Thread end finding arrangement system for automatic thread end finding equipment of automatic bobbin winder

A technology of automatic winding machine and head equipment, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc. It can solve the problems of reducing equipment operation efficiency, thread ends cannot be normally sucked out, and affecting equipment operation, etc., to achieve The effect of improving equipment operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

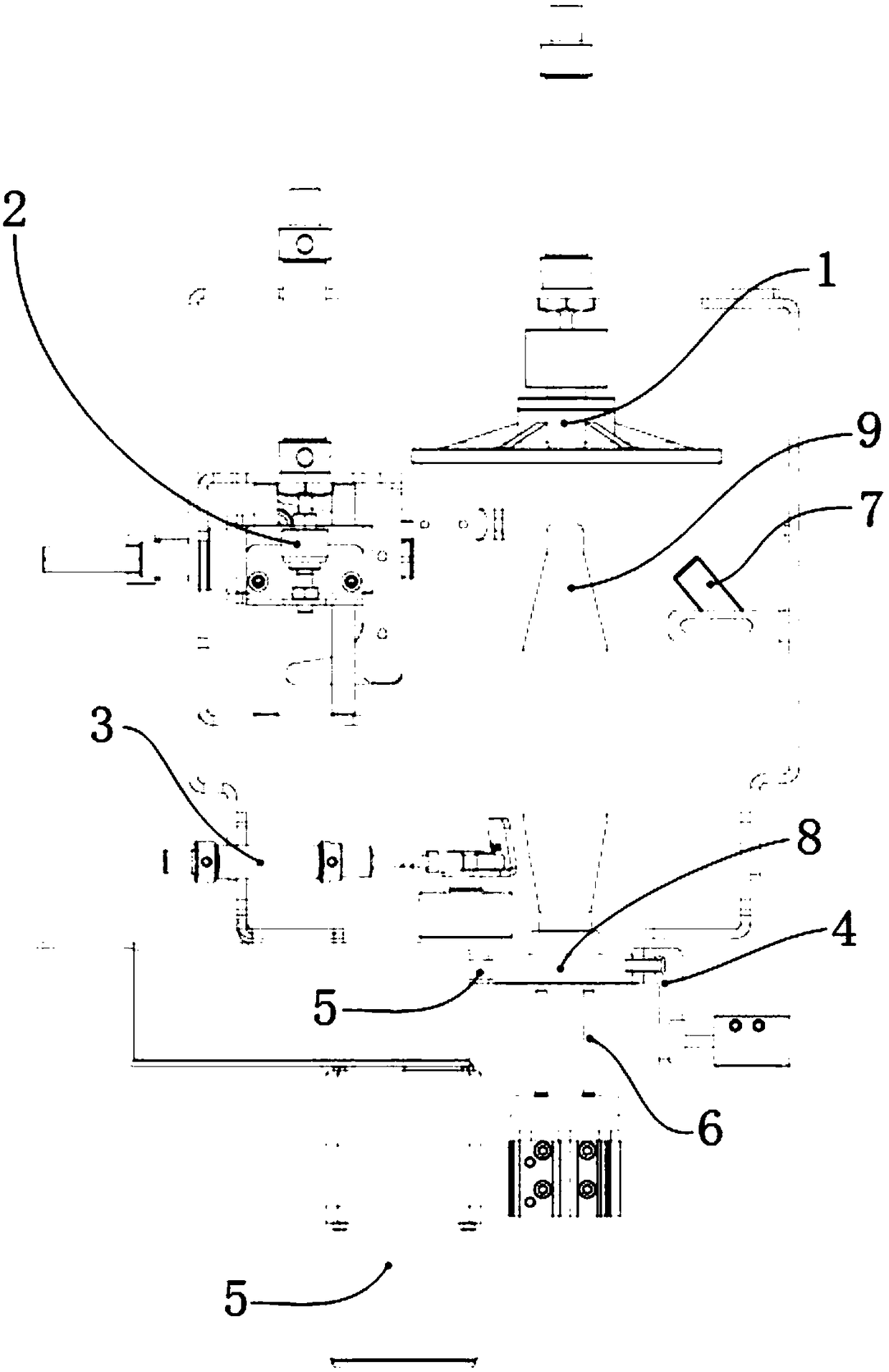

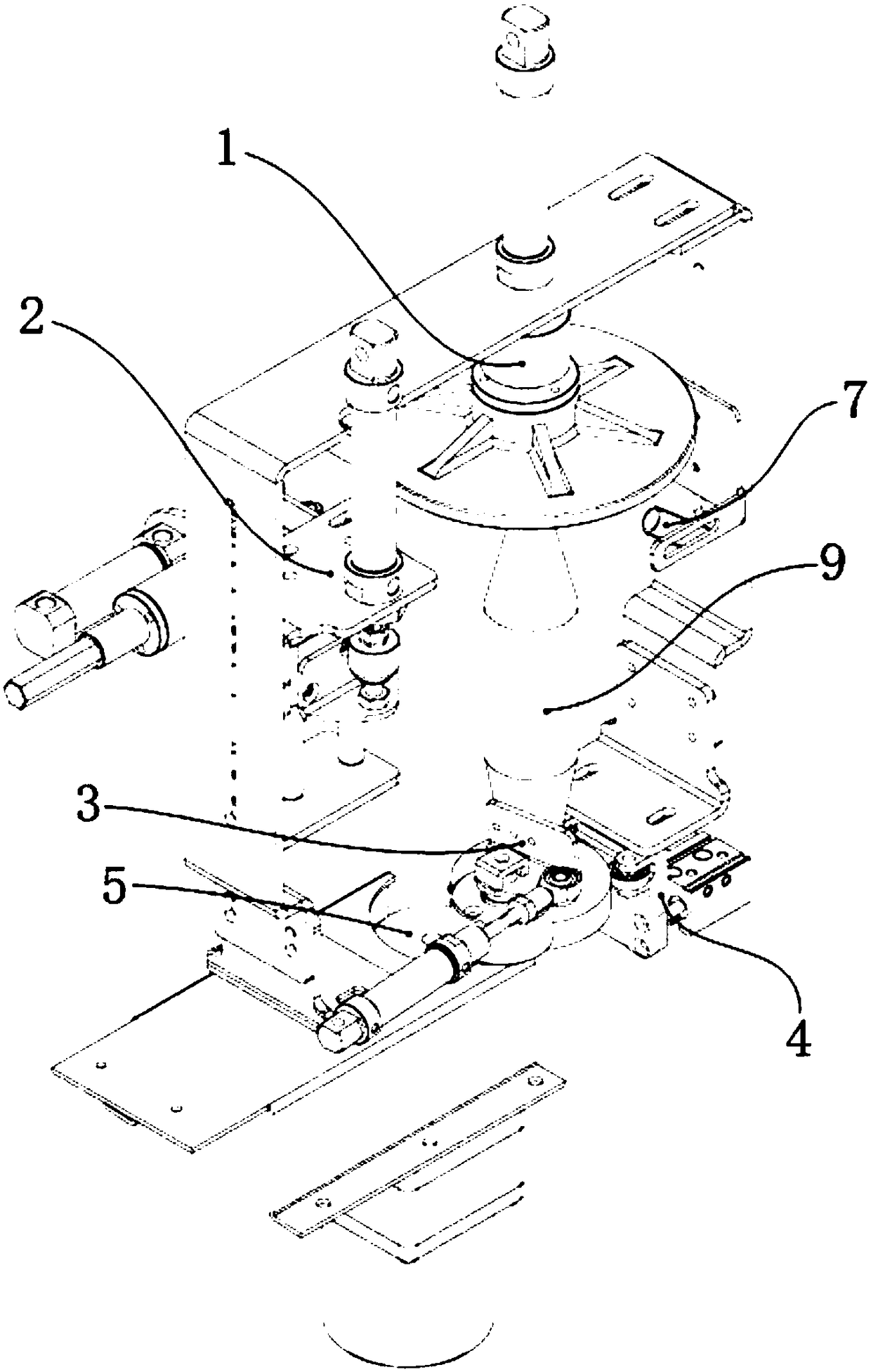

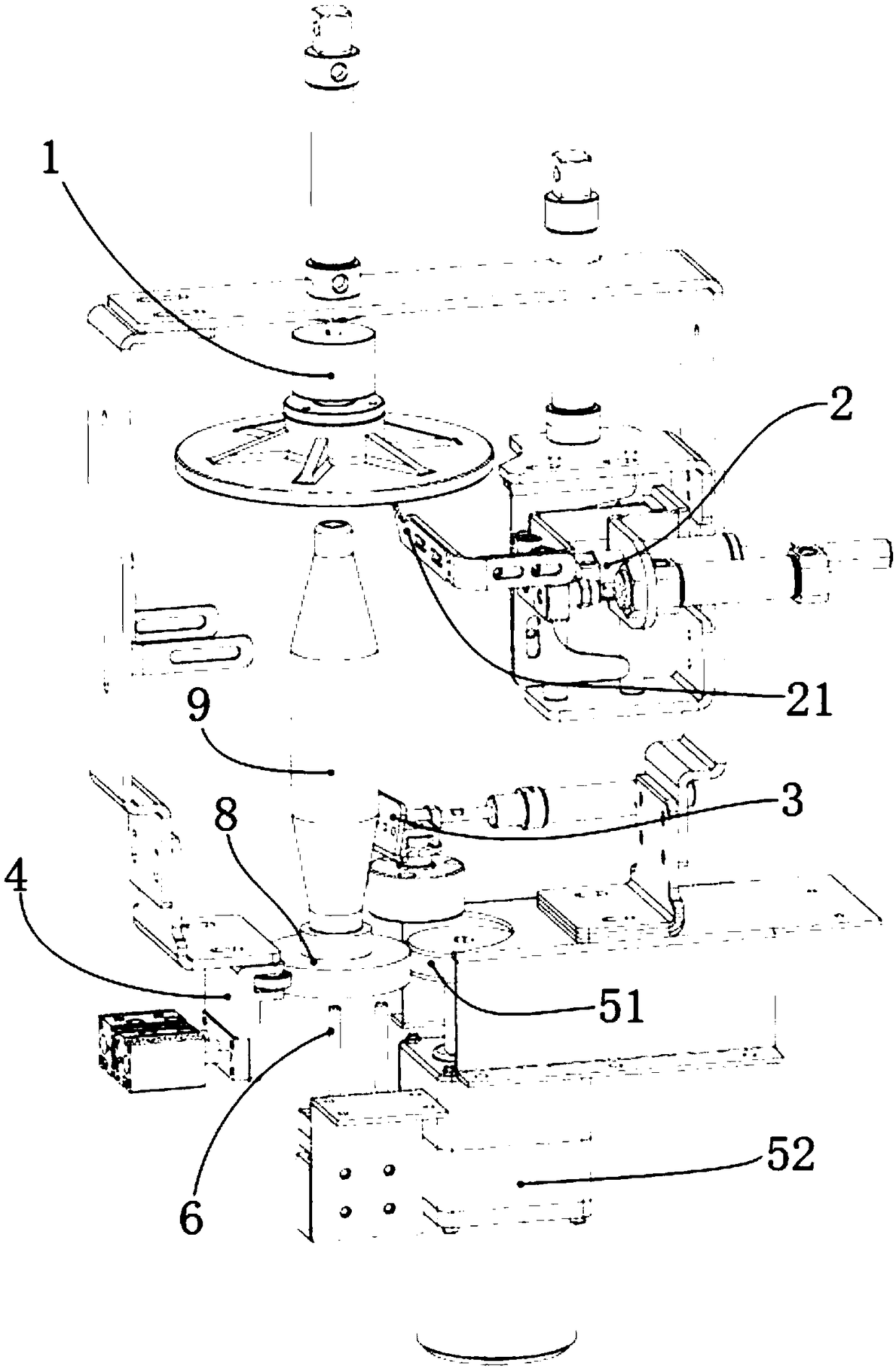

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 , 2As shown in , 3, a kind of head-finding finishing system for automatic winder automatic head-finding equipment is arranged on the feeding channel of automatic winding machine automatic head-finding equipment, and the feeding channel includes a round belt for conveying, including a bottom The support moves forward with the round belt drive. The head finding arrangement system includes a limit mechanism 6, a clamping mechanism 4, a rotary drive mechanism 5, a pressure head mechanism 1, a thread loosening mechanism 2, and a blowing head air nozzle 7.

[0034] The limit mechanism 6 is located below the head-finding finishing station, which can limit the bobbin-containing bottom support moving to the head-finding finishing station with the round belt to move on. Specifically, the limit mechanism 6 includes a telescopic cylinder capable of exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com