A kind of food waste pretreatment equipment and process

A food waste and pretreatment technology, which is applied to the removal of solid waste, etc., can solve the problems of poor dynamic adsorption capacity, slow treatment efficiency, and masking to treat the symptoms but not the root cause.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the drawings and embodiments.

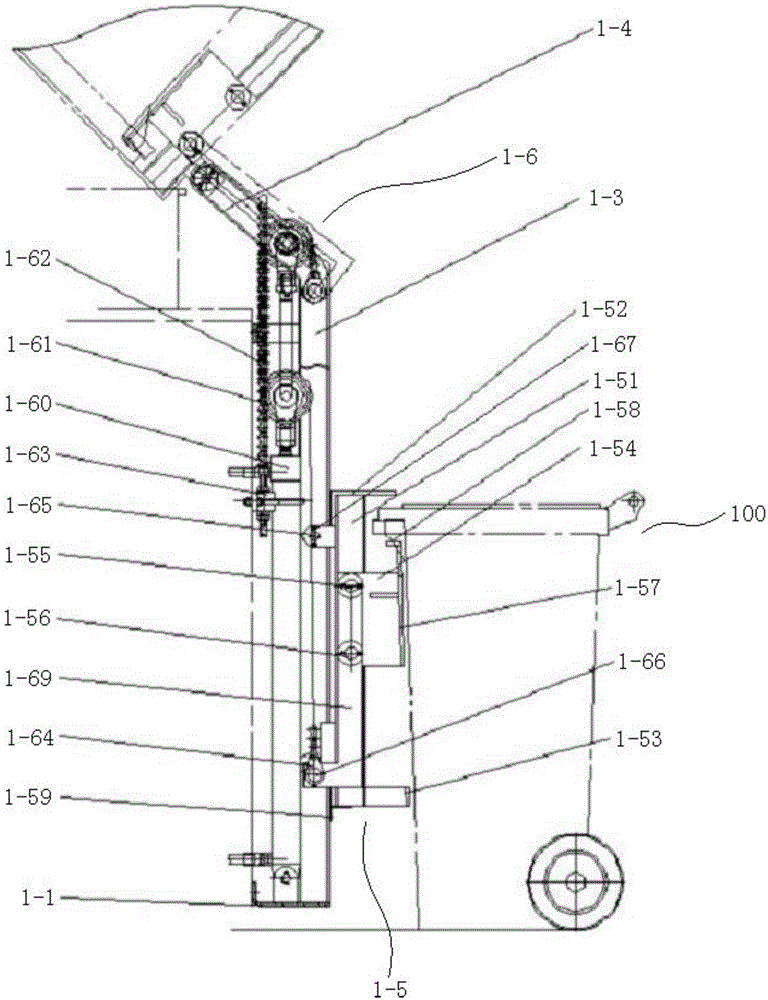

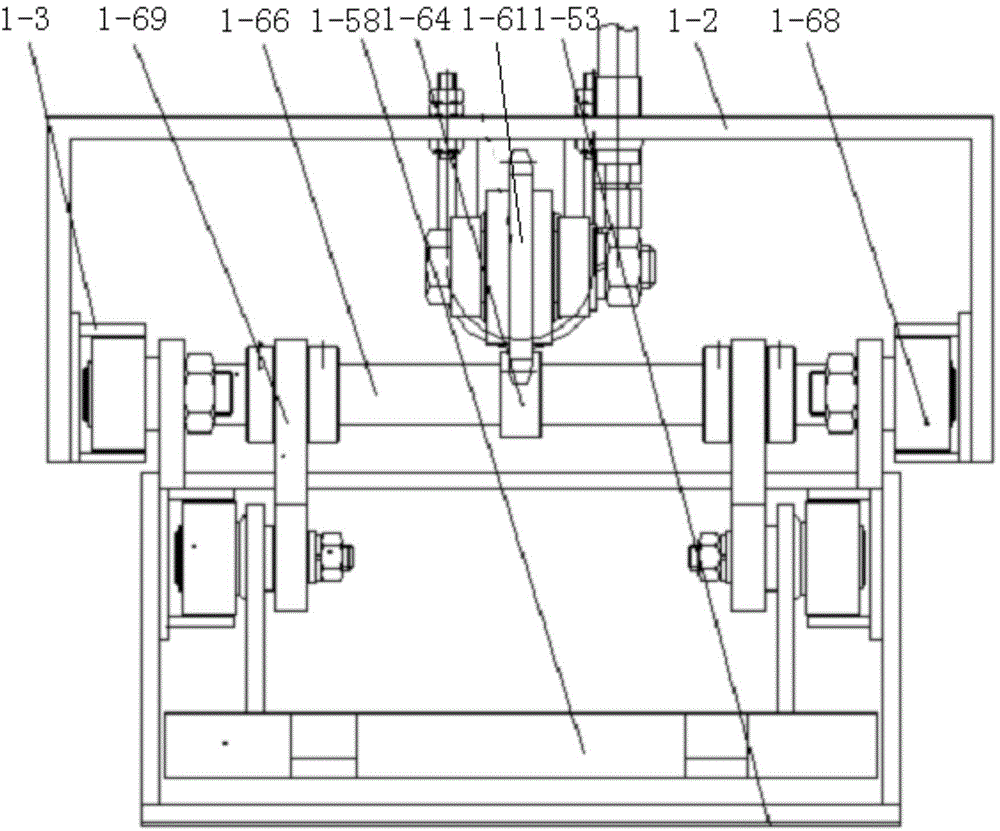

[0044] Such as Figure 1-Figure 8 As shown, the present invention includes a trash can lifting device 100, a feeding device 200, an automatic sorting device 300, a squeezing device 400, a crushing device 500, a fermentation and drying device 600, an ionization deodorizing device 700 and a housing (not shown in the figure) Out). Among them, the trash can lifting device 100 is installed on one side of the housing, and the feeding device is installed on the upper part of the housing. The automatic sorting device 300, the squeezing device 400, the crushing device 500, the fermentation drying device 600 and the ionization deodorizing device 700 are all installed. Installed inside the shell.

[0045] Such as figure 1 , figure 2 As shown, the trash can lifting device 100 includes a base 1-1, a fixing frame 1-2, a lifting slide 1-3, a supporting slide 1-4, a trash can positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com