Plastic mold for fixing tiles on surface of precast concrete unit

A technology of prefabricated concrete and plastic molds, which is applied in the field of construction engineering, can solve the problems that the wall surface effect is difficult to meet the quality standards, the operator's technical requirements are high, and the labor cost is high, so as to achieve low cost, reduce production cost, and improve operation. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

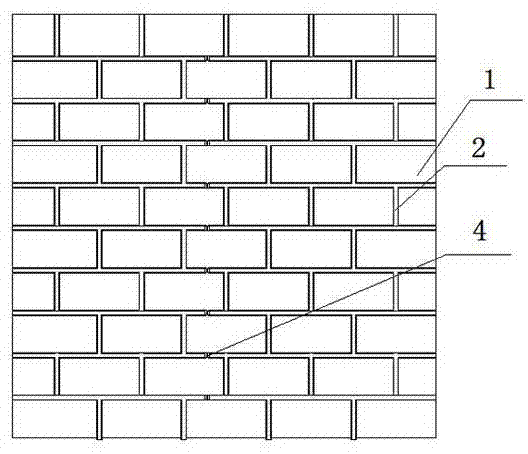

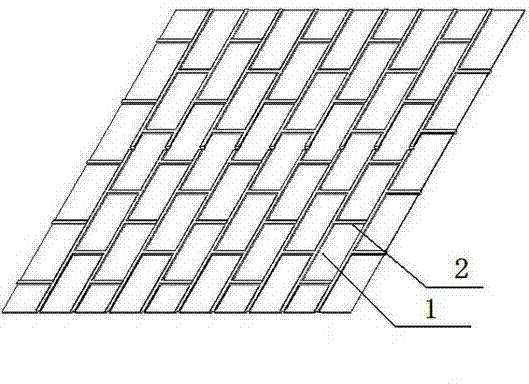

[0022] A plastic mold for laying ceramic tiles on the surface of prefabricated concrete components. A plurality of concave molds distributed according to the design are formed on the whole smooth thin plastic plate. The locking structure is: the periphery of the die is a convex-concave arc surface, the convex-concave arc surface around the die is convex, the mouth is small, the bottom is concave, and the bottom is large, which can be embedded into ceramic tiles and locked. The gap between the die and the die is Hollow partition ribs, the hollow partition ribs are large at the top and small at the bottom.

[0023] The width of the above-mentioned hollow ribs 2 can be adjusted according to the size of the design drawings.

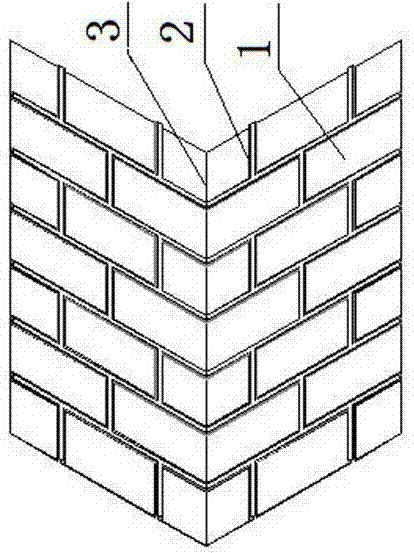

[0024] Above-mentioned plastic mold can be made into folding type, can carry out 90 degree corners 3 at the corner of wall.

[0025] The above-mentioned plastic mold can be formed by overlapping multiple plastic molds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com