Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

381results about How to "Beautiful surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

New macromolecule fiber composite material

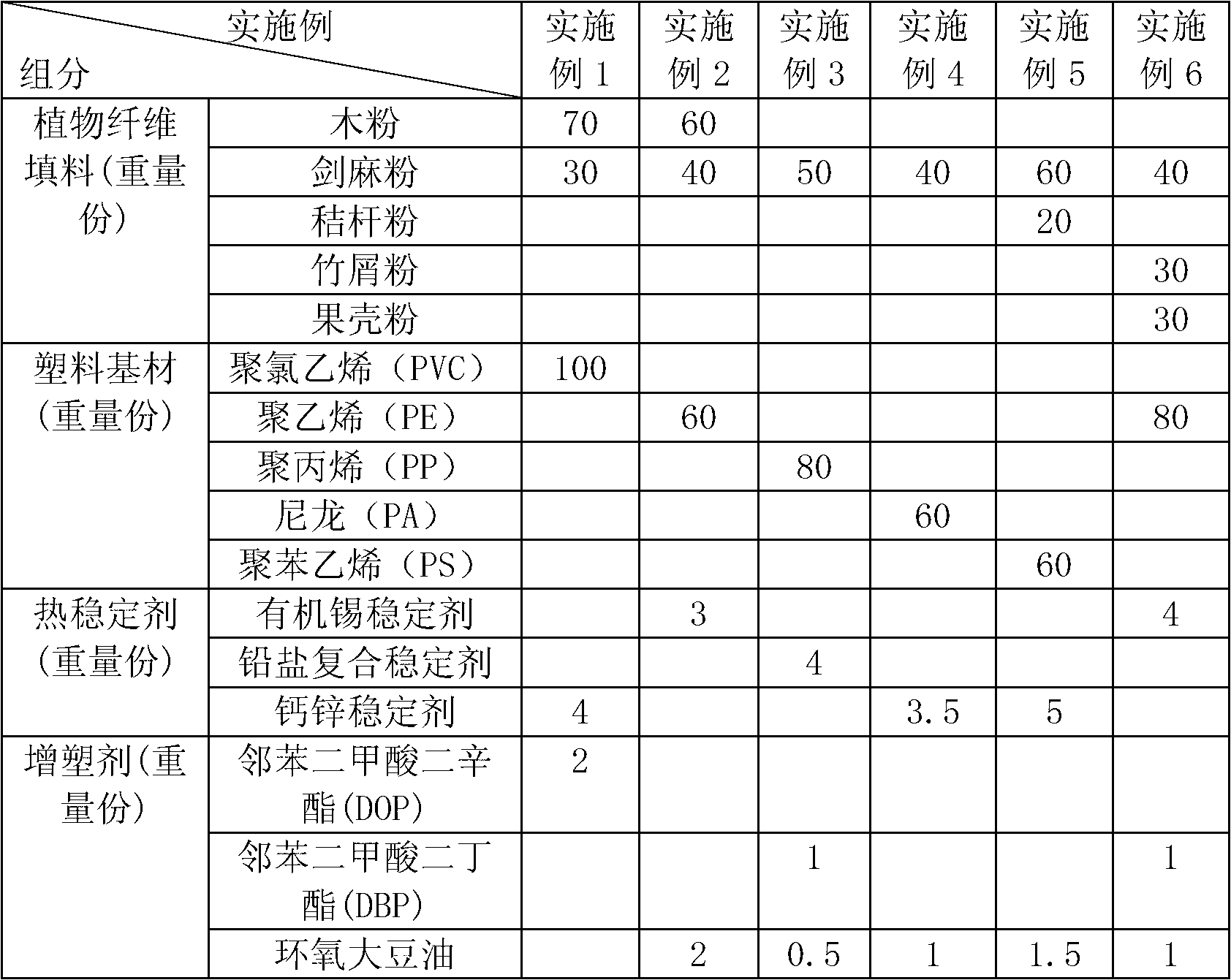

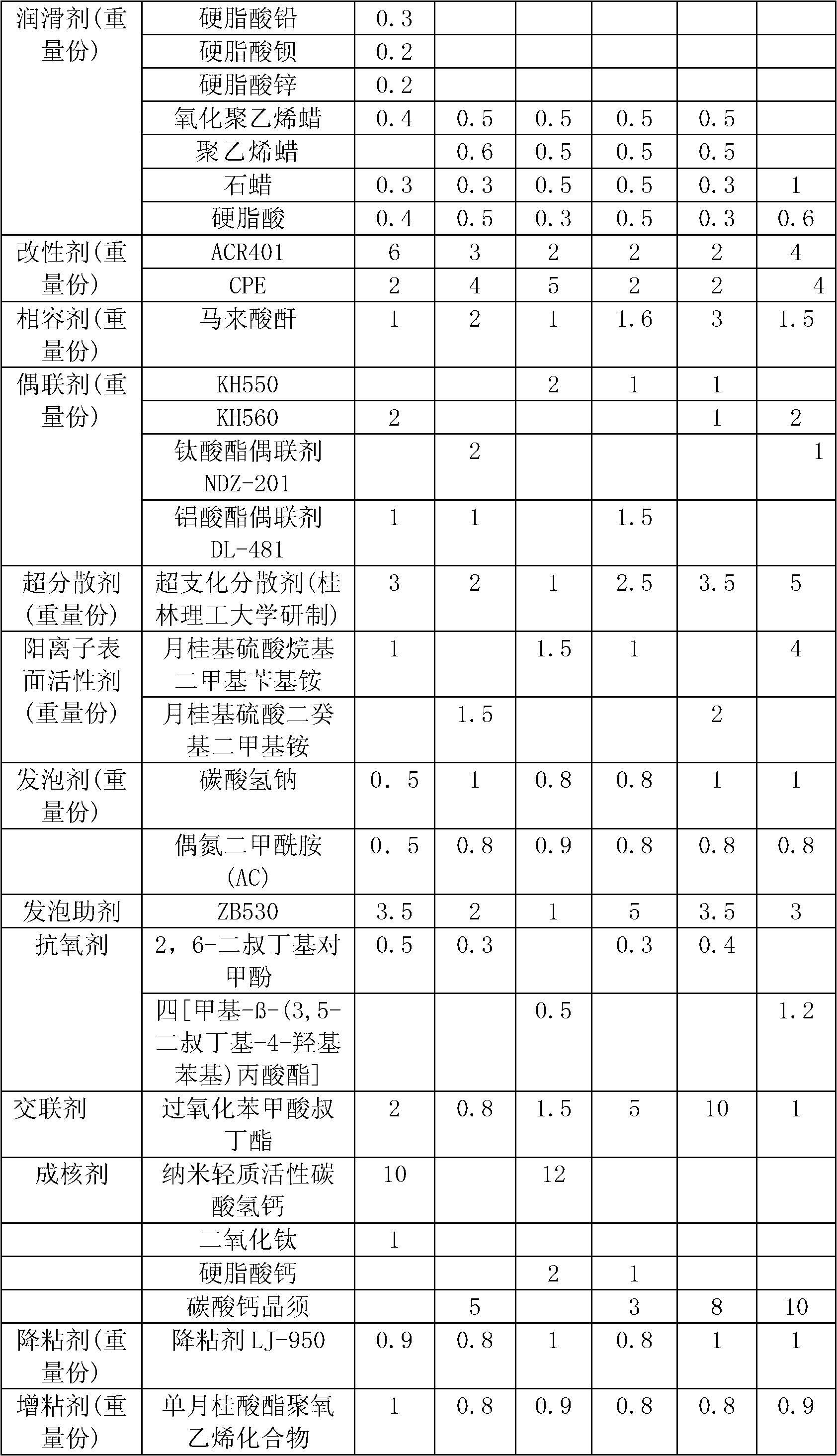

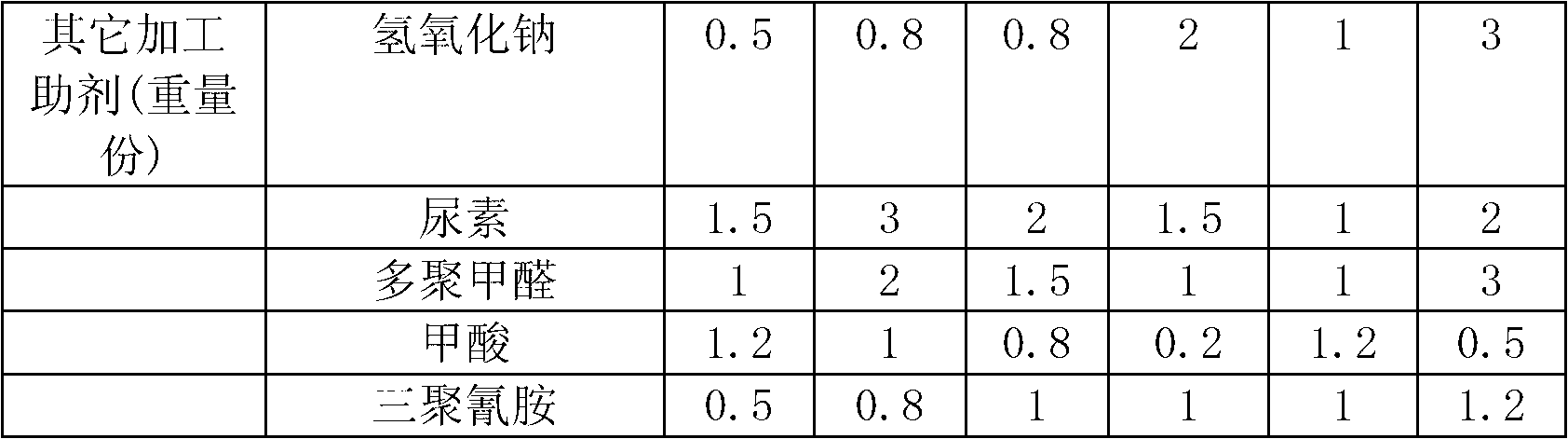

The invention discloses a new macromolecule fiber composite material which is prepared by the following components in parts by weight, 40-100 parts of plant fiberfill, 60-100 parts of plastic base material, 3.5-5 parts of heat stabilizer, 1-2 parts of plasticizer, 1.6-2 parts of lubricating agent, 4-8 parts of modifying agent, 1-3 parts of compatilizer, 2-3 parts of coupling reagent, 1-5 parts of super dispersing agent, 1-4 parts of positive ion surface active agent, 1-1.8 parts of foaming agent, 1-5 parts of blowing promoter, 0.3-1.2 parts of antioxygen, 1-10 parts of cross-linking agent, 1-20 parts of nucleating agent, 0.8-1 part of viscosity reducer, 0.8-1 part of tackifier and 3.2-13.4 parts of other auxiliaries. The new composite material can not easily cause wet swelling and air shrinkage, and is low in expansibility and water absorbability, so that the prepared product has good stability.

Owner:GUILIN SHUKANG BUILDING MATERIAL

Method and device for printing pictures and texts on surface of irregular object

InactiveCN101734030ASimple color printingEfficient Color PrintingDecorative surface effectsDuplicating/marking methodsPlastic moldingElectrical and Electronics engineering

The invention relates to a method and a device for printing pictures and texts, particularly to a method and a device for printing fine pictures and texts on the surface of an irregular object, which comprises the following steps of: a. manufacturing a compound transfer printing film; b. pre-deforming the compound transfer printing film; c. placing the deformed compound transfer printing film in a plastic hollow blow molding mould, realizing transfer printing in the plastic molding process, or clinging the deformed compound transfer printing film to a printing undertaking object, and sharing through one or more modes of heating, infrared illumination, ultraviolet illumination and pressurization to realize transfer printing; and d. removing a substrate layer and a stripping layer. The invention has the advantages that the printing of fine pictures and texts can be carried out on the surfaces of a regular object and the irregular object, pictures and texts are continuous, whether the local surface or the entire surface can be printed once through the invention, and the invention has a good solution particularly for an object with a complicated surface.

Owner:赵东林

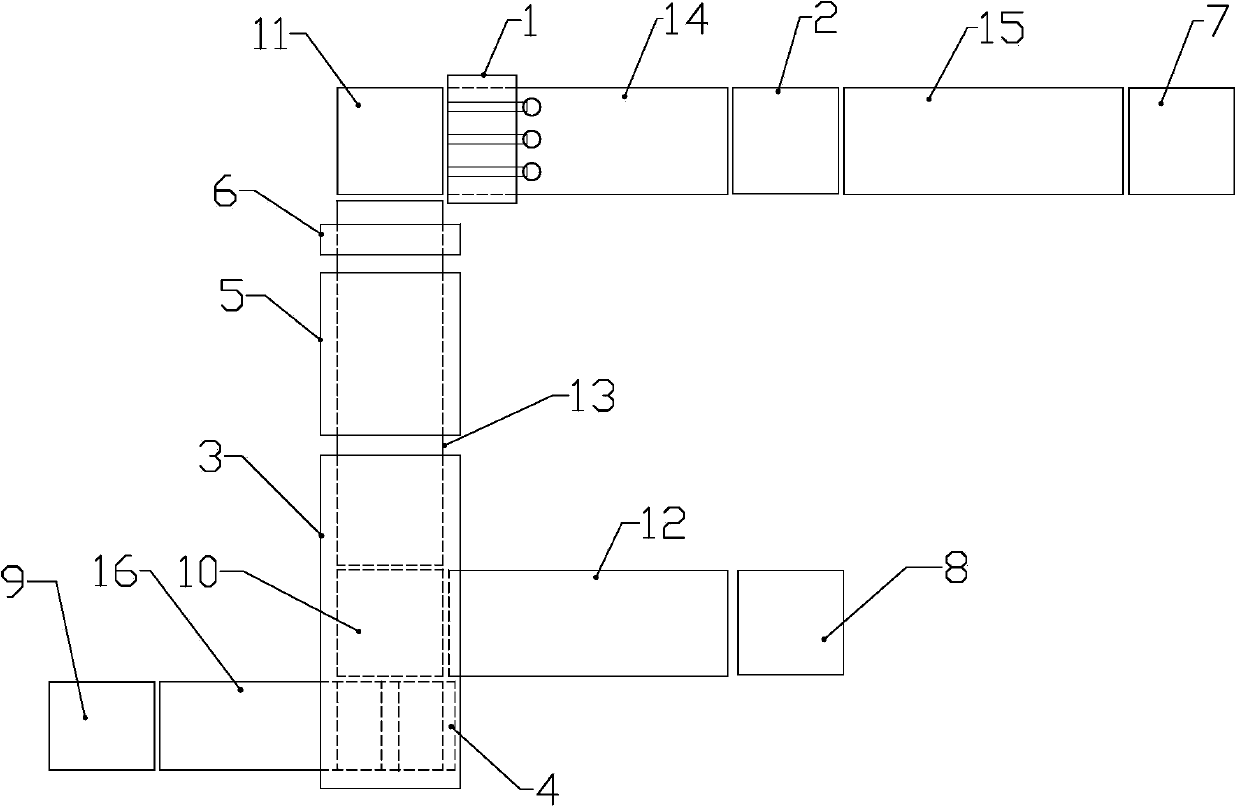

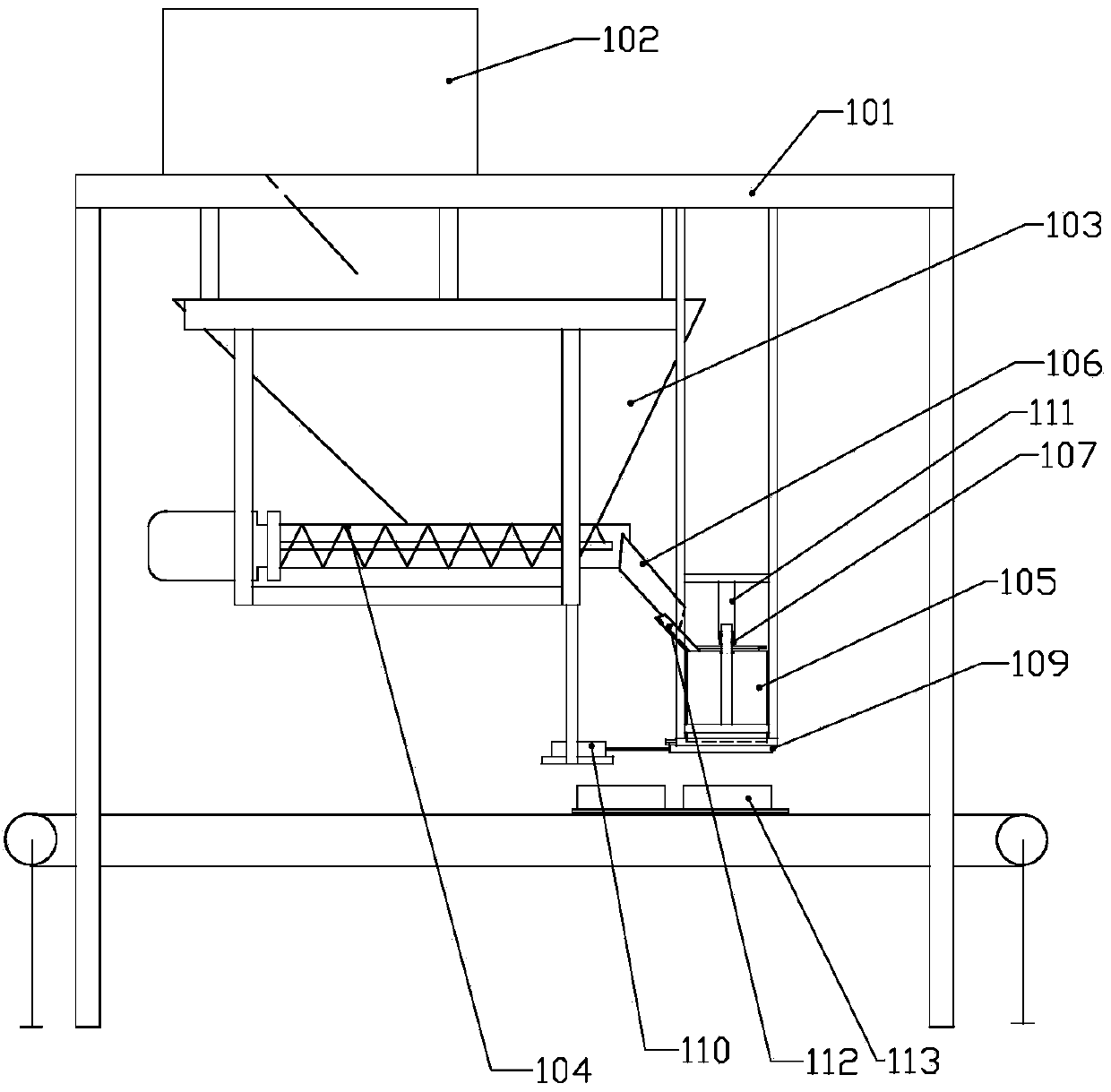

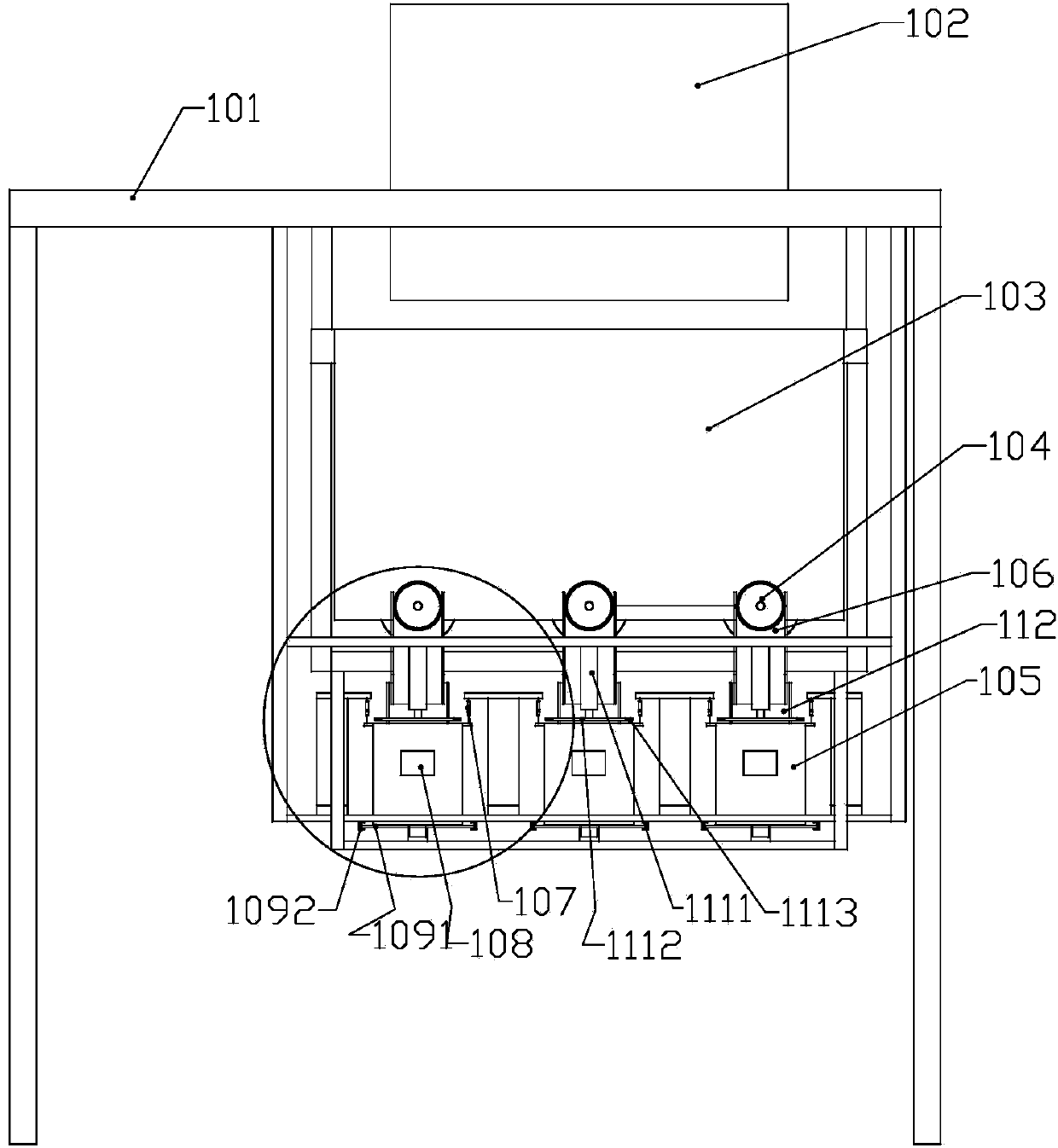

Automatic production line of small plastic-concrete components

ActiveCN104191513AObvious price advantageIncrease production capacityDischarging arrangementDischarging apparatusProduction lineHigh volume manufacturing

The invention discloses an automatic production line of small plastic-concrete components, and belongs to production equipment of small plastic-concrete components. The automatic production line of the small plastic-concrete components structurally comprises a metering pouring machine, a vibration table, a mechanical grip transporter, a turnover stripper machine, a die cleaning machine, a color pouring machine, stacking machines, turning platforms and conveyers. The stacking machines comprise the first stacking machine, the second stacking machine and the third stacking machine. The turning platforms comprises the first turning platform and the second turning platform. The conveyors comprise the first conveyor, the second conveyor, the third conveyor, the fourth conveyor and the fifth conveyor. The mechanical grip transporter is arranged at the upper portion of the front of the turnover stripper machine, the first turning platform and the second turning platform and the die cleaning machine and the color pouring machine are sequentially arranged at the upper portion of the second conveyor behind the mechanical grip transporter from front to back. The automatic production line of the small plastic-concrete components has the advantages of reducing the labor intensity of workers, saving time and labor, improving the production efficiency, improving the product quality, being capable of meeting the requirements for mass production within short time and the like.

Owner:JINAN DONGYUAN CEMENT PROD CO LTD

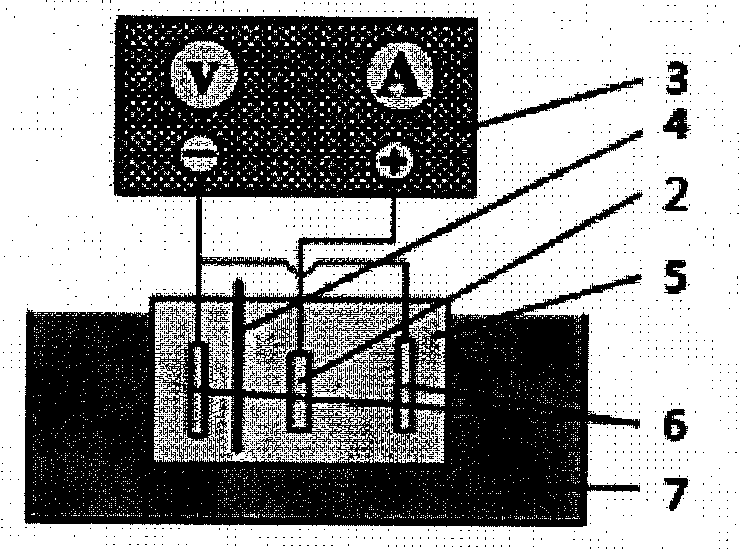

Metal coating plumbago composite material and method of producing the same

InactiveCN101508596ABeautiful surfaceWith metallic lusterLiquid/solution decomposition chemical coatingHeat sinkChemical plating

The invention provides a metal plating (copper or nickel or zinc) graphite compound material and a preparation method thereof. One of the preparation method is degreasing and coarsening the surface of the graphite radiating material; soaking and washing the processed material in sensitizing solution and activating solution; and finally carrying out chemical plating of copper or nickel or zinc and the like in plating solution, drying and post-treatment to obtain the finish product. The other preparation method is carrying out degreasing, coarsening and other pre-processing on the surface of the graphite radiating material before electroplating, and then carrying out electroplating in electroplating solution to obtain the finish product. By both of the preparation methods provided by the invention, whether chemical plating or electroplating, a graphite board material which can beautify the graphite cooling plate, improve the strength of the graphite cooling plate and add the connecting mode (like welding) of the graphite cooling plate and the metal base material can be obtained. The metal plating graphite compound material has the characteristics of low density, high heat conductivity and strength, and easy joining with metals, is an outstanding radiating material, and can be widely used in thermal management systems of electronic products.

Owner:晟茂(青岛)能源替代产品研发有限公司

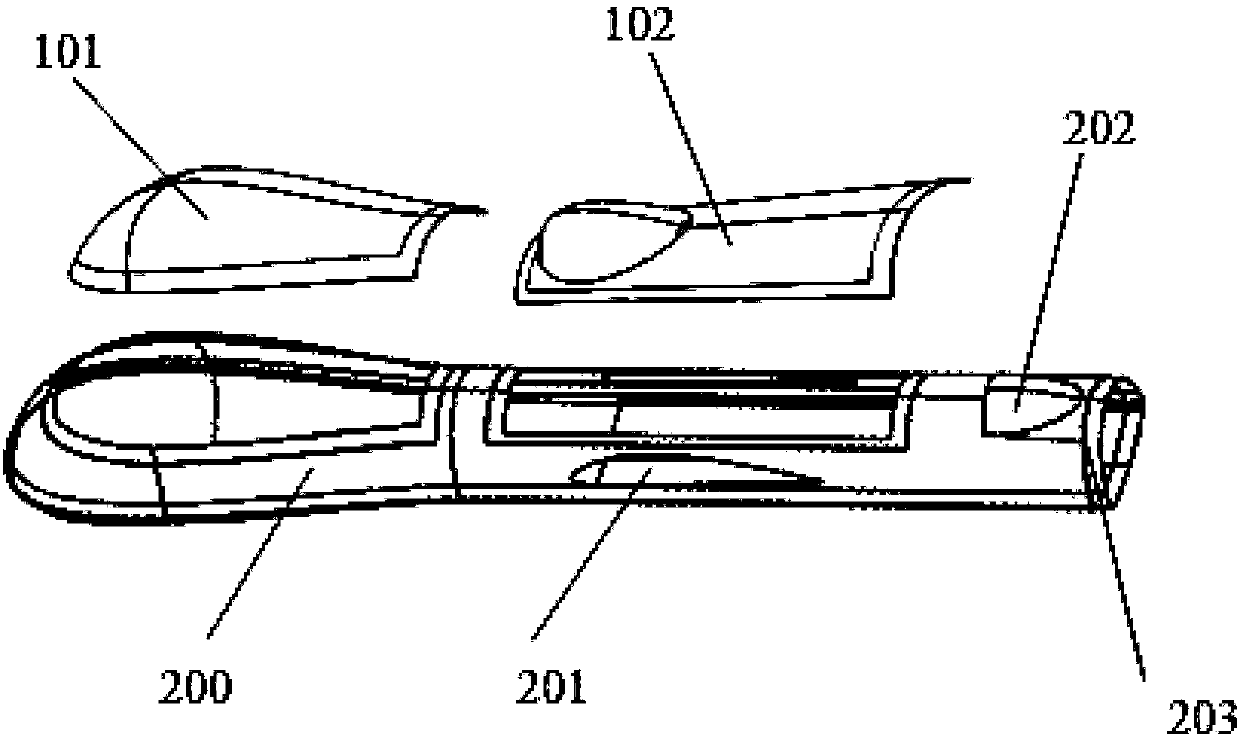

Metal-plastic composite mobile phone shell and forming method thereof

InactiveCN103722668AUniform wall thicknessBeautiful surfaceDomestic articlesCoatingsConvex structureUltimate tensile strength

The invention provides a metal-plastic composite mobile phone shell and a forming method thereof. The provided mobile phone shell has a metal surface and a plastic structure feature, wherein the external surface of the mobile phone shell is made of a sheet metal and is small in wall thickness, high in strength and beautiful in appearance; a convex structure feature of the internal surface of the mobile phone shell is made of plastics, so that the formation of a complex installation structure is facilitated, and the functional requirements on assembling and shock absorption and the like are satisfied. According to the forming method, structure features of the sheet metal and the plastic are firmly combined together and form an integral structure. Meanwhile, according to the forming method, the combination strength of plastics and metals is high, so that the mobile phone shell satisfies the assembling and application requirements of mobile phones, and also can be applied to the shell production fields of household appliances, computers and other industrial products.

Owner:ZHEJIANG NORMAL UNIVERSITY

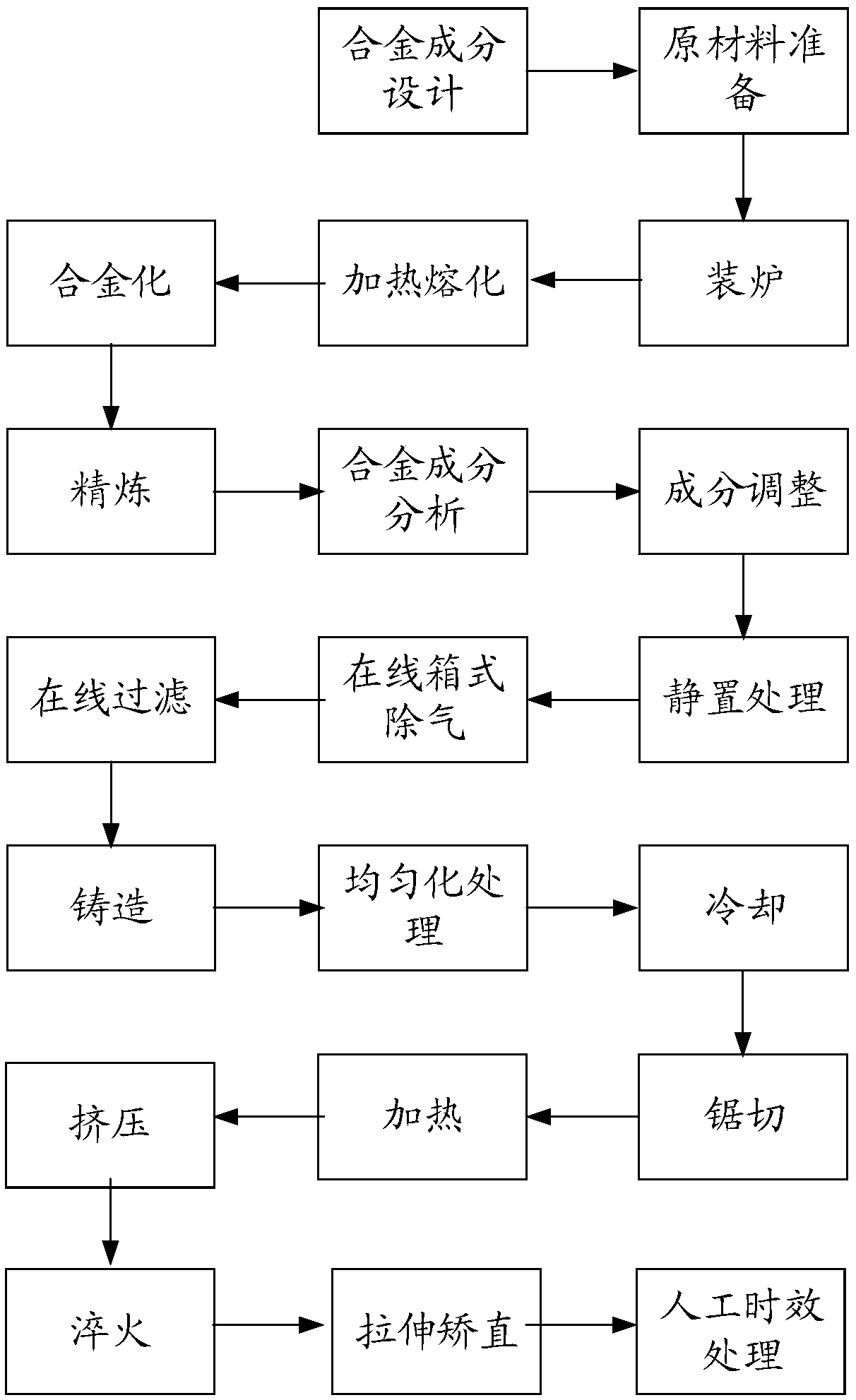

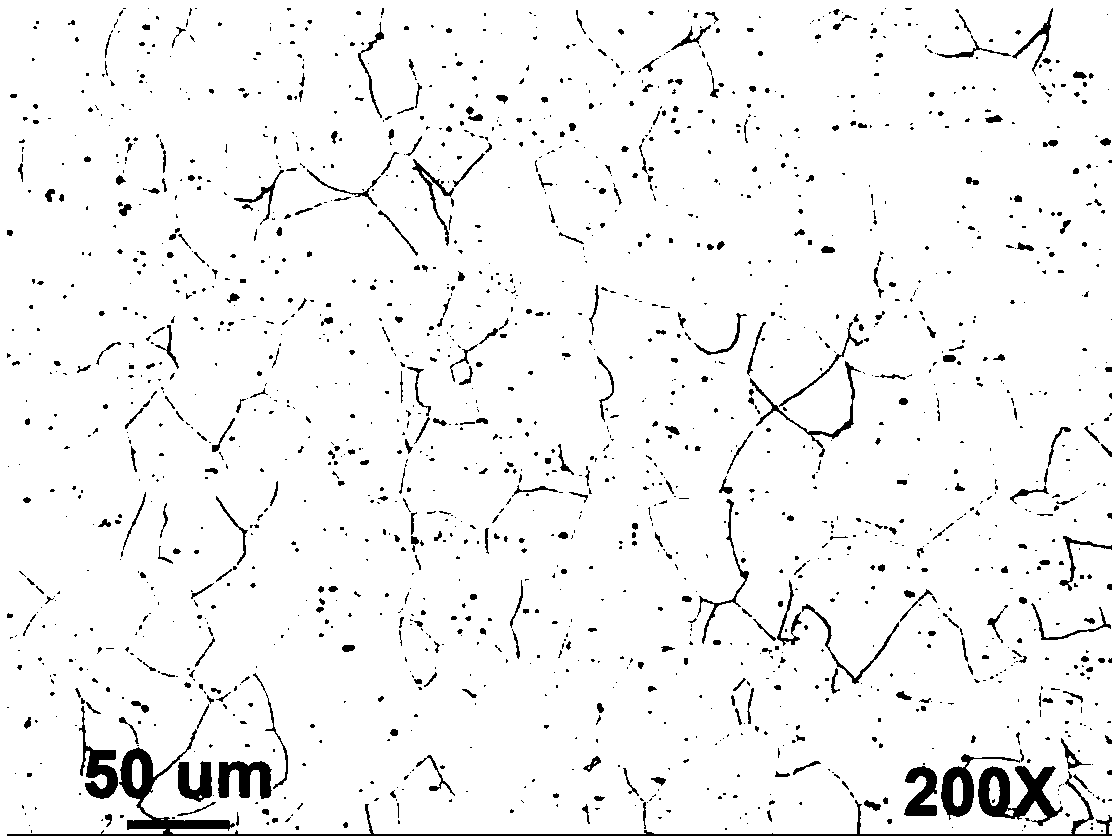

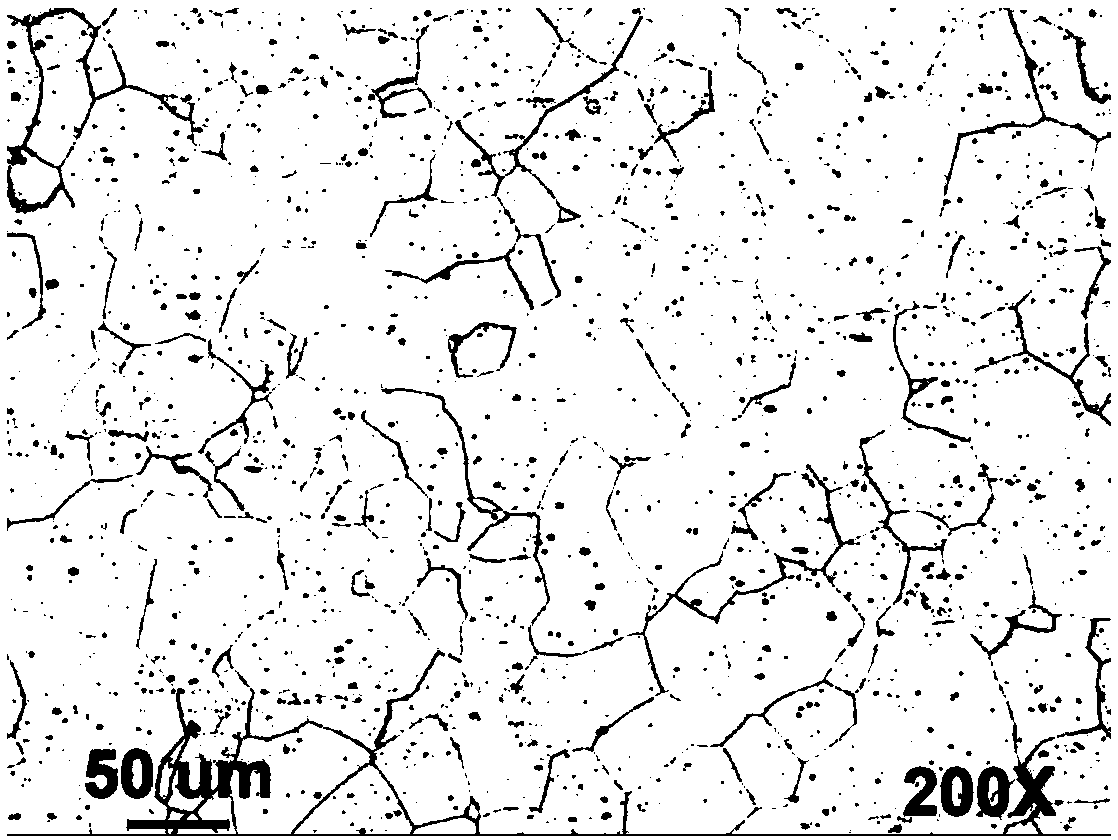

Al-Mg-Si-Cu-Mn alloy and preparation method thereof

The invention provides an Al-Mg-Si-Cu-Mn alloy including the following chemical composition by mass: 0.50-0.75% of Si, 0.85-1.00% of Mg, 0.08-0.18% of Mn, 0.48-0.63% of Cu, 0.003-0.012% of Ti, no morethan 0.1% of Fe, no more than 0.15% of impurities and the balance Al. The mass ratio of the Mg element to the Si element is that Mg / Si = 1.15-1.60. The alloy has the advantages of high tensile strength, high yield strength, excellent anodizing performance and attractive surface, and solves the problems of easy wear and deformation under pressure caused by moderate strength of the 6061 aluminum alloy for portable electronic equipment.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

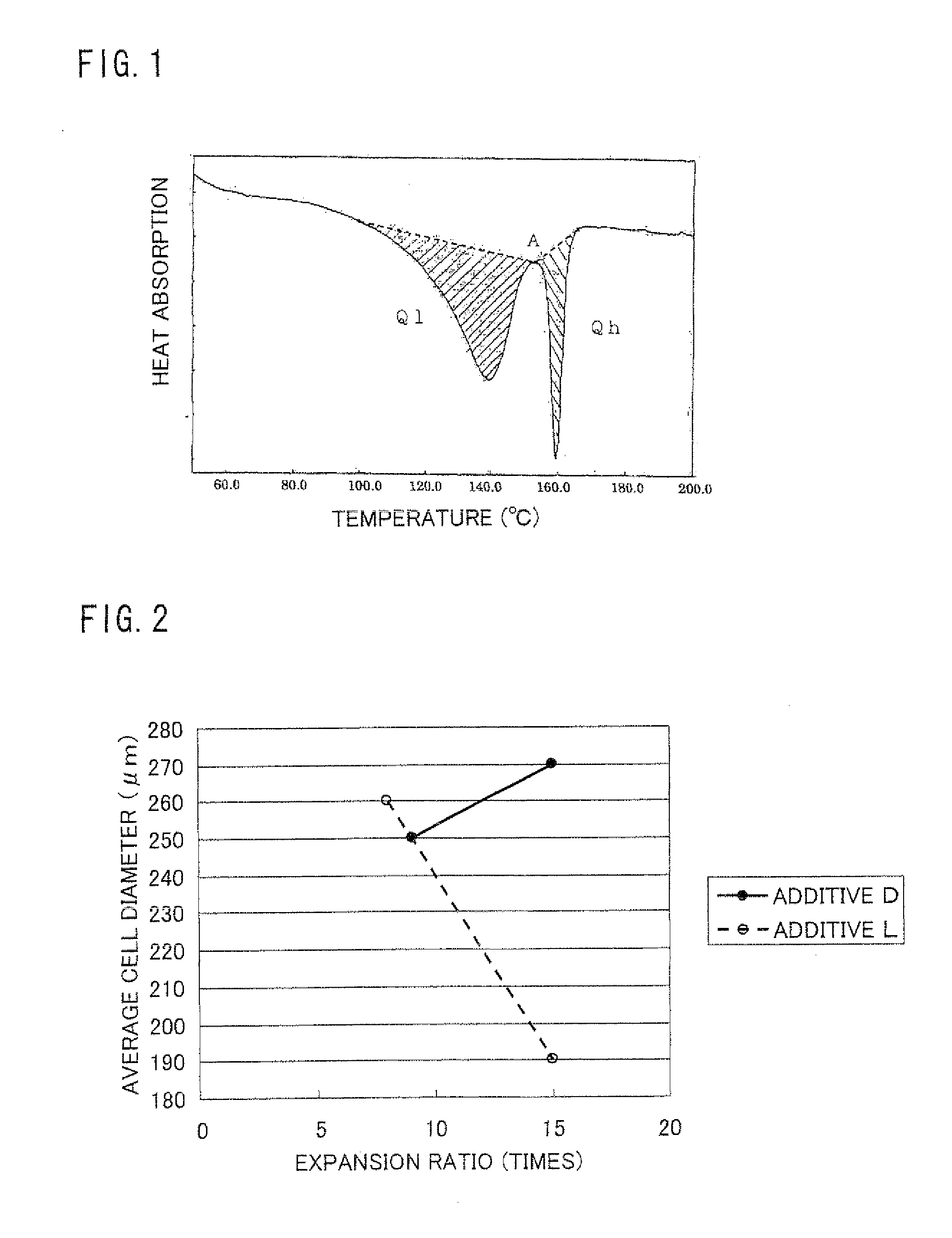

Process for producing expanded polyolefin resin particles and expanded polyolefin resin particles

ActiveUS20100267850A1High expansion ratioHigh dimensional accuracyThin material handlingPolyolefinPolyethylene glycol

Provided is a process for producing expanded polyolefin resin particles whose cells are not made nonuniform or extremely smaller as seen in conventional expanded particles, whose cell diameter and expansion ratio can be easily controlled independently, and which, when subjected to in-mold expansion molding, give in-mold expanded molded products satisfactory in fusibility and excellent in surface properties. The process is a process for producing expanded polyolefin resin particles by: dispersing polyolefin resin particles together with an aqueous dispersion medium into a closed vessel; heating the polyolefin resin particles up to or above a softening temperature of the polyolefin resin particles; and releasing the polyolefin resin particles into a zone whose pressure is lower than an internal pressure of the closed vessel, with use as a foaming agent of water serving as the dispersion medium, the polyolefin resin particles being composed of a polyolefin resin composition including: polyolefin resin; a substance selected from among polyethylene glycol, polyvalent alcohol having a carbon number of not less than 3 to not more than 6, and a water-absorbing substance having no function of forming foaming nuclei; and a foam nucleating agent.

Owner:KANEKA CORP

Unmanned aerial vehicle body integrated molding technology

InactiveCN107738457AImprove performanceImprove mobilityFuselage framesWeight reductionFiberCarbon fibers

The invention discloses an unmanned aerial vehicle body integrated molding technology. Carbon fiber prepreg and lightweight foam are used as raw materials, are paved on the inner wall of a double-female mold combination mold by adopting a prepreg lapping joint integral layering technology, and then are integrally solidified and molded by adopting an autoclave molding technology. The unmanned aerial vehicle body integrated molding technology has the beneficial effects that the technology is simple and is easy to operate; the molding time is short; the product size is accurate and controllable;and a manufactured unmanned aerial vehicle body has high strength, good rigidity, light dead weight and a smooth and fat surface, is easy to maintain routinely and is suitable for large batch production.

Owner:CGN JUNER NEW MATERIALS +1

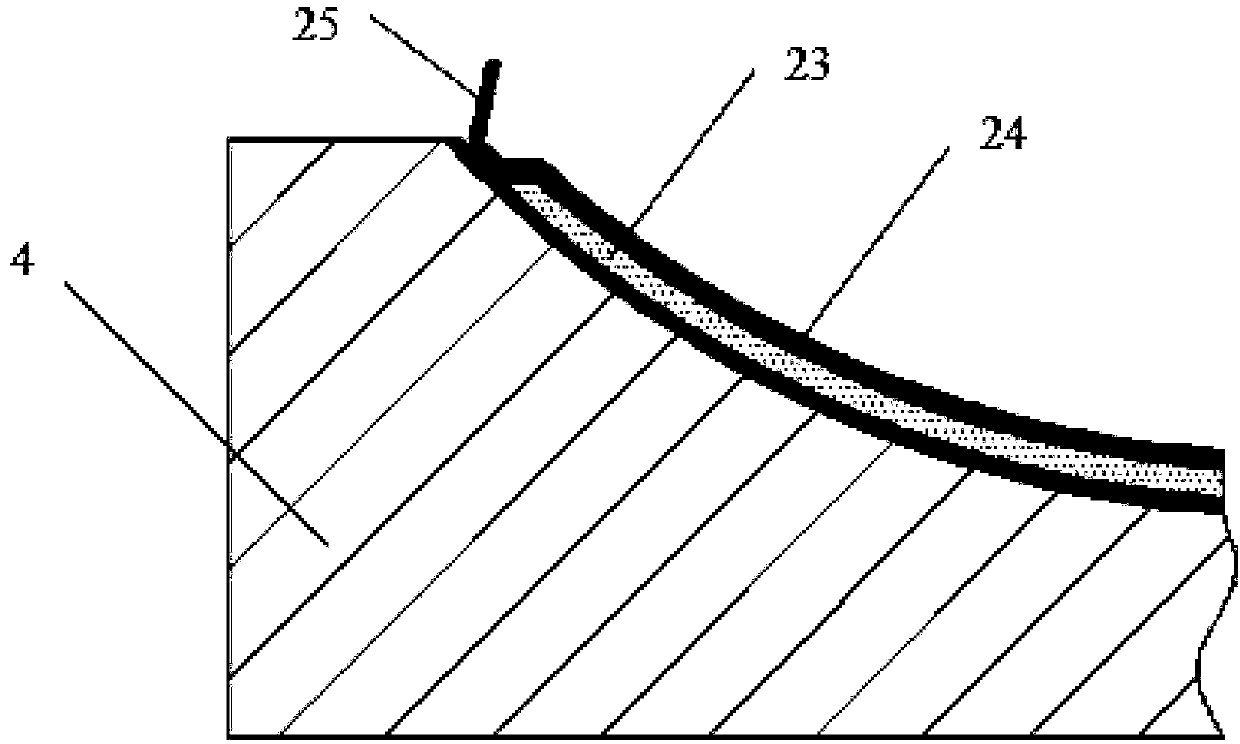

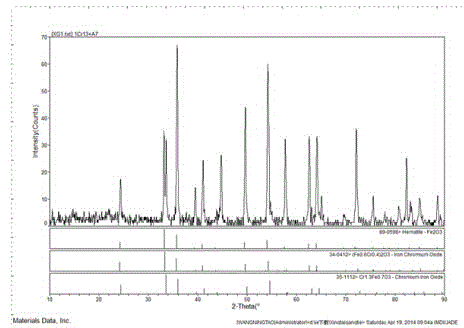

Hydrochloric-acid acid washing liquid and acid washing method for 400-series stainless steel hot-rolled annealing wire

The invention relates to a hydrochloric-acid acid washing liquid and an acid washing method for a 400-series stainless steel hot-rolled annealing wire. The acid washing liquid comprises hydrochloric acid, nitric acid, a corrosion inhibitor, a surface active agent, an accelerant, a solution stabilizer and water. The acid washing liquid comprises the substances at a mass ratio as follows: 8wt%-22wt% of hydrochloric acid, 0.01wt%-10wt% of nitric acid, 0.01wt%-1wt% of the corrosion inhibitor, 0.05wt%-1wt% of the surface active agent, 0.05wt%-1wt% of the accelerant, 0.05wt%-1wt% of the solution stabilizer and the balance of water. The acid washing method comprises steps as follows: the acid washing liquid is injected to an acid washing tank, the whole coil of the hot-rolled wire after annealing is directly placed in the acid washing tank for acid washing, the acid washing temperature is in a range from 45 DEG C to 85 DEG C, and the acid washing time is 0.5-2 h. The treated wire rod surface is clean, white and bright, oxide scale residues are avoided, the acid washing process is stable, the surface is slightly frosted and suitable for wire drawing, and a follow-up passivation process can be omitted.

Owner:XINGTAI IRON & STEEL

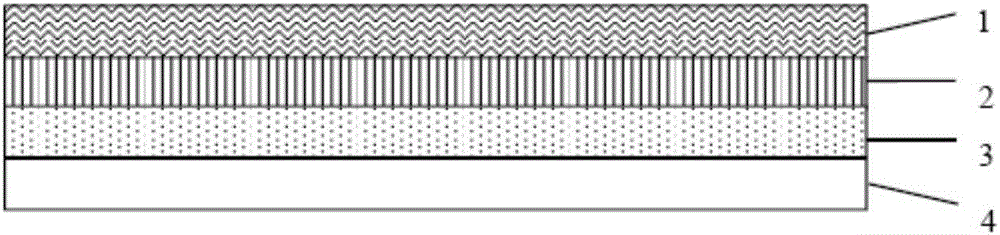

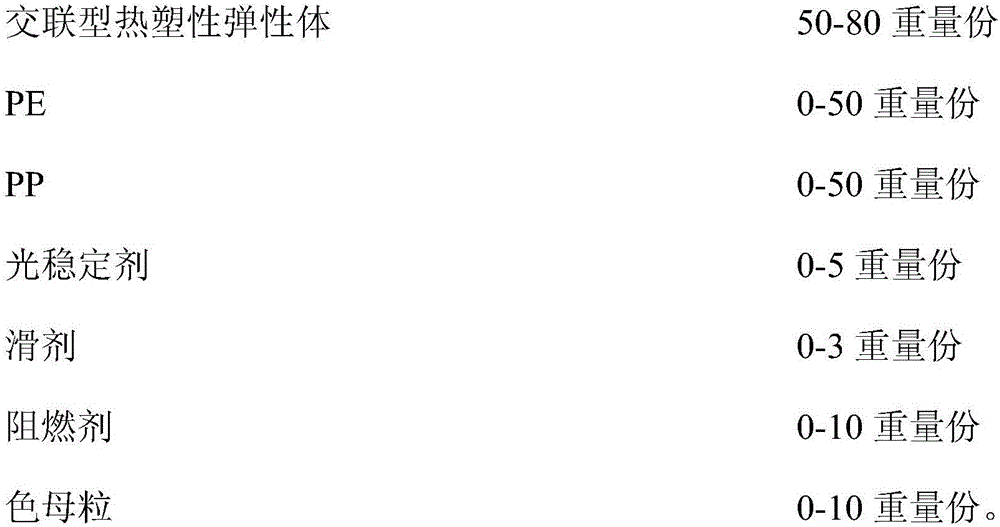

Environmentally-friendly automotive trim composite material and preparation method thereof

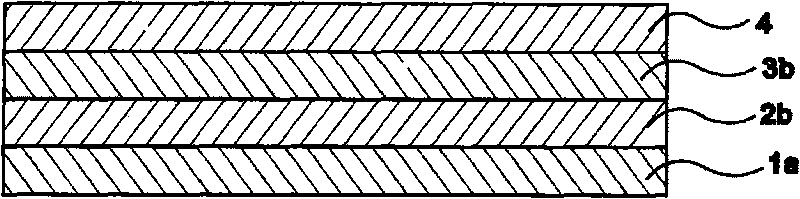

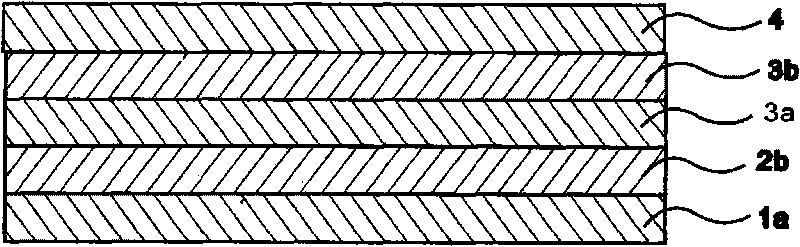

ActiveCN106827751AImprove wear resistanceExcellent formabilityPolyureas/polyurethane adhesivesSynthetic resin layered productsFiberThermoplastic

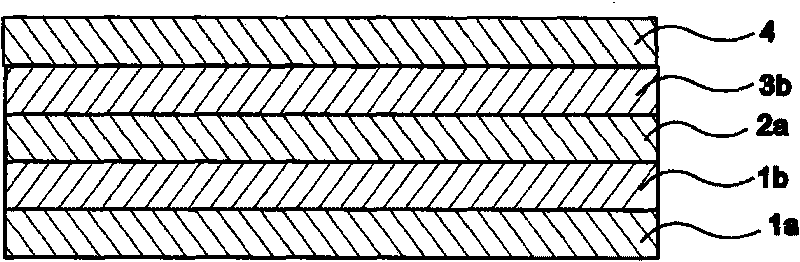

The invention provides an environmentally-friendly automotive trim composite material and a preparation method thereof. The automotive trim composite material comprises a surface layer, a foaming layer, a hot melt glue layer and a skeleton structure layer, wherein the surface layer is a TPU (Thermoplastic Polyurethanes) film layer, a TPO (Thermoplastic Polyolefin) film layer, a PU (Poly Urethane) film layer, a PP (Propene Polymer) film layer or a genuine leather layer; the foaming layer is a PP foaming layer, a PPF foaming layer, a PU foaming layer or a PE (Poly Ethylene) foaming layer; the hot melt glue layer is a TPU hot melt glue layer, an EVA (Ethylene-vinyl Acetate Copolymer) hot melt glue layer, a PE hot melt glue layer, a PA (Poly A) hot melt glue layer or other hot melt glue layers; the skeleton structure layer is made of a glass fiber modified PP composite material, a carbon fiber modified PP composite material, or an ABS (Acrylonitrile Butadiene Styrene) modified PP composite material. According to the environmentally-friendly automotive trim composite material and the preparation method thereof provided by the invention, the surface layer with the foaming layer is glued with a skeleton structure through an environmentally-friendly hot melt glue, so that the gluing degree is good, the rejection rate is low, the product forming quality is effectively ensured, and the manpower is saved; the product is wear-resisting, high in tearing strength and dimensional stability, not easy to strip, attractive in appearance, and environmentally-friendly in production process without pollution; the product can be recycled.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

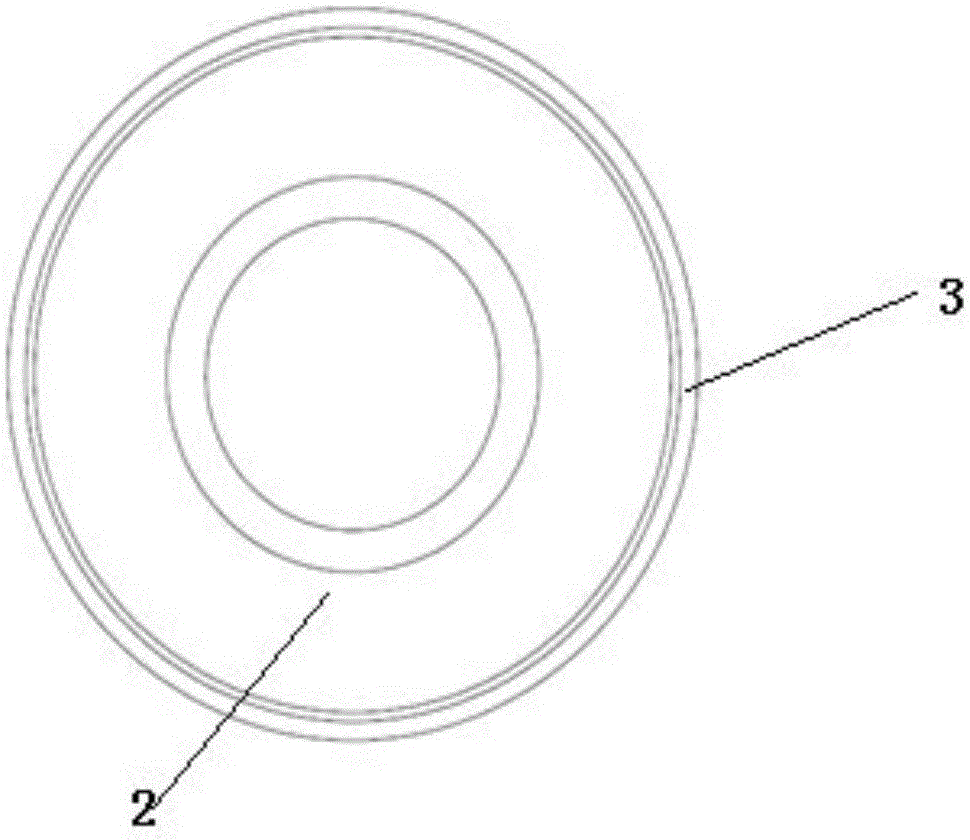

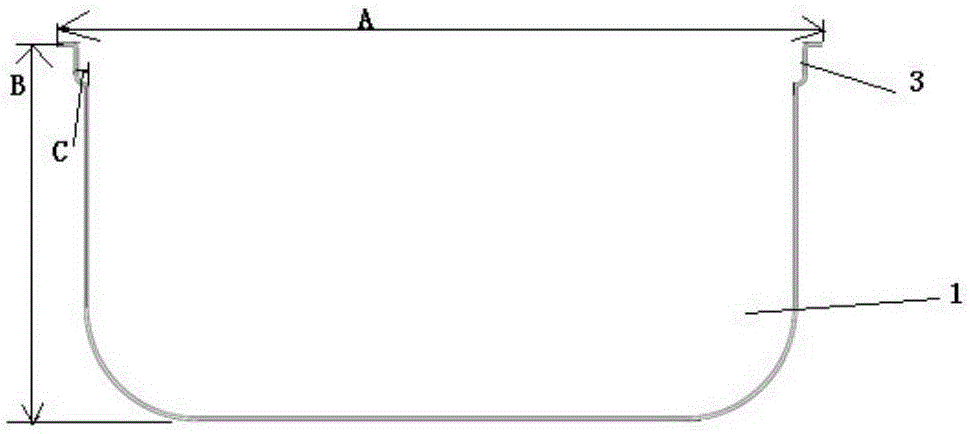

Tinplate two-piece can stretch-forming processing method and mold, and product thereof

ActiveCN105127267ABreak through the limitations of useLarge capacityShaping toolsCoatingsForm processingMaterials science

The invention relates to the technical field of metal packaging, and particularly discloses a tinplate two-piece can stretch-forming processing method which comprises the following steps: (1) plate preparation; (2) cup pre-stretch-forming; (3) cup secondary stretch-forming; and (4) stretch forming and neck expansion by flanging. The invention also discloses a special mold adopted by the tinplate two-piece can stretch-forming processing method and a tinplate two-piece can prepared by the special mold. The method breaks through the limitations in the existing tinplate two-piece can for food through the innovation on the mold, technique and material; and the diameter of the can body can reach 105mm, and the stretch-forming height is 51.5mm or above. The method has the advantages of accurate technique, fewer steps, low cost and high safety, is free of cleaning, obviously enhances the sealability and safety of the can body, saves the cost, lowers the technical complexity, and can not have the phenomenon of material stretch-forming cracking. The tinplate two-piece can can not be scratched when in use, and can be widely used in packaging canned food and other types of food.

Owner:英联金属科技(汕头)有限公司

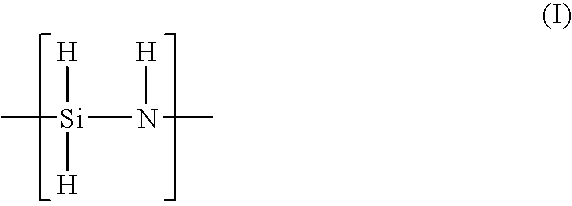

Hydrophilization-accelerating and hydrophilicity-keeping agents for polysilazane-containing coating films

InactiveUS20050119402A1Improve hydrophilicityLess of a smellOther chemical processesPretreated surfacesHydrophilizationOrganic acid

An aqueous solution is prepared comprising 5 to 25% by weight of an anionic surfactant, 0.5 to 20% by weight of an amphoteric surfactant, 4 to 6% by weight of a nonionic surfactant and, if necessary, an antiseptic and the aqueous solution is adjusted with an organic acid to pH in the range of 4.5 to 7.0, which is used as an undiluted solution of a hydrophilicity maintaining and promoting agent for a polysilazane-containing coating film. The undiluted solution is diluted with water to from 3 to 15 times and the resulting solution is used as a hydrophilicity promoting agent. While the undiluted solution is diluted with water to from 30 to 70 times and the resulting solution is used as a hydrophilicity maintaining agent. The hydrophilicity promoting agent is applied on an anti-fouling coating film which is formed by applying on a substrate a coating solution comprising polysilazane and, if necessary, silica conversion catalyst, and thereby the coating film is made hydrophilic in an extremely short time. Further the hydrophilicity maintaining agent is used for removing stains which adhere to the coating film and maintaining the hydrophilicity of the film.

Owner:MERCK PATENT GMBH

8B cold-rolling precision steel belt and manufacturing method thereof

ActiveCN105195510AReduce lossImprove post-spot welding workabilityFurnace typesWork cleaning devicesAcid washingManganese

The invention belongs to the technical field of manufacturing of strip steel and discloses a manufacturing method of an 8B cold-rolling precision steel belt. The manufacturing method comprises the following steps: carrying out sizing vertical shearing on a raw material steel coil; carrying out cold rolling on the vertically-sheared steel coil; degreasing the coldly-rolled steel coil, and carrying out bright whole-soft-cover type annealing; carrying out small-ductility flattening on the annealed steel coil and carrying out large-ductility oil flattening and tempering; splitting the flattened steel coil to obtain the cold-rolling precision steel belt, wherein the raw material steel coil is a hot-rolling acid washing coil, and is prepared from the following components in mass percent: 0.02 to 0.055 percent of carbon, 0.002 to 0.30 percent of silicon, 0.0120 to 0.20 percent of manganese, less than or equal to 0.025 percent of phosphorus, less than or equal to 0.09 percent of aluminum and the balance of iron and unavoidable impurities, and the equivalent weight of the carbon of the acid washing coil is not more than 0.30 percent, the thickness range is 2.5mm to 3.5mm, and the width range is 1250mm to 1280mm. According to the manufacturing method provided by the invention, a technical process from material selection to cold rolling is optimized, the quality is improved and the performance requirements of products are adapted.

Owner:宝武轻材(武汉)有限公司

4B cold-rolled precise steel strip and manufacturing method thereof

ActiveCN105234171AReduce lossImprove post-spot welding workabilityRoll mill control devicesMetal rolling arrangementsManganeseStrip steel

The invention belongs to the technical field of strip steel manufacturing, and discloses a manufacturing method of a 4B cold-rolled precise steel strip. The manufacturing method comprises the steps of conducting fixed-length longitudinal shearing on raw steel coils, conducting cold rolling on the longitudinally-sheared steel coils, degreasing the cold-rolled steel coils, then conducting bright fully-soft cover annealing, conducting small-ductility pre-flattening and then large-ductility oil flattening and hardening and tempering on the annealed steel coils, and splitting the flattened steel coils to obtain cold-rolled precise strip steel. The raw steel coils are hot-rolled acid-pickled coils and comprise, by mass, 0.025%-0.060% of carbon, 0.002%-0.35% of silicon, 0.015%-0.250% of manganese, 0-0.025% of phosphorus, 0-0.09% of aluminum, and the balance iron and inevitable impurities; the carbon equivalent of the acid-pickled coils is not larger than 0.35%, the thickness ranges from 2.5 mm to 3.5 mm, and the width ranges from 1250 mm to 1280 mm. According to the manufacturing method, the process from material selection to cold rolling is optimized, the quality is improved, and the performance requirement of products is met.

Owner:宝武轻材(武汉)有限公司

Surface processing process of aluminum and aluminum alloy workpieces

InactiveCN103624636ASurface crystal structure vibrationNot easy to scratchPolishing machinesElectrophoretic coatingsSteel ballDrying time

The invention discloses a surface processing process of aluminum and aluminum alloy workpieces, and has the advantages that the process operation is simple and easy, the cost is low, and the noise and dust pollution is low. The surface processing process is realized through the following steps that firstly, a plurality of stainless steel balls are poured into a grinding chamber of a vibration grinding machine for forming stainless steel bead balls, then, clean water is poured into the grinding chamber of the vibration grinding machine, in addition, stainless steel ball piles are immersed by the poured clean water, finally, aluminum and aluminum alloy workpieces to be processed are poured into the grinding chamber of the vibration grinding chamber, aluminum alloy cleaning agents are added into the grinding chamber of the vibration grinding machine for carrying out grinding vibration cleaning, and the grinding vibration cleaning time is 3 to 5 minutes; aluminum alloy brightening agents are added into the grinding chamber of the vibration grinding machine for carrying out grinding and brightening treatment, and the grinding and brightening time is 8 to 12 minutes; the aluminum and aluminum alloy workpieces processed in the third step are taken out to be subjected to cleaning treatment, the aluminum and aluminum alloy workpieces processed in the fourth step are placed into a drying box to be dried, the drying temperature is 130 to 150 DEG C, and the drying time is 5 to 8 minutes.

Owner:福建天广消防有限公司

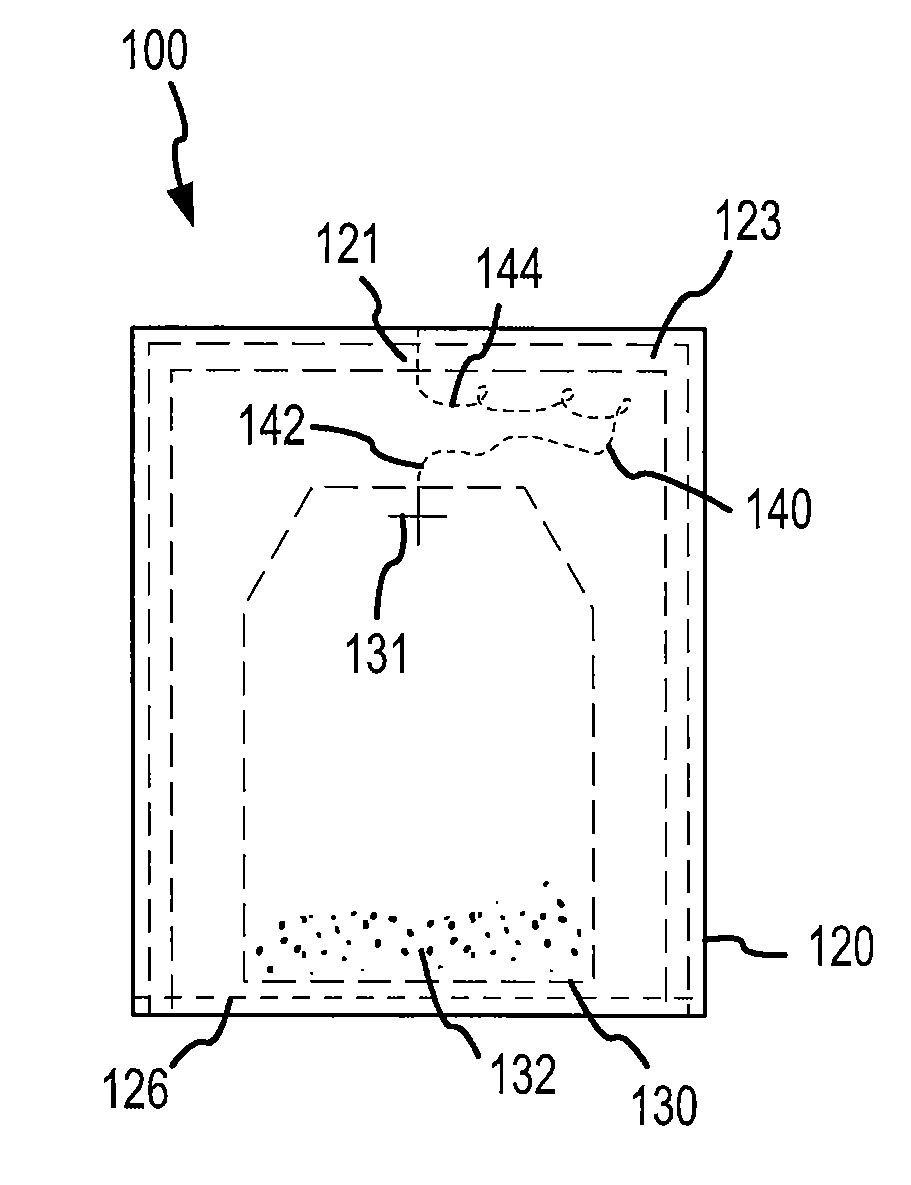

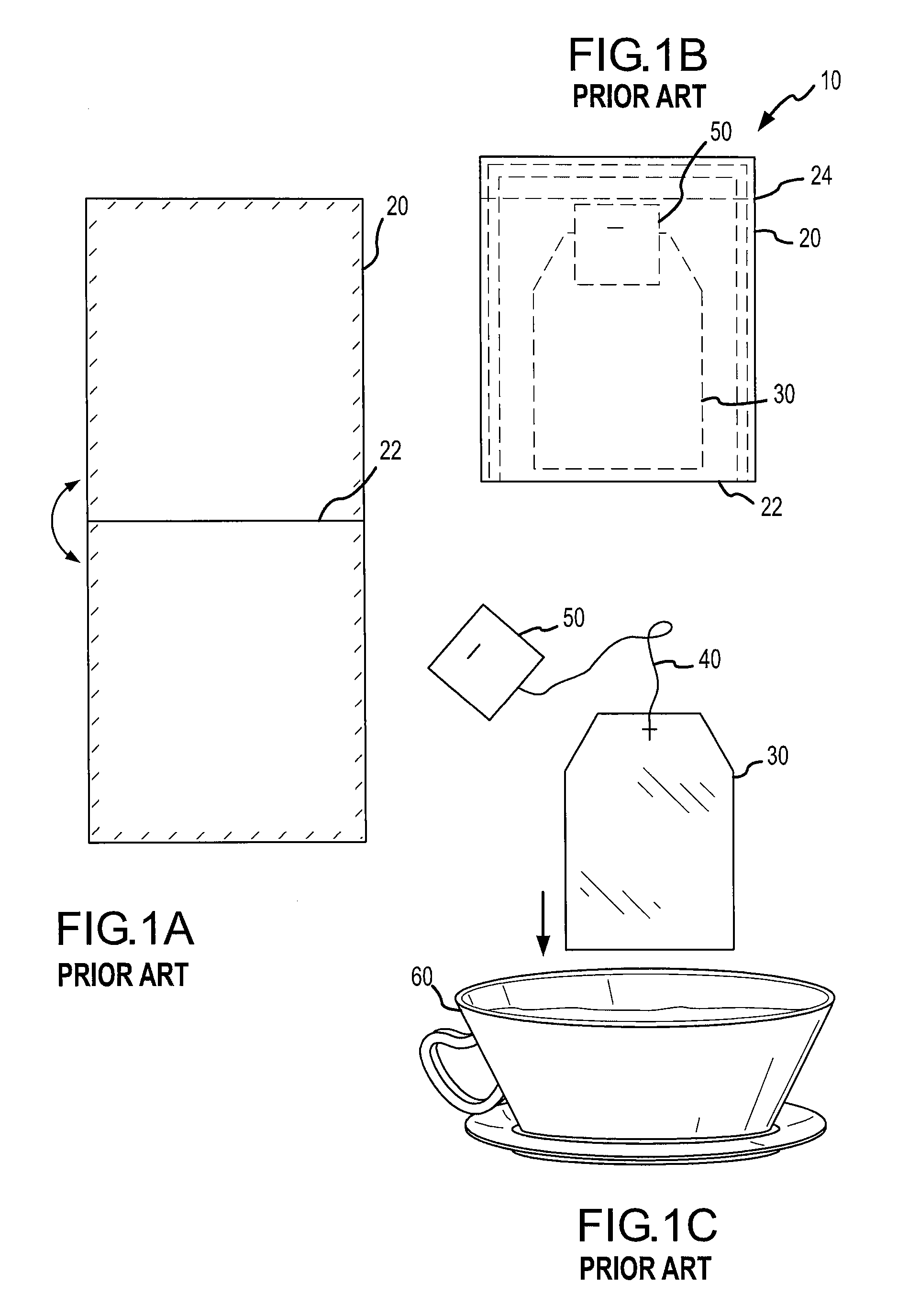

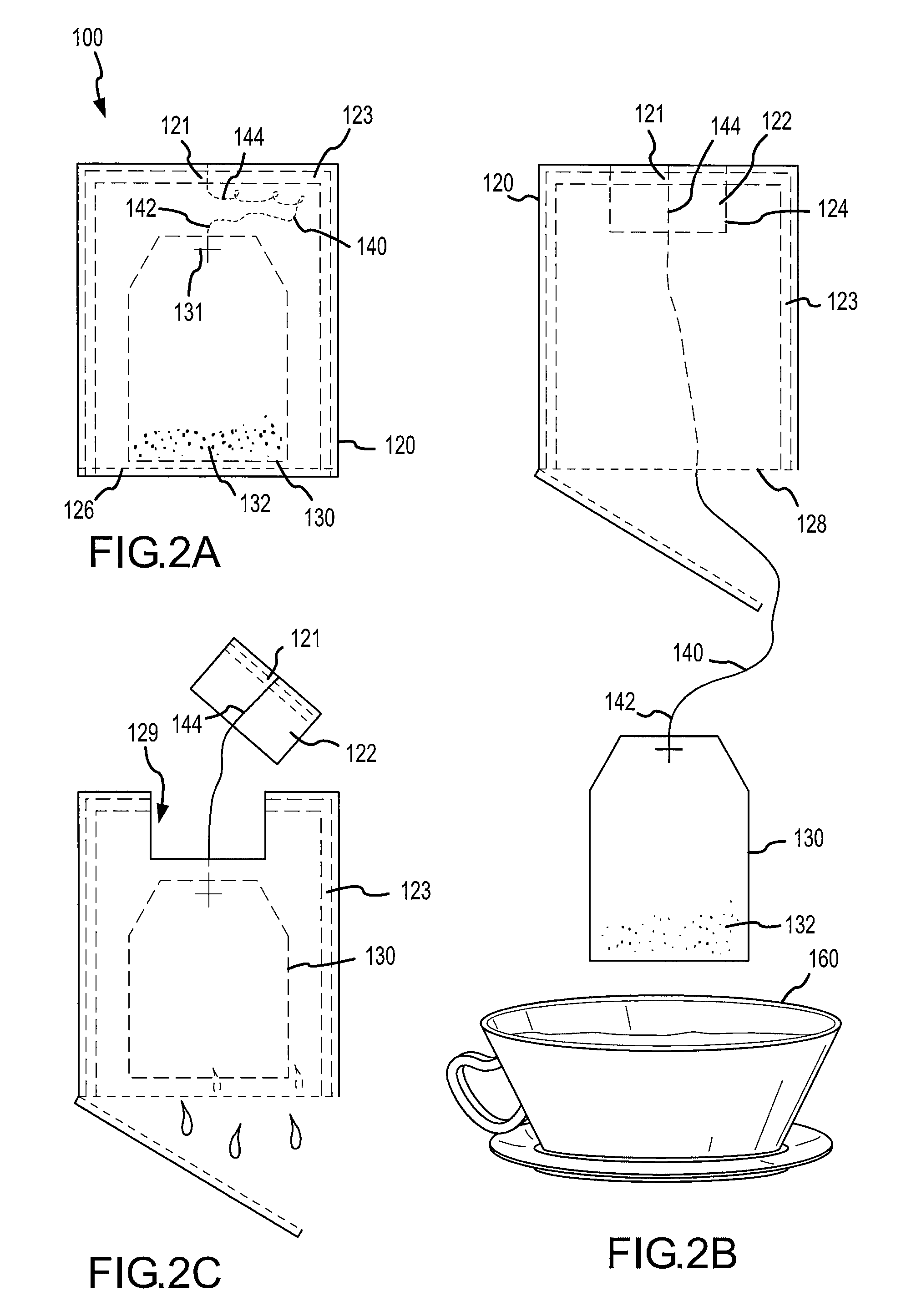

Tea bag cozy

InactiveUS20070087083A1Increased level of controlPleasant ritual to brewing processPackaging foodstuffsBiomedical engineeringBrewing

An infusion system for processing a brewing material includes a pouch configured to contain a brewing material, a sealable packet configured to house the pouch, and an attachment member coupled with the pouch and the packet.

Owner:RILEY WILLIAM T

Production method of stainless steel belt for electronic film

The invention relates to a production method of a stainless steel belt for an electronic film. The production method comprises the following steps: (1) selecting and using a 12Cr17Ni7 stainless steel belt billet with the thickness of 0.7-1.0 mm; (2) rolling the stainless steel belt into a steel belt with the thickness of 0.16-0.18 mm by a 20-roll precision cold rolling machine set; (3) washing the steel belt for one time; (4) passing a continuous hydrogen-spraying bright annealing furnace by the steel belt; (5) rolling the steel belt into a steel belt with the thickness of 0.03-0.05 mm by the 20-roll precision cold rolling machine set; (6) passing a continuous degreasing washing machine set by the steel belt; (7) straightening the steel belt by a 23-roll precision stretch bending straightening machine; (8) passing the continuous hydrogen-spraying bright annealing furnace by a rusted steel belt; (9) straightening the steel belt in the direction opposite to the warping direction by the 23-roll precision stretch bending straightening machine; (10) cutting the steel belt into a steel belt with the required size so as to obtain the stainless steel belt for the electronic film. The stainless steel belt produced by the method is good in elasticity, high in strength and uniform in thickness.

Owner:WUXI BAOSHUN STAINLESS STEEL

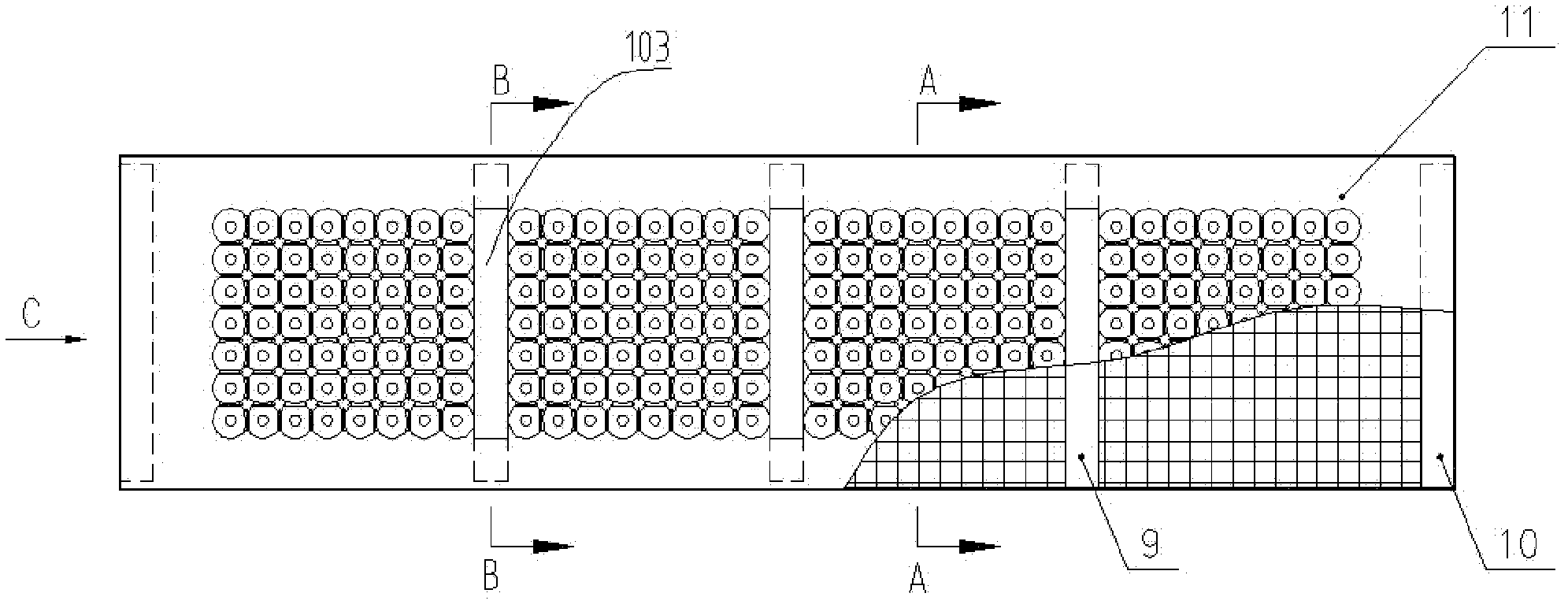

Cup-shaped noise reduction and sound absorption member

ActiveCN102926334AImprove sound absorptionAchieve Impedance MatchingNoise reduction constructionWoolEngineering

The invention belongs to the technical field of a sound barrier acoustic member, and specifically relates to a cup-shaped noise reduction and sound absorption member of a sound barrier. The cup-shaped noise reduction and sound absorption member is composed of a plurality of cup-shaped noise reduction and sound absorption member units, wherein a panel of each unit is composed of a plurality of rectangular arrays and trapezoidal transverse bars; each rectangular array is composed of a plurality of uniformly distributed reflector cups with a paraboloid-shaped acoustic construction; diffraction holes are formed in the bottom of each reflector cup; a rectangular connecting groove is respectively arranged in the longitudinal center on the upper surface and the lower surface of a back plate of each unit; the connecting groove and the rectangular connecting grooves of other sound absorption member units in the same position form a square cavity during installation, wherein a square steel pipe is embedded in the cavity as a connecting piece for clamping two adjacent cup-shaped noise reduction and sound absorption member units; a sound insulation plate is mounted in a tubular cavity which is formed by connecting the panel and the back plate; support frames are arranged on the transverse bars inside the cavity; and spaces divided by the support frame are filled with sound absorption wools and gauzes. The cup-shaped noise reduction and sound absorption member has stronger sound absorption ability, and the low-frequency sound absorption ability is improved.

Owner:秦皇岛耀华装备集团股份有限公司

Stainless steel rail pickling and passivation treatment method

ActiveCN104674247AImprove corrosion resistanceBeautiful surfaceMetallic material coating processesCorrosionMegasonic cleaning

The invention discloses a stainless steel rail pickling and passivation treatment method. The stainless steel rail pickling and passivation treatment method comprises the following steps: a cleaned and degreased stainless steel rail workpiece is completely soaked in a pickling solution for 30 to 120 minutes; the pickled stainless steel rail workpiece is placed in a cleaning basket, and the cleaning basket is then placed in an ultrasonic cleaning machine containing a cleaning solution for 15 to 20 minutes of cleaning; after cleaning, the stainless steel rail workpiece is blow-dried and then placed in an oven for baking; the stainless steel rail workpiece is placed in a passivation pool, which contains a passivation solution, of a passivation treatment box for 25 to 35 minutes of passivation treatment; the passivation pool is aerated during the passivation process; the stainless steel rail workpiece is placed in a neutralization pool containing a neutralization solution for 25 to 35 minutes of neutralization. The technique has the advantages that the surface cleanness of the stainless steel rail is totally guaranteed through pickling, ultrasonic cleaning, passivation and neutralization, and a compact oxidation film is formed, so that the corrosion resistance of the stainless steel rail is effectively improved, the stainless steel rail can be protected from rust for a long time, and the surface of the stainless steel rail looks beautiful.

Owner:珠海市椿田机械科技有限公司

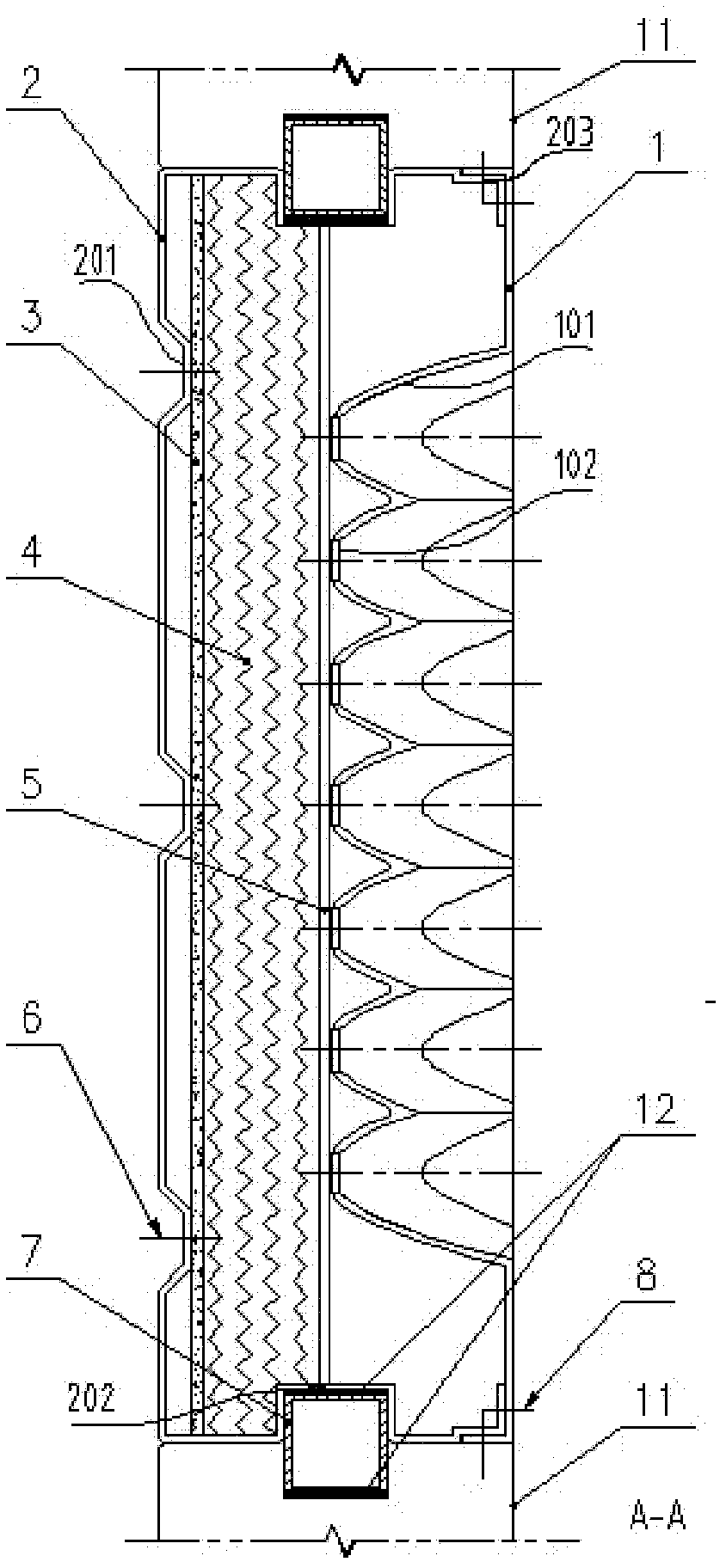

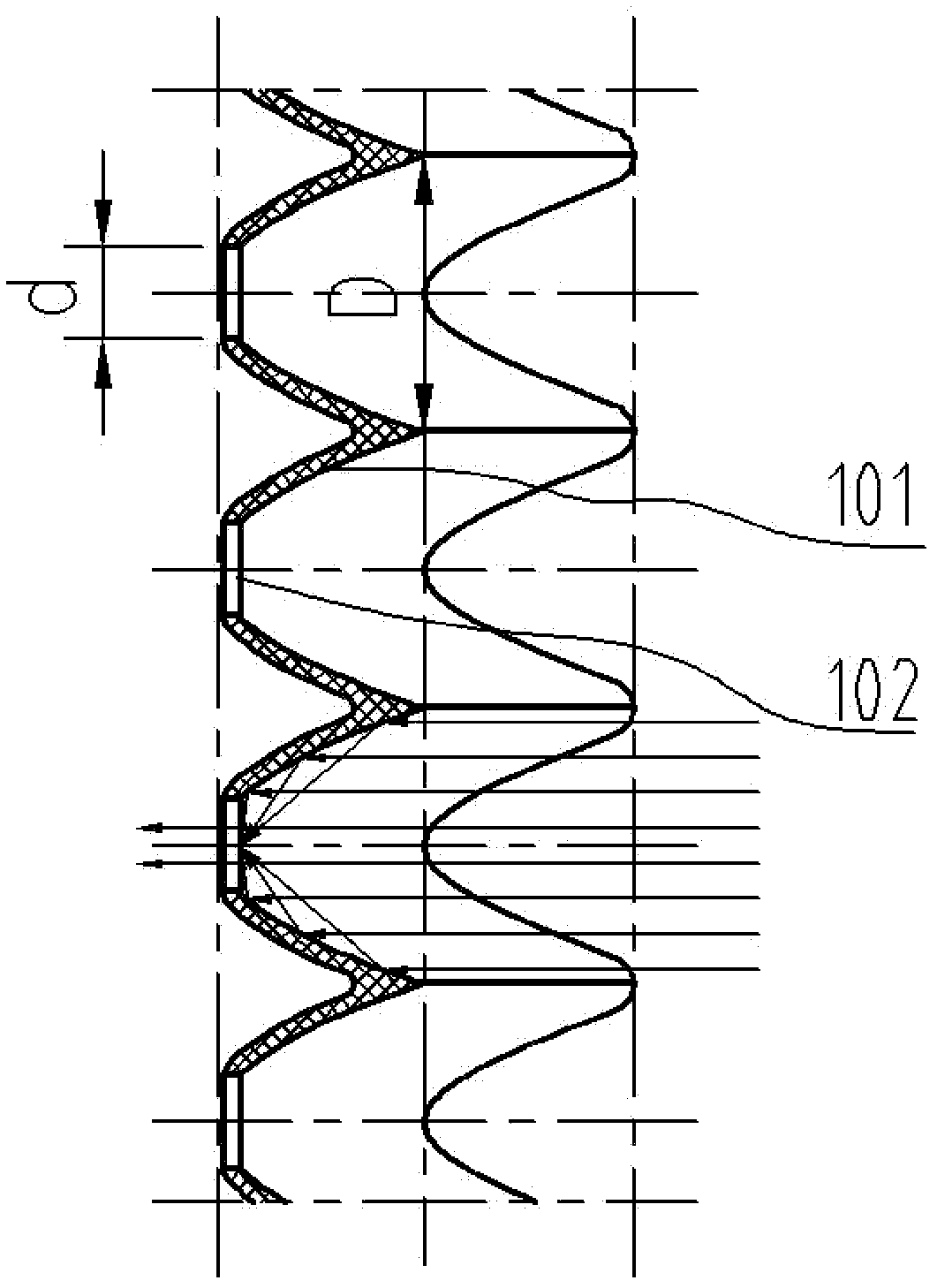

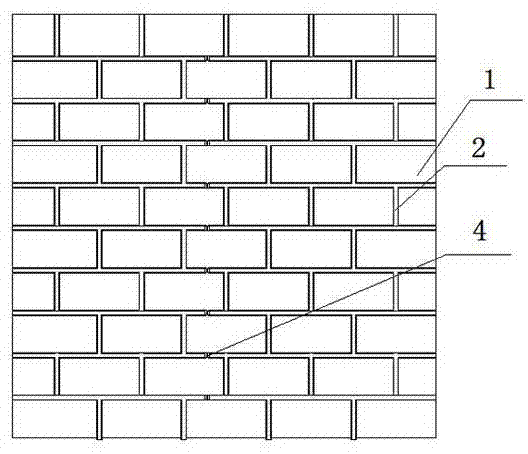

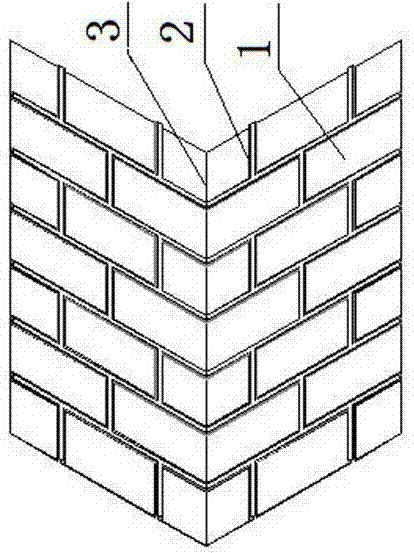

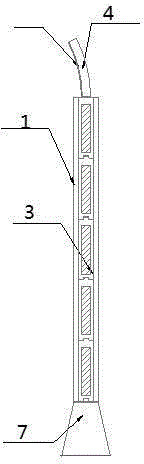

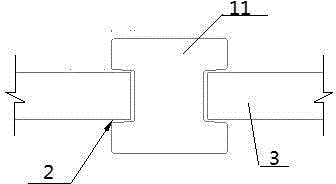

Plastic mold for fixing tiles on surface of precast concrete unit

ActiveCN103496036AGuaranteed costTo achieve unified standardizationMould separation apparatusMouldsLap jointOperation mode

The invention provides a plastic mold for fixing tiles on the surface of cast-in-place concrete. A plurality of female molds distributed according to the design are formed in a whole smooth thin plastic plate, the shapes of the female molds are similar to the shapes of the fixed tiles, and locking structures are arranged on the peripheries of the female molds. The locking structures are characterized in that convex-concave cambered surfaces are arranged on the peripheries of the female molds, upward convex openings of the peripheries of the convex molds are small, downward concave bottoms of the peripheries of the convex molds are large, then, the tiles can be inserted and locked, and hollow separation ribs are arranged between the female molds, wherein the upper portions of the hollow separation ribs are large, and the lower portions of the hollow separation ribs are small. The plastic mold can be manufactured into a folded type, 90-degree corners can be formed at the corners of a wall, and the plastic mold can be also formed by connecting a plurality of molds in a lap joint mode. According to the plastic mold, the original backward operation mode that traditionally the tiles are manually fixed one by one is completely changed, and therefore cost is effectively reduced, working efficiency is greatly improved, environmental pollution is avoided, the energy saving and consumption reduction effects are achieved, quality can be guaranteed, and the national standard can be met.

Owner:QINGDAO SHANGLIU YUANDA HOUSE IND CO LTD

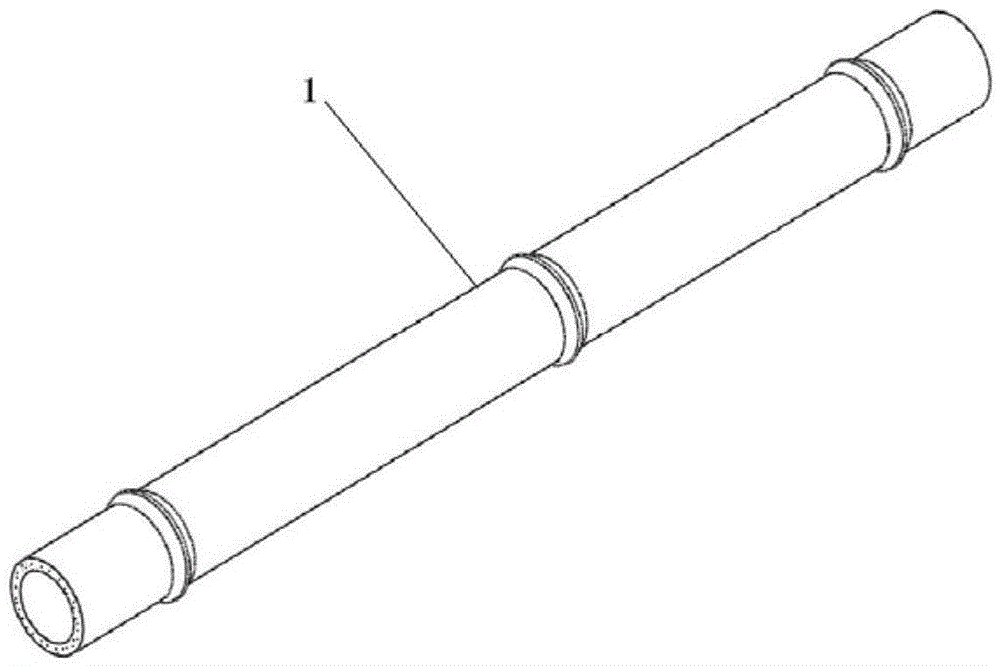

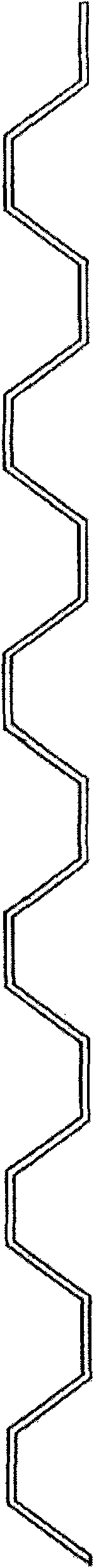

Pollution-free non-adhesive bamboo and/or wood reconstructed material and manufacturing method thereof

InactiveCN104924407AAdjustable stressImprove stabilityWood compressionWood treatment detailsAdhesiveEngineering

The invention provides a pollution-free non-adhesive bamboo and / or wood reconstructed material which comprises a plurality of unit bodies with set lengths. The unit bodies are connected into a whole through connecting structures to form the reconstructed material. The reconstructed material can be expanded in the horizontal direction and the longitudinal direction through the connecting structures. The invention provides a manufacturing method which comprises the steps of manufacturing of the unit bodies, molding and assembling, manufacturing of the molded material, manufacturing of the reconstructed material and the like, and the finished pollution-free non-adhesive reconstructed material is obtained after material maintenance and surface green treatment. The reconstructed material has no pollution or adhesives and is friendly to environment; internal stress of the material can be adjusted, so that the cracking phenomenon is avoided; the reconstructed material can be applied to the fields of building beam columns, structural members, furniture and decoration materials. By means of the manufacturing method, the reconstructed material without pollution and adhesives can be manufactured, and chemical pollution in the processing process of the reconstructed material is eliminated.

Owner:FUJIAN YAKANG IND & TRADE +1

Styrene butadiene styrene (SBS) modified bituminous waterproof sheet material and preparation technology thereof

InactiveCN101644095AIncrease elasticityBright appearanceRoadwaysUnderground chambersBituminous waterproofingPolyester

The invention provides a styrene butadiene styrene (SBS) modified bituminous waterproof sheet material and preparation technology thereof. The waterproof sheet material comprises polyester cloths, animmersion oil coating layer and a film-mulching layer. The immersion oil coating layer comprises the following materials in parts by mass: 32-52 parts of bitumen, 12-22 parts of residual oil, 9-19 parts of EPDM rubber powder, 2-7 parts of butyl rubber powder, 11-21 parts of talc powder and 5.6-10.6 parts of SBS rubber. The bitumen is the mixture of 9-19 parts of 10# bitumen and 23-33 parts of 60#bitumen. The invention is characterized by wide high temperature and low temperature resistance range, good elasticity and good hardness, is not easy to deform and is suitable for various levels of waterproofing works of roofing of industrial and civil buildings, underground, bridges, highways, swimming pools and the like in the south and in the north.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD

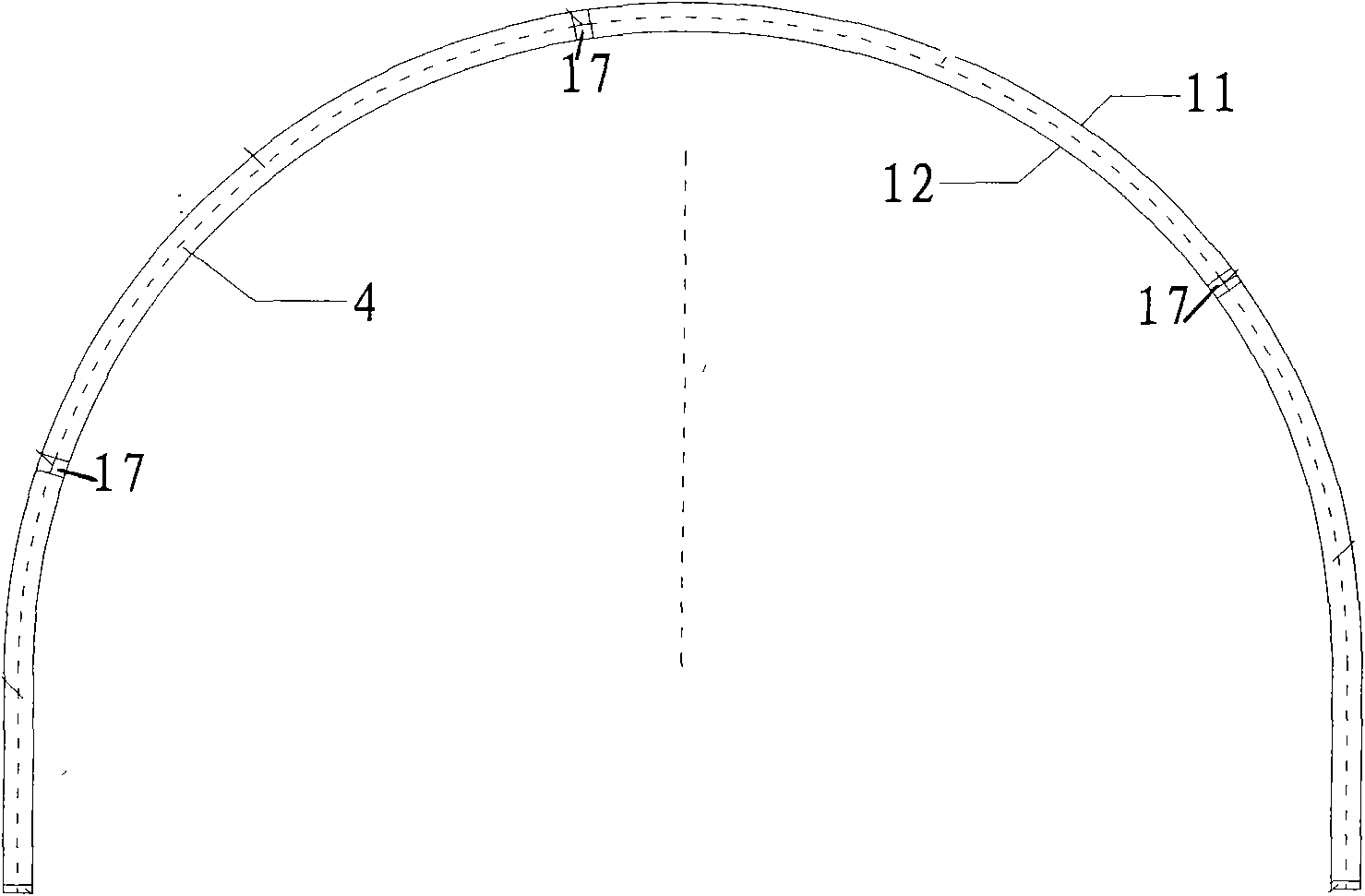

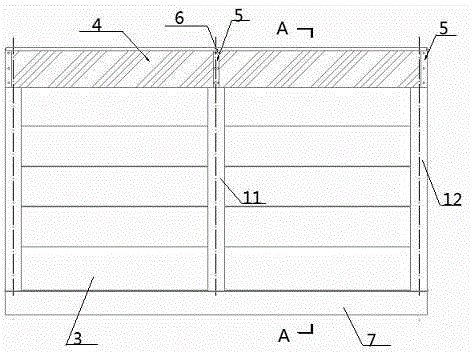

Construction method for newly increasing arched open cut tunnel at railway operating line tunnel portal

The invention relates to the field of tunnel construction, in particular to a construction method for newly increasing an arched open cut tunnel at a railway operating line tunnel portal. The construction method solves the problems that the conventional construction method for newly increasing the arched open cut tunnel at the railway operating line tunnel portal has complex process, difficult operation, low construction efficiency, large safety risk, poor construction quality and the like. The construction method comprises the following steps of: surveying setting-out, construction of manually digging hole piles, fiber concrete slab prefabrication, joist construction, processing and assembly of an H profile steel frame, short side wall construction, arch construction of the arched open cut tunnel, end-sealing concrete construction and the like. The fiber concrete slab and the profile steel frame form an integral structure, so the stability is good, and the safety is ensured; the method avoids formwork removal operation after arch concrete pouring is finished, simplifies the construction process, accelerates the construction progress, and has considerable economic benefit; the profile steel frame is uniformly processed in a processing factory and pre-assembled and hoisted on site so as to shorten the operation time and improve the construction efficiency; and the fiber concrete slab is prefabricated in the factory and then arranged on site, so the arched open cut tunnel has surface finish and attractive appearance.

Owner:THE 2ND ENG OF THE 12TH BUREAU GROUP OF CHINA RAILWAY

Method for preparing reinforced tungsten carbide abrasion-resistant composite plate

InactiveCN102212821AIncrease productivityReduce manufacturing costMetallic material coating processesMetal layered productsSlagComposite plate

The invention discloses a method for preparing a reinforced tungsten carbide abrasion-resistant composite plate. The method comprises the following steps of: selecting a low-carbon steel plate or a low-alloy steel plate adapted with the size of a hearth of a heating furnace as a substrate, uniformly spreading film removing agent, alloy powder, tungsten carbide powder and slag forming agent powder on a cleared surface, horizontally putting the substrate into the heating furnace, and heating the substrate to obtain the reinforced tungsten carbide abrasion-resistant composite plate. The abrasion-resistant alloy surface of the working layer of the reinforced tungsten carbide abrasion-resistant composite plate produced by using the method is flat and attractive; the composite plate can be directly used for the working conditions (such as a baffle plate and the like) requiring flat surfaces, so a machining process and corresponding production cost are saved; and the composite plate can be widely applied to the working condition of high abrasive abrasion, and has longer service life.

Owner:SHANDONG UNIV

Noise barrier

ActiveCN104894991ACancel noiseIdeal sound insulationSolid waste managementNoise reduction constructionNoise barrierEngineering

The invention discloses a noise barrier which comprises a plurality of columns and a plurality of wall plates which are arranged between the adjacent columns and are connected up and down, wherein a curved plate is arranged on the topmost wall plate; each wall plate is formed by arranging a noise absorbing plate between two noise insulation plates. According to the noise barrier, the noise is eliminated by using a way of insulation-absorption-insulation, and the effect is more ideal than the traditional single noise insulation or absorption effect.

Owner:黄贺明

Medium density fiberboard with decorative surface covered by impregnated film adhesive paper and preparation method thereof

InactiveCN101767353AStrong three-dimensional senseImprove the decorative effectWood veneer joiningWood layered productsSurface layerAdhesive

The invention relates to wood processing field, in particular to a medium density fiberboard with decorative surface covered by impregnated film adhesive paper, wherein a surface layer film adhesive paper and a decorative layer film adhesive paper of the decorative surface film adhesive paper are sequentially adhered on the upper surface of the medium density fiberboard; the lower surface thereof is sequentially adhered with the surface layer film adhesive paper and the decorative layer film adhesive layer of the decorative surface film adhesive paper, or is adhered with a bottom layer film adhesive paper; a concave groove and / or a convex rib with depth more than and equal to 1.2mm is thermally pressed on the upper surface and / or the lower surface of the medium density fiberboard. The invention has good stereoscopic impression and can well satisfy the market demands.

Owner:费恺

High sealing cold punching press shaped bubble cup plustic aluminium composite hard sheet and its production technology

A laminated hard plastics / aluminium plate with surficial PVC layer, and high sealing nature and able to be shaped by punch is prepared from at least one polyester (or polyamide) film treated by corona impact, at least one aluminium foil and one surficial PVC film through adhering them together by use of high-adhesion adhesive.

Owner:刘继福

Instant salted pig gristle food and processing technology thereof

InactiveCN102613588APreserve the flavorCompact structureFood preparationBiotechnologyReady to eat food

The invention relates to an instant salted pig gristle food and a processing technology thereof, and belongs to the fields of instant foods and processing technologies thereof. 100 to 105 parts of pig ear serving as a main material is matched with auxiliary material to be prepared into the instant salted pig gristle food. By the formula, the problem that slated meat foods cannot maintain the flavor of marinade for a long time and have thin salty flavor according to the formula in the prior art is solved, a formula and a proportion of the instant salted pig gristle food are provided, and a salted meat food with excellent taste can be provided and can maintain the flavor of the marinade for a long time. By the processing technology for the n instant salted pig gristle food, the product has a compact structure, good mouthfeel and attractive appearance without cutin, and the bag breakage or inflation rate is obviously reduced.

Owner:SICHUAN GAOJIN FOOD CO LTD

Nickel aluminum bronze plastic mould material and preparation method thereof

ActiveCN104745861AHigh compressive strengthImprove thermal conductivityThermal fatigueWear resistance

The invention discloses a nickel aluminum bronze plastic mould material. The nickel aluminum bronze plastic mould material comprises the following components by weight percent: 10-12% of Al, 3-5% of Ni, 3-5% of Fe, 1-2% of Mn, 0.2-0.3% of Ti, 0.2-0.3% of B, 0.05-0.1% of Zn and the balance of Cu. The material provided by the invention is high in compression strength and excellent in heat conduction, heat dissipation, thermal fatigue resistance, abrasive resistance and corrosion resistance; the service life of the mould is 3-6 times higher than that of the traditional iron alloy steel plastic mould material; the material is excellent in cold and heat process molding and smooth in mould processing surface, is used for high polymer plastic forming, is high in plastic product size precision, clear in ornamentation and beautiful on the surface and has higher performance than that of the iron alloy mould material. The invention also discloses a preparation method of the nickel aluminum bronze plastic mould material.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

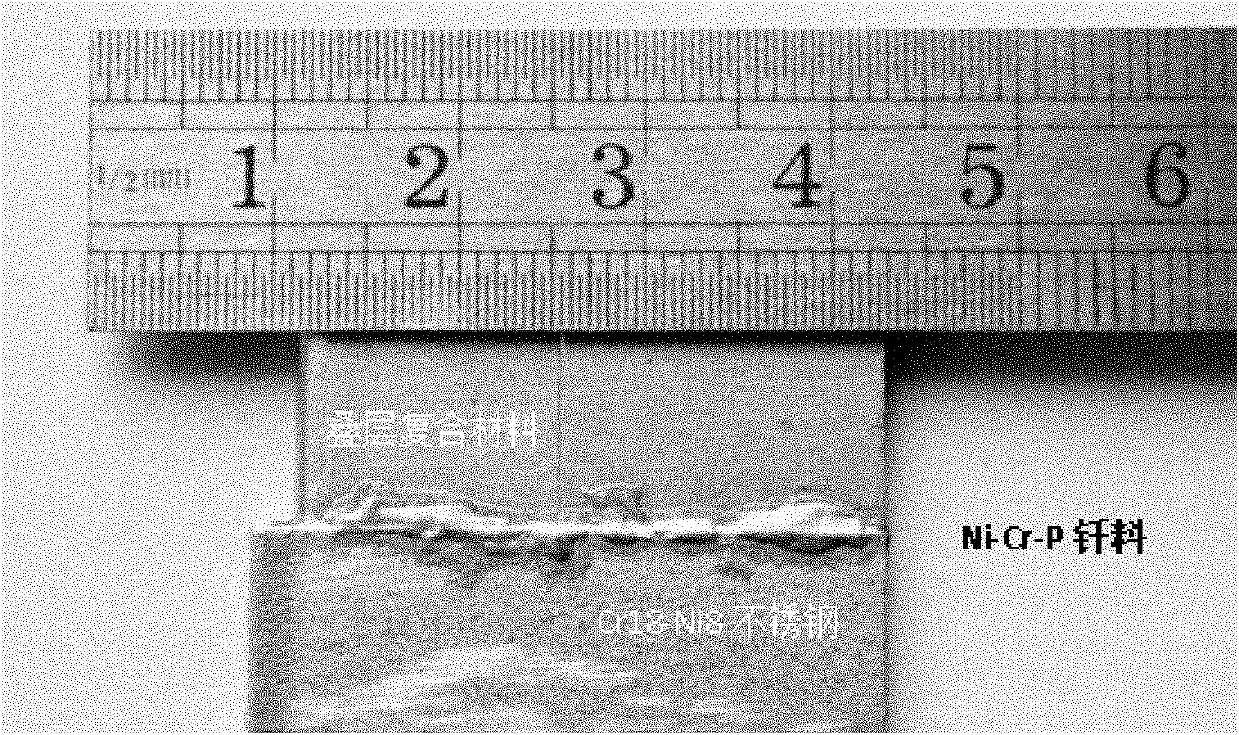

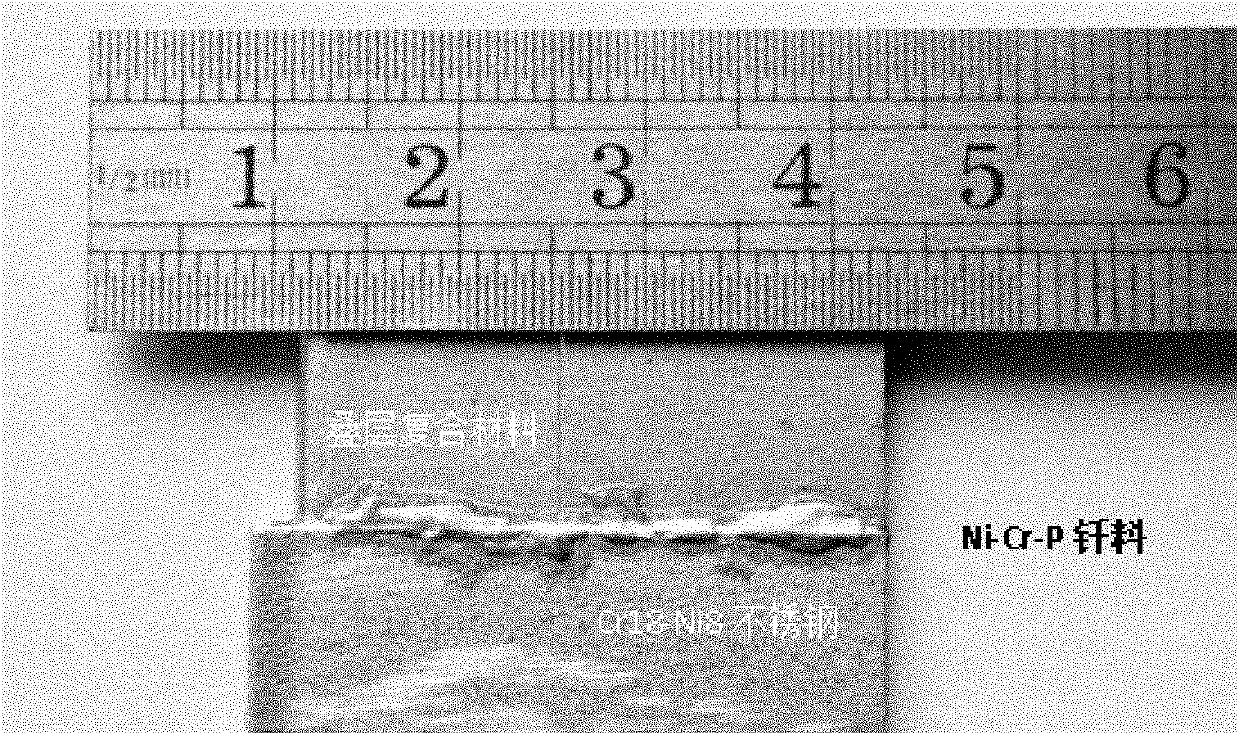

Vacuum brazing process for super-Ni laminated material and Cr18-Ni8 stainless steel

InactiveCN101992331AImprove performanceBeautiful brazing seamWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalMetallic Nickel

The invention discloses a vacuum brazing process for a super-Ni laminated material and Cr18-Ni8 stainless steel, which is characterized by comprising the following steps: (1) prior to brazing, cleaning the super-Ni laminated material and the Cr18-Ni8 stainless steel, and removing oil stains on the surfaces of parts and the oxidation film on the surfaces to be brazed; (2) carrying pick-up fitting and fixing on the parts to be brazed in a super-Ni laminated material-brazing filler metal-stainless steel mode, wherein the brazing filler metal is Ni-Cr-P nickel-based brazing filler metal; and (3) carrying out vacuum brazing on the fixed workpiece in a vacuum brazing furnace, wherein the vacuum degree of the vacuum brazing furnace is greater than 1.33*10<-3>Pa, the brazing heat temperature is 920-1100 DEG C, and the holding time is 5-25 min. By using the method, brazed joints having the advantages of no crack, fine interface combination and beautiful surface appearance can be obtained, and the reliable connection of laminated materials can be realized, thereby meeting the requirements of aerospace, power and other fields for high-performance materials.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com