Preparation method of Sr, Ni and Cr co-doped LaAlO3 ceramic material and product thereof

A ceramic material and co-doping technology, which is applied in the field of preparation of Sr, Ni and Cr co-doped LaAlO3 ceramic materials, can solve the problems of reducing thermal conductivity and not considering the compactness of lanthanum aluminate ceramic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

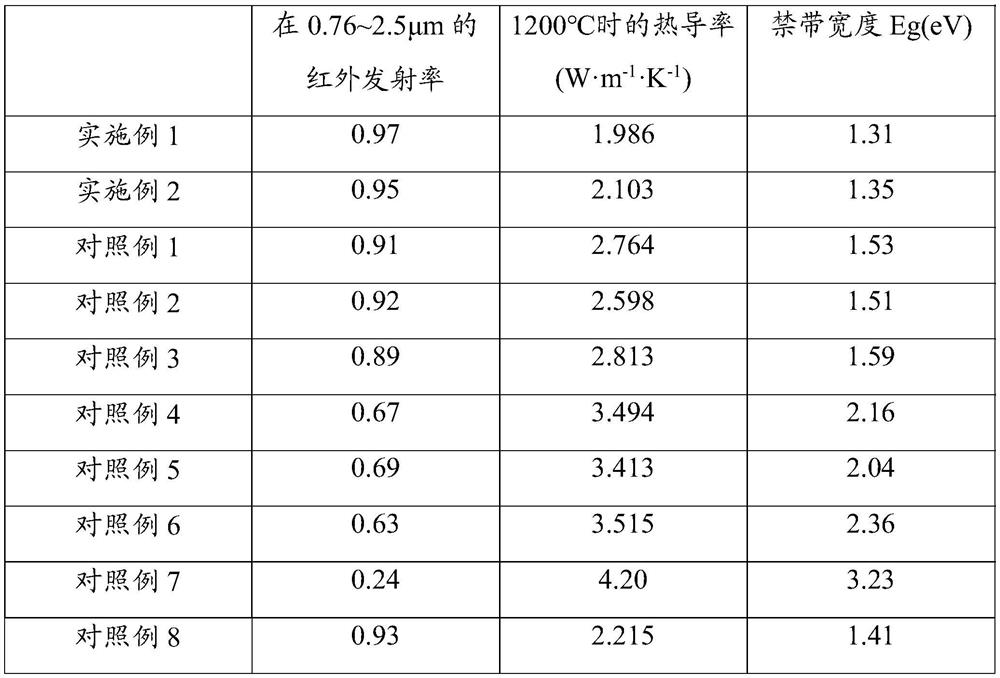

Examples

preparation example Construction

[0023] A kind of Sr, Ni and Cr co-doped LaAlO provided by the invention 3 A method for preparing a ceramic material, comprising the steps of:

[0024] 1) According to the chemical formula La a Sr b Ni c al d Cr e o 3 stoichiometric ratio, wherein a=0.7~0.9, b=0.05~0.15, c=0.05~0.15, d=0.7~0.9, e=0.1~0.3, weigh strontium nitrate, nickel nitrate, chromium nitrate, lanthanum nitrate and Put aluminum nitrate into a beaker, add appropriate amount of distilled water and stir to dissolve;

[0025] 2) Add urea 1 to 1.5 times the total molar amount of metal ions to the beaker under stirring conditions, ultrasonically disperse for 1 to 3 hours, then microwave in a microwave chemical reactor at 70 to 90°C for 1 to 3 hours, and evaporate to obtain intermediate Product A;

[0026] 3) Put product A in a drying oven at 100-140°C for 10-16 hours, then grind the dried sample, then put it in a muffle furnace for 1-3 roasting at 1100-1300°C, take out the sample and wait to cool to room t...

Embodiment 1

[0030] A Sr, Ni and Cr co-doped LaAlO 3 A method for preparing a ceramic material, comprising the steps of:

[0031] 1) According to the chemical formula La a Sr b Ni c Al d Cr e o 3 stoichiometric ratio, where a=0.8, b=0.1, c=0.1, d=0.8, e=0.2, weigh strontium nitrate, nickel nitrate, chromium nitrate, lanthanum nitrate and aluminum nitrate into a beaker, add an appropriate amount of Distilled water was stirred thoroughly to dissolve;

[0032] 2) Add urea 1.5 times the total molar amount of metal ions to the beaker under stirring conditions, ultrasonically disperse for 2 hours, then heat in microwave at 85°C for 2 hours in a microwave chemical reactor, and evaporate to obtain intermediate product A;

[0033] 3) Put the product A in a drying oven at 120°C for 14 hours, then grind the dried sample, then put it into a muffle furnace and bake it at 1250°C for 2 hours, take out the sample and wait for it to cool to room temperature before fully grinding to obtain a loose p...

Embodiment 2

[0036] A Sr, Ni and Cr co-doped LaAlO 3 A method for preparing a ceramic material, comprising the steps of:

[0037] 1) According to the chemical formula La a Sr b Ni c Al d Cr e o 3 stoichiometric ratio, wherein a=0.8, b=0.15, c=0.05, d=085, e=0.15, weigh strontium nitrate, nickel nitrate, chromium nitrate, lanthanum nitrate and aluminum nitrate into a beaker, add an appropriate amount of Distilled water was stirred thoroughly to dissolve;

[0038] 2) Add urea 1 times the total molar amount of metal ions to the beaker under stirring conditions, ultrasonically disperse for 3 hours, then heat in a microwave chemical reactor at 75°C for 3 hours, and evaporate to obtain intermediate product A;

[0039] 3) Put product A in a drying oven at 100°C for 16 hours, then grind the dried sample, then put it into a muffle furnace and bake it at 1300°C for 1 hour, take out the sample and wait for it to cool to room temperature before fully grinding to obtain a loose powder;

[0040...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com