A self-emulsifying epoxy resin sizing agent with a macromolecular emulsifier for carbon fibers

A macromolecular emulsifier, epoxy resin technology, used in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of poor storage stability, high fiber stiffness, affecting fiber post-processing performance, etc., to achieve low cost, interface Good adhesion and excellent emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

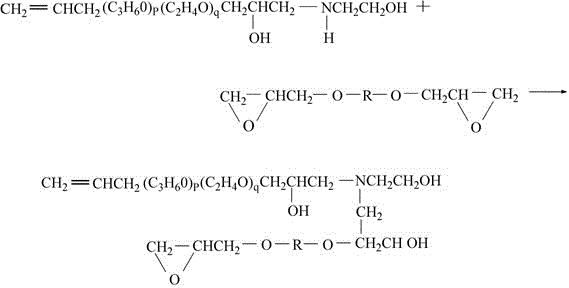

[0036] Preparation of emulsifier: (1) Add the ethanol solution of ethanolamine into a three-necked flask equipped with a condensing reflux device, and raise the temperature to 70°C. Add the ethanol solution of AEPH dropwise into the three-necked flask, stir at constant temperature, and react for 3 hours to obtain the AEPH-ethanolamine adduct AEPH-MEA. (2) Add E-51 into the three-necked flask, and continue to stir and react at 70°C for 3 hours to prepare AEPH, ethanolamine, and epoxy resin adduct AEPH-MEA-DGEBA. (3) Take glacial acetic acid with an amount of 80% ethanolamine, dilute it to a concentration of 60% with deionized water, and add it dropwise at 60°C to neutralize the product into a salt; after the addition is completed, stir at constant temperature for 30 minutes, and distill under reduced pressure The solvent is removed to obtain a macromolecular emulsifier. In the above reaction process, the mass ratio of ethanolamine to ethanol is 50:50; the mass ratio of AEPH to...

Embodiment 2

[0058] Preparation of emulsifier: (1) Add the ethanol solution of ethanolamine into a three-necked flask equipped with a condensing reflux device, and raise the temperature to 80°C. Add the ethanol solution of AEPH dropwise into the three-necked flask, stir at constant temperature, and react for 3 hours to obtain the AEPH-ethanolamine adduct AEPH-MEA. (2) Add ring E-51 into the three-necked flask, and continue to stir and react at 60°C for 3 hours to prepare AEPH, ethanolamine, and epoxy resin adduct AEPH-MEA-DGEBA. (3) Take glacial acetic acid with an amount of 90% ethanolamine, dilute it to a concentration of 60% with deionized water, and add it dropwise at 60°C to neutralize the product to form a salt; after the addition is completed, stir at constant temperature for 30 minutes, and distill under reduced pressure The solvent is removed to obtain a macromolecular emulsifier. In the above-mentioned reaction process, the mass ratio of ethanolamine and ethanol is 30:70; The ma...

Embodiment 3

[0062] Preparation of emulsifier: (1) Add the ethanol solution of ethanolamine into a three-necked flask equipped with a condensing reflux device, and raise the temperature to 80°C. Add the ethanol solution of AEPH dropwise into the three-necked flask, stir at constant temperature, and react for 3 hours to obtain the AEPH-ethanolamine adduct AEPH-MEA. (2) Add E-51 into the three-necked flask, and continue to stir and react at 80°C for 3 hours to prepare AEPH, ethanolamine, and epoxy resin adduct AEPH-MEA-DGEBA. (3) Take glacial acetic acid with 100% ethanolamine content, dilute it to a concentration of 60% with deionized water, and add it dropwise at 60°C to neutralize the product to form a salt; after the addition is completed, stir at constant temperature for 30 minutes, and distill under reduced pressure The solvent is removed to obtain a macromolecular emulsifier. In the above reaction process, the mass ratio of ethanolamine to ethanol is 40:60; the mass ratio of AEPH to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com