Waste cotton recycling and utilizing device

A cotton feeding and stripping roller technology, applied in the field of textile machinery, can solve the problems of easy generation of spun yarn, stiff flakes, affecting the yarn production rate, affecting the yarn quality, etc., so as to improve the utilization rate of waste cotton and reduce work Quantity, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

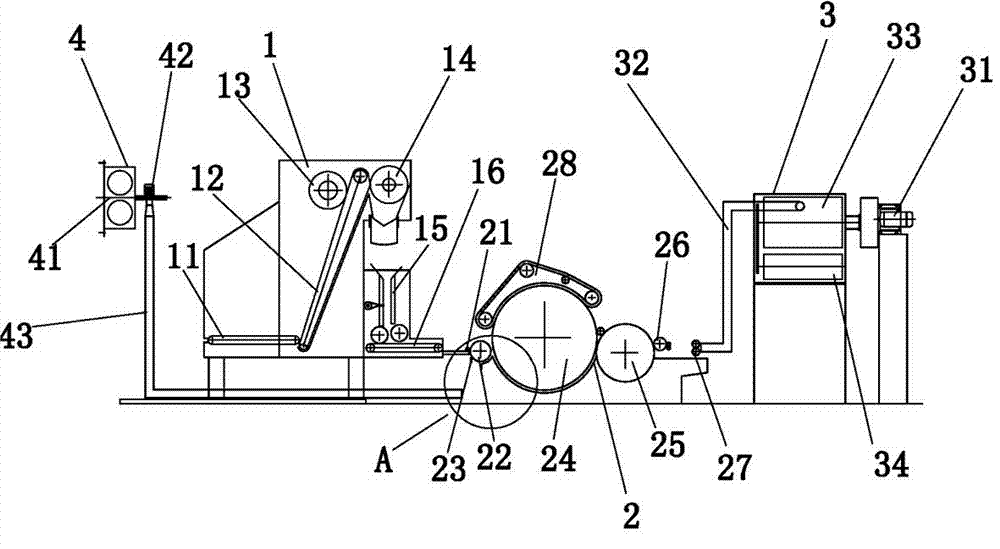

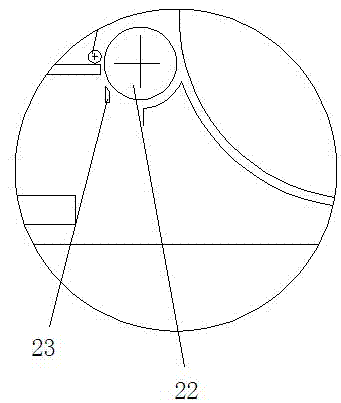

[0012] see Figure 1-2 , a waste cotton recycling device, the waste cotton recycling device includes a continuous cotton feeding device 1, a carding and removing impurities device 2, a sliver processing device 3 and a trash collection device 4; the continuous cotton feeding device 1 includes a flat curtain 11, Inclined nail curtain 12, cotton equalizing roller 13, first cotton stripping roller 14, vibrating cotton box 15, conveying flat curtain 16 and cotton output roller, one end of the oblique nail curtain 12 is connected with the output end of the flat curtain 11, and the oblique nail curtain 12 The two sides of the other end are respectively provided with a cotton equalizing roller 13 and a first stripping roller 14 cooperating with the oblique nail curtain 12, the oblique nail curtain 12 is provided with horn nails, and the vibrating cotton box 15 is located below the first cotton stripping roller 14 , the vibrating cotton box 15 is provided with a light control switch, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com