Briquette binder and briquette preparation method based on binder

A binder and briquette technology, which is applied in the field of binder for pulverized coal molding, can solve the problems of few suitable coal types, limited sources of raw materials, and difficult processing.

Inactive Publication Date: 2010-08-25

SHAANXI UNIV OF SCI & TECH

View PDF6 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are more or less deficiencies in the existing technology: such as poor combustion performance, poor moisture and water resistance, low thermal strength, low sulfur fixation rate, difficult processing, few suitable coal types, high cost, pollution Serious, limited sources of raw materials, complex pulverized coal molding process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Login to View More

Abstract

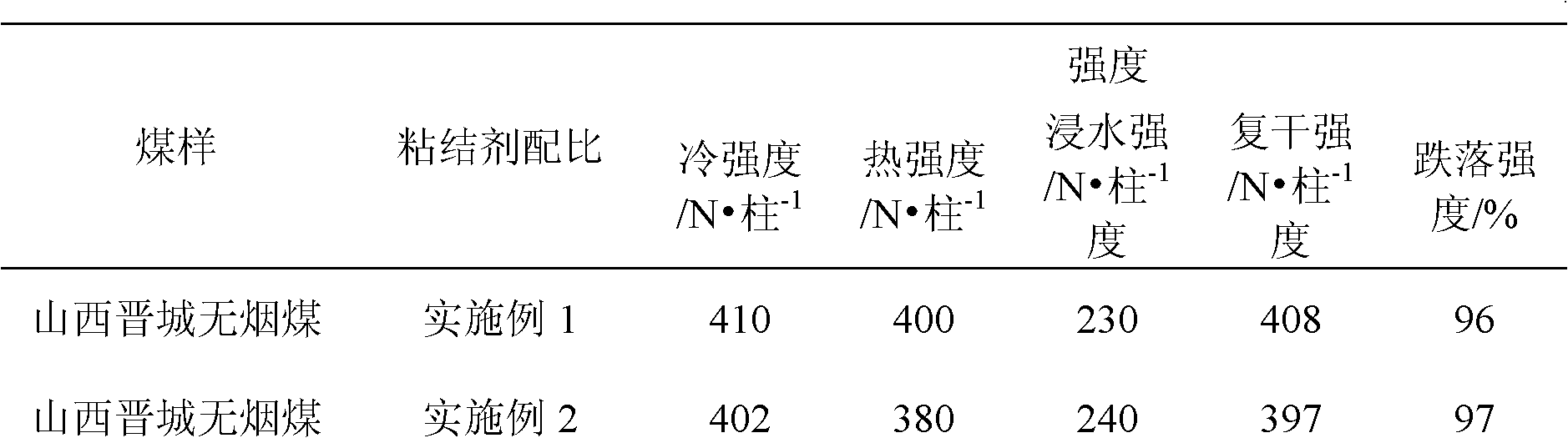

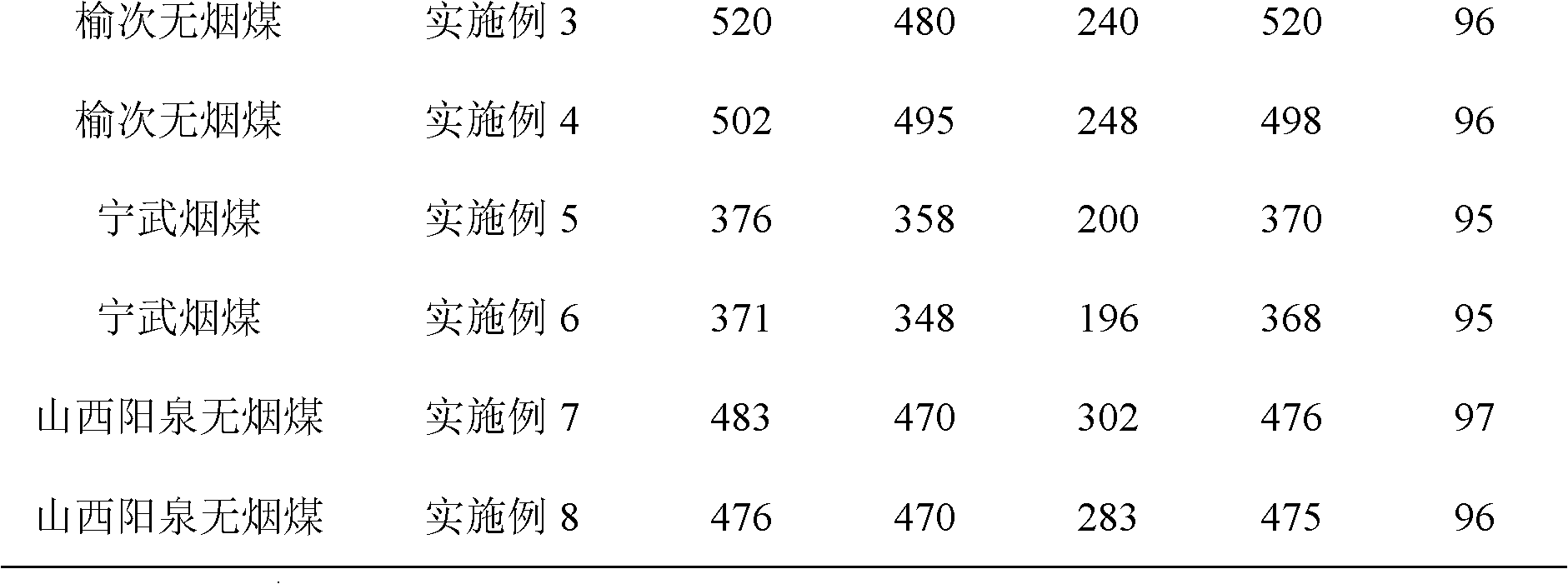

The invention provides a briquette binder and a briquette preparation method based on the binder. The binder comprises 45 to 75 mass percent of humic acid, 8 to 20 mass percent of bentonite, 5 to 18 mass percent of kaolin, 1 to 5 mass percent of quartz sand, 2 to 8 mass percent of quicklime, 0.1 to 2 mass percent of sodium chloride, 0.1 to 2 mass percent of potassium permanganate and 0.05 to 0.1 mass percent of polyacrylamide. The binder has a simple preparation process, low cost, convenient use and no any secondary pollution and is applicable to various types of coal. The process for preparing the briquette by using the binder comprises the following steps of: only making little pretreatment on raw material coal and the binder, mixing the raw material coal and the binder in proportion, adding water into the mixture, uniformly stirring, pressing the mixture into a cylindrical briquette by using a press machine, and air-drying or drying the cylindrical briquette. The briquette prepared by using the binder of the invention has the characteristics of high cold strength, high water resistance, low cost, low ash increment, high thermal strength, high sulfur retention rate and wide source of raw materials.

Description

technical field The invention belongs to the field of binders for fuel, in particular to a binder for pulverized coal molding. Background technique Coal is an important part of the world's primary energy. In the past 40 years, the proportion of world coal in the production and consumption structure has remained at about 30%, which has played a decisive role in the development of the world economy. Coal has made great contributions to the development of the world economy, but it has also brought about a series of environmental pollution problems in the process of its development and utilization. Produced a major impact, endangering the ecological balance and human survival. Since the 1980s, some developed countries have launched clean coal technology one after another, which has attracted more and more attention from the international community. The governments of some countries have formulated development paths, plans and plans for clean coal technology according to their ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10L5/10C10L5/14C10L5/12

Inventor 仝建波刘淑玲

Owner SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com