Method and device for printing pictures and texts on surface of irregular object

A technology of object surface and printing method, which is applied in the direction of printing device, printing, printing of special varieties of printed matter, etc. It can solve the problems that cannot be solved, the movement and deformation of graphics and text are irregular, and cannot be reached.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] Fine graphic printing on the entire surface of the Christmas ball molding process in embodiment 1

[0129] Step 1: Make composite thermal transfer film type I, with a total of five layers.

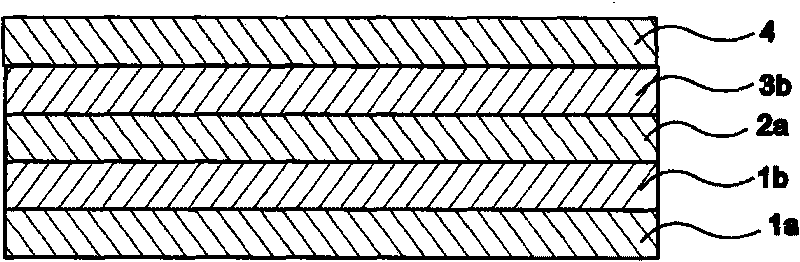

[0130] Such as Figure 1A Shown: choose PS sheet, thickness 0.1mm is plastic substrate 1a; choose PE film, thickness 0.05mm is release layer 2a; choose PU two-component laminating adhesive as composite glue 1b, adopt traditional dry lamination process , compound 1a and 2a; use gravure printing to reverse print the printed graphic on the peeling layer 2a to form the printed graphic layer 3b; use traditional EVA hot melt adhesive to thermally coat the printed layer 3b to form a glue layer 4.

[0131] The second step: the composite transfer film is pre-deformed, and the surface of the Christmas ball 5a can be divided into two symmetrical hemispherical surfaces. Therefore take the mode of central dividing line 6 to make left and right two hemispherical deformed molds 7, can share equa...

Embodiment 2

[0136] The printing of the surface of embodiment two Christmas balls under post-curing glue condition

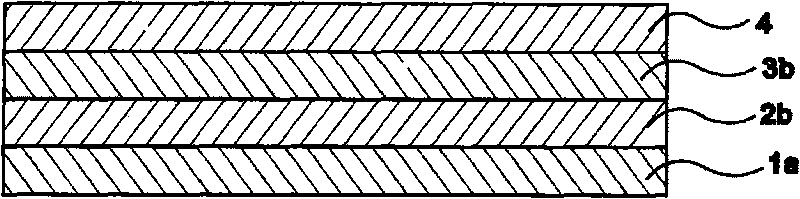

[0137] The first step: making composite heat transfer film type II, a total of four layers

[0138] Such as Figure 1A Shown: choose PVC sheet, thickness 0.15mm is plastic substrate 1a;

[0139] Select a release agent for printing to be directly coated on the substrate by coating, with a thickness of 0.05mm as the release layer 2a;

[0140] Using gravure printing to reverse print the printed graphic on the release layer 2a to form the printed graphic layer 3b;

[0141] The adhesive layer 4 is formed on the printing layer 3 by hot-coating the moisture-curing reactive polyurethane hot melt adhesive.

[0142] The second step, the third step are together with embodiment;

[0143] Step 4: Stripping and post-curing.

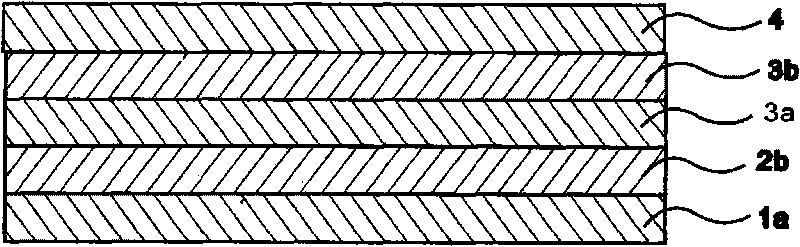

[0144] After demoulding, cool, and the 31 that the substrate layer 1a release agent layer 2a of composite transfer printing film is combined is peeled off, as Fi...

Embodiment 3

[0145] Embodiment 3 Printing of the entire surface of the Christmas ball - under the condition of having a positive mold

[0146] The first step together with the example

[0147] The second step: making plastic deformation composite transfer film, the surface of the Christmas ball 5 can be divided into two symmetrical hemispherical surfaces. Therefore, the left and right hemisphere plastic deformation molds are made by adopting the method of center line 6, and the left and right hemispheres can be shared, such as image 3 shown. On the heating vacuum plastic deformation device, as shown in Figure 4, the composite transfer film 10a of the plane (printed with the picture and text corresponding to the left hemisphere), 10b (printed with the picture and text corresponding to the right hemisphere) is placed on the plastic deformation The top of the mold 7, and the sealing between 10a, 10b and 7 is realized by the pressing device 11. Through the heating device 18, the male mold 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com