Process of spraying ceramic on epoxy resin base carbon fiber composite material article surface

A composite material and epoxy resin technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of deformation of composite material products, limit the promotion and popularization of epoxy resin-based carbon fiber composite materials, etc. Increase the service life, improve the safety performance, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

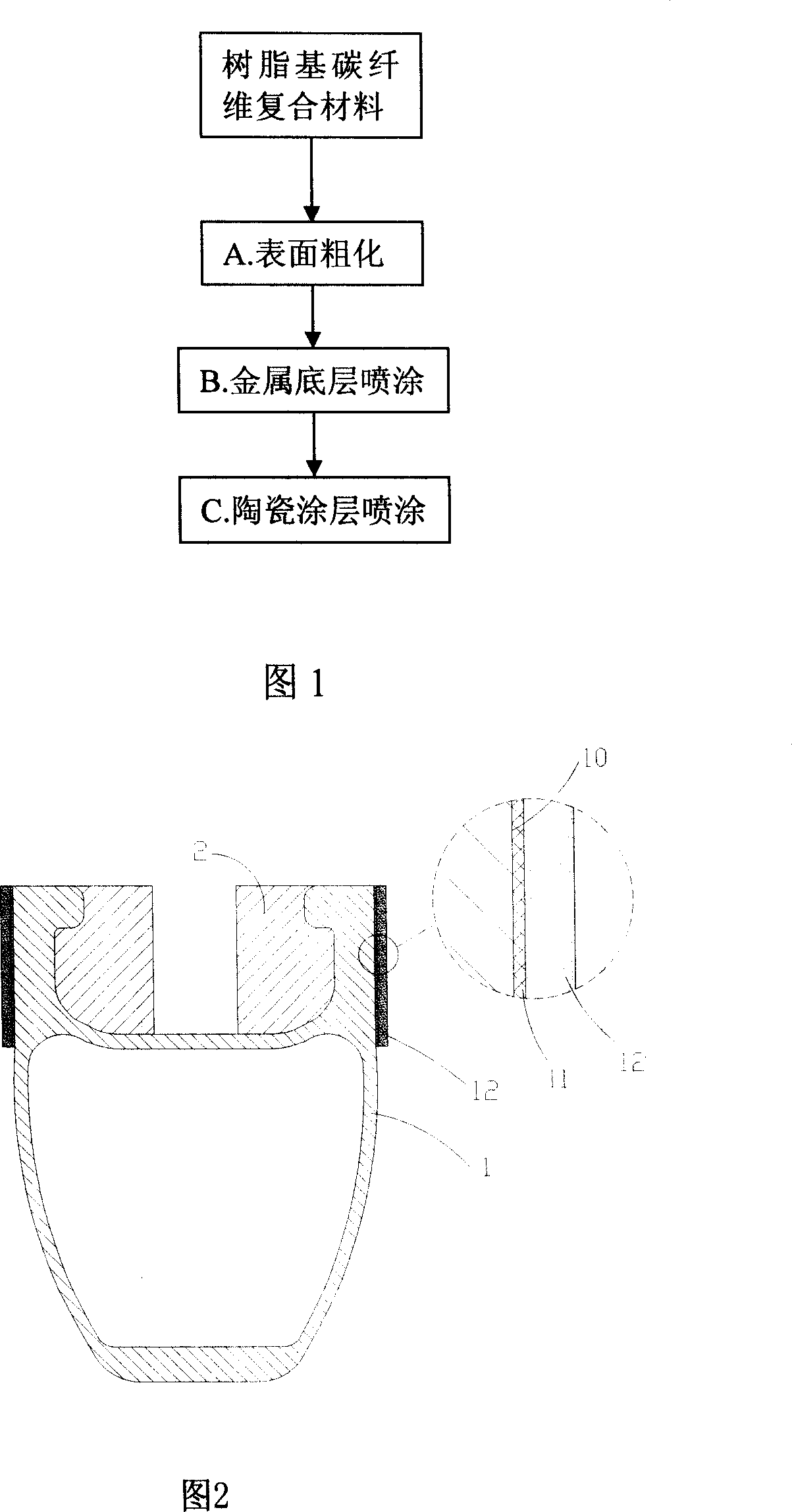

[0044]As shown in Figure 2, the present invention is used in the manufacture of epoxy resin-based carbon fiber composite material bicycle rims. Because the rim is made of epoxy resin-based carbon fiber composite material, to prevent the high temperature generated during braking from deforming the rim, a ceramic coating can be provided on the braking surface to insulate heat and increase wear resistance.

[0045] Get the finished product of bicycle rim 1, set stop body 2 on the inner side of rim braking surface 10, its purpose is to avoid deformation of braking surface 10 under the effect of pressure and heat generated during spraying, and keep product characteristics. After being prepared, the braking surface 10 is subjected to sandblasting and roughening treatment, the size of the sand particles is 40 meshes, and then an arc spraying equipment is used to uniformly spray a layer of zinc-aluminum alloy metal bottom layer 11, the thickness of the metal bottom layer is 0.05mm, and...

Embodiment 2

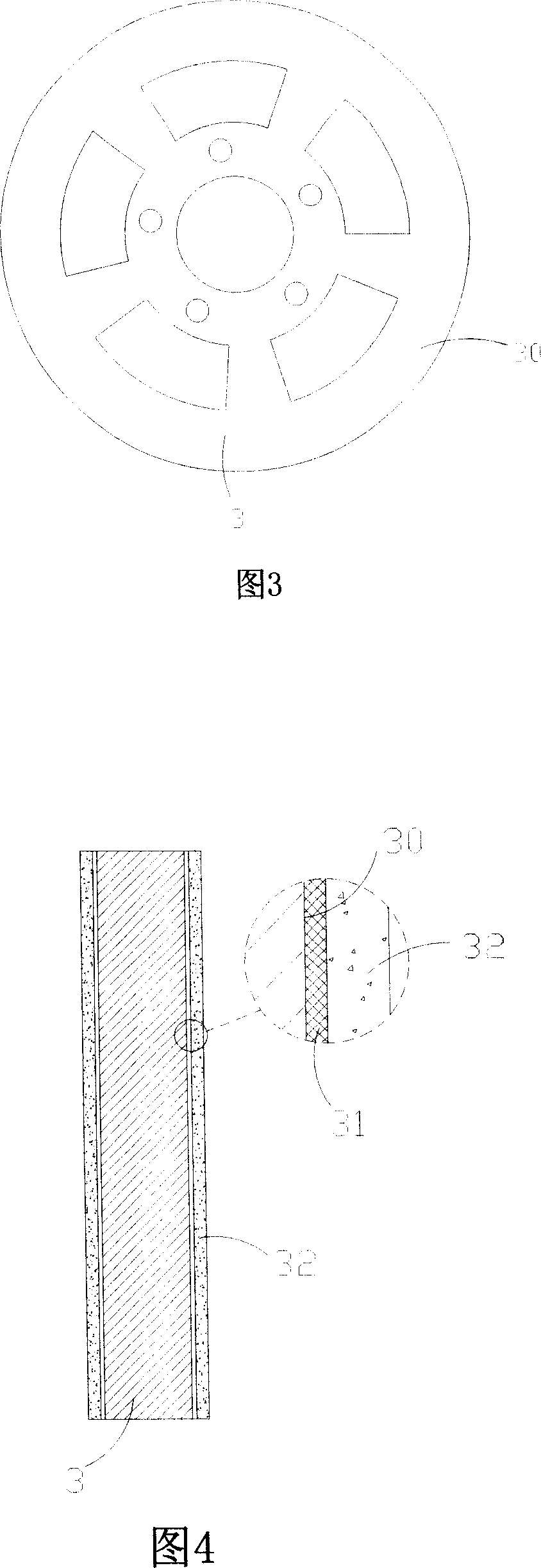

[0047] As shown in Figures 3 and 4, similar to the embodiment, the present invention is used in the manufacture of epoxy resin-based carbon fiber composite disc brake discs.

[0048] Take the finished disc brake disc, first set a stop body on one side of the disc brake disc 3, and carry out sandblasting and roughening treatment on the braking surface 30 on the other side. Al-Mg alloy metal bottom layer 31, the thickness of the metal bottom layer is 0.25mm, and finally spray ceramic powder with plasma spraying equipment, the composition of ceramic powder is alumina, the powder diameter is 5 microns, when spraying, the voltage of the arc is 120V, and the current is 700A , the distance between the nozzle of the spray gun and the surface of the substrate is 100mm, and the ceramic coating 32 with a thickness of 0.5mm is uniformly sprayed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com