Sizing and sizing systems and sizing processes for carbon fibers

A technology of carbon fiber and carbon fiber tow, which is applied in liquid/gas/steam fiber/sliver/roving treatment, removal of liquid/gas/steam with squeeze rollers, equipment configuration for processing textile materials, etc. , affecting the performance of composite materials, poor workmanship, etc., to achieve the effect of widening the width of the silk, reasonable structural design, and reducing the amount of wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

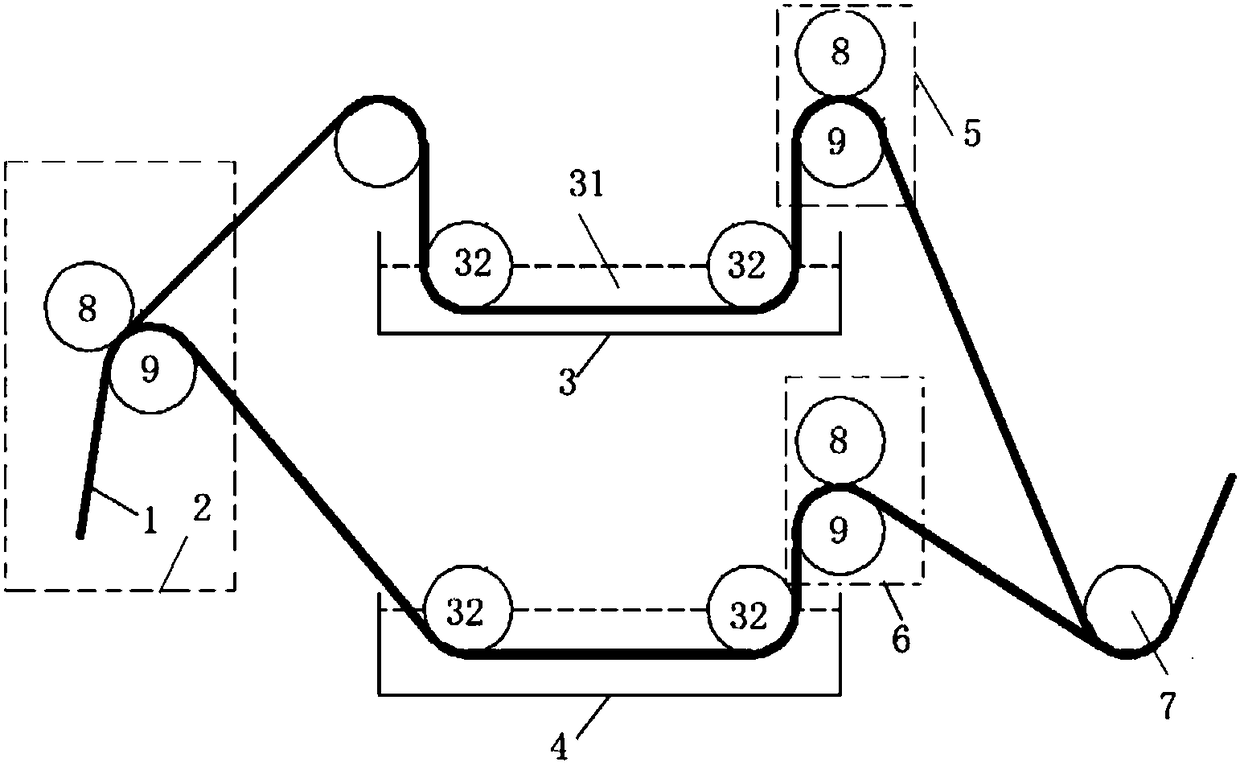

Method used

Image

Examples

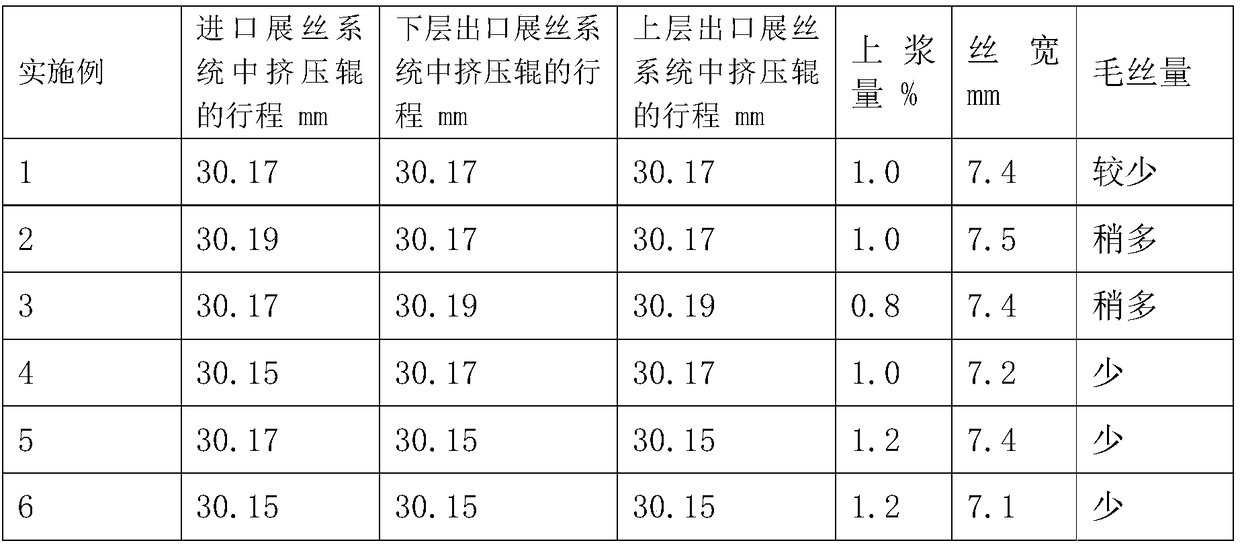

Embodiment 1

[0032] First prepare a slurry with a concentration of 5.1%, mix it evenly, and pour it into the sizing tank through a metering pump, and then turn on the first temperature control system respectively. When the temperature in the tank is stable at 23±2°C, it is ready to be connected to the Carbon fiber tow processed by the filament system. Number the carbon fiber tows processed by the imported filament spreading system, and guide the carbon filaments with odd-numbered tow numbers into the upper sizing tank for sizing treatment, and then pass through two stainless steel smooth rollers half-immersed in the sizing agent in turn before entering the upper layer Export spinning system for spinning treatment. The carbon fiber with an even number of tows is introduced into the lower sizing tank for sizing treatment, and then passes through two stainless steel smooth rollers half-immersed in the sizing agent in turn, and then enters the lower export spinning system for spinning treatmen...

Embodiment 2

[0034] The same procedure and size concentration as in Example 1 were adopted, except that the stroke on both sides of the first squeeze roller in the inlet spreading system was 30.19 mm.

Embodiment 3

[0036] The same process and slurry concentration as in Example 1 were adopted, except that the strokes on both sides of the first squeezing rollers of the upper outlet spreading system and the lower export spreading system were both 30.19 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com