Kitchen waste pretreatment equipment

A kitchen waste and pretreatment technology, applied to the removal of solid waste, etc., can solve the problems of unfixed fermentation time, poor dynamic adsorption capacity, and poor solid-liquid separation effect, so as to improve the separation effect and reduce the resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

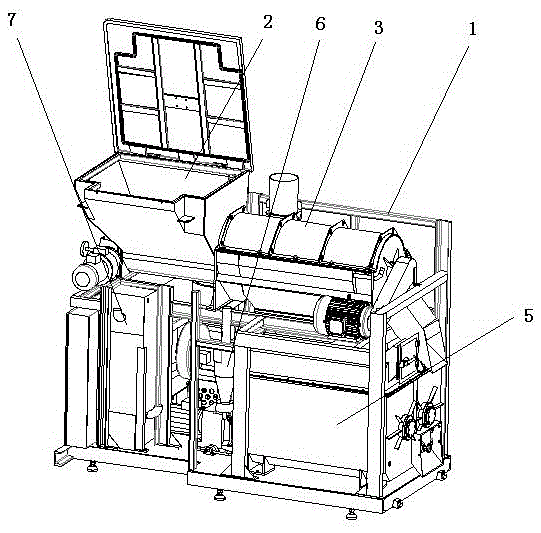

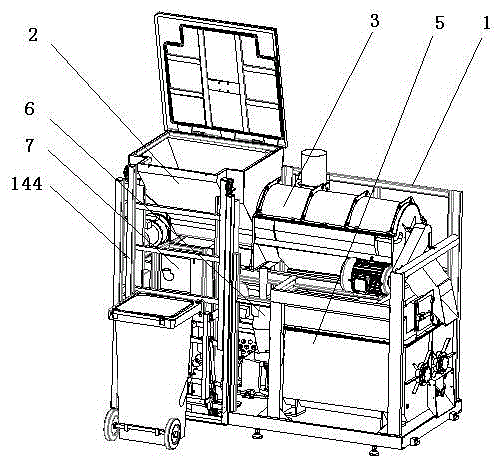

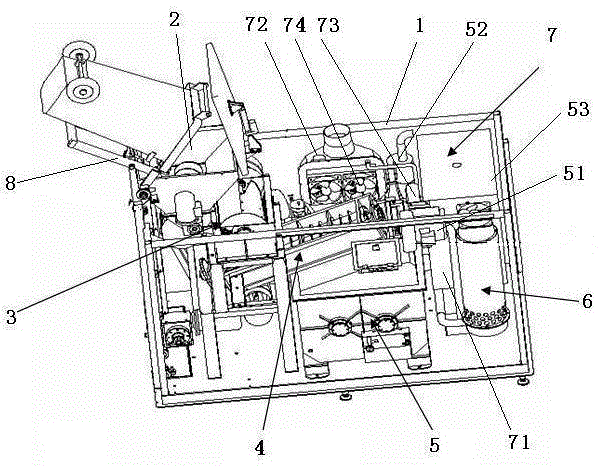

[0092] Embodiment 1: A kind of kitchen waste pretreatment equipment, comprises airtight casing 1 and control system, and described control system comprises man-machine interface, PLC controller and electric control box, man-machine interface, PLC controller and electric control box The connection relationship of the control box is the same as that of the existing technology (not shown in the figure), so it will not be repeated here. The upper end of the housing 1 is provided with a loading hopper 2 and a feeding motor, and the housing 1 is provided with an automatic sorting device 3 for biological fermentation and drying. Device 5, oil-water separation device, ionization deodorization device 6 and vapor condensation device 7, as attached Figure 10 , 11, 12, and 13, the feeding hopper 2 is provided with a feeding screw blade 15, and the two ends of the feeding screw blade are respectively connected with the feeding hopper and driven by a feeding motor. The upper hopper 2 comm...

Embodiment 2

[0093]Embodiment 2: A kind of kitchen waste pretreatment equipment, comprises airtight housing 1 and control system, and described control system comprises man-machine interface, PLC controller and electric control box, man-machine interface, PLC controller and electric control box The connection relationship of the control box is the same as that of the existing technology (not shown in the figure), so it will not be repeated here. The upper end of the housing 1 is provided with a loading hopper 2 and a feeding motor, and the housing 1 is provided with an automatic sorting device 3 for biological fermentation and drying. Device 5, oil-water separation device, ionization deodorization device 6 and vapor condensation device 7, biological fermentation drying device 5, oil-water separation device, ionization deodorization device 6 and vapor condensation device 7 can adopt prior art, described upper hopper 2 is provided with a feeding spiral blade 15, and the feeding spiral blade i...

Embodiment 3

[0099]Embodiment 3: A kind of kitchen waste pretreatment equipment, comprises airtight casing 1 and control system, and described control system comprises man-machine interface, PLC controller and electric control box, man-machine interface, PLC controller and electric control box The connection relationship of the control box is the same as that of the existing technology (not shown in the figure), so it will not be repeated here. The upper end of the housing 1 is provided with a loading hopper 2 and a feeding motor, and the housing 1 is provided with an automatic sorting device 3 for biological fermentation and drying. Device 5, oil-water separation device, ionization deodorization device 6 and vapor condensation device 7, biological fermentation drying device 5, oil-water separation device, ionization deodorization device 6 and vapor condensation device 7 can adopt prior art, described upper hopper 2 is provided with a feeding spiral blade 15, and the feeding spiral blade is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com