Automatic cylindrical battery cap welding machine

A cylindrical battery and automatic welding technology, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as low efficiency, a large amount of labor, and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

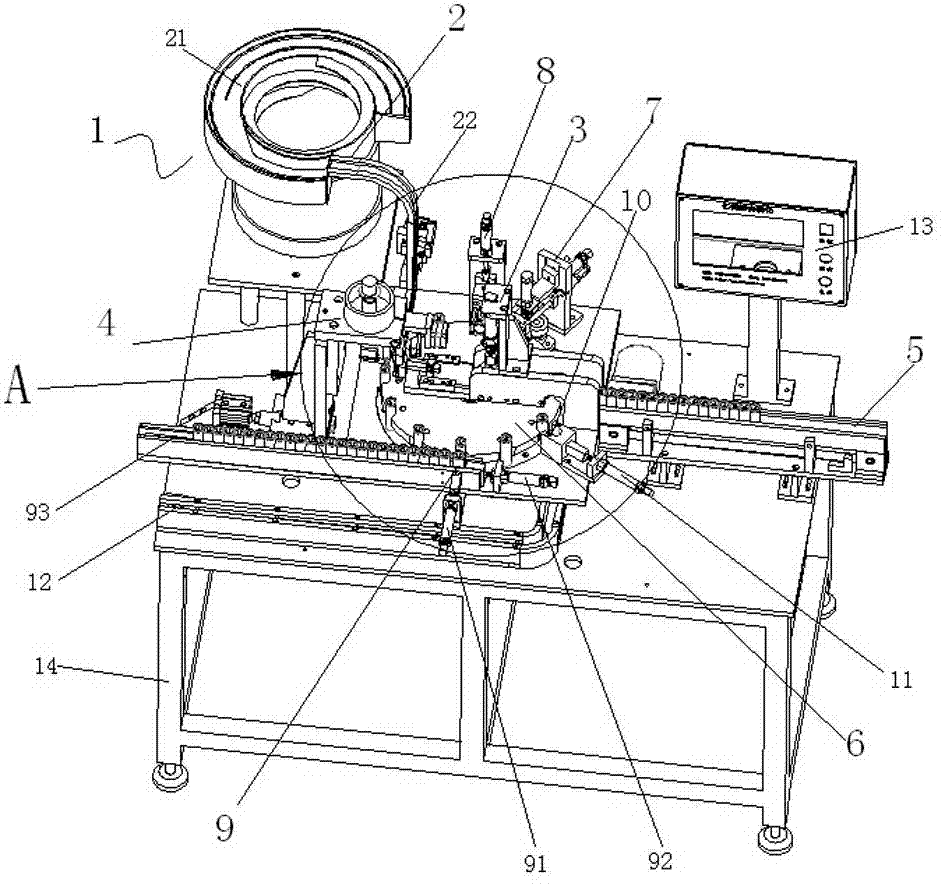

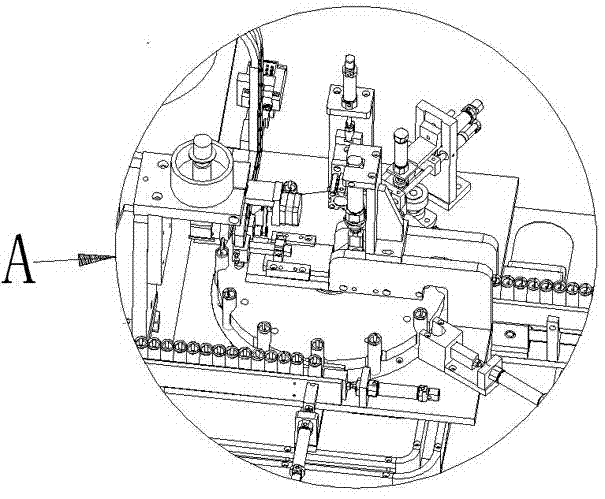

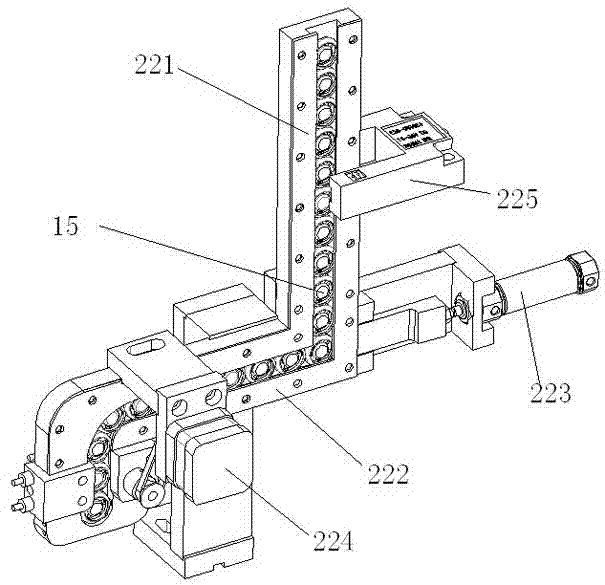

[0024] like Figure 1~4 As shown, an automatic cap welding machine for cylindrical batteries includes a feeding trough 5, a tab positioning device 7, a tab shaping device 8, a welding cap device 1, and a qualified Product discharge device 9 and defective product discharge device 10. The above-mentioned devices on each station are all arranged on the frame 14, and are controlled by the control box 13 arranged on the frame 14, so as to realize the tabbing of the battery positive tabs of the semi-finished batteries that have been welded and grooved. Positioning, tab shaping, and then welding the positive tab and the cap by ultrasonic welding, and detecting unqualified products at the same time, and releasing them separately from qualified products, so as to realize the fully automatic and ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com