Offshore oil drilling platform rig disc brake pad and preparation method thereof

A drilling platform, disc brake technology, applied in mechanical equipment, friction linings, etc., can solve problems such as restricting development, and achieve the effects of simple manufacturing, low cost, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

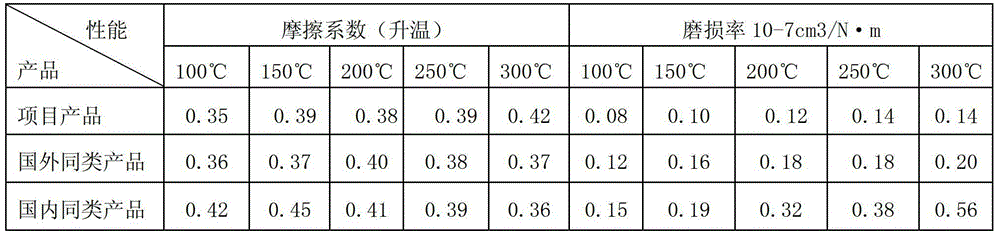

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

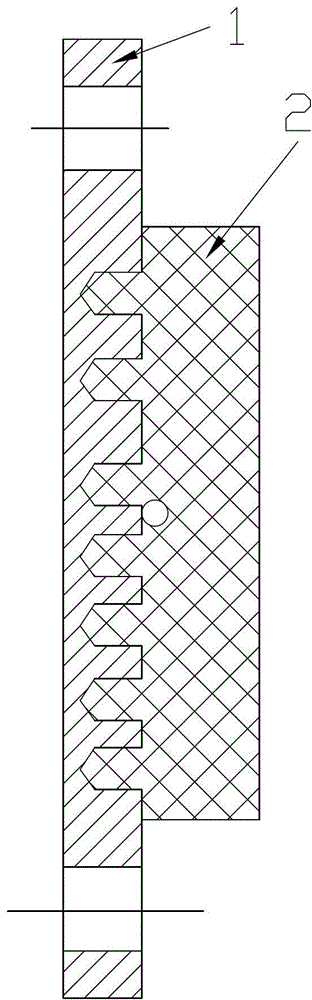

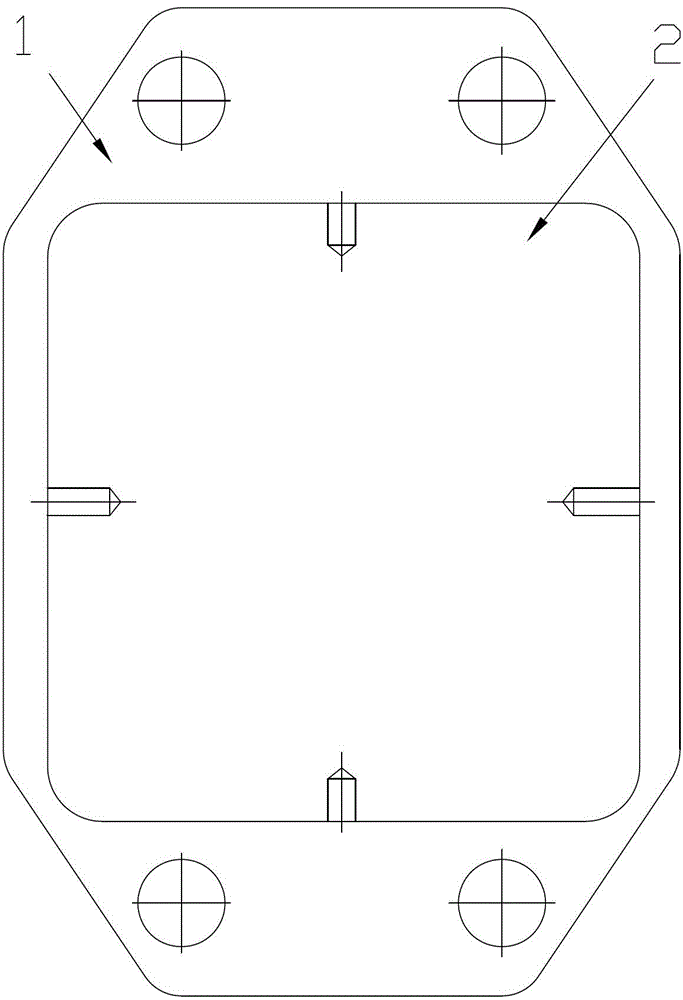

[0025] The offshore oil drilling platform drilling rig disc brake pad includes a metal skeleton 1 and a friction material layer 2 bonded to the bonding surface of the metal skeleton; wherein the friction material layer is composed of the following raw materials in parts by weight: boric acid-tung oil double modified 10 parts of phenolic resin, 12 parts of aramid pulp fiber, 6 parts of carbon fiber, 12 parts of sisal fiber, 18 parts of precipitated barium sulfate, 1 part of sodium fluoride, 5 parts of vulcanized ladder, 6 parts of aluminum hydroxide, 6 parts of diatomaceous earth 5 parts, polytetrafluoroethylene suspension resin 5 parts, zinc stearate 0.5 parts, cashew nut shell oil friction powder 3 parts, artificial graphite 3 parts, foam iron powder 3 parts, chalcopyrite powder 8 parts, hydrogenated nitrile rubber 2 parts , 3 parts of nitrile latex.

[0026] Preparation method: Weigh the raw materials → mix and stir various raw materials for 9 minutes → put the mixed materia...

Embodiment 2

[0028] The disc brake pad of an oil drilling rig includes a metal skeleton 1 and a friction material layer 2 bonded to the bonding surface of the metal skeleton; wherein the friction material layer is composed of the following raw materials: 11 parts of boric acid-tung oil double-modified phenolic resin, 15 parts of aramid pulp fiber, 4 parts of carbon fiber, 10 parts of sisal fiber, 15 parts of precipitated barium sulfate, 2 parts of sodium fluoride, 6 parts of vulcanized ladder, 5 parts of aluminum hydroxide, 5 parts of diatomaceous earth, polytetrafluoroethylene 5 parts of vinyl fluoride suspension resin, 0.5 parts of zinc stearate, 3 parts of cashew nut shell oil friction powder, 3 parts of artificial graphite, 3 parts of foam iron powder, 6 parts of chalcopyrite powder, 3 parts of hydrogenated nitrile rubber, nitrile latex 4 parts.

[0029] Preparation method: Weigh the raw materials → mix and stir various raw materials for 7 minutes → put the mixed materials into the mol...

Embodiment 3

[0031] The disc brake pad of an oil drilling rig includes a metal skeleton 1 and a friction material layer 2 bonded to the bonding surface of the metal skeleton; wherein the friction material layer is composed of the following raw materials: 13 parts of boric acid-tung oil double-modified phenolic resin, 16 parts of aramid pulp fiber, 5 parts of carbon fiber, 14 parts of sisal fiber, 10 parts of precipitated barium sulfate, 3 parts of sodium fluoride, 7 parts of vulcanized ladder, 6 parts of aluminum hydroxide, 4 parts of diatomaceous earth, polytetrafluoroethylene 7 parts of ethylene suspension resin, 0.5 parts of zinc stearate, 3 parts of cashew shell oil friction powder, 3 parts of artificial graphite, 2 parts of foam iron powder, 4 parts of chalcopyrite powder, 3 parts of hydrogenated nitrile rubber, 5 parts of nitrile latex share.

[0032] Preparation method: Weigh the raw materials → mix and stir various raw materials for 8 minutes → put the mixed materials into the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com