Ultra-high damping rubber composite material and preparation process of rubber composite material

A damping rubber and composite material technology, applied in the field of rubber, can solve the problems of low damping performance, large energy dissipation capacity, narrow frequency band of vibration isolation of lead rubber bearings, etc., and achieve the effect of excellent fatigue resistance and excellent damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

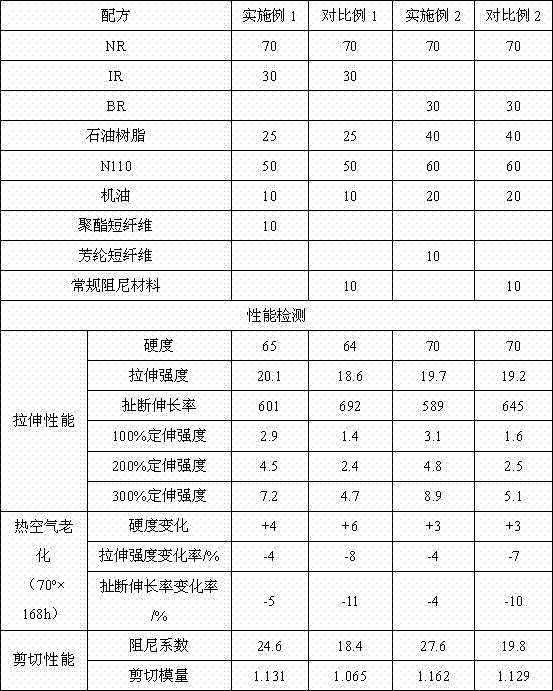

Embodiment 1

[0038] The preparation technology of ultra-high damping rubber composite material of the present invention comprises the following steps:

[0039] Step 1 Preparation of unvulcanized ultra-high damping rubber composite

[0040] The first small step is to masticate 100 parts by weight of rubber and 15 parts by weight of petroleum resin in an internal mixer for 40 seconds;

[0041] In the second small step, add 4 parts by weight of active agent and 1 part by weight of anti-aging agent successively, mix for 30 seconds, add 20 parts by weight of carbon black, 5 parts by weight of plasticizer, continue mixing for 60 seconds, add 3 parts by weight of short fiber, Mixing for 20 seconds to remove glue; a section of masterbatch is placed for 8 hours;

[0042] The third small step is to put a section of masterbatch into the internal mixer, add 1 part by weight of vulcanizing agent and 1 part by weight of accelerator in turn, mix for 30 seconds to remove the glue, and park the rubber for...

Embodiment 2

[0046] The preparation technology of ultra-high damping rubber composite material of the present invention comprises the following steps:

[0047] Step 1 Preparation of unvulcanized ultra-high damping rubber composite

[0048] The first small step 100 parts by weight of rubber and 32.5 parts by weight of petroleum resin are masticated for 110 seconds in an internal mixer;

[0049] In the second small step, add 6 parts by weight of active agent and 2 parts by weight of anti-aging agent successively, mix for 75 seconds, add 45 parts by weight of carbon black, 15 parts by weight of plasticizer, continue mixing for 130 seconds, add 9 parts by weight of short fibers, Mixing for 30 seconds to remove glue; a section of masterbatch is placed for 8 hours;

[0050] The third small step is to put a section of masterbatch into the internal mixer, add 2 parts by weight of vulcanizing agent and 2 parts by weight of accelerator in sequence, mix for 60 seconds to discharge the glue, and park...

Embodiment 3

[0054] The preparation technology of ultra-high damping rubber composite material of the present invention comprises the following steps:

[0055] Step 1 Preparation of unvulcanized ultra-high damping rubber composite

[0056] The first small step 100 parts by weight of rubber and 50 parts by weight of petroleum resin are masticated for 180 seconds in an internal mixer;

[0057] In the second small step, add 8 parts by weight of active agent and 3 parts by weight of anti-aging agent successively, mix for 120 seconds, add 70 parts by weight of carbon black, 25 parts by weight of plasticizer, continue mixing for 200 seconds, add 15 parts by weight of short fibers, Mixing for 40 seconds to remove glue; a section of masterbatch is placed for 8 hours;

[0058] The third small step is to put a section of masterbatch into the internal mixer, add 3 parts by weight of vulcanizing agent and 3 parts by weight of accelerator in sequence, mix for 90 seconds to discharge the glue, and park...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com