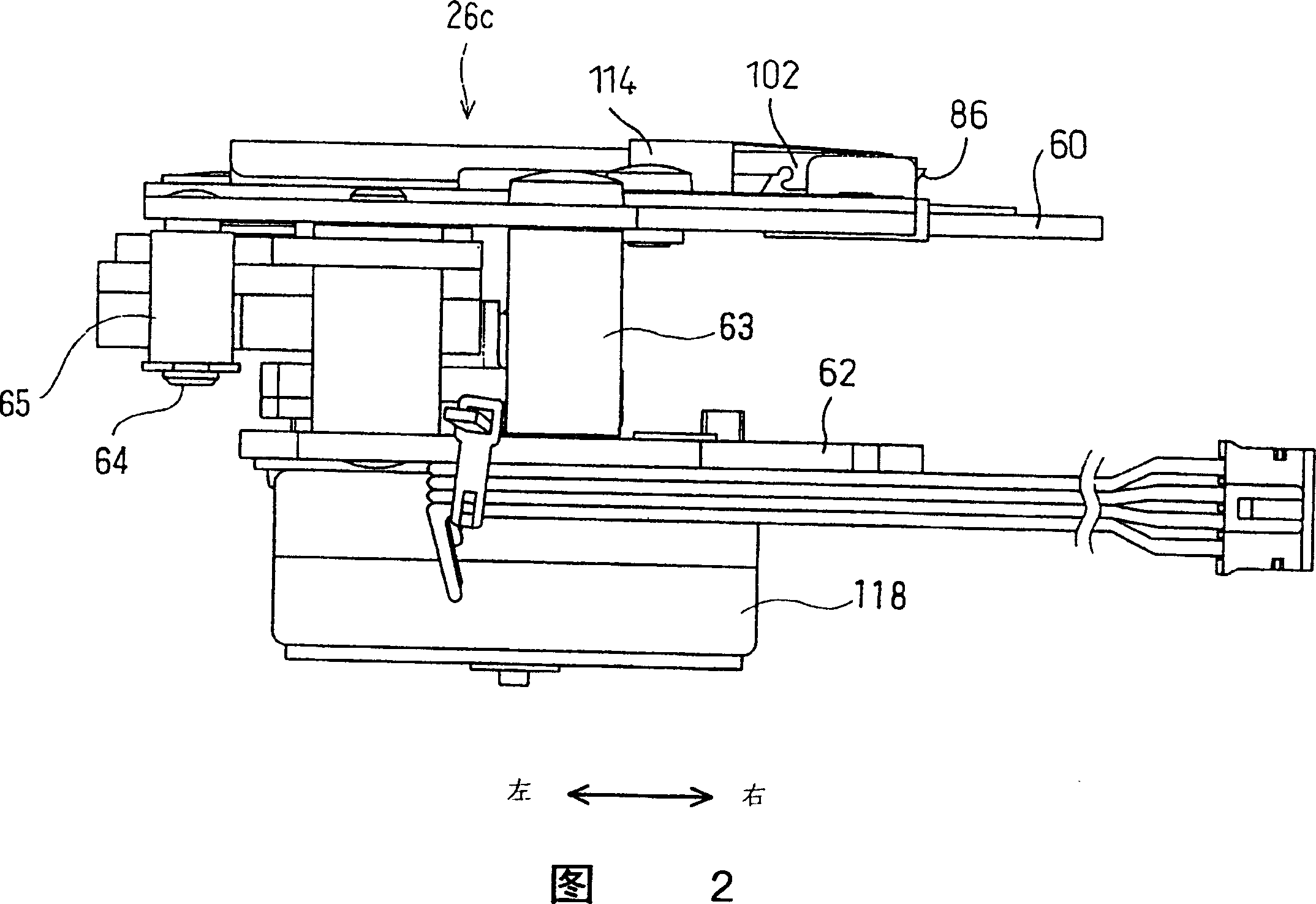

[0051] A lower shaft 24 made of metal is supported on the rear cabinet 22 so as to extend longitudinally inside the bottom plate 12 as viewed in FIG. 1B . A lower mechanism 26 is mounted on the rear housing 22 at the left-hand end of the shaft 24 . The lower mechanism 26 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com